Mechanical structure crashworthiness simulation experiment platform

A technology of simulation experiment and performance, applied in the field of mechanical environment simulation experiment platform, can solve the problems of the collision table too small in size, difficult to operate, poor collision waveform, etc., to achieve height adjustment accuracy and flexibility, ensure accuracy, good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

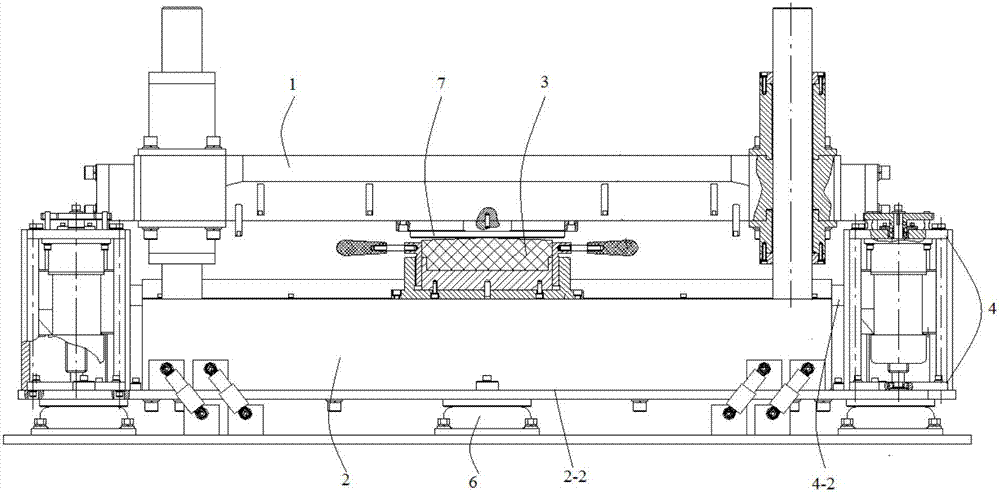

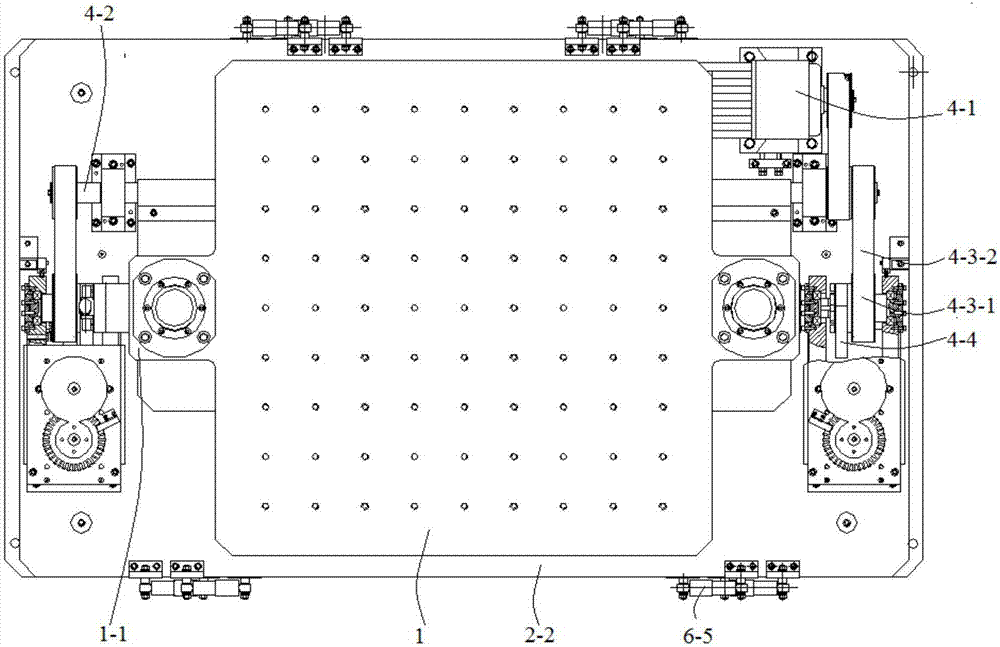

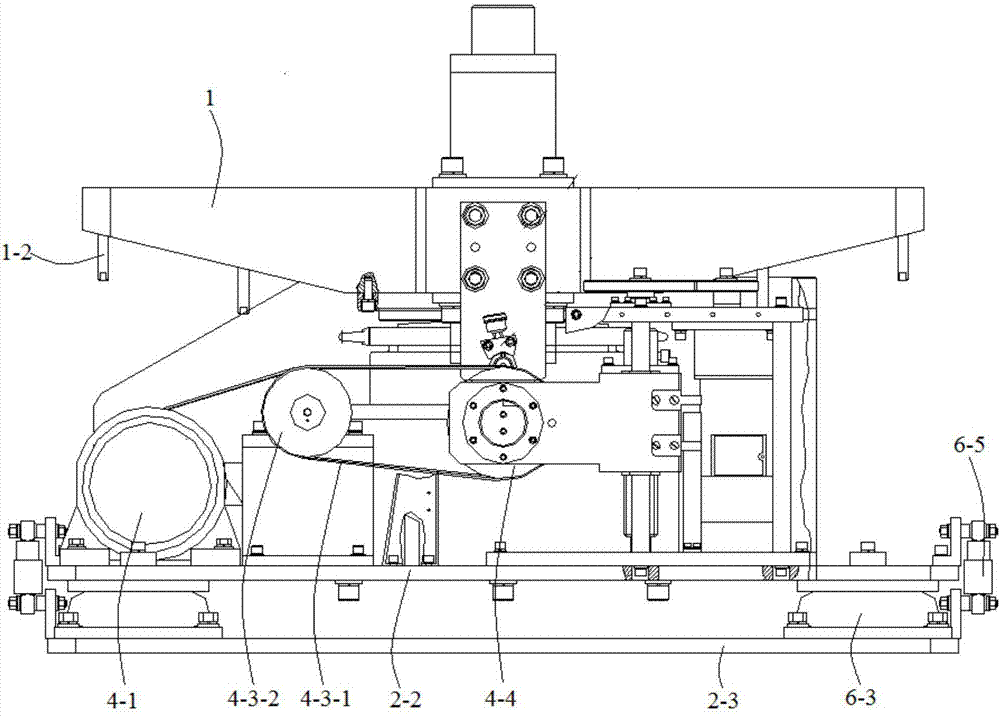

[0071] In conjunction with the accompanying drawings, this embodiment provides a mechanical structure collision performance simulation experiment platform, including a table top 1, a table body 2, a waveform generator 3, a synchronous transmission system 4, a cam center height adjustment system 5 and a vibration isolation platform 6;

[0072] The table top 1 is square, the size of the table top 1 is 1.2m×1.2m, there are dynamic transmission 1-1 on both sides of the table top 1, and the dynamic transmission 1-1 is installed on the table body 2 through the support plate 10; the table body 2 includes the base 2- 1. The upper base plate 2-2 and the lower base plate 2-3, the base 2-1 is placed above the upper base plate 2-2, the lower base plate 2-3 is placed under the upper base plate 2-2; the punch 7 is arranged under the table top 1, The punch 7 is located at the center of the table top 1, and one end surface of the punch 7 is an outwardly convex curved surface; a plurality of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com