Method for analyzing crushing property of composite material coated twelve-rectangular-cross-section thin-walled beam

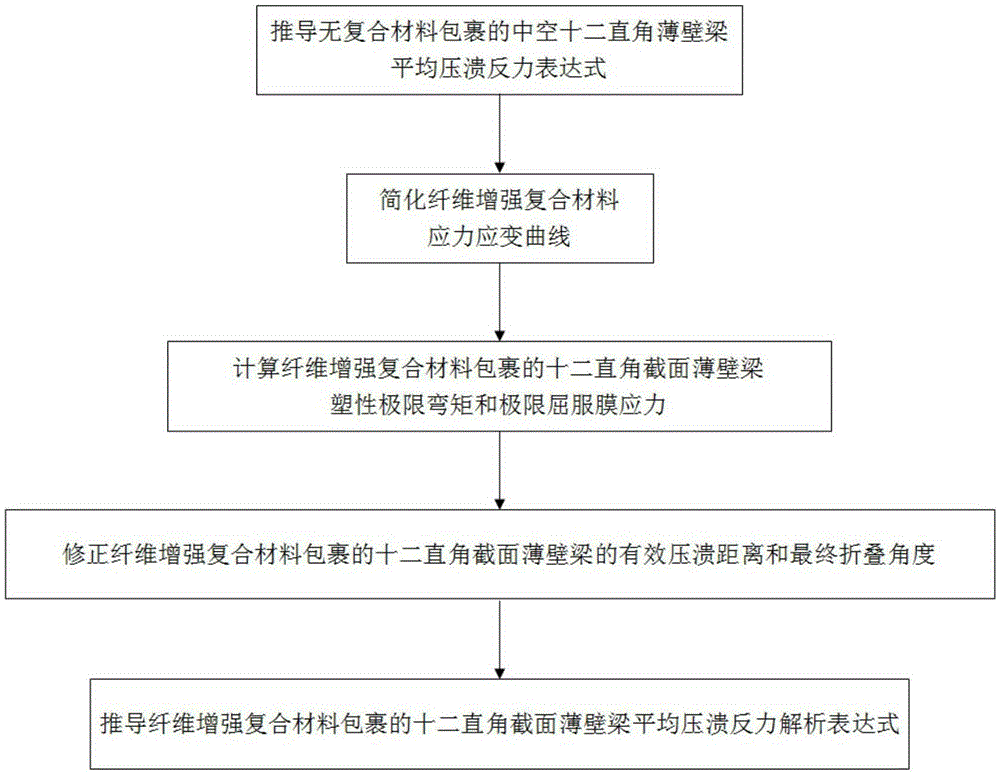

A technology of composite materials and twelve right angles, which is applied in the field of analysis of the crushing characteristics of thin-walled beams with twelve right angles, can solve the problems of lacking and inability to use finite element methods or test methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

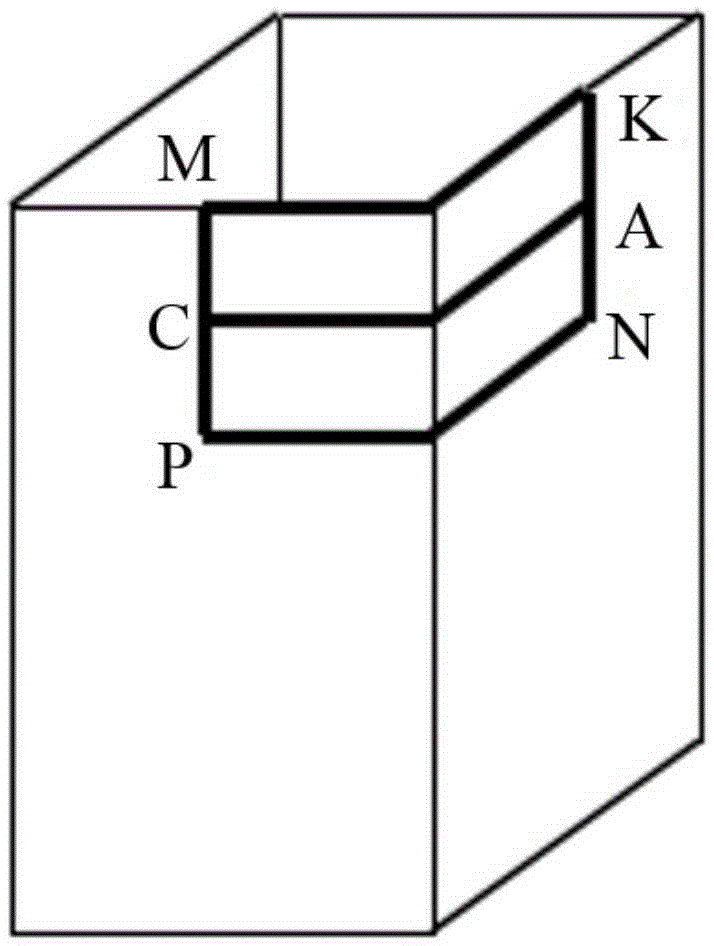

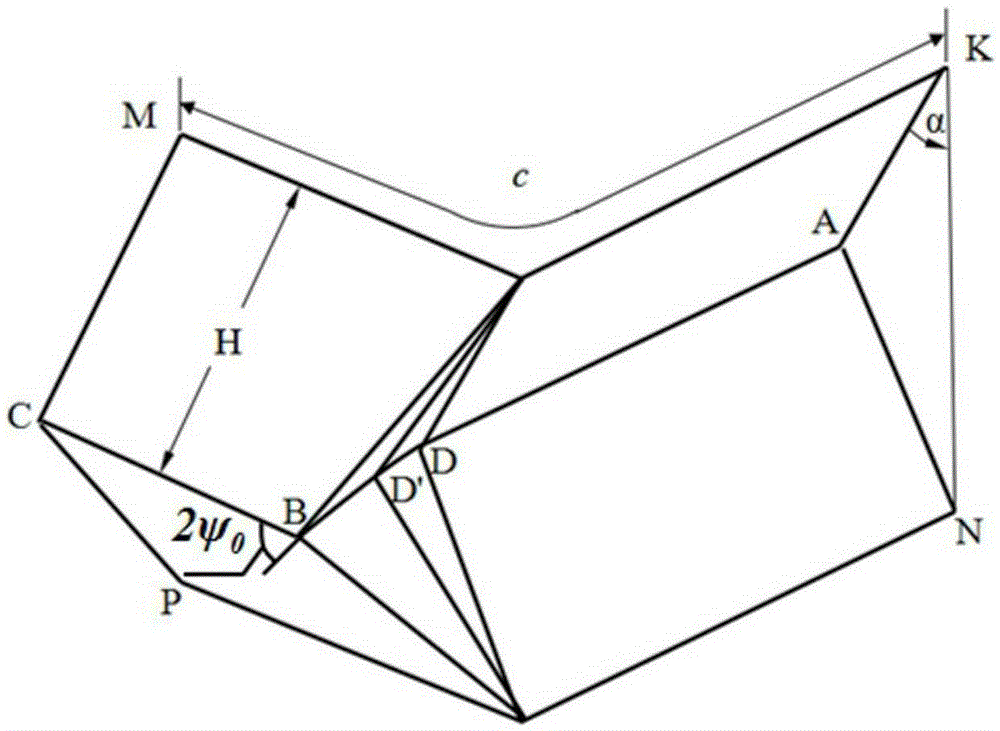

[0208] Next, the present invention introduces the analysis method for the crushing characteristics of the thin-walled beam with twelve right-angled sections wrapped by the fiber-reinforced composite material proposed by the present invention in conjunction with the examples.

[0209] The fiber-reinforced composite material selected in the embodiment is a glass fiber epoxy resin composite material, and its material mechanical properties are as shown in table 1, and the fiber of the used E glass fiber reinforced epoxy resin (GF / Epoxy) composite material is along the metal thin wall The beam walls are arranged circumferentially, perpendicular to the axis of the thin-walled beam. The material of the metal thin-walled beam is RSt37, and the yield stress σ of the metal thin-walled beam m =275MPa, the cross-sectional dimensions of twelve right-angle thin-walled beams are as follows Figure 6 shown. Metal thin-walled beam thickness h m = 1mm, the number of wrapping layers is 2, cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com