Heat-hardened steel with excellent crashworthiness and method for manufacturing heat-hardenable parts using same

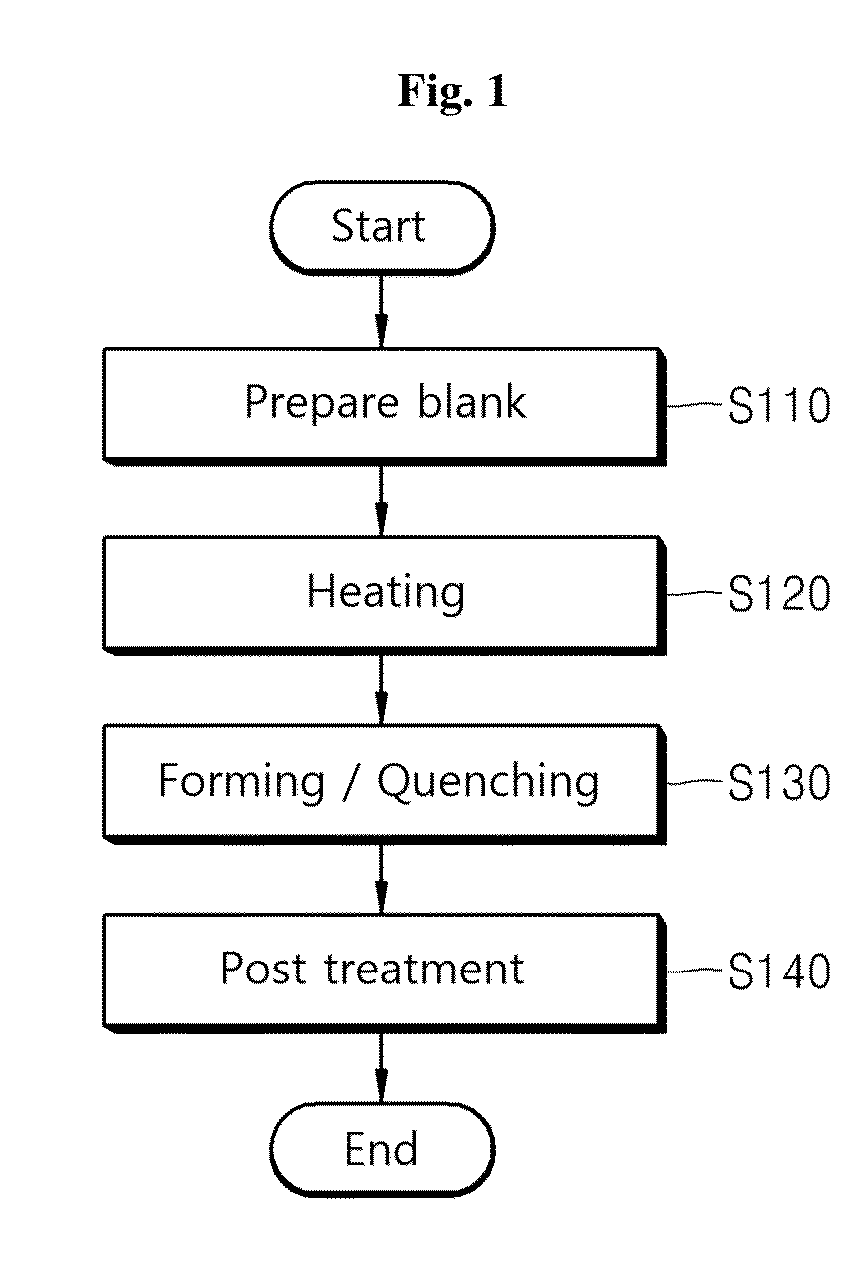

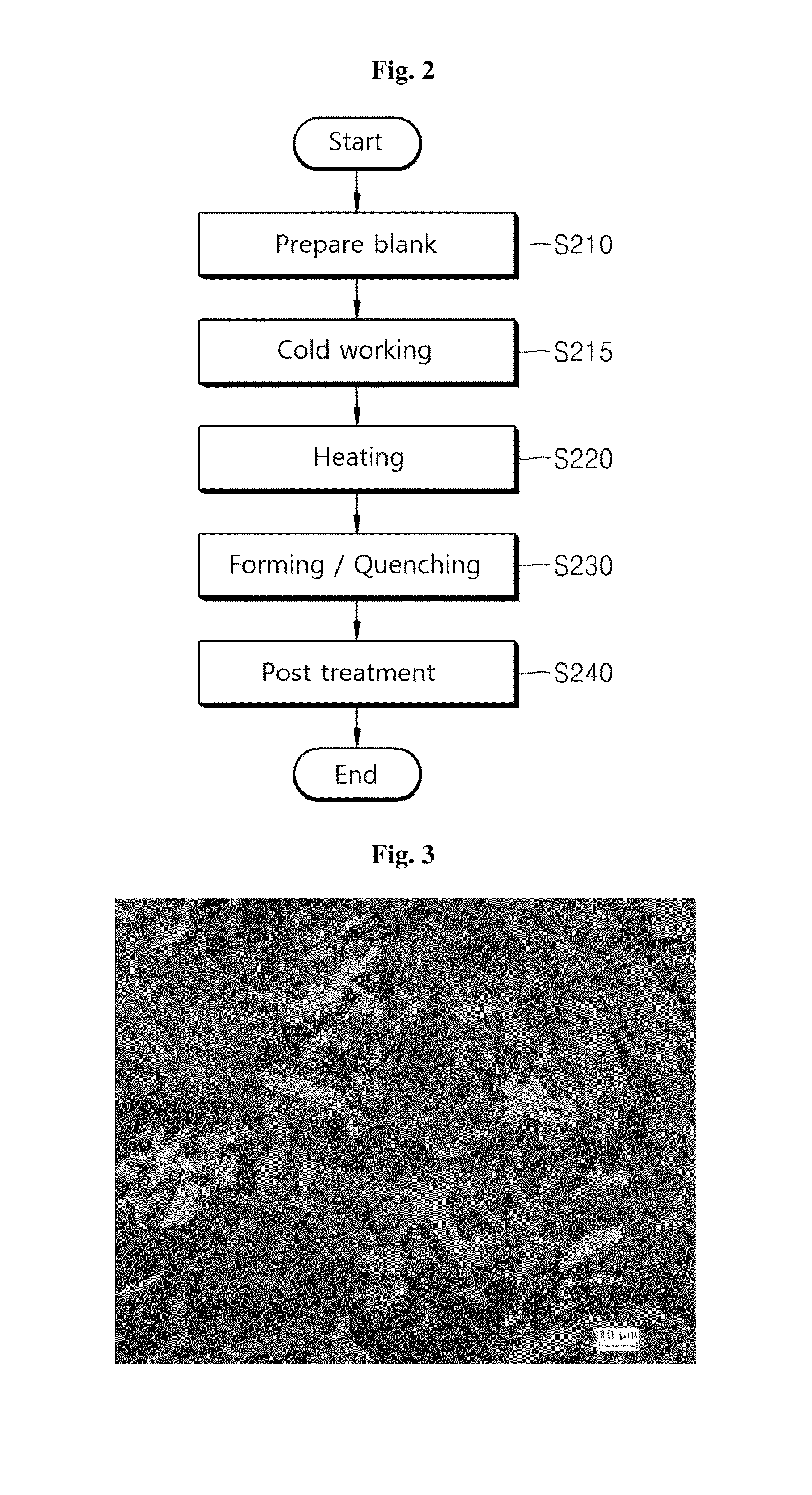

a technology of heat treatment hardening steel and high strength, which is applied in the direction of metal layered products, metal material coating processes, thin material processing, etc., can solve the problems of component brittleness failure, low elongation of 6% to 7%, etc., and achieve high strength, improved crashworthiness, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086]Next, the present invention will be described in more detail with reference to examples. Here, the following examples are provided for illustration only and should not be construed in any way as limiting the present invention.

[0087]Descriptions of details apparent to those skilled in the art will be omitted.

[0088]1. Preparation of Specimen

[0089]In order to observe heat-treatment hardening properties of steel according to alloy compositions, specimens of Examples 1 to 4 and Comparative Example 1 having compositions as listed in Table 1 and mechanical properties before heat treatment as listed in Table 2 were heated to 900° C., left for 5 minutes, and cooled to 100° C. at an average cooling rate of 50° C. / sec.

TABLE 1(Unit: wt %)CSiMnCrMoAlTiNbBNiSbComparative0.2290.2381.190.1830.00250.030.036—0.002——Example 1Example 10.31.07.50.30.011.50.05—0.003—0.8Example 20.30.43.00.30.012.00.050.010.0052.00.8Example 30.41.55.50.20.010.050.050.050.0033.00.8Example 40.41.76.00.20.012.0—0.100.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com