Gas cylinder fixing rack, gas cylinder frame, LNG gas supply system and vehicle

A fixed frame and gas cylinder technology, which is applied in the field of LNG gas supply system and vehicles, can solve the problems of long time, difficulty and self-heavy connection of upper and lower pipelines, so as to improve accuracy and quality stability, reduce vehicle self-weight, reduce The effect of the product's own weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

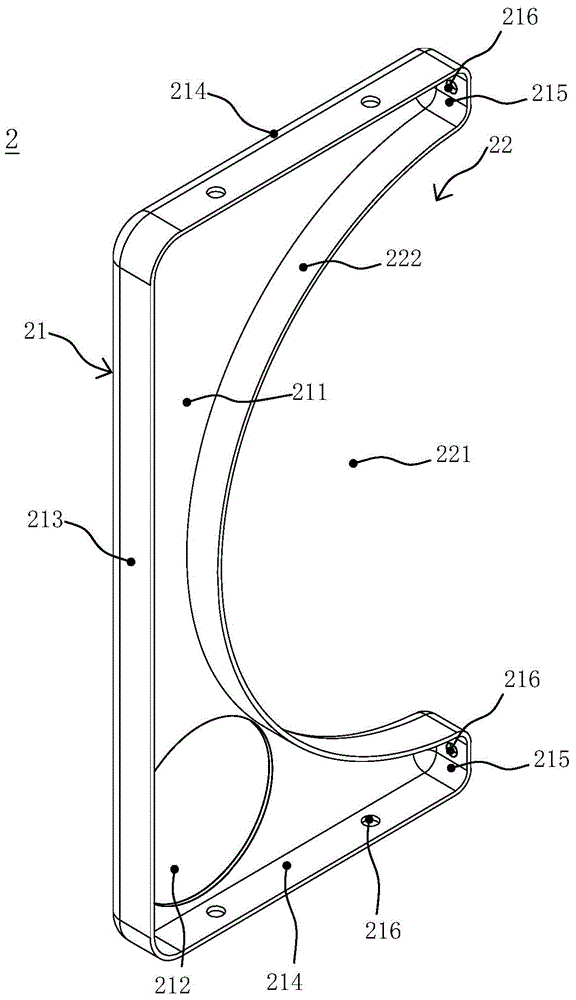

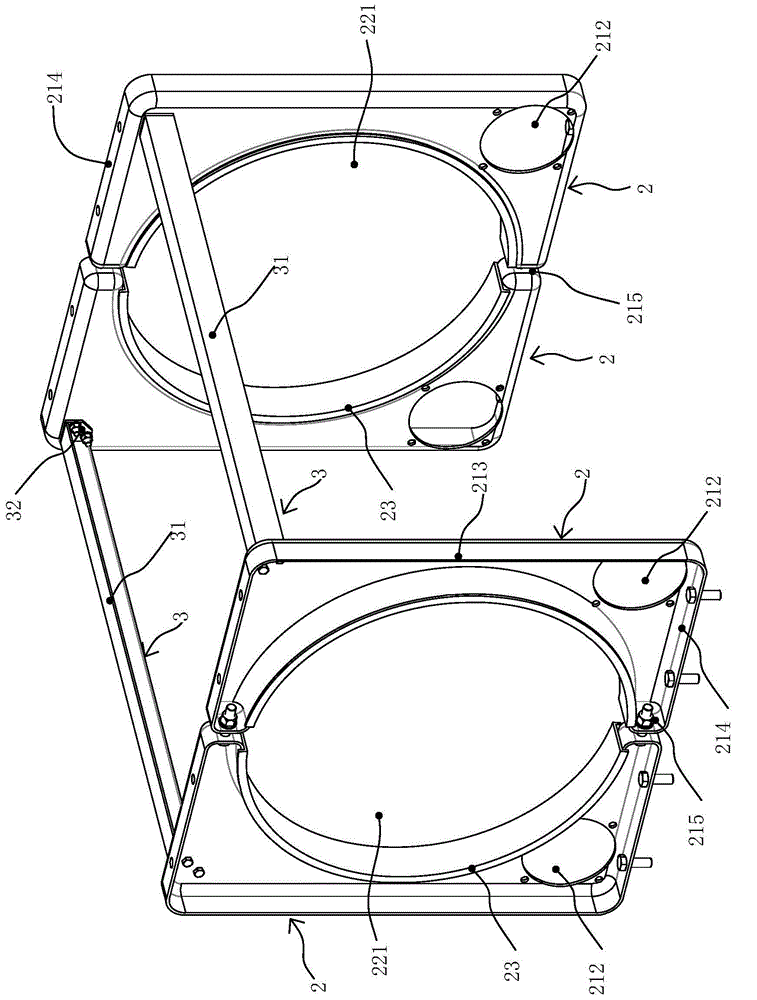

[0042] Such as Figure 1 to Figure 2 As shown, this embodiment provides a modular frame for gas cylinders, including: two modular fixing frames 2 , and the fixing frames 2 have a main body 21 and a holding portion 22 .

[0043] Such as figure 1 As shown, the main body 21 of the fixed mount 2 can be an integral stamping plate, and its length dimension can be slightly larger than the gas cylinder (see figure 2), the width dimension of the main body 21 can be slightly larger than half of the radial outer dimension of the gas cylinder, and the width dimension of the main body 21 can be basically equal to half of its length dimension, so that nearly half of the gas cylinder section can be enveloped in inside the mount. The holding part 22 can have a notch 221 recessed into the main body 21 from the side of the main body 21 in the longitudinal direction. The shape of the notch 221 can correspond to the outer contour of the gas cylinder. The shape can be arc-shaped (corresponding...

no. 2 example

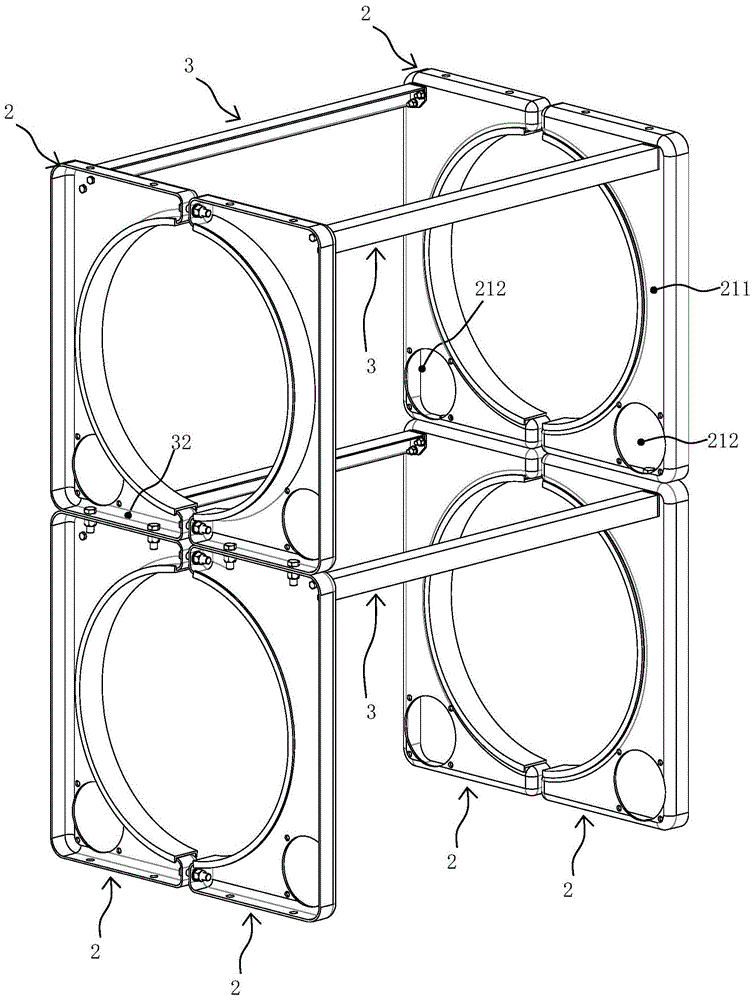

[0054] refer to image 3 , Figure 4 , is another embodiment of the present invention, when two gas cylinders need to be fixed at the same time, the frame described in the above embodiment can be used to fix the first gas cylinder first with at least two pairs of modular fixing frames 2 . Then fix the second gas cylinder with the above-mentioned frame, and the two parts of the fixing frame can be connected and assembled together for use.

[0055] Example of LNG gas supply system

[0056] Such as Figure 5 As shown, the LNG gas supply system in this embodiment includes at least one gas cylinder 1, pipeline 5 and vaporizer 4; the gas cylinder 1 is fixed with the aforementioned gas cylinder frame, the gas cylinder 1 and the vaporizer 4 are communicated with the pipeline 5, and the Road 5 connects the carburetor 4 to the gas device. A cut-off valve 6 is installed on the pipeline 5 between the gas cylinder 1 and the vaporizer 4, and / or the pipeline 5 between the vaporizer 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com