A high crashworthiness al-si-mg alloy and methods for producing automotive casting

A technology of alloys and castings, which is applied in the field of casting aluminum alloys and can solve problems such as poor extrudability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

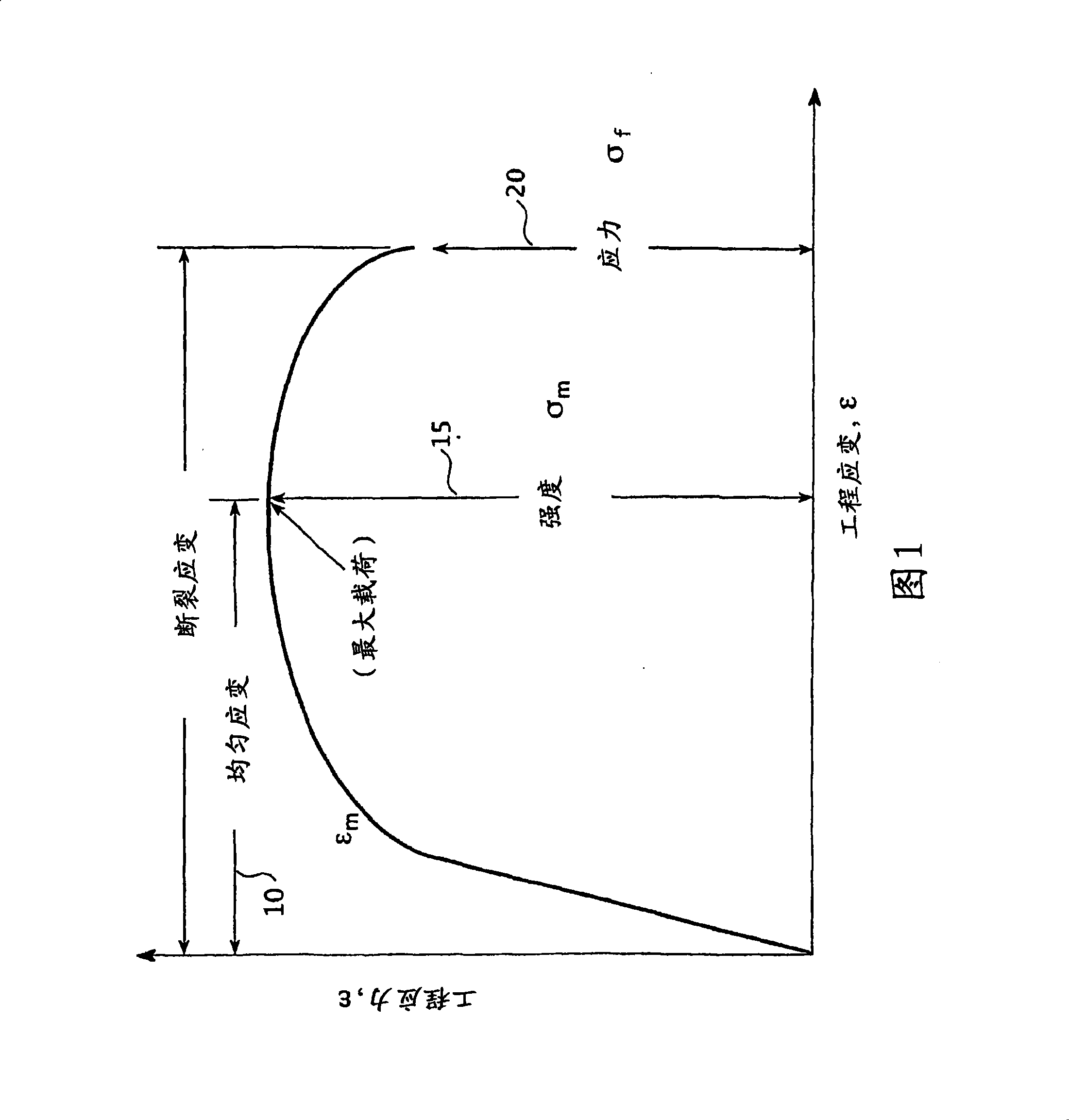

Example 1: Critical Fracture Strain

[0047] Castings representing the three alloy compositions within the alloy compositions of the present invention were prepared from directionally solidified and permanent molds. An example of a permanent casting system includes vacuum riser casting / pressure riser casting. The composition of each alloy sample tested is provided in Table I, where sample A was prepared at laboratory scale from directional solidification molds, and samples B and C were produced at production scale by vacuum riserless casting / pressure free casting. Riser castings were prepared using sand cores to provide hollow castings with a wall thickness of approximately 4 mm.

Table I Alloy Composition

Alloy composition Si Mg Cu Zn Fe A 7.05 0.1 0 2.57 0.02 B 7.03 0.16 0.35 0 0.06 C 7.01 0.177 0 0.0025 0.087

[0048] After casting, the samples were cooled with air. Regardless of the casting process, the solidification r...

Embodiment II

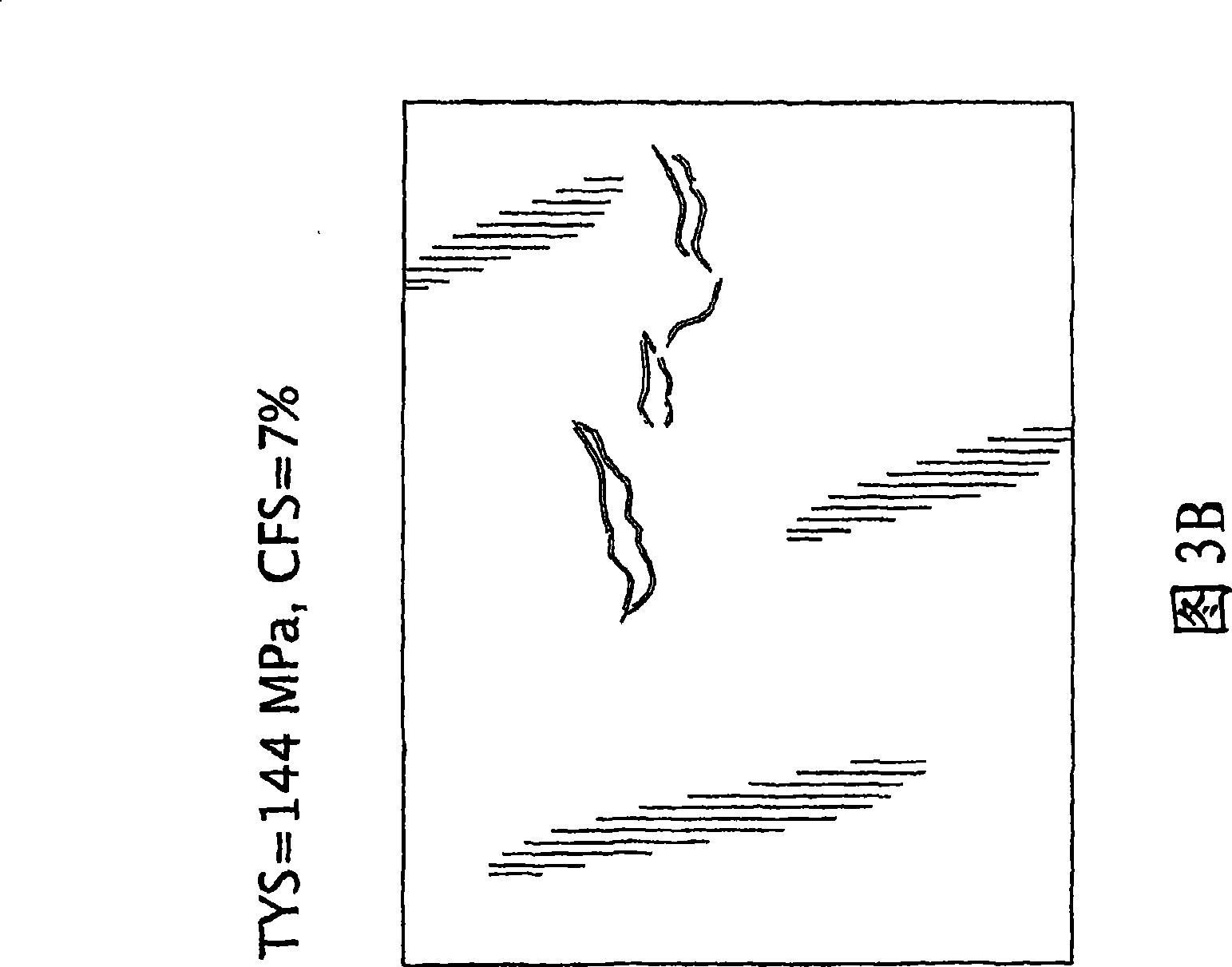

Example II: Visual Inspection of Cracks in a Bend Test

[0050] VRC / PRC castings were then prepared with alloy composition C as listed in Table I, conditioned to T5 and T6 tempers and then subjected to bend testing and visual inspection for cracks. Castings were prepared by the (VRC) / (PRC) casting technique as described above and using sand cores to provide a wall thickness of approximately 4.0 mm. The temperatures for the T5 and T6 heat treatments were similar to the heat treatment description described in Example 1. The period of heat treatment was varied in order to test the bend properties for varying strengths of the particular alloy. Table III shows casting samples and heat treatments.

Table III Composition and state of the alloy

sample Test scale state TYS (MPa) CFS(%) 1 factory T5 144 7 2 factory T5 110 10 3 factory T6 135 24 4 factory T6 180 9

[0051] Samples 1 and 2 were treated to a T5 temper where the ...

Embodiment III

Example III: Comparison of Bending Properties of High Pressure Die Casting and Vacuum Riser Casting (VRC) / Pressure Riser Casting (PRC)

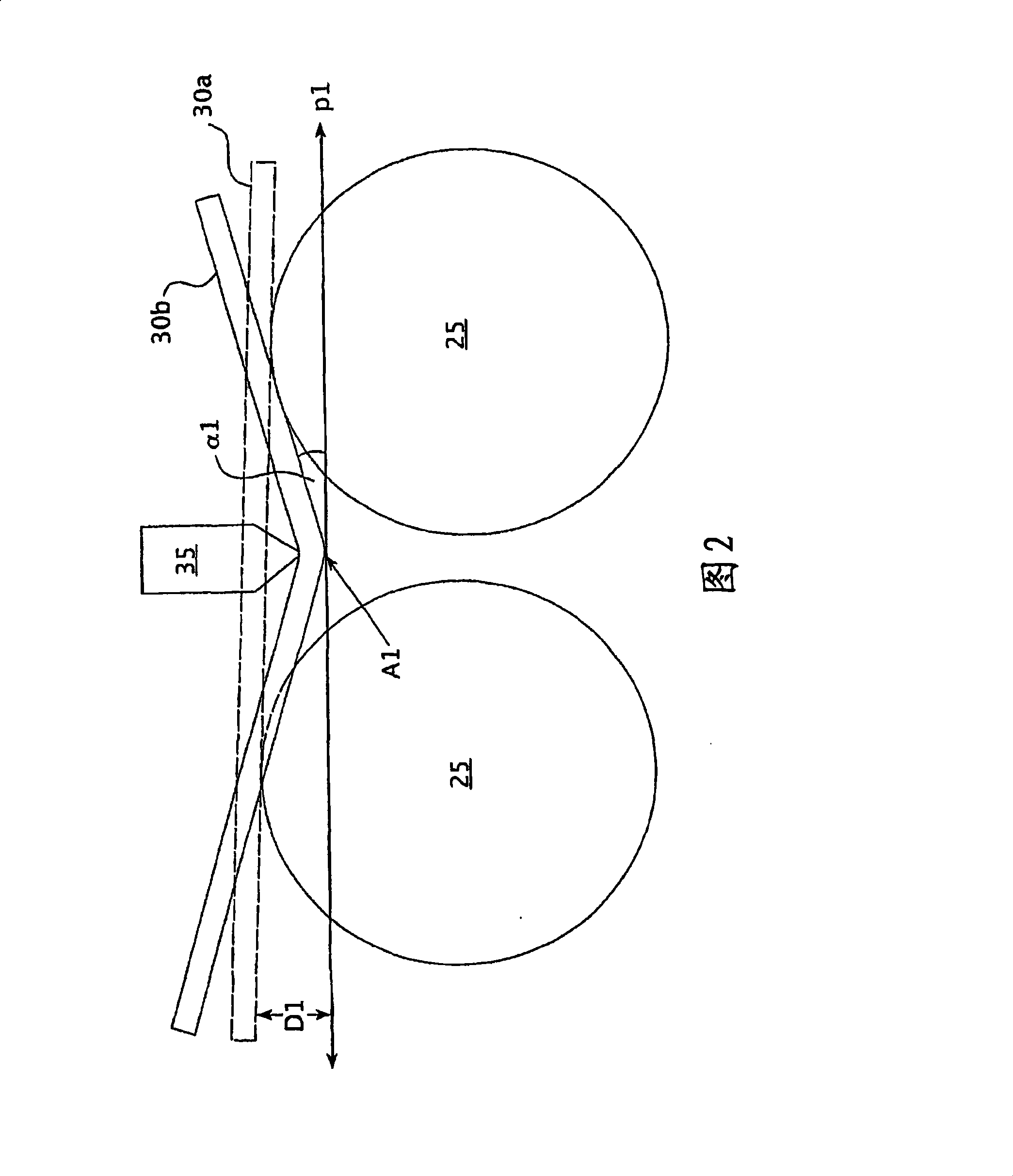

[0061] Test samples representing alloy compositions of the present invention were prepared using vacuum riser casting / pressure riser casting and high pressure die casting. The test samples were heat treated, machined into test panels 30a, 30b and subjected to bending tests. The alloy composition consists of about 9.0-10.0 wt% Si, about 0.2 wt% Mg, about 0.5-0.6 wt% Mn, and the balance aluminum and impurities.

[0062] VRC / PRC test samples were cast using sand cores to provide a wall thickness of approximately 4.0 mm. The thickness of the die cast test samples was about 2.5 mm.

[0063] The test samples formed by the VRC / PRC casting process were heat treated to the T6 temper. T6 treatment includes solution heat treatment at a temperature of 450°C to 550°C for about 1 / 2 hour to 6 hours, liquid quenching and artificial aging at a temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com