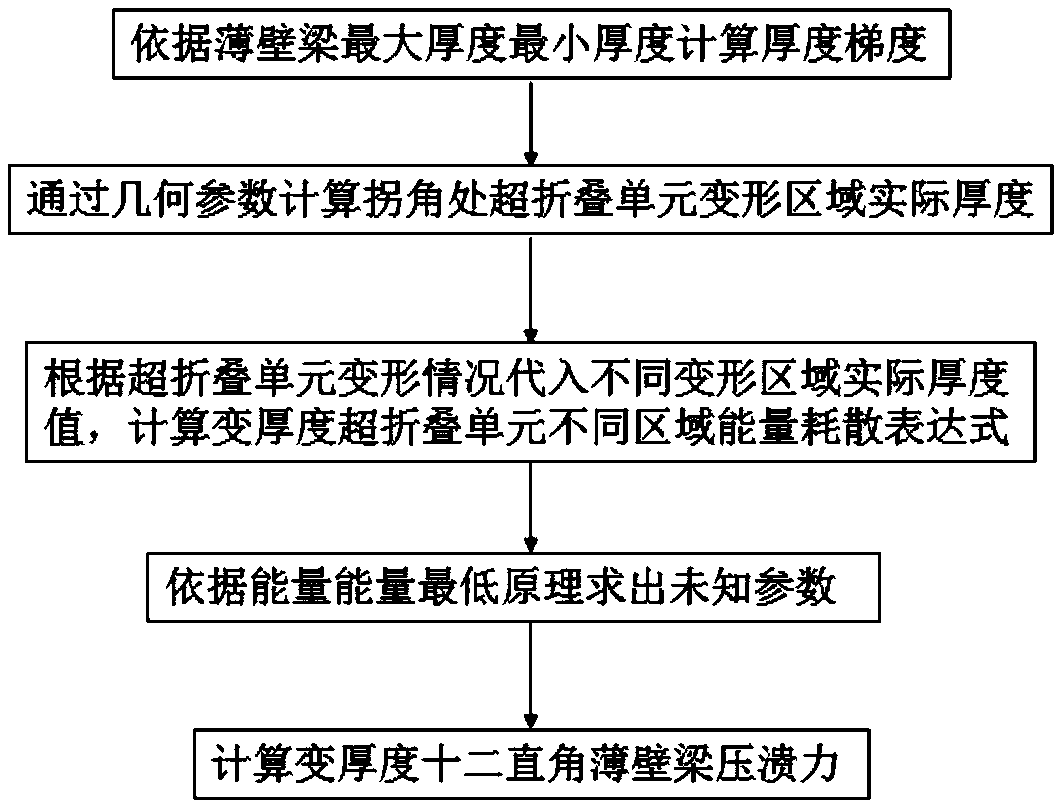

A method for analyzing the crushing characteristics of a thin-walled beam with a twelve-right-angle section with variable thicknes

A technique of twelve right angles and characteristic analysis, applied in special data processing applications, instruments, geometric CAD, etc., can solve problems such as lack of, inability to use finite element method or test method, and analysis of thin-walled beam crush performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0231] Next, the present invention introduces the method for analyzing the crushing characteristics of the thin-walled beam with variable thickness with twelve right-angled sections in combination with the embodiments.

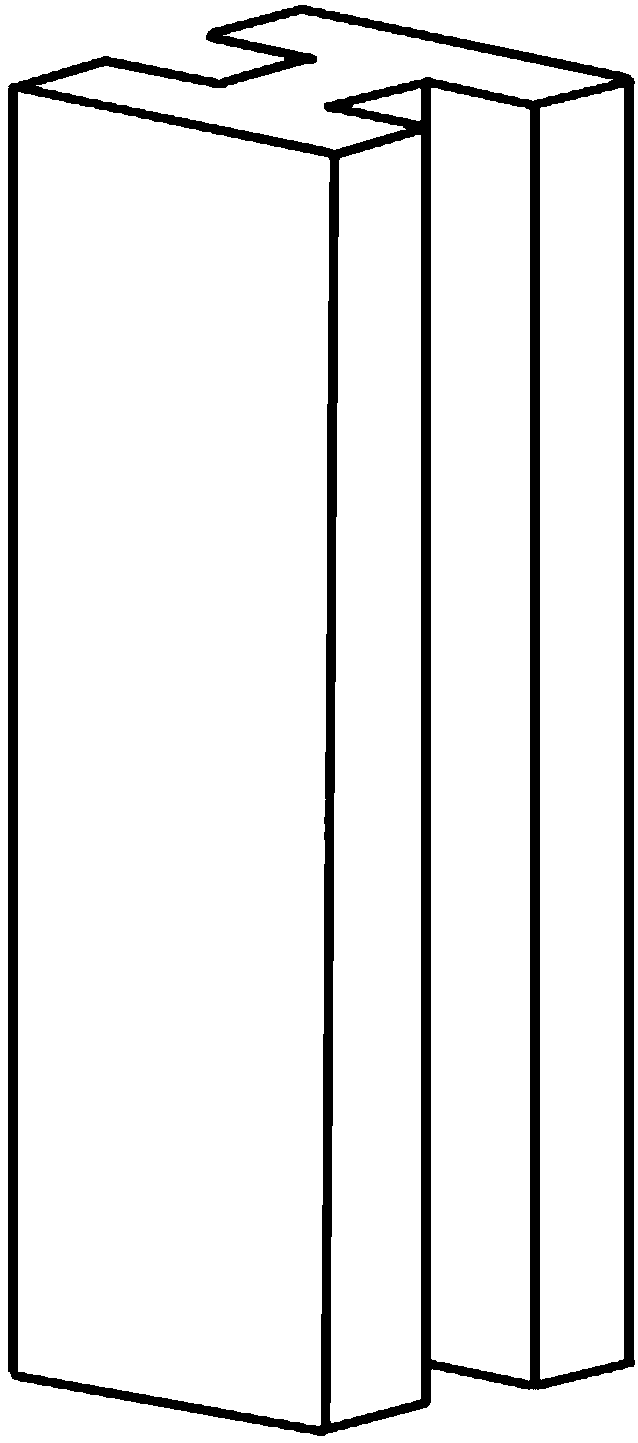

[0232] The variable thickness twelve right-angle thin-walled beams selected in the embodiment are made of aluminum alloy, the grade is Al6061T6, and its stress-strain curve is as follows Figure 5 The mechanical properties of the material are shown in Table 1, and the schematic diagram of the thin-walled beam section is shown in Figure 4, where d 1 =20mm,d 2 =20mm,d 3 = 20mm, a = 20mm, t max =2.5mm,t min = 1.5 mm.

[0233] Table 1 Table of mechanical properties of AL6061T6 material

[0234]

[0235] Ⅰ According to formula (1), substitute the maximum thickness t max =2.5mm, minimum thickness t min = 1.5mm, d 1 =20mm, the calculated thickness gradient k=0.1.

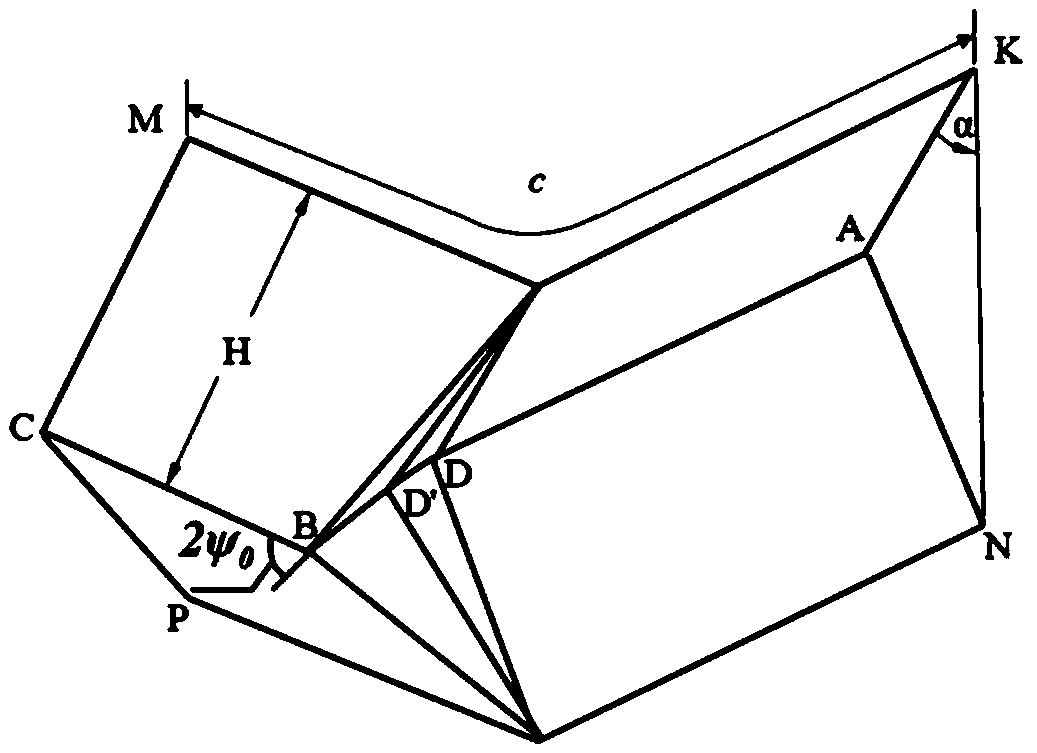

[0236] Ⅱ Calculate the actual thickness t of the corner part of the ultra-folded unit of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com