High manganese high strength steel sheets with excellent crashworthiness and method for manufacturing of it

a high-strength, high-carbon steel technology, applied in the direction of metal rolling arrangement, etc., can solve the problems of affecting the welding process, difficult to manufacture parts with complicated structures, deterioration in elongation of steel, etc., and achieve excellent impact absorption ability, high strength, and high elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0048]The inventive steels and the comparative steels are listed in the following Table 1, and molten steel ingots were kept in a 1200° C. heating furnace for one hour, and then hot-rolled. At this time, a hot rolling finish temperature was 900° C., and a coiling temperature was 650° C. Some of the hot-rolled steel sheets were processed into tensile test samples according to the JIS5 standard, and the tensile test samples were tested for tensile strength using a conventional universal testing machine. And, the hot-rolled steel sheets were pickled and cold-rolled at a cold reduction ratio of 50%. The cold-rolled test samples were continuously annealed, simulated and heat-treated at an annealing temperature of 800° C. and an over-aging temperature of 400° C. After the continuous annealing, simulation and heat-treatment processes, the cold-rolled test samples were tested for tensile strength using a conventional universal testing machine. Meanwhile, the cold-rolled test samples were co...

example 2

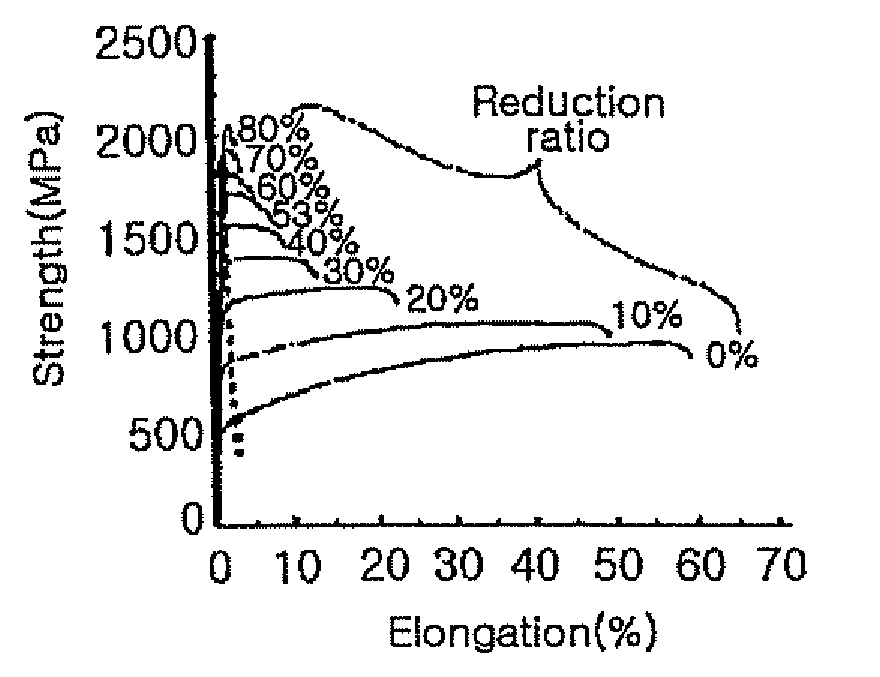

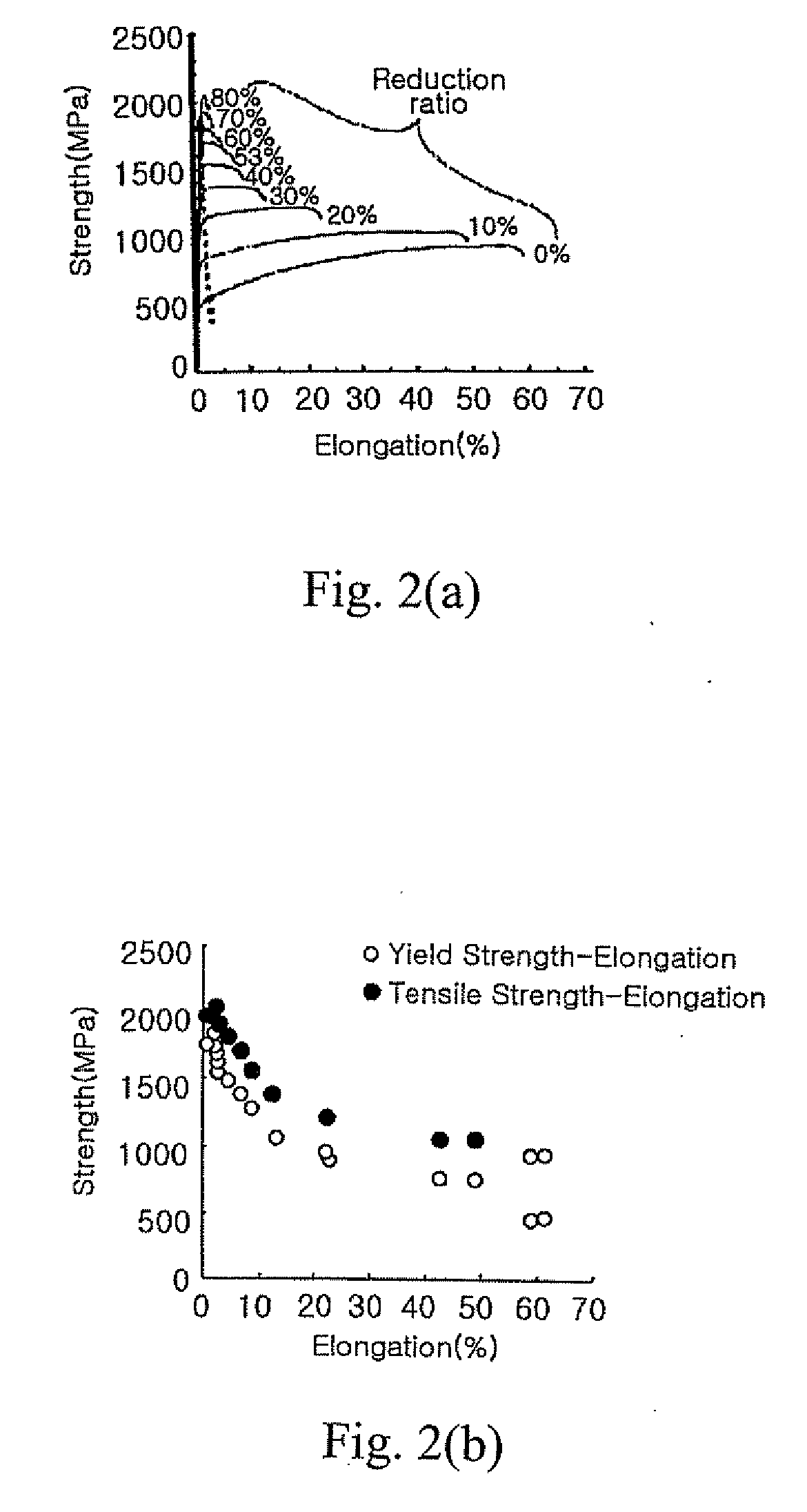

[0053]The high strength steel sheets with high workability and high manganese having an austenite single phase, prepared in Example 1, were cold-rolled again, and measured for mechanical properties. The results are listed in the following Table 3.

TABLE 3RollingYSTST-ElamountNote19471.3939.960.40Comparative Steel19-1750.51047.244.610Inventive Steel19-2930.51209.722.220Inventive Steel19-31088.31371.312.530Inventive Steel19-41247.71554.28.640Inventive Steel19-51388.21704.16.850Inventive Steel19-61503.61808.64.660Inventive Steel19-71612.81924.52.870Inventive Steel

[0054]As shown in Table 3, it was revealed that the yield strengths of the high strength steel sheets are enhanced. It was usually seen that the yield strengths are increased to 750 MPa or more in the 10% phase transformation, and the elongation is excellent at 44%, indicating that the high strength steel sheets have excellent formability and crash-worthiness as the structural members.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com