Crash resistant aluminum alloy sheet products and method of making same

a technology of aluminum alloy and sheet products, applied in the field of aluminum alloys, can solve the problems of poor bending performance, surface irregularities and water staining that are unacceptable for outer auto body applications, and achieve good as-processed formability and shape, good crashworthiness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

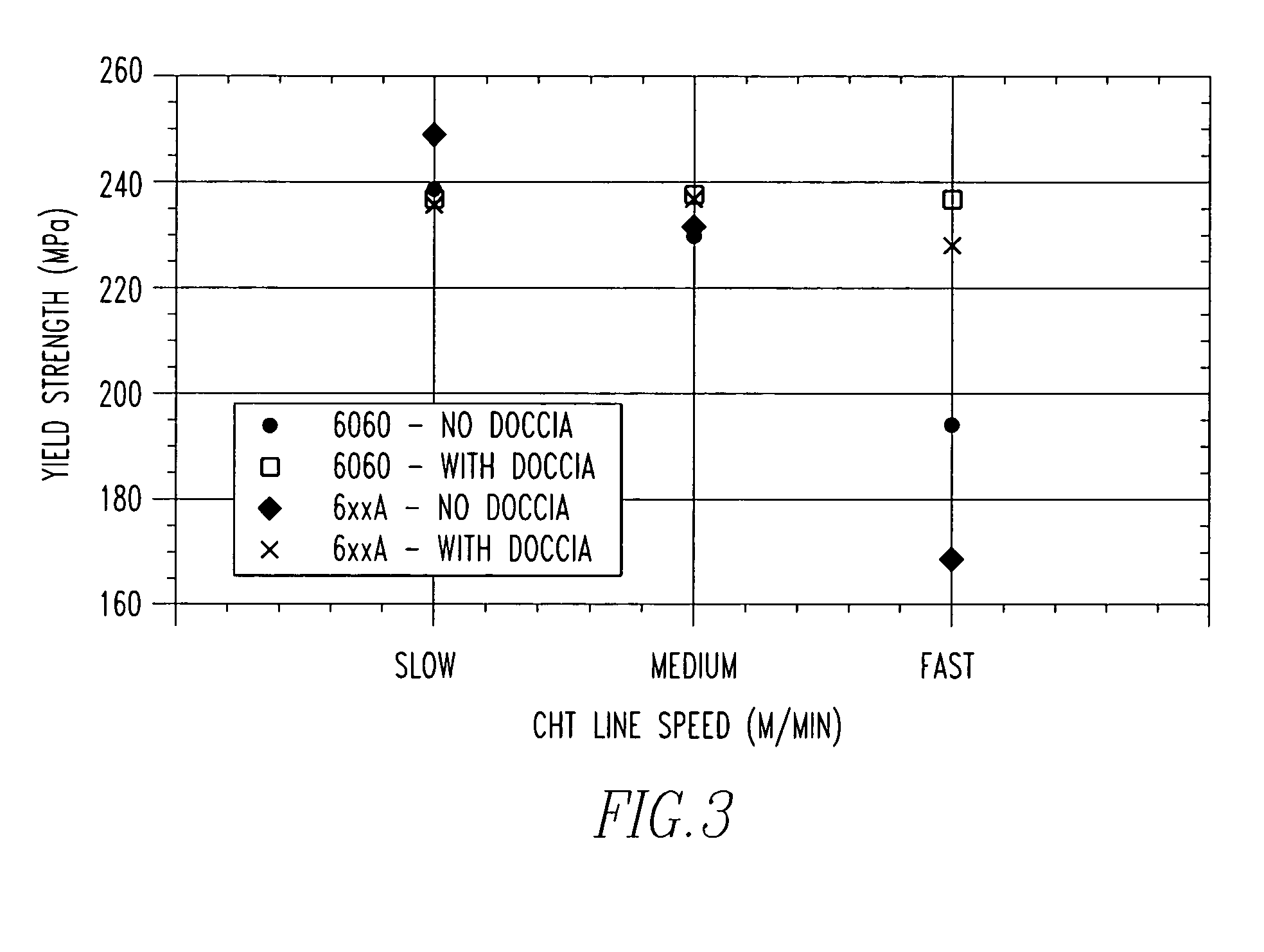

The present invention provides aluminum alloy sheet products having favorable crash resistant properties. As used herein, the term “sheet” refers to aluminum alloy products having thicknesses from 0.2 to 6.3 mm. For auto body sheet products, thicknesses of from 0.7 to 3.5 mm are preferred. The aluminum alloy sheet products exhibit favorable crash resistance or crashworthiness properties. For the purpose of this invention, crashworthiness is defined as the ability of a material to absorb energy by plastic deformation without appreciable cracking. The crashworthiness of the sheet products can be quantified by critical fracture strain (CFS).

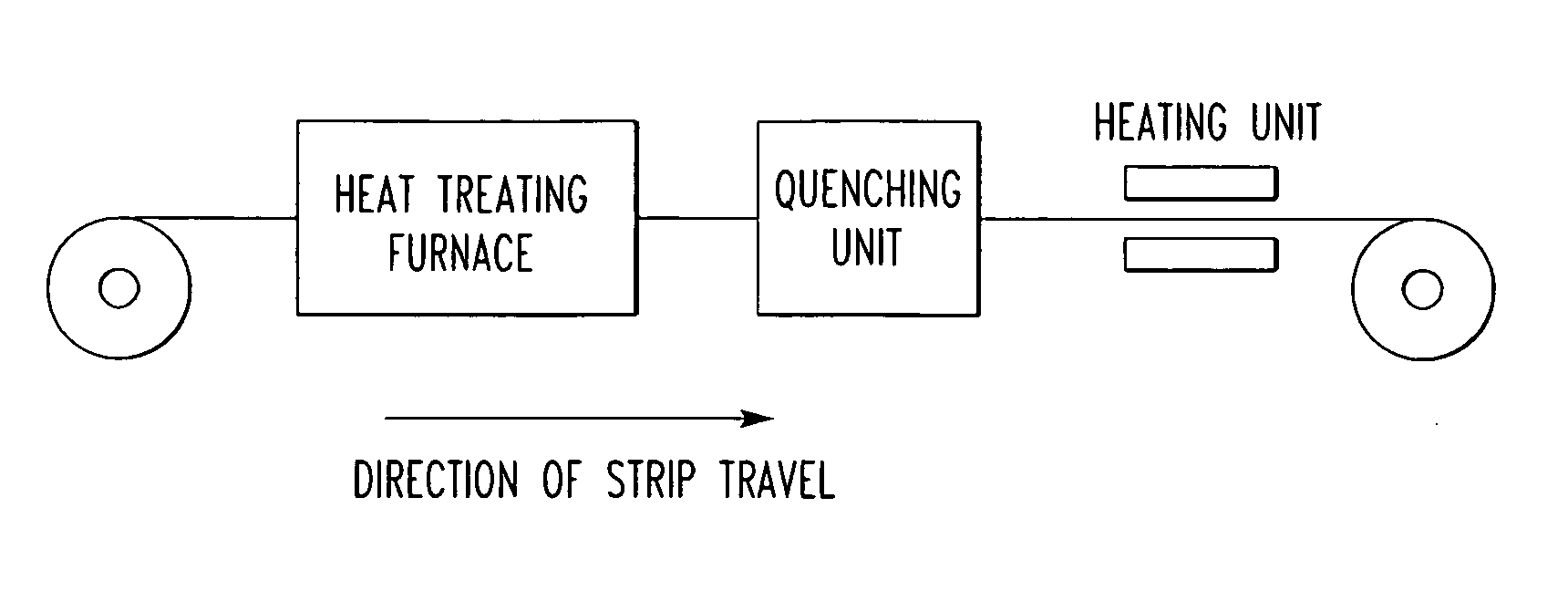

A preferred process path includes the following steps: casting of an aluminum alloy ingot by conventional or continuous methods; hot rolling; intermediate annealing; cold rolling; solution heat treating; and slow quenching, e.g., air quench or minimum distortion water quench. The steps of solution heat treating and slow quenching preferably occur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com