Patents

Literature

31results about How to "Cost minimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

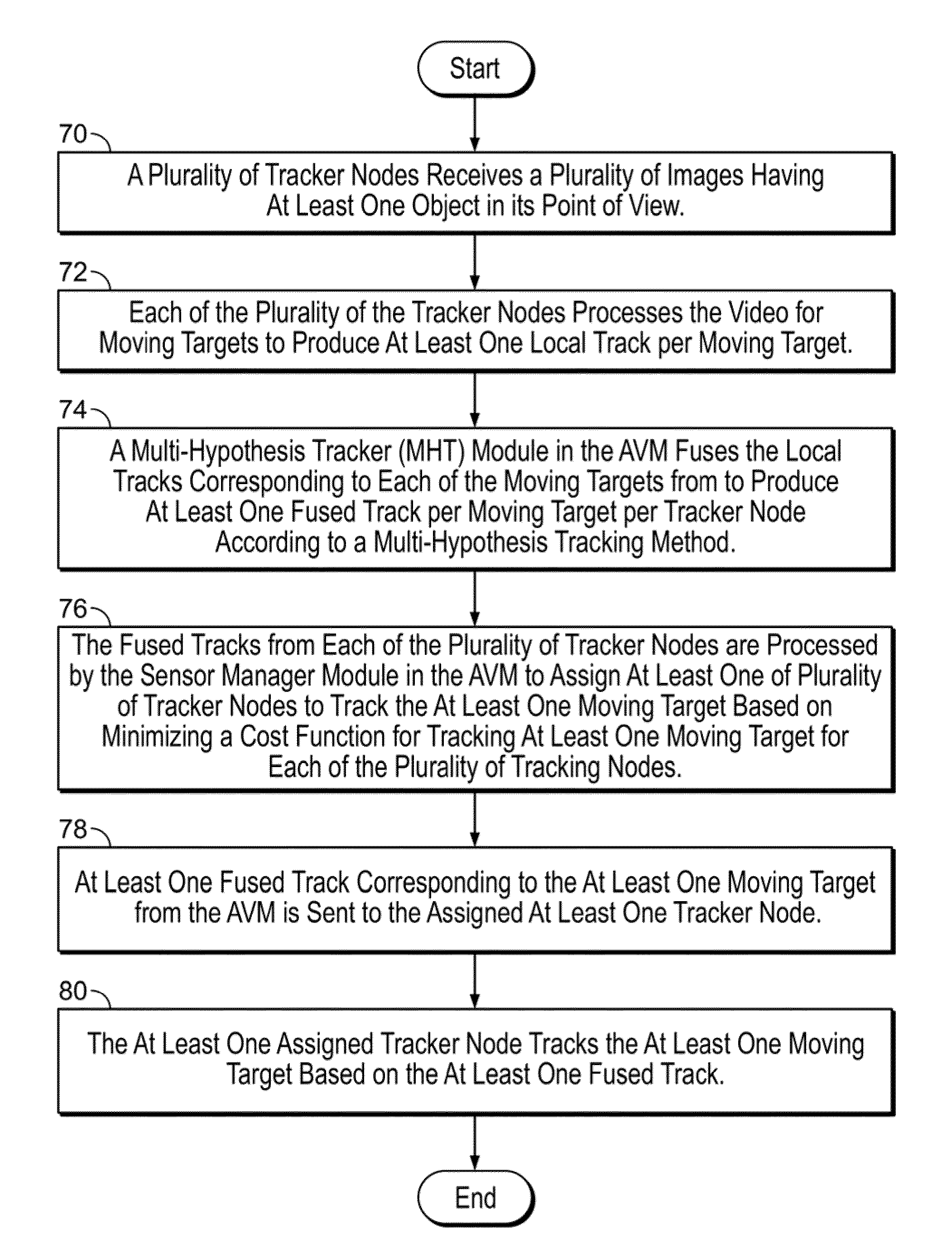

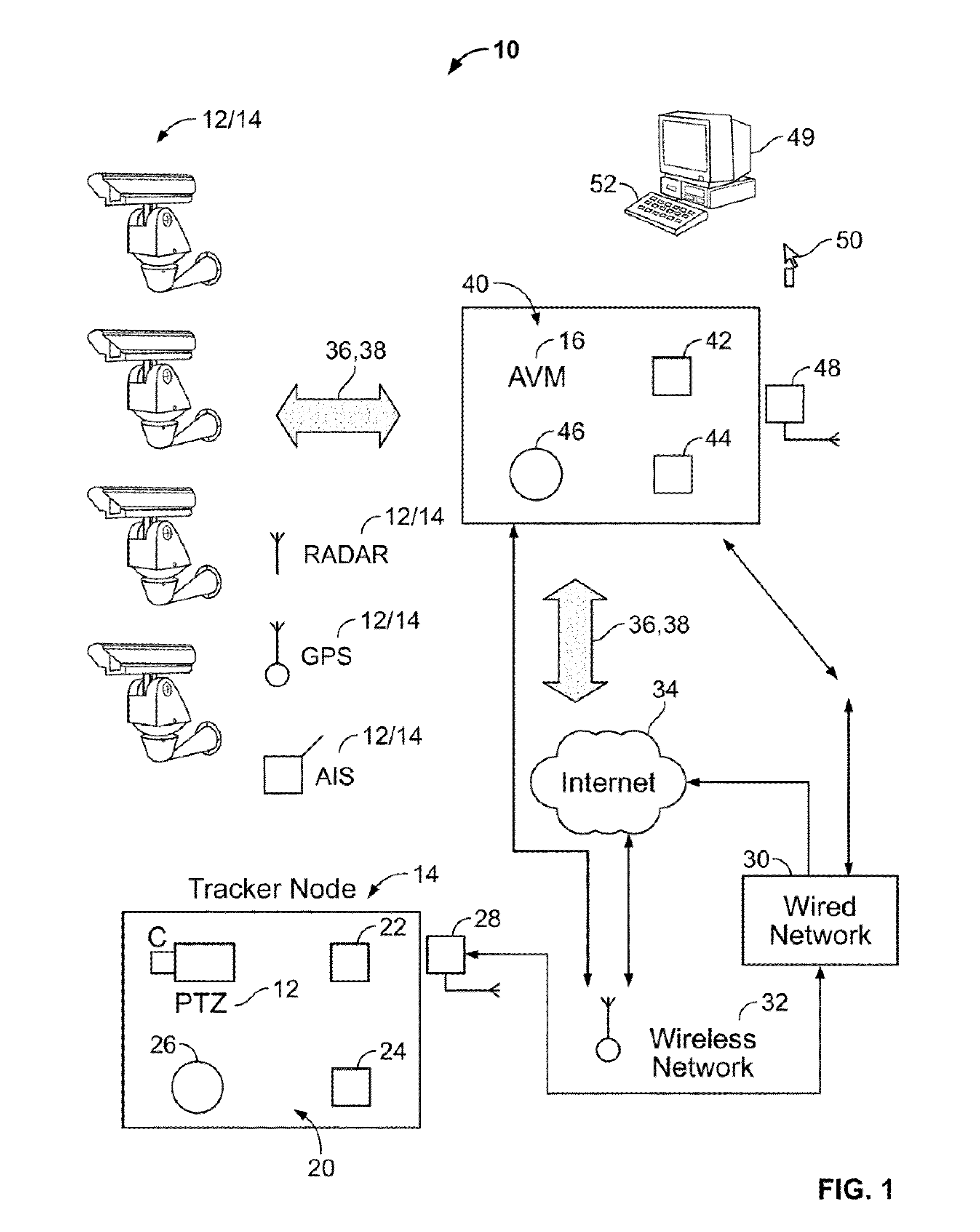

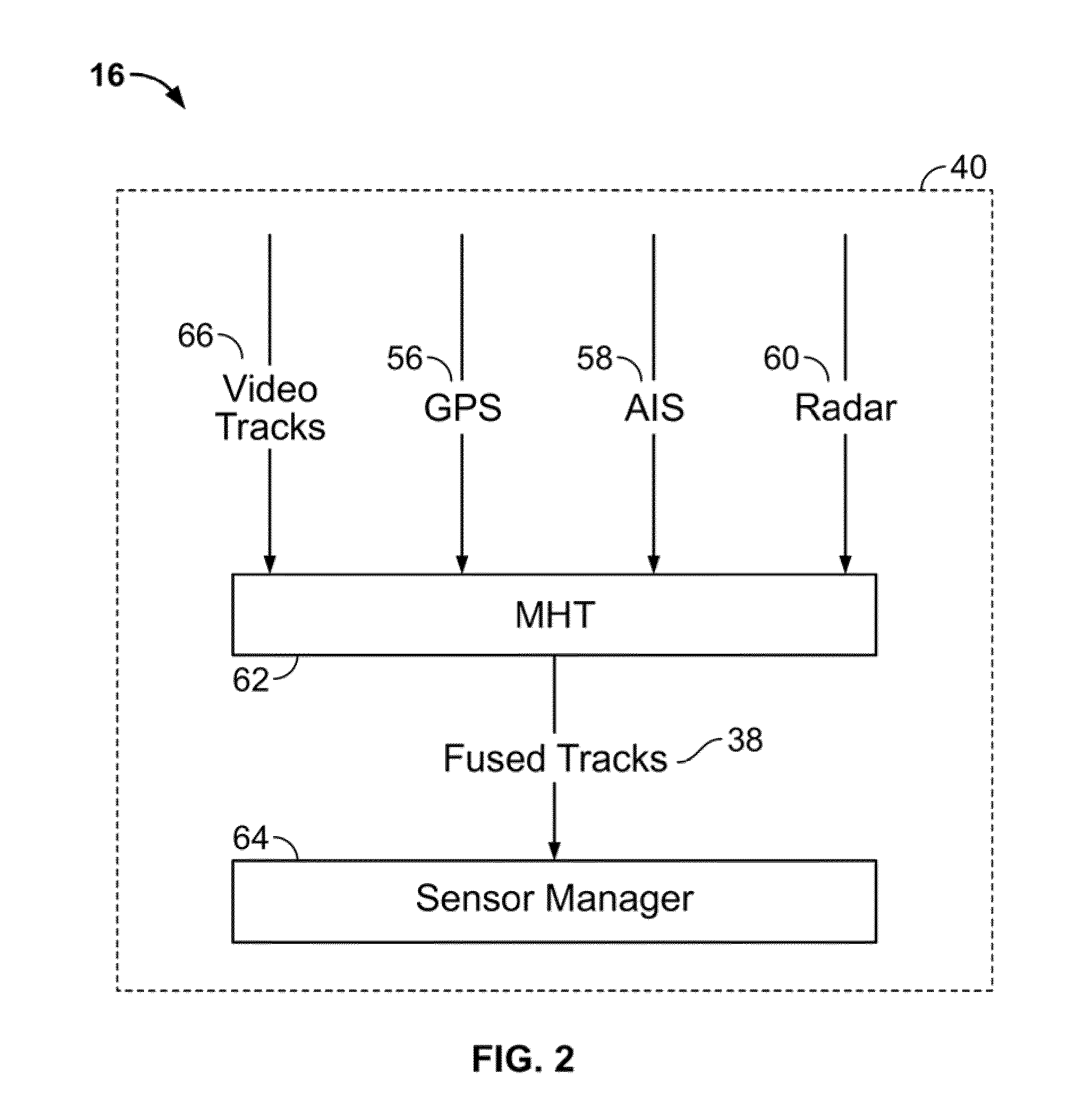

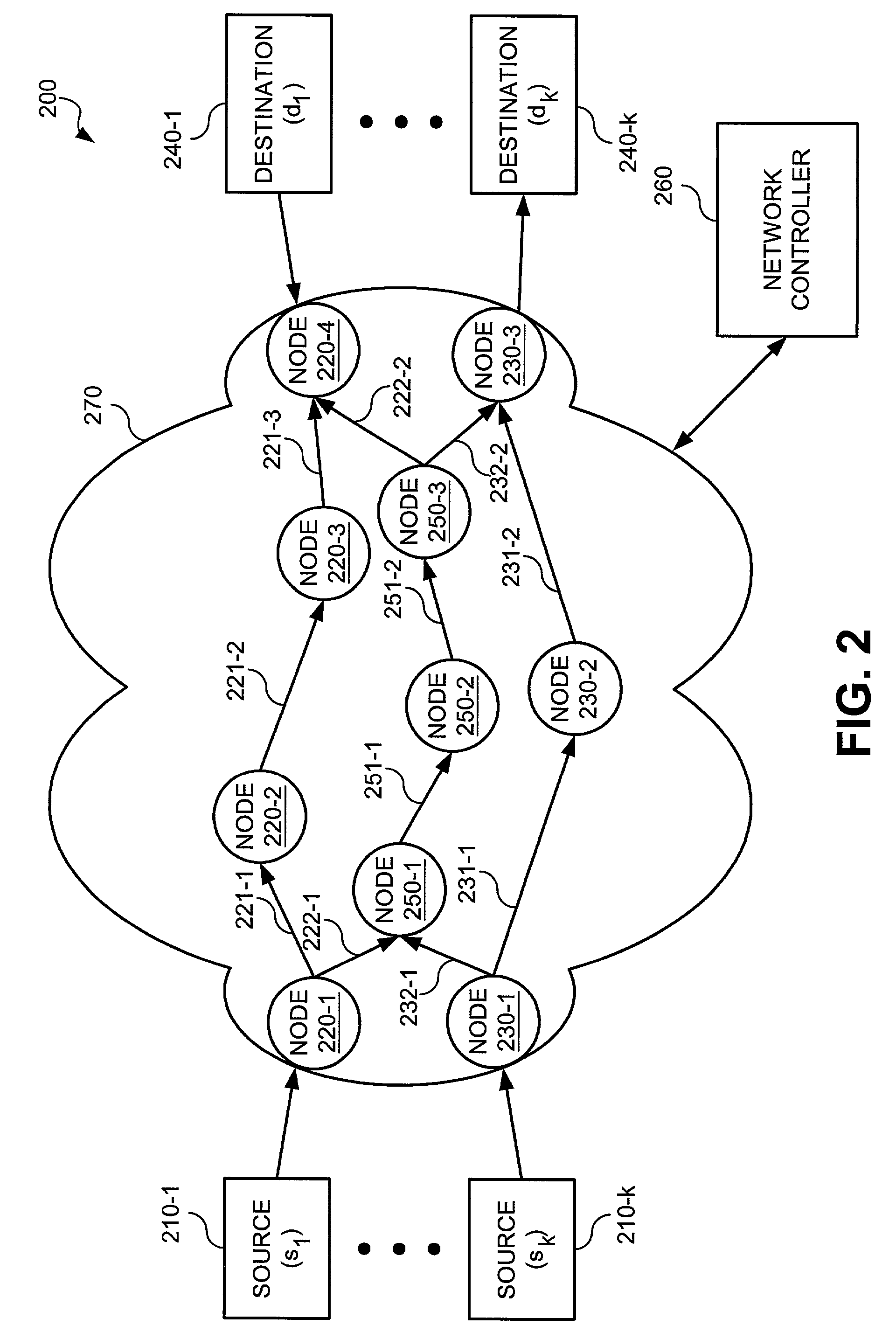

Active coordinated tracking for multi-camera systems

ActiveUS20100208941A1Cost minimizationMinimize cost functionImage enhancementImage analysisCost matrixMulti camera

A method and system for coordinated tracking of objects is disclosed. A plurality of images is received from a plurality of nodes, each node comprising at least one image capturing device. At least one target in the plurality of images is identified to produce at least one local track corresponding to each of the plurality of nodes having the at least one target in its field of view. The at least one local track corresponding to each of the plurality of nodes is fused according to a multi-hypothesis tracking method to produce at least one fused track corresponding to the at least one target. At least one of the plurality of nodes is assigned to track the at least one target based on minimizing at least one cost function comprising a cost matrix using the k-best algorithm for tracking at least one target for each of the plurality of nodes. The at least one fused track is sent to the at least one of the plurality of nodes assigned to track the at least one target based on the at least one fused track.

Owner:SRI INTERNATIONAL

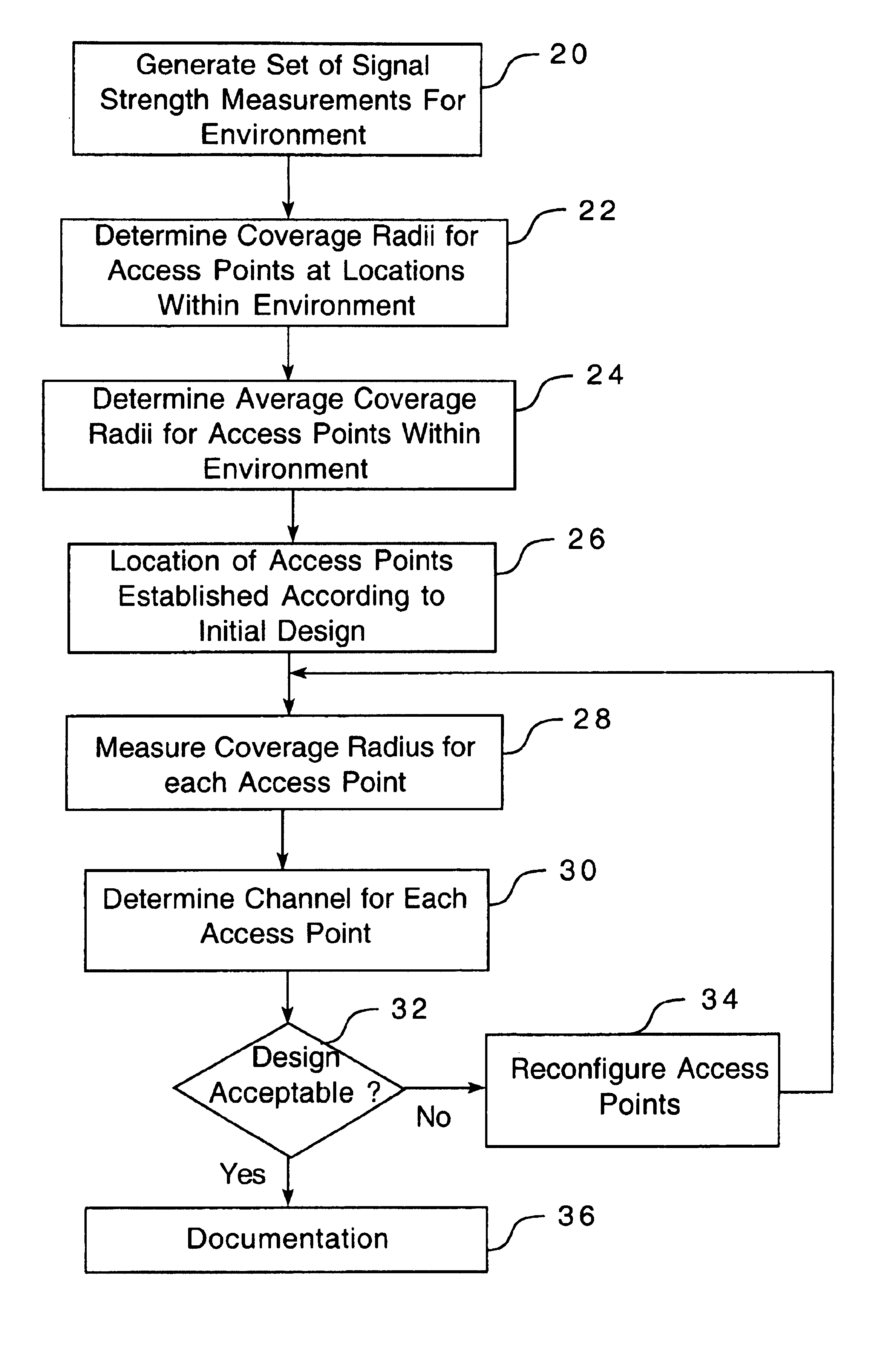

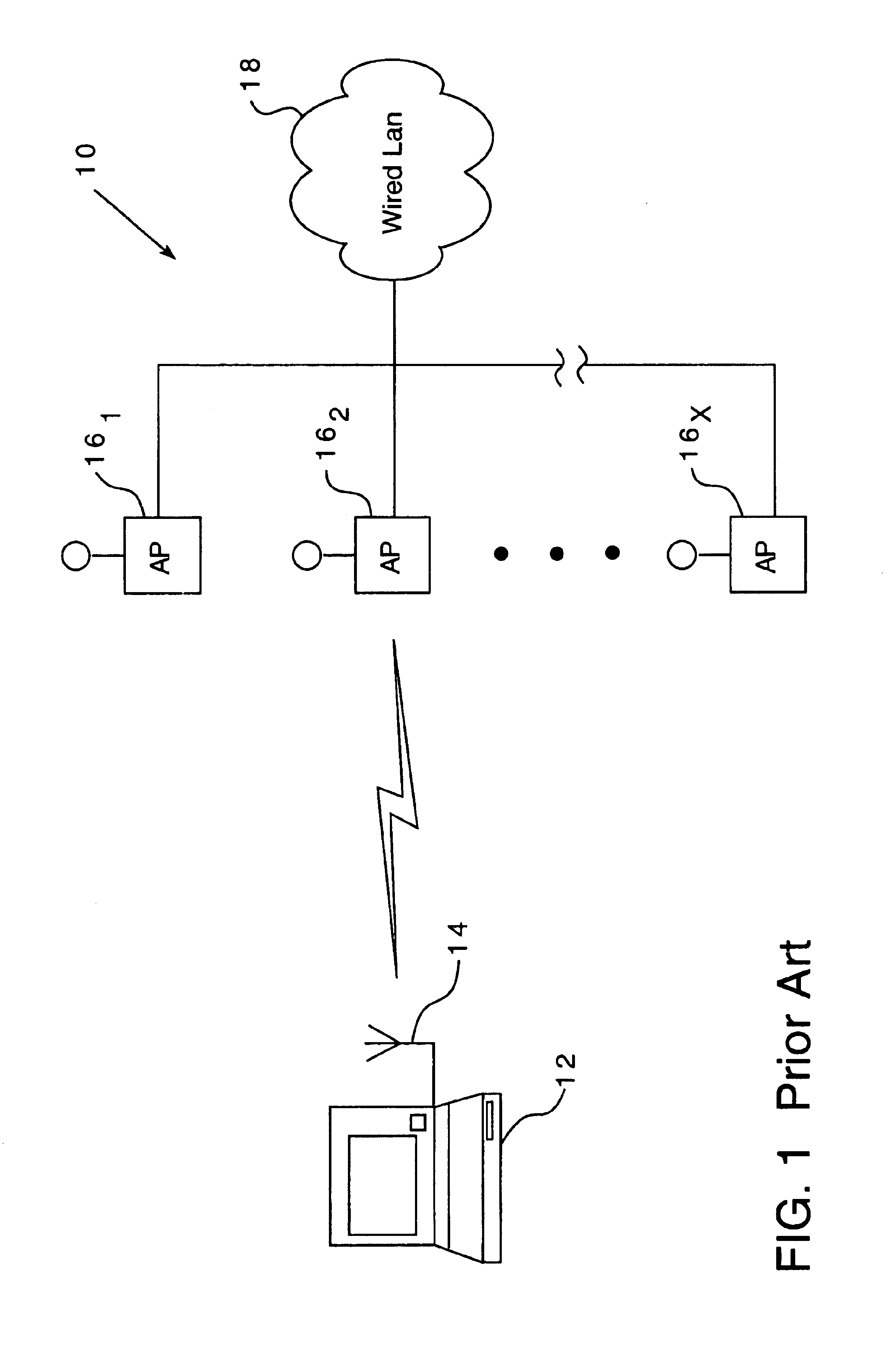

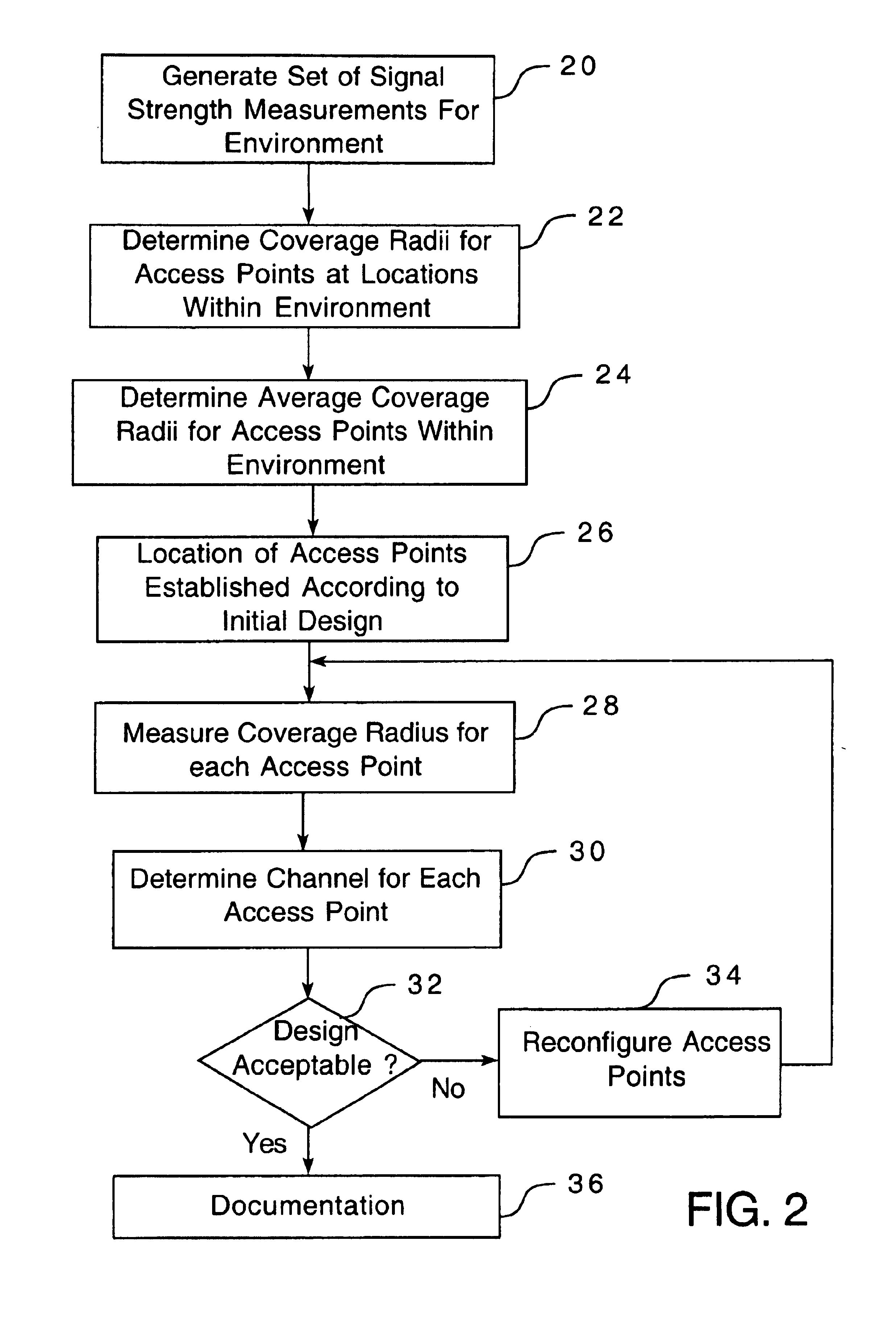

Method for configuring a wireless network

InactiveUS6711148B1Minimize coverage overlapCost minimizationData switching by path configurationRadio/inductive link selection arrangementsTelecommunicationsWireless network

A method for establishing the location of access points for a network providing wireless communications coverage for an environment, including determining a coverage radius of an access point at certain locations within the environment, determining an average coverage radius of the access points for the environment based on the determined coverage radii, and positioning the access points at locations within the environment to provide continuous wireless coverage for the environment based on the average coverage radius.

Owner:CARNEGIE MELLON UNIV

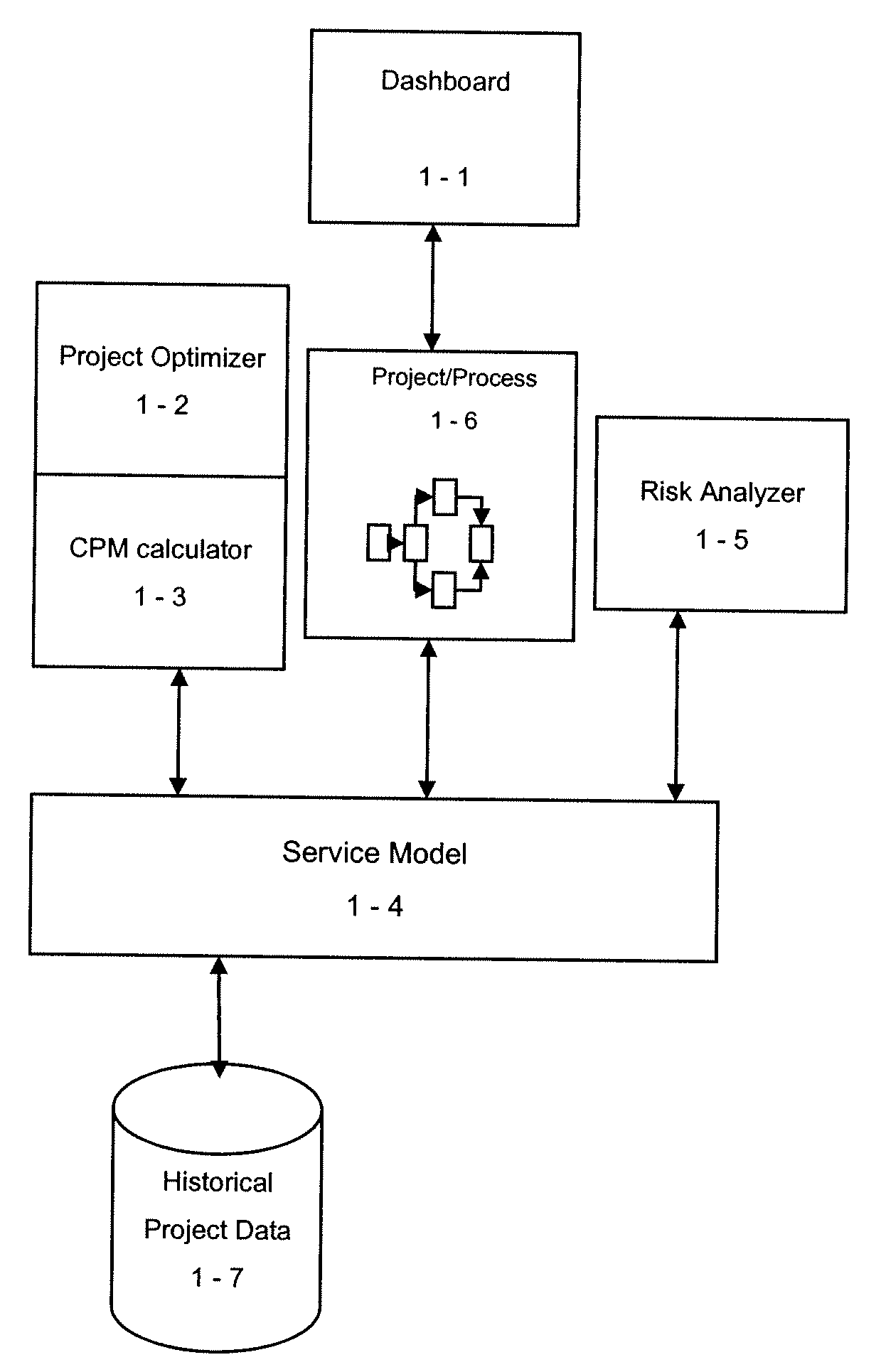

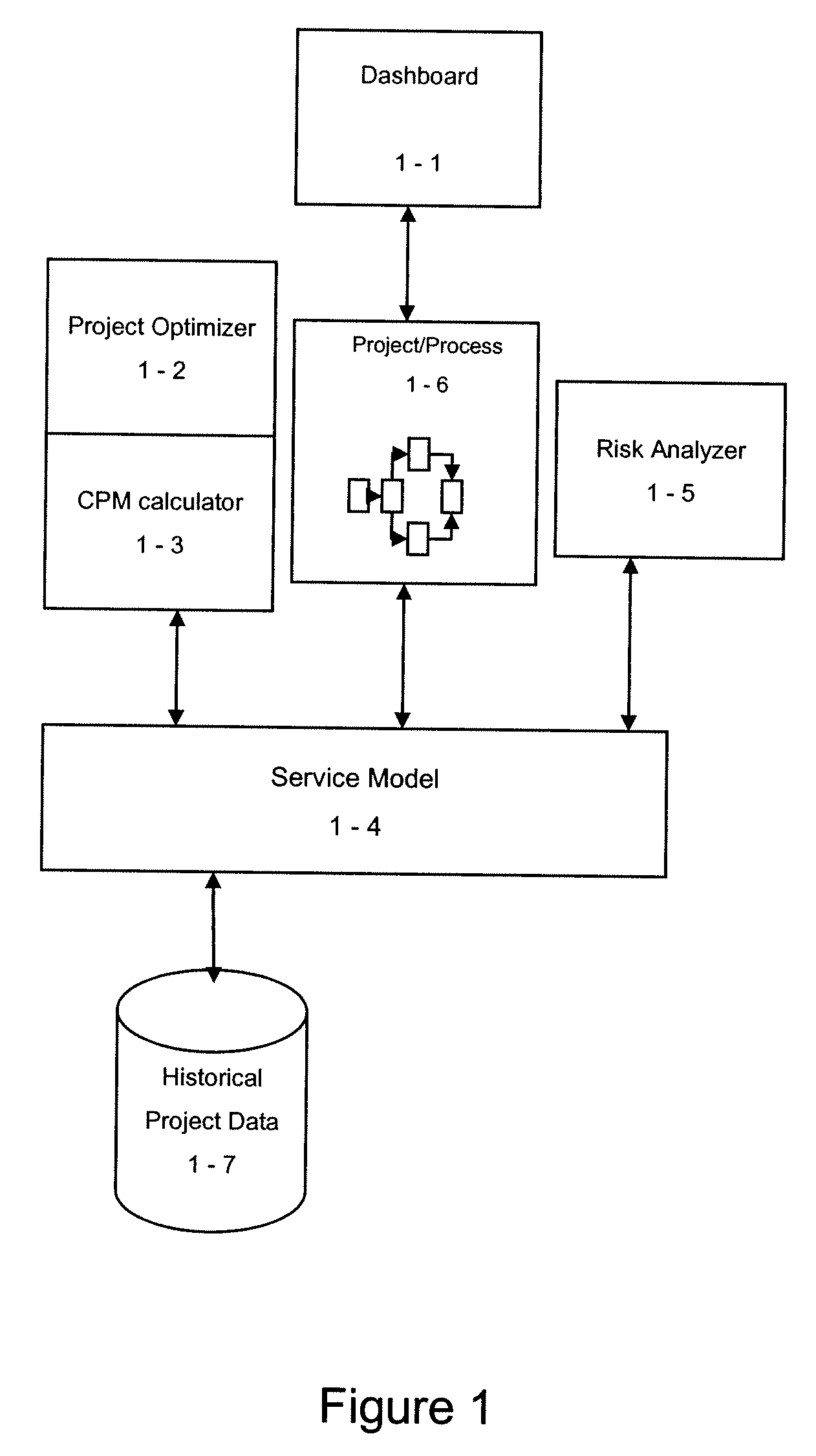

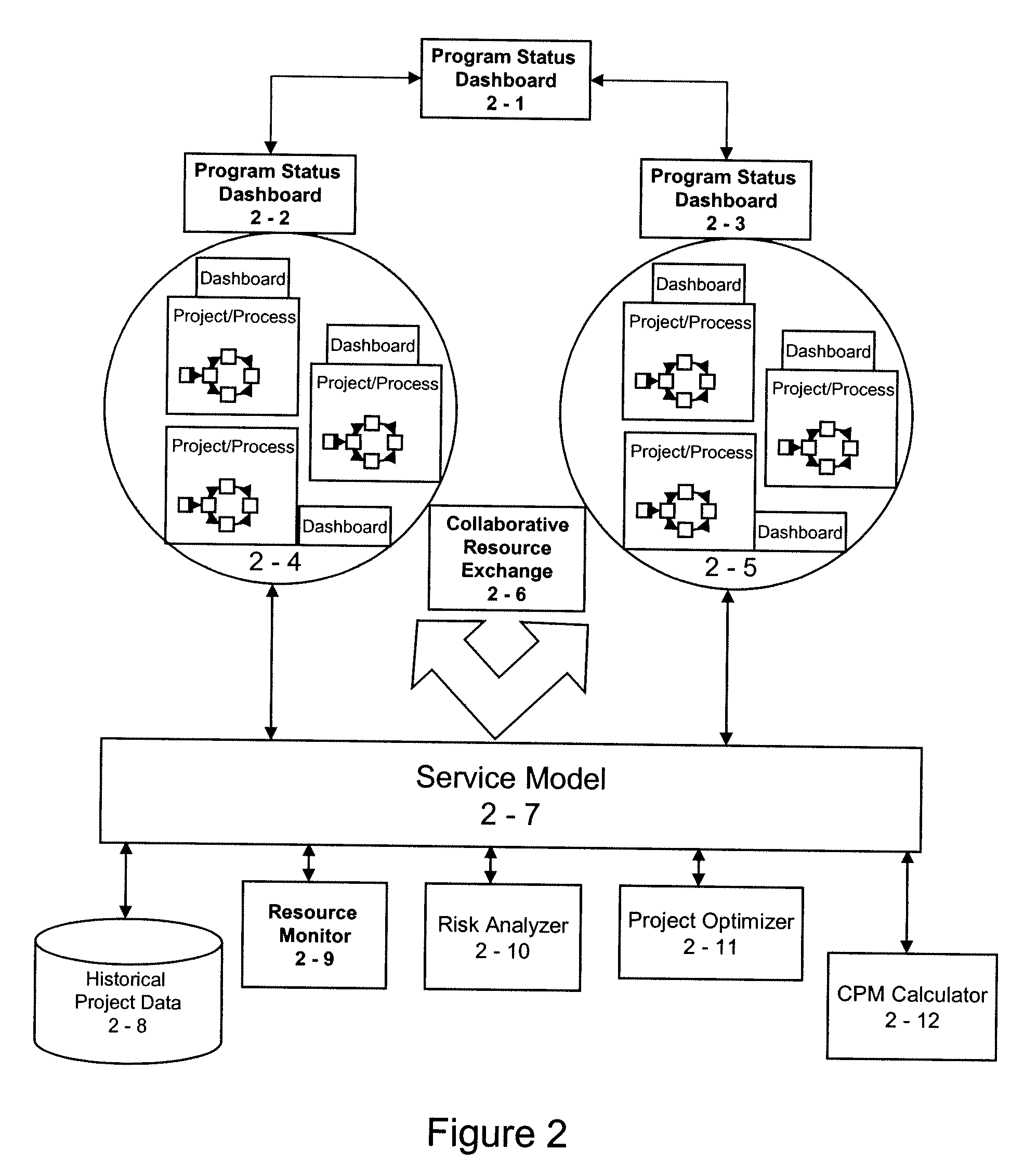

Method and System for Adaptive Project Risk Management

InactiveUS20080255910A1Cost minimizationDelayed recoveryFinanceMultiprogramming arrangementsRisk profileProgram planning

A computer implemented method for improving project risk management based on (a) a quantitative analysis of risks affecting activities, i.e., the root factors leading to cost and time overruns on an activity by activity basis, and (b) an optimization of the resources allocation to each activity in the project plan, is employed to maximize the probability of completing projects on time and within-budget. The method can be employed prior to proceeding with one or more projects, but is also advantageous in that it is adaptive in the sense that more information can be learned during the course of a project about the risk factors present in the project, and this information is used to enable dynamically re-allocating resources to ensure a better outcome given an updated risk profile. Preferably, a Bayesian Belief Network (BBN) is used to capture how risk factors identified by project managers influence individual activity durations.

Owner:IBM CORP

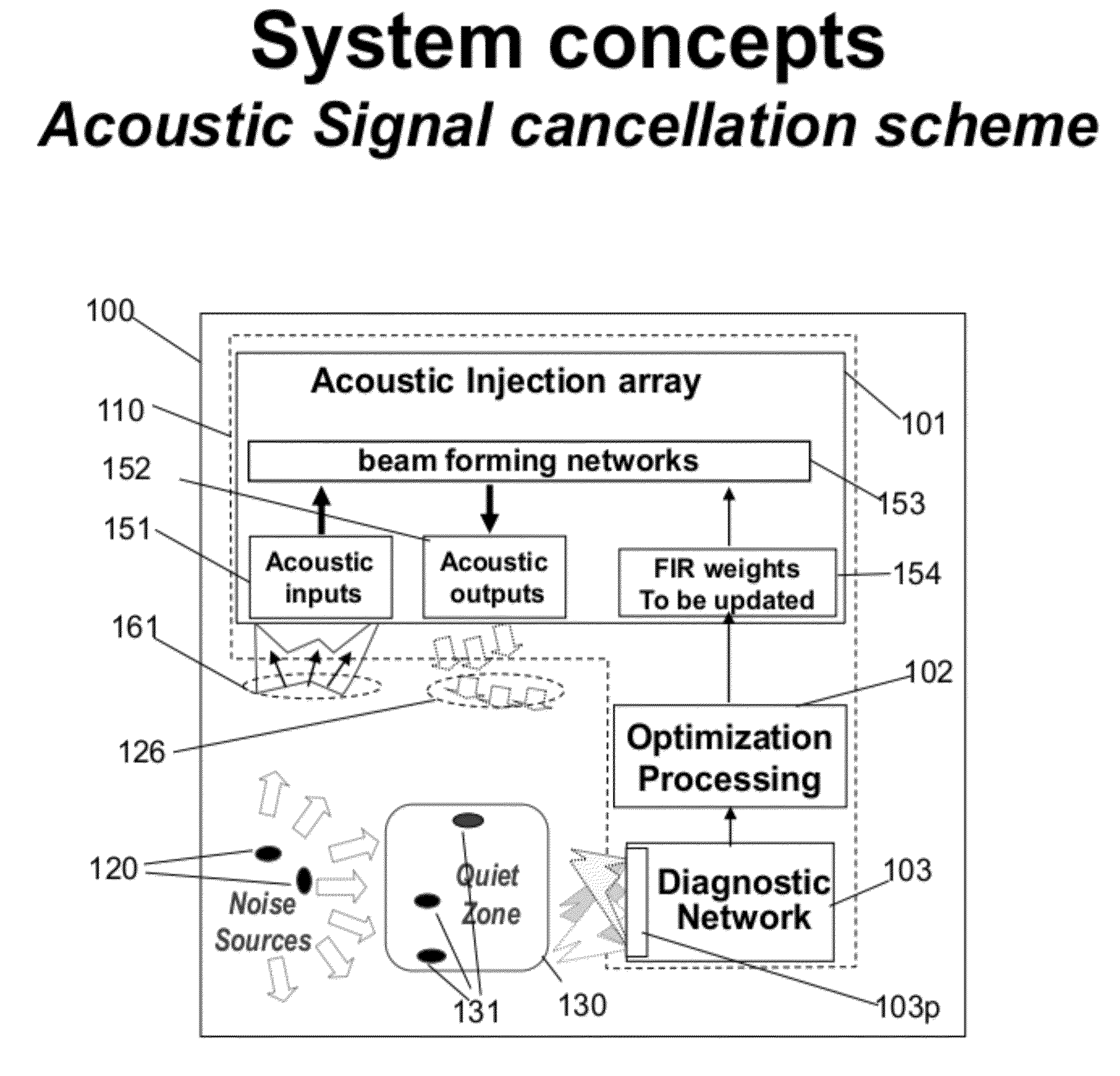

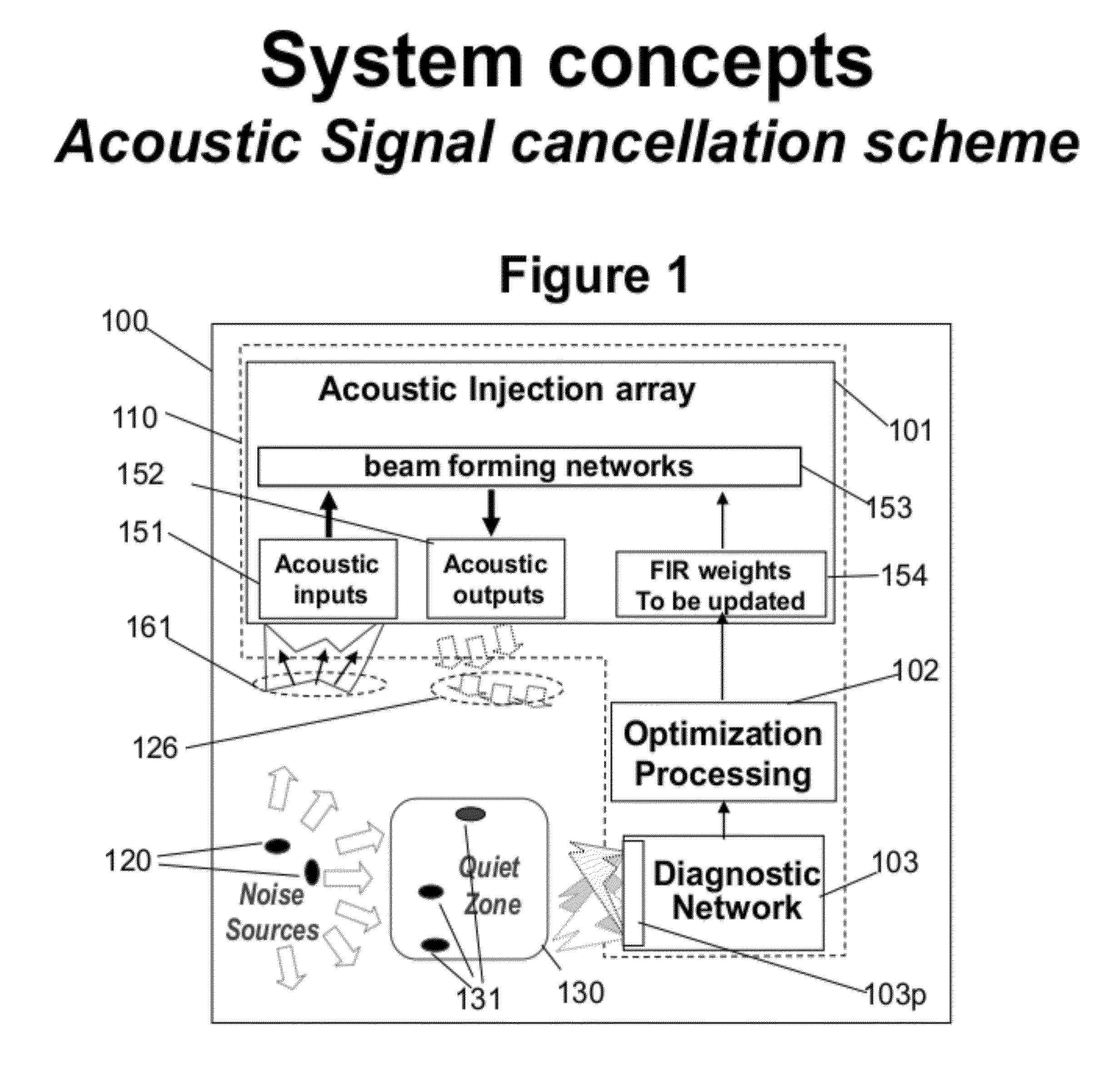

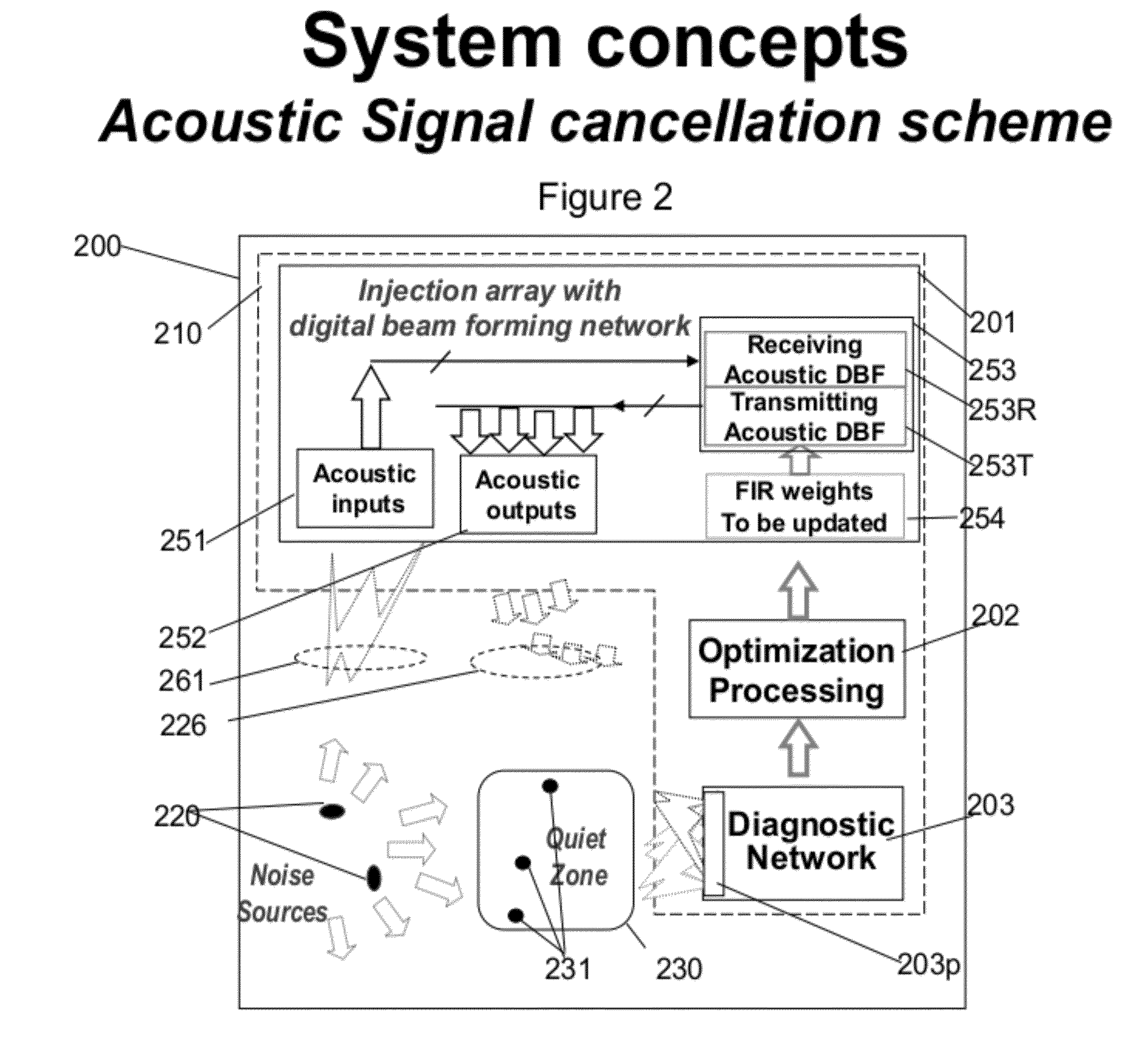

Generating Acoustic Quiet Zone by Noise Injection Techniques

ActiveUS20120057716A1Cost minimizationCost reductionEar treatmentNoise generationAudio signalEngineering

A quiet zone generation technique for acoustic / audio signals is proposed for mitigation of selected noise or interferences over limited areas in free space by injecting the very acoustic noise, interference, or audio feedback signals via iterative processing, generating quiet zones dynamically. This creates undesired noise-free quiet zones. Optimization loops operating iteratively to electronically process cancellation signals consist of three interconnected functional blocks: (1) an acoustic injection array, consisting of pick-up arrays to obtain the interference signals, beam forming networks for element weighting and / or re-positioning, and array elements for noise injections, (2) a diagnostic network with strategically located probes, and (3) an optimization processor with cost minimization algorithms to calculate element weights for updating.

Owner:SPATIAL DIGITAL SYST

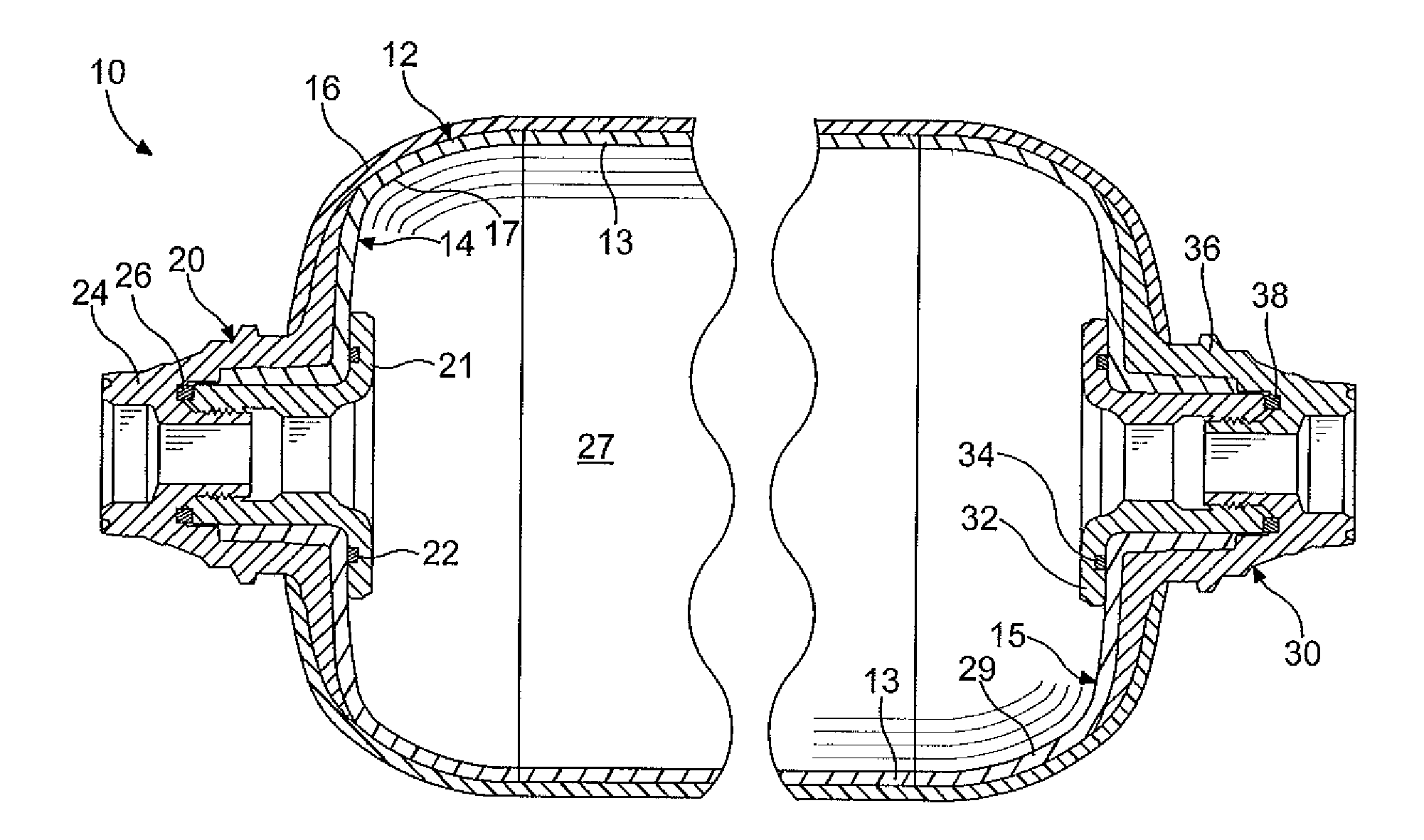

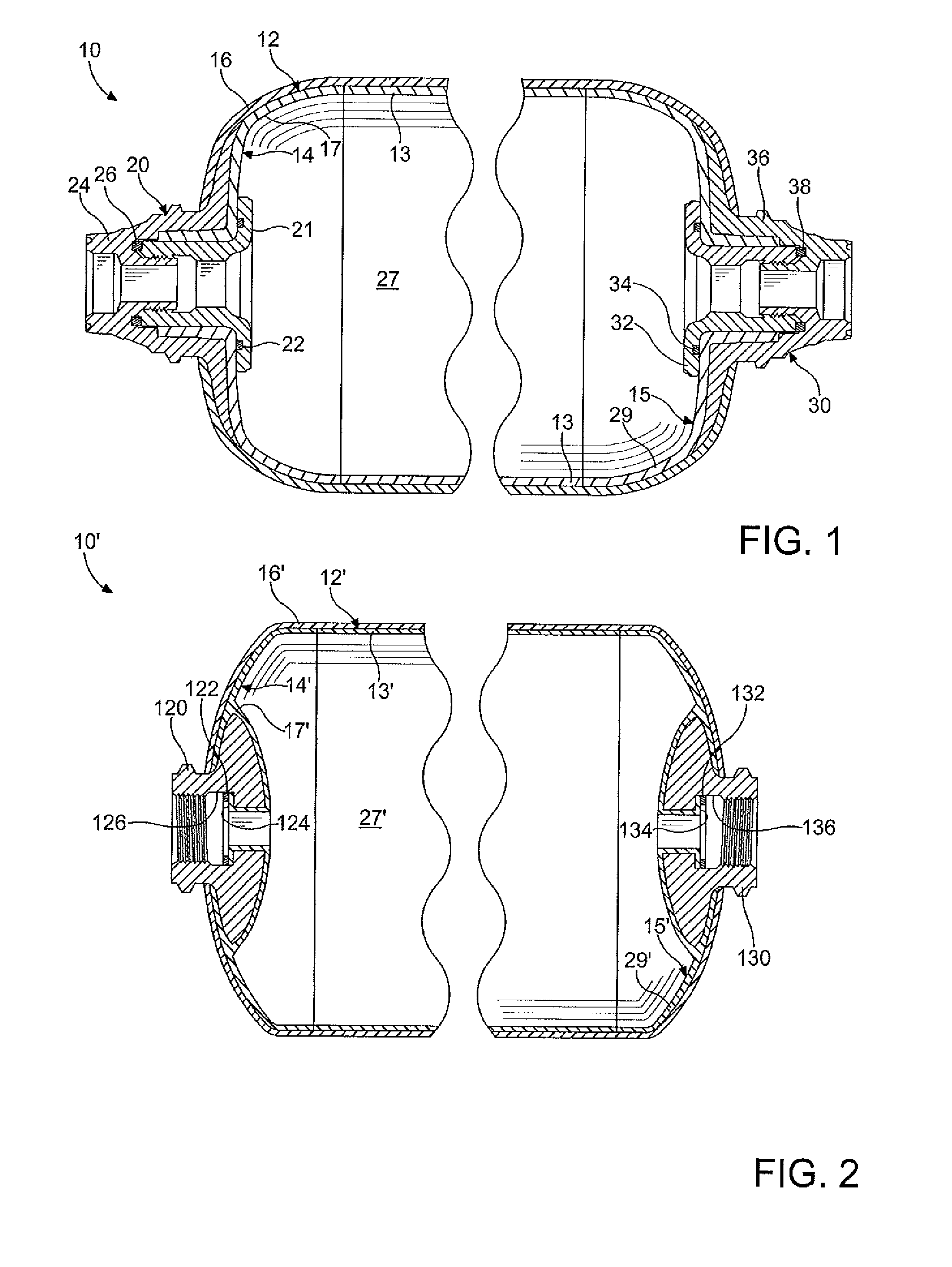

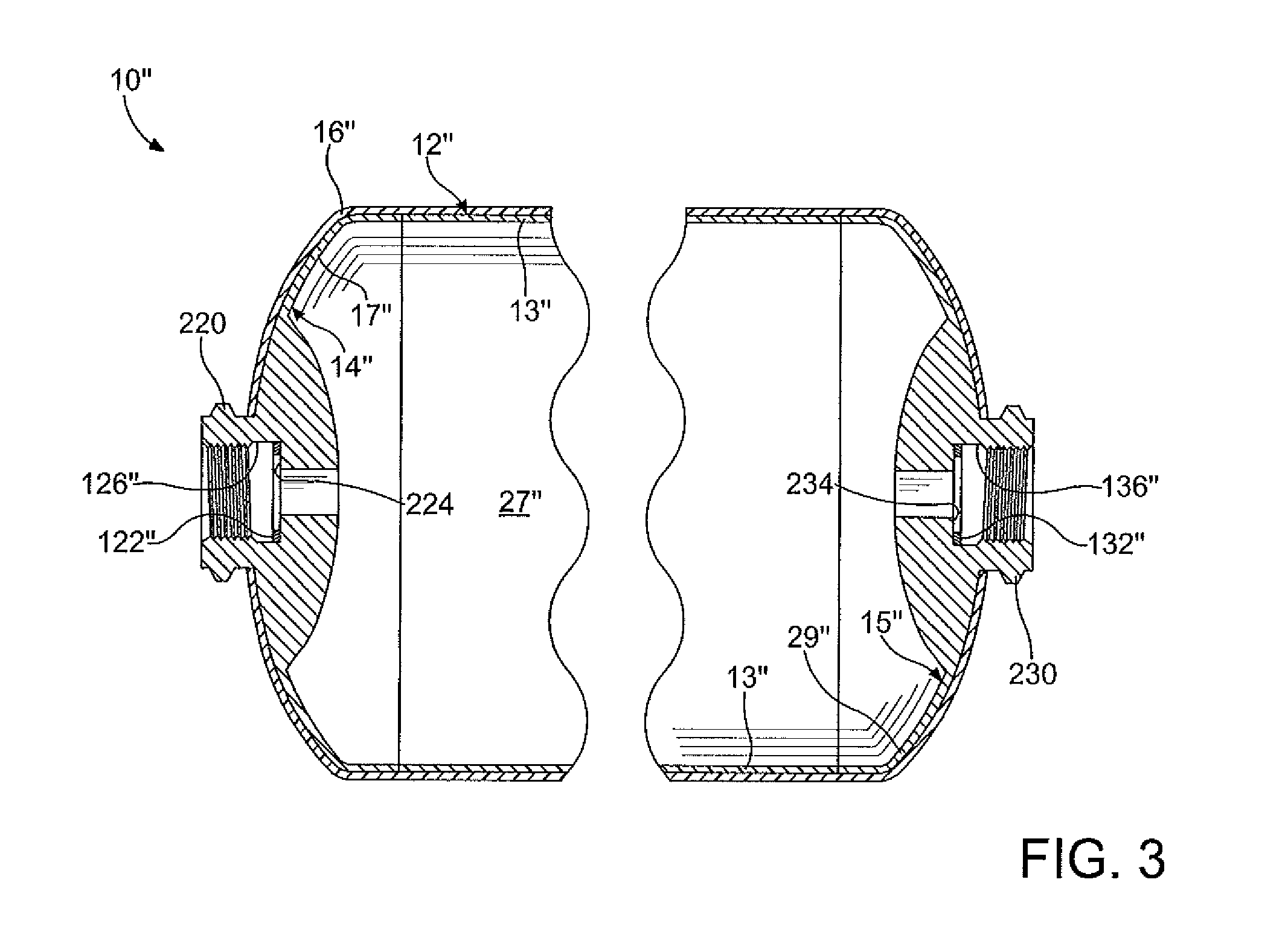

Process for forming a vessel

ActiveUS20110220660A1Efficient methodCost minimizationVessel mounting detailsVessel manufacturingCo extrusionMarine engineering

A vessel and method for forming the vessel is disclosed, the vessel having a hollow liner, at least one boss, and a filament wound outer shell, wherein at least a portion of the hollow liner if formed by at least one of an co-extrusion blow film molding process, a thermoplastic foiling process, and a coating process.

Owner:GM GLOBAL TECH OPERATIONS LLC

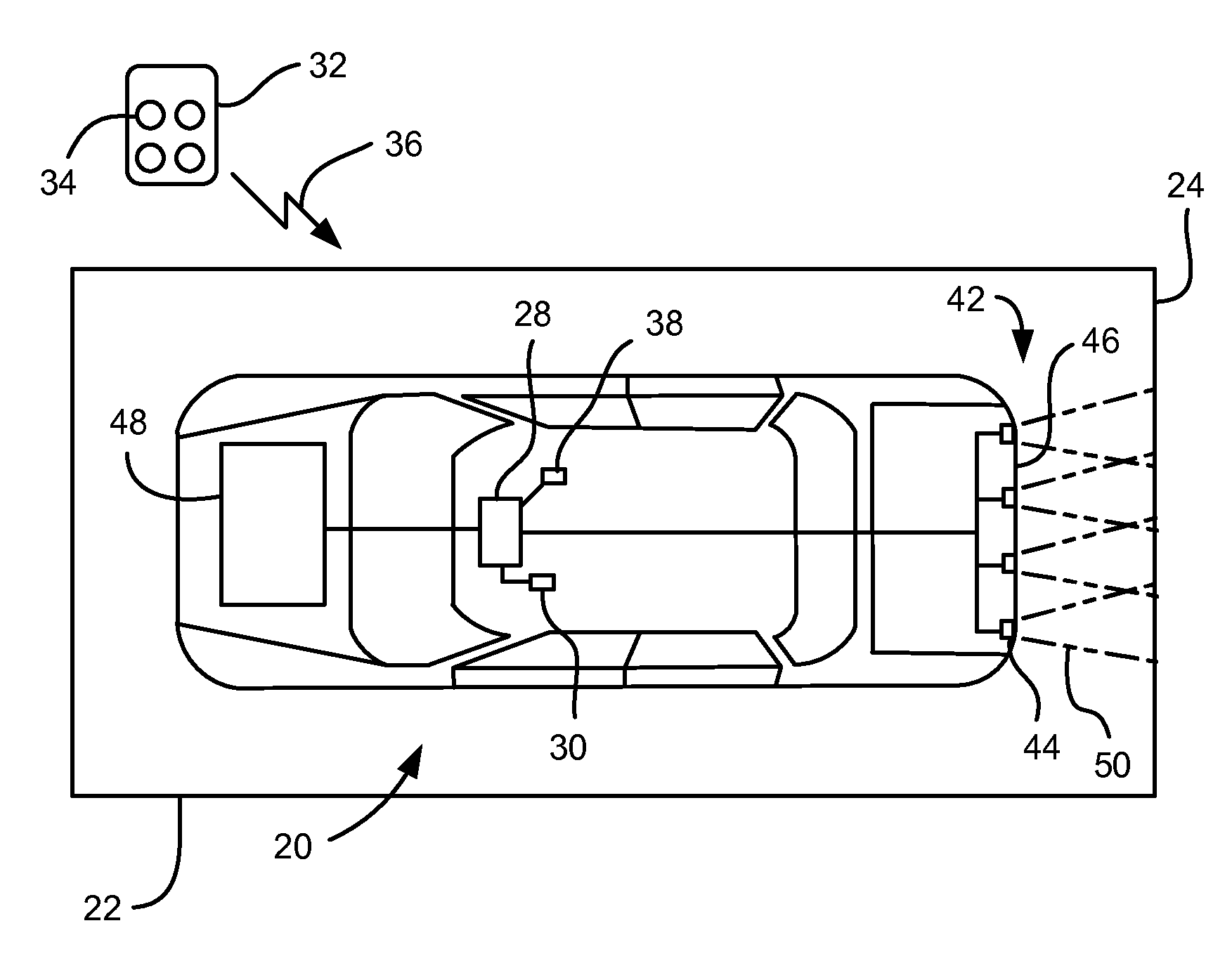

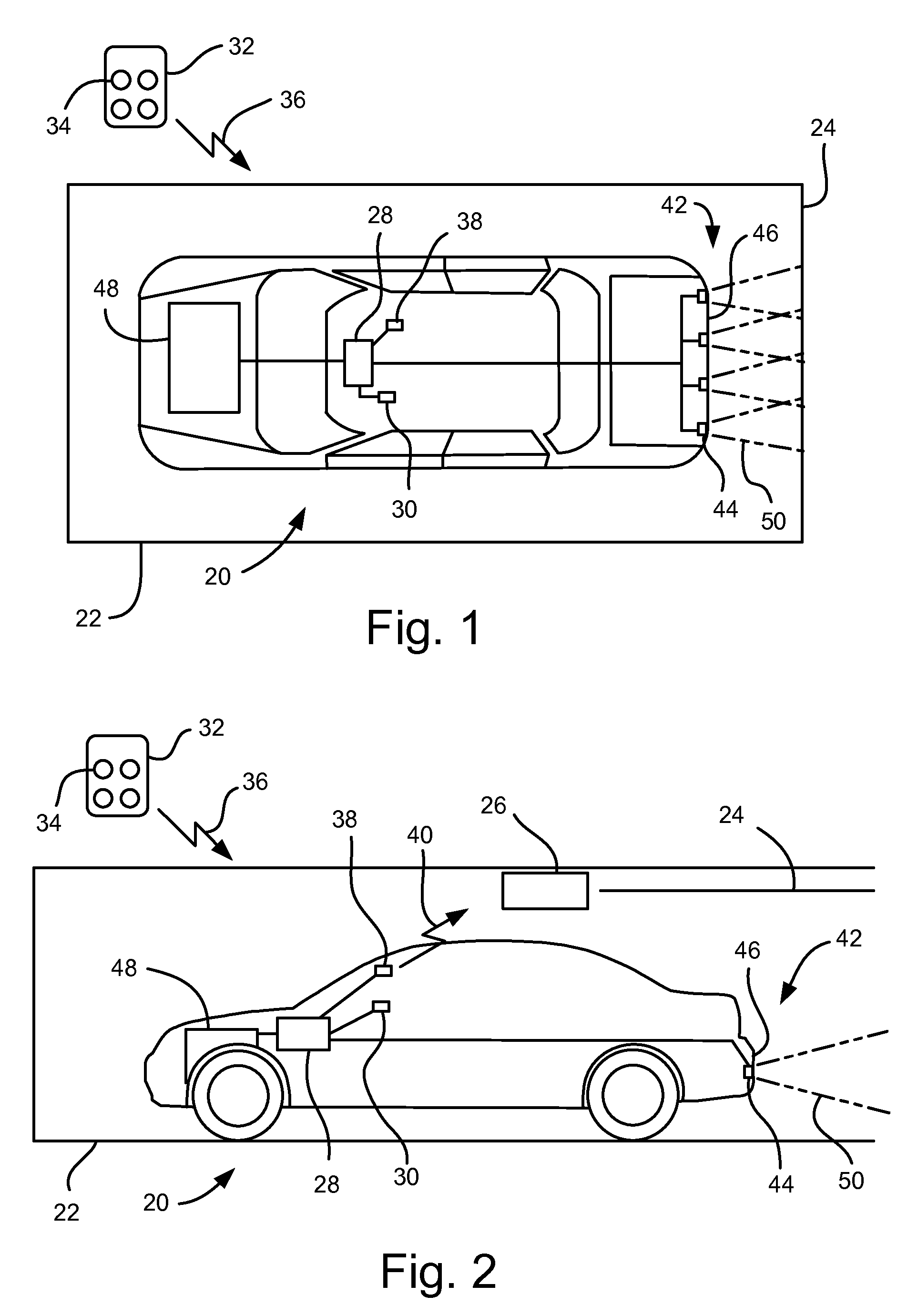

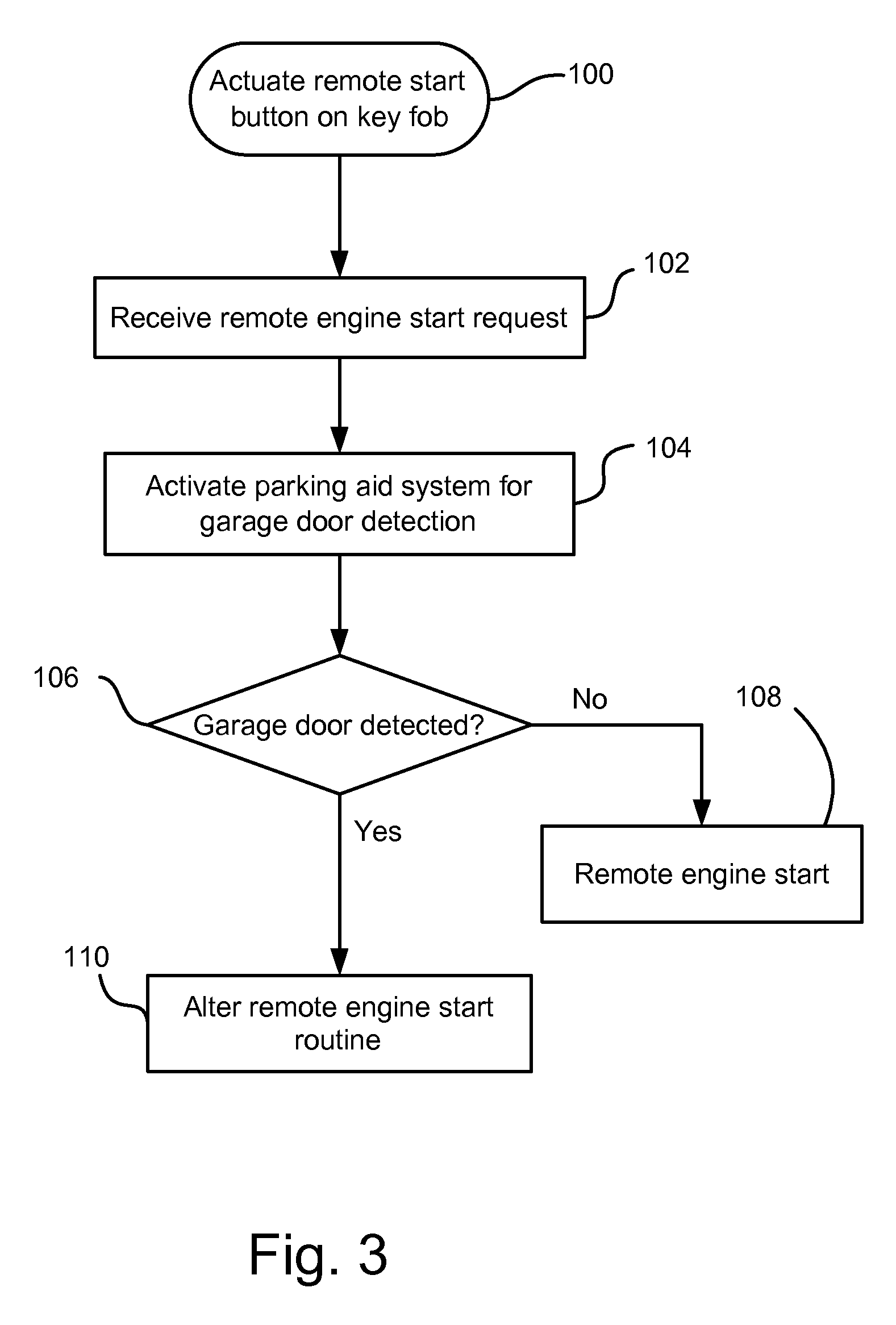

Vehicle Having Remote Start and Enclosed Space Detection

InactiveUS20110032115A1Reduce chanceCost minimizationElectric signal transmission systemsDigital data processing detailsStart signalEngineering

The subject of the present invention is a method for remote starting an internal combustion engine of a vehicle comprising the steps of: detecting a wireless remote start signal; after detecting the wireless remote start signal, activating a parking aid system to detect the presence or absence of a garage door; and if no garage door is detected by the parking aid system, remote starting the internal combustion engine. A carbon monoxide detector or an automatic garage door opener may also be employed in the remote start process.

Owner:FORD GLOBAL TECH LLC

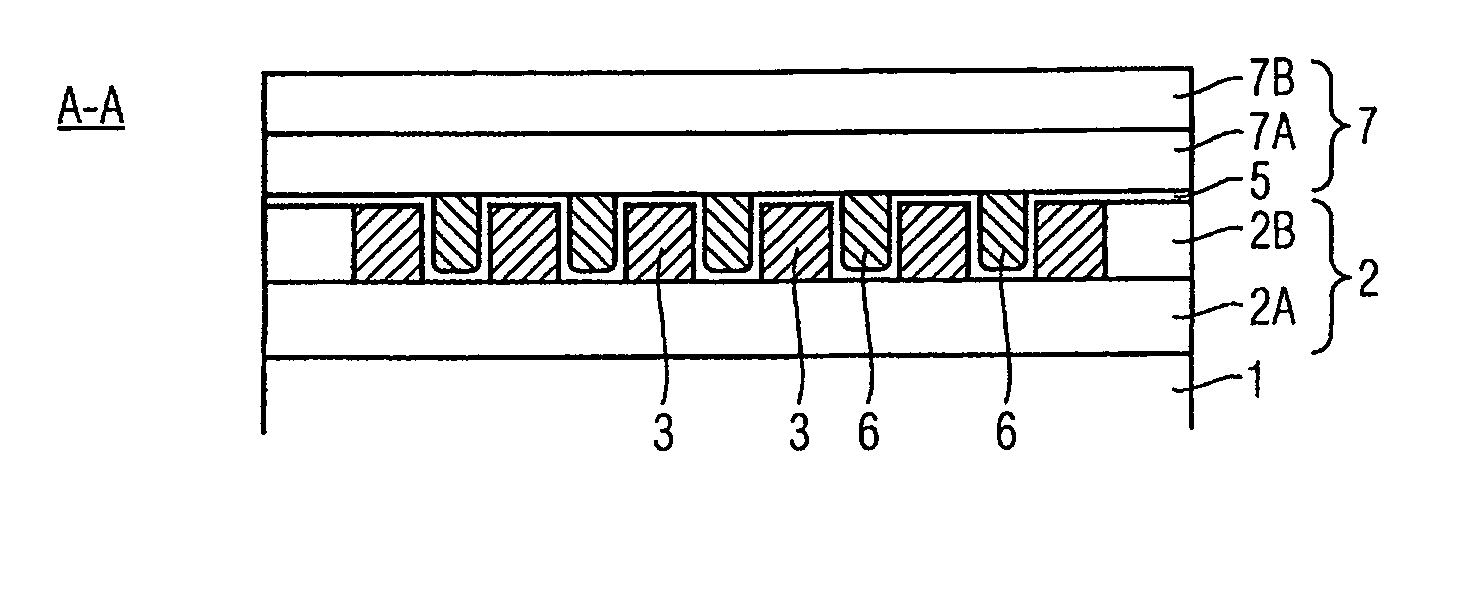

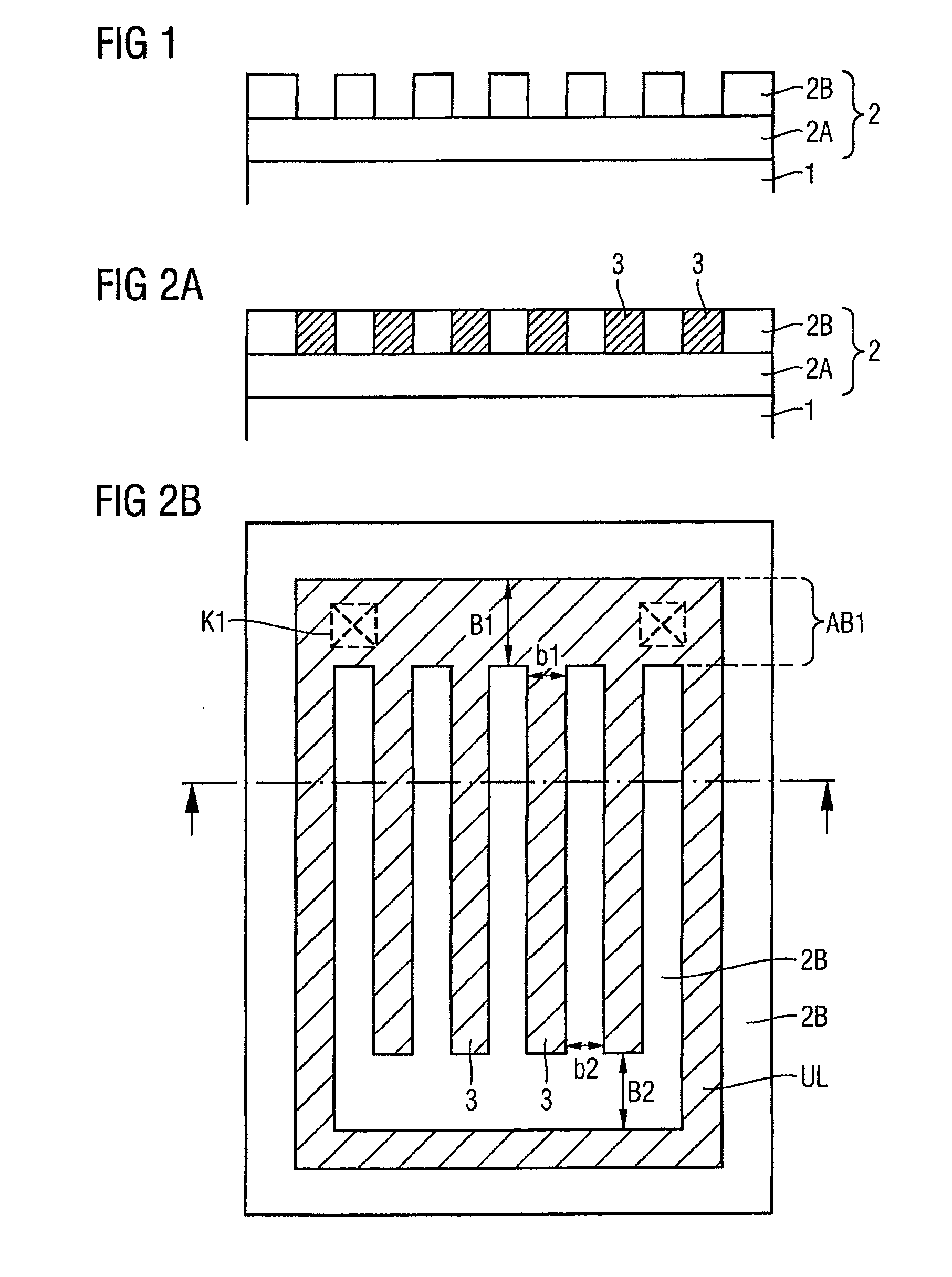

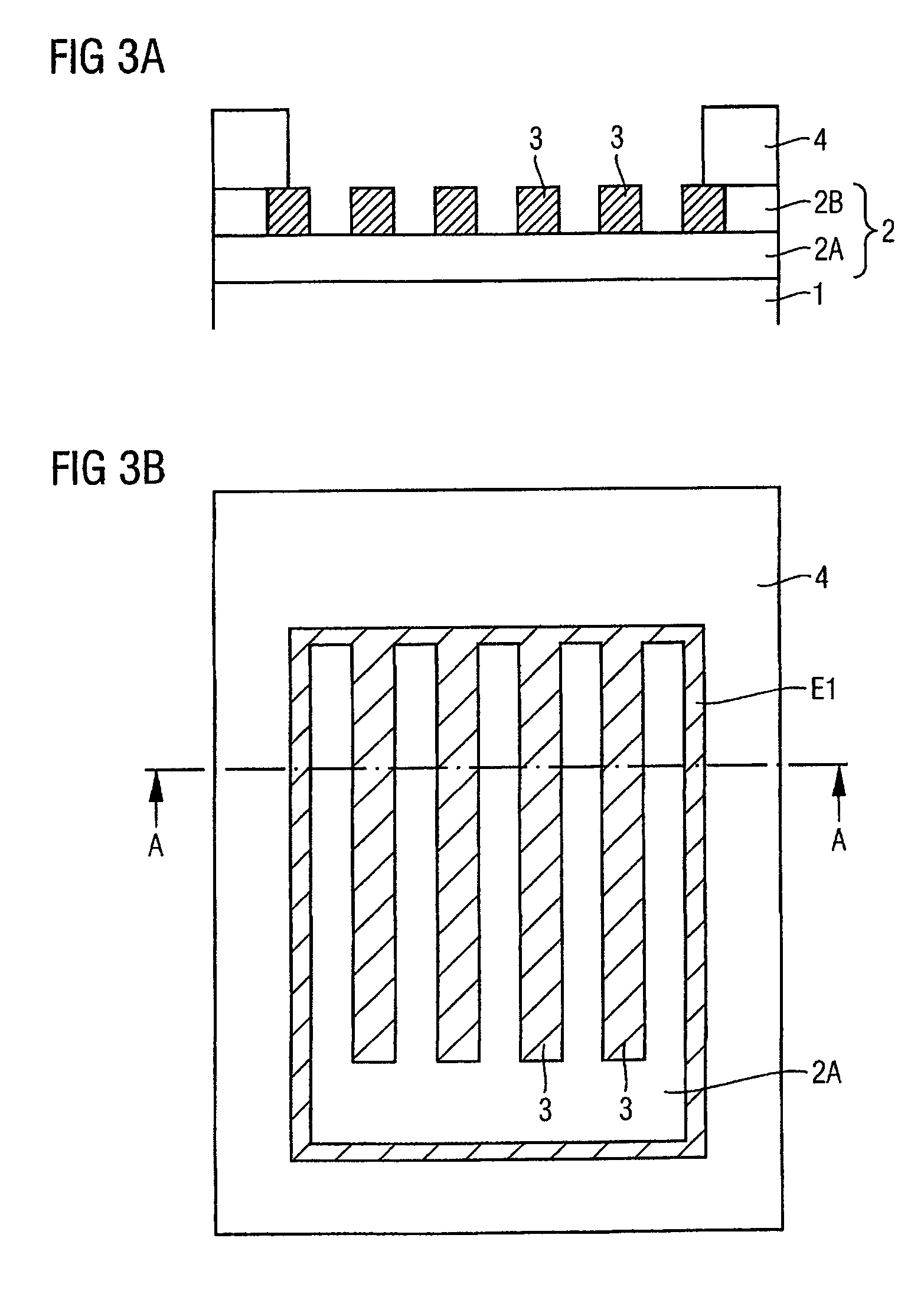

Corresponding capacitor arrangement and method for making the same

InactiveUS20070155090A1Simple methodCost minimizationSemiconductor/solid-state device detailsSolid-state devicesCapacitanceEngineering

The invention relates to a method for producing a capacitor arrangement, and to a corresponding capacitor arrangement, wherein the first insulating layer is formed at the surface of a carrier substrate and a first capacitor electrode with a multiplicity of interspaced first interconnects is produced in said insulating layer. Using a mask layer, partial regions of the first insulating layer are removed for the purpose of uncovering the multiplicity of first interconnects, and after the formation of a capacitor dielectric at the surface of the uncovered first interconnects, a second capacitor electrode is formed with a multiplicity of interspaced second interconnects lying between the first interconnects coated with capacitor dielectric. This additionally simplified production method enables self-aligning and cost-effective production of capacitors having a high capacitance per unit area and mechanical stability.

Owner:INFINEON TECH AG

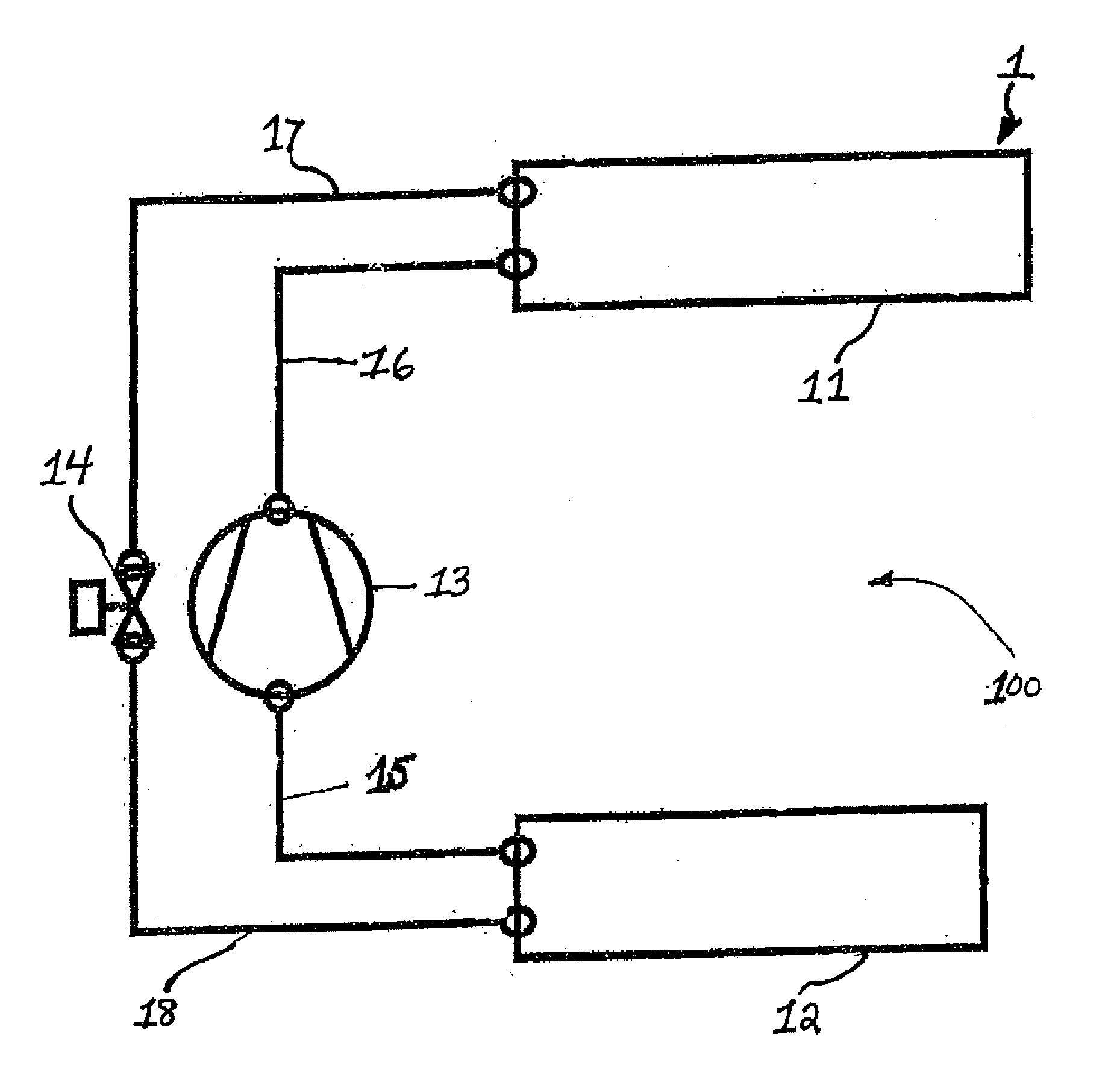

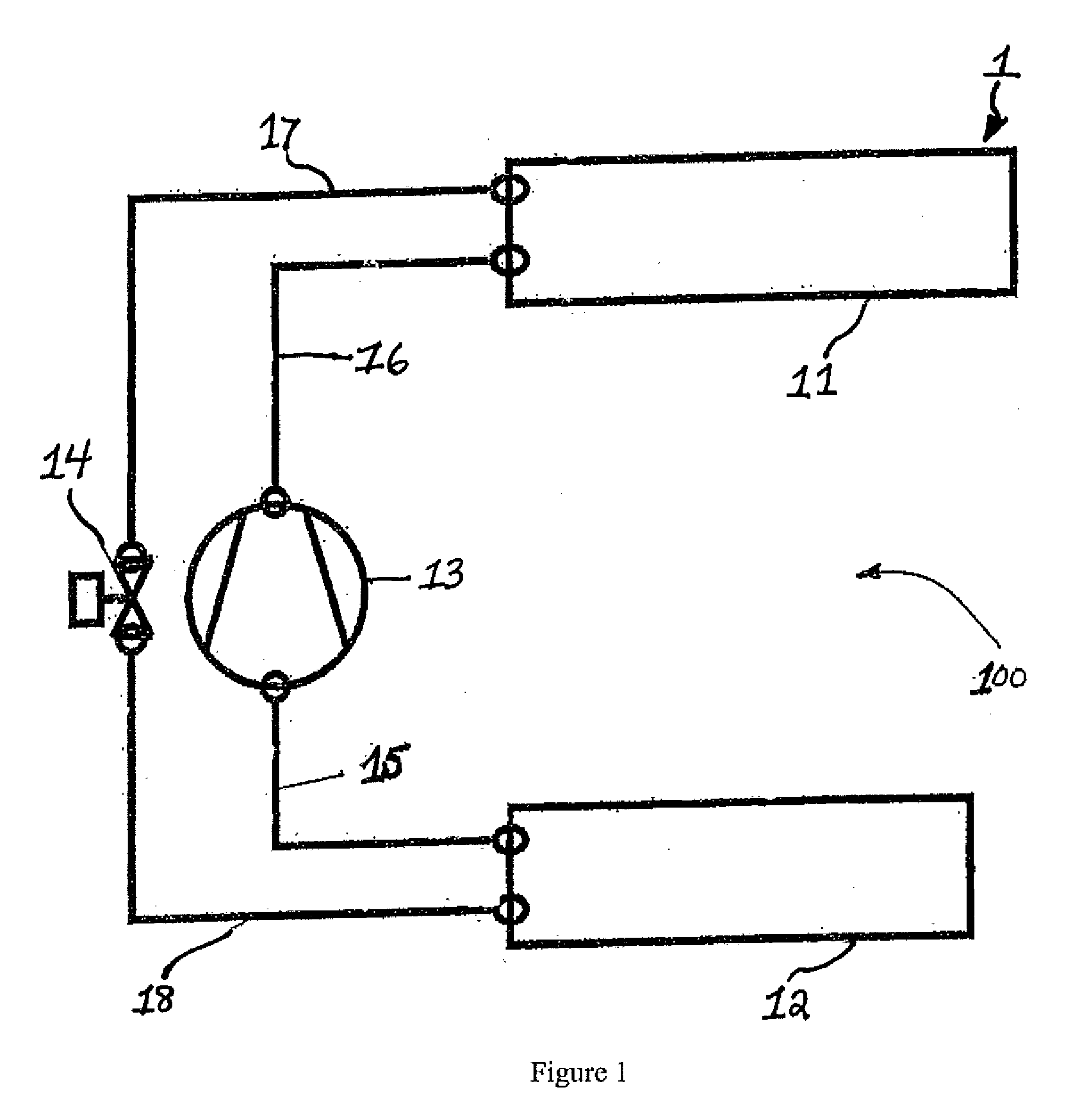

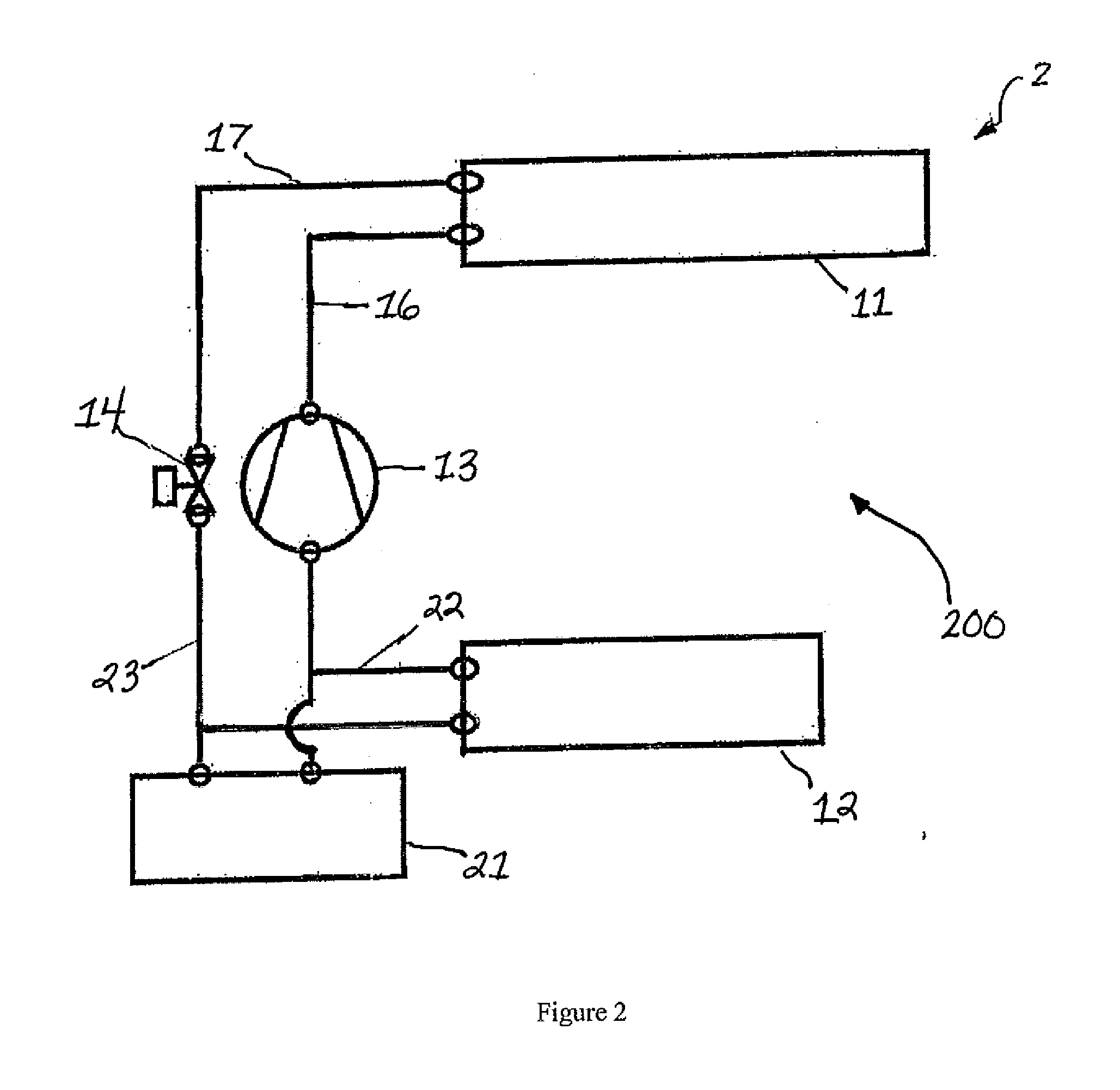

Modular air conditioning system with heat pump functionality

ActiveUS20130042637A1Maximizes performance and efficiencyCost minimizationVehicle heating/cooling devicesCompression machines with cascade operationRefrigerantEvaporator

A modular vehicle air-conditioning unit for heating and cooling air includes a housing having at least one blower and a plurality of flaps for setting air flow paths and a refrigerant circuit in fluid communication with the housing. The refrigerant circuit includes a condenser, an evaporator, a compressor, and an expansion device. An evaporator air flow path through the evaporator and a condenser air flow path through the condenser are formed in the housing. At least one of the evaporator air flow path and the condenser air flow path receives air from at least one of an environment, a passenger compartment of a vehicle, and any mixture of thereof.

Owner:HANON SYST

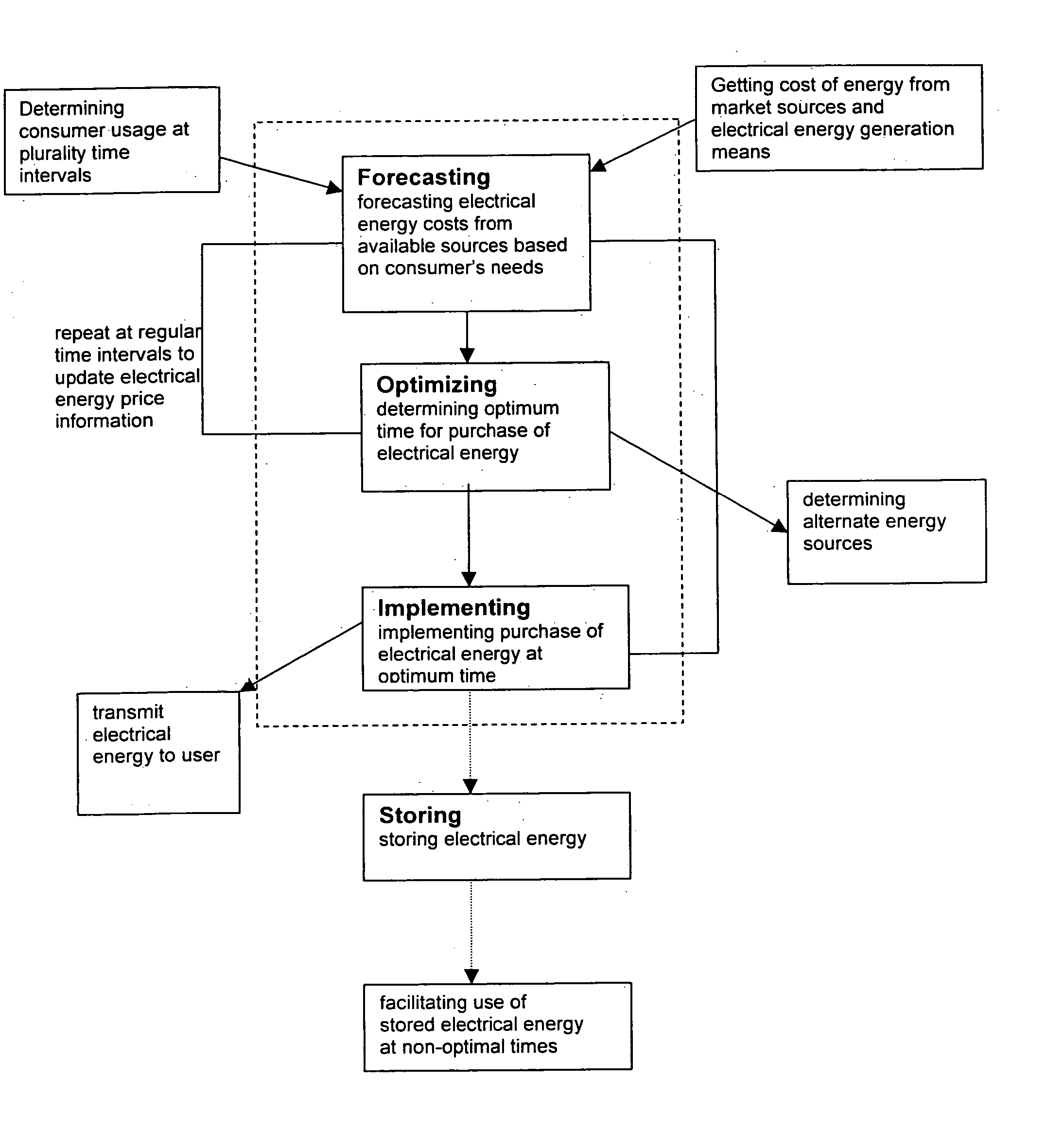

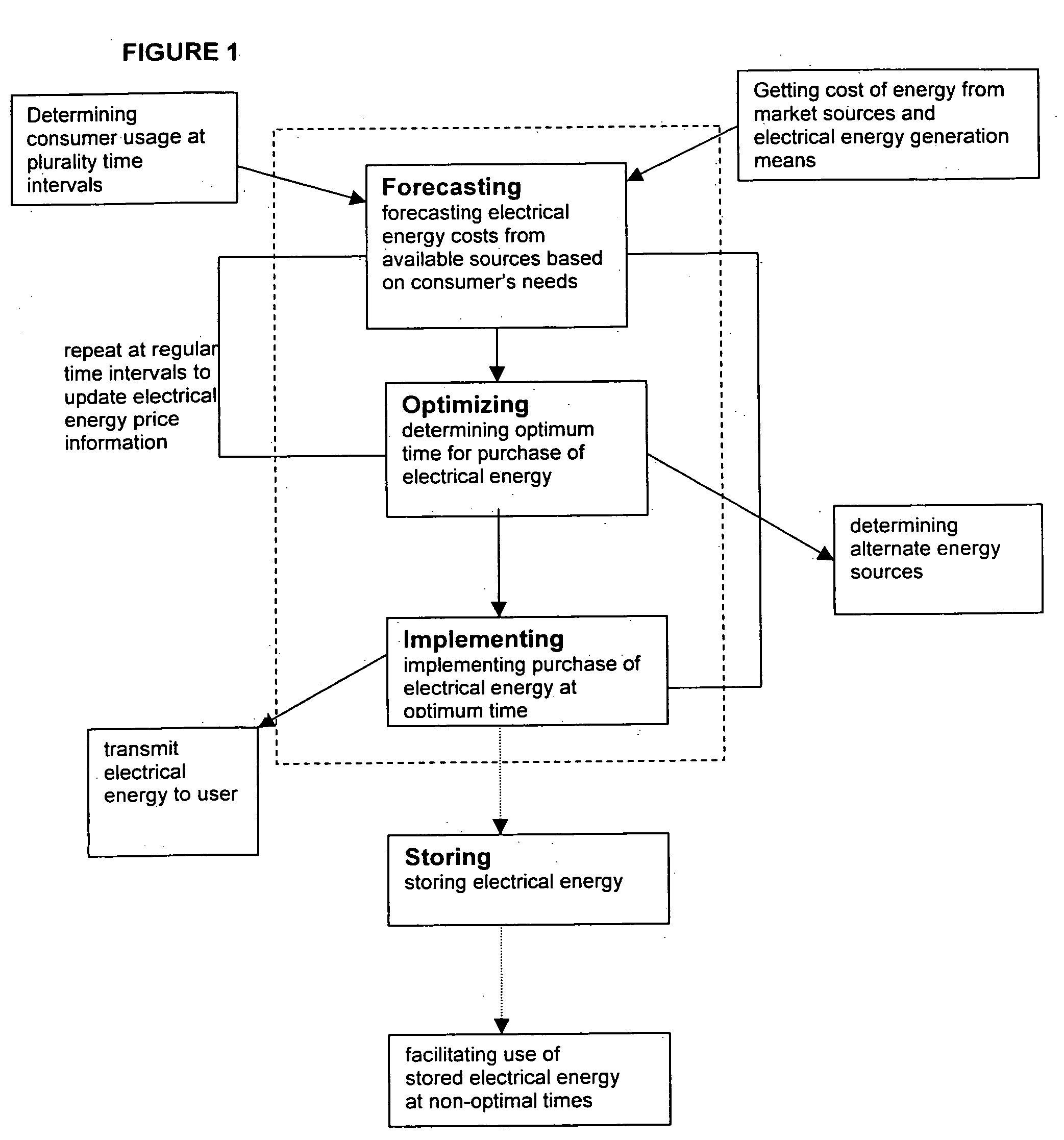

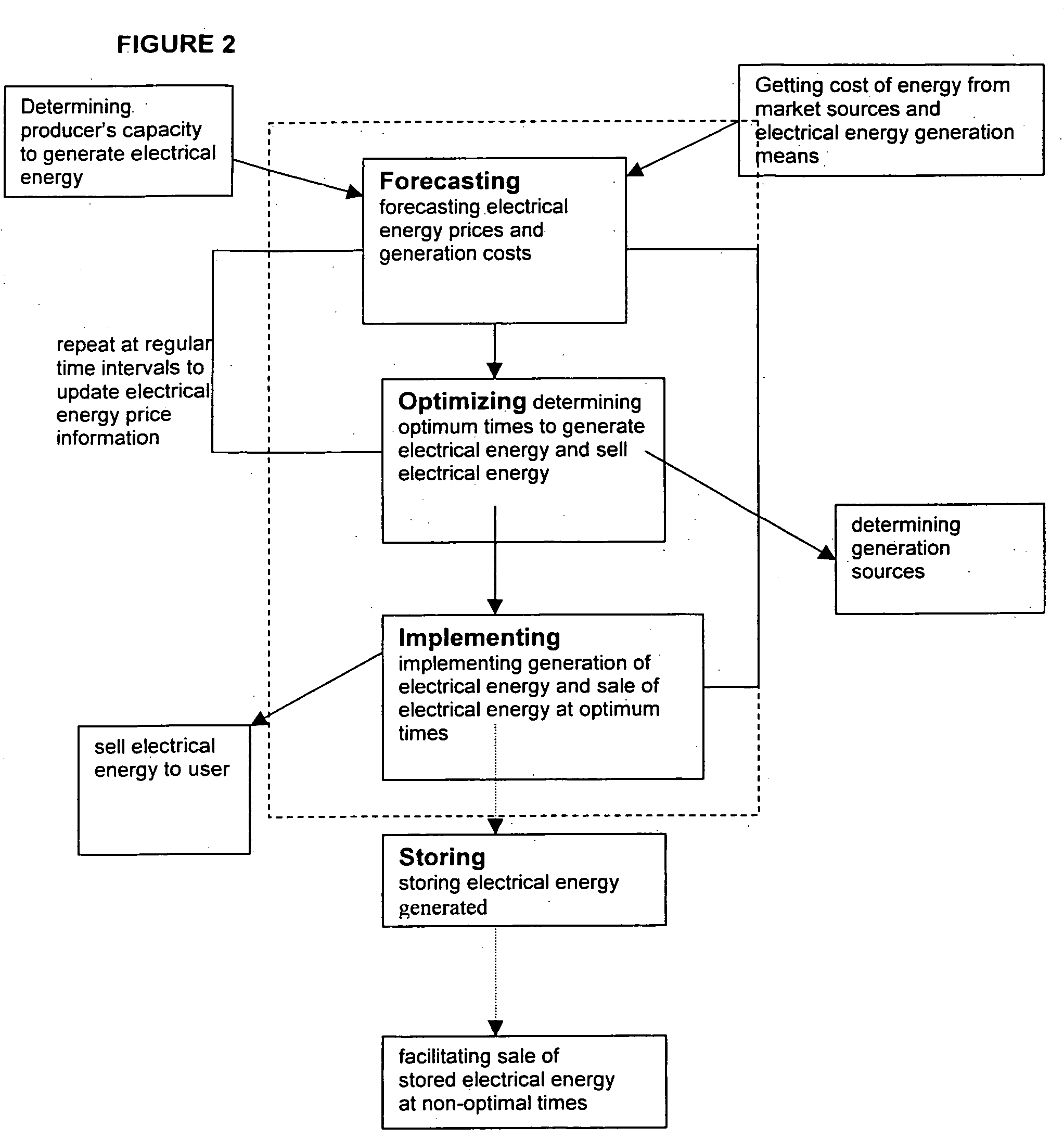

System and method for optimizing the cost of buying and selling electrical energy

InactiveUS20050246220A1Cost minimizationMaximize priceMarket predictionsFinanceElectric energyProcess engineering

The invention provides a system and method for optimizing the cost of buying and price for selling electrical energy by forecasting the price from a plurality of sources of electrical energy for a plurality of time intervals within a set time period, determining an optimum time within the set time period for purchasing or selling electrical energy, and implementing the purchase or sale of electrical energy at the optimum time.

Owner:NRGEN

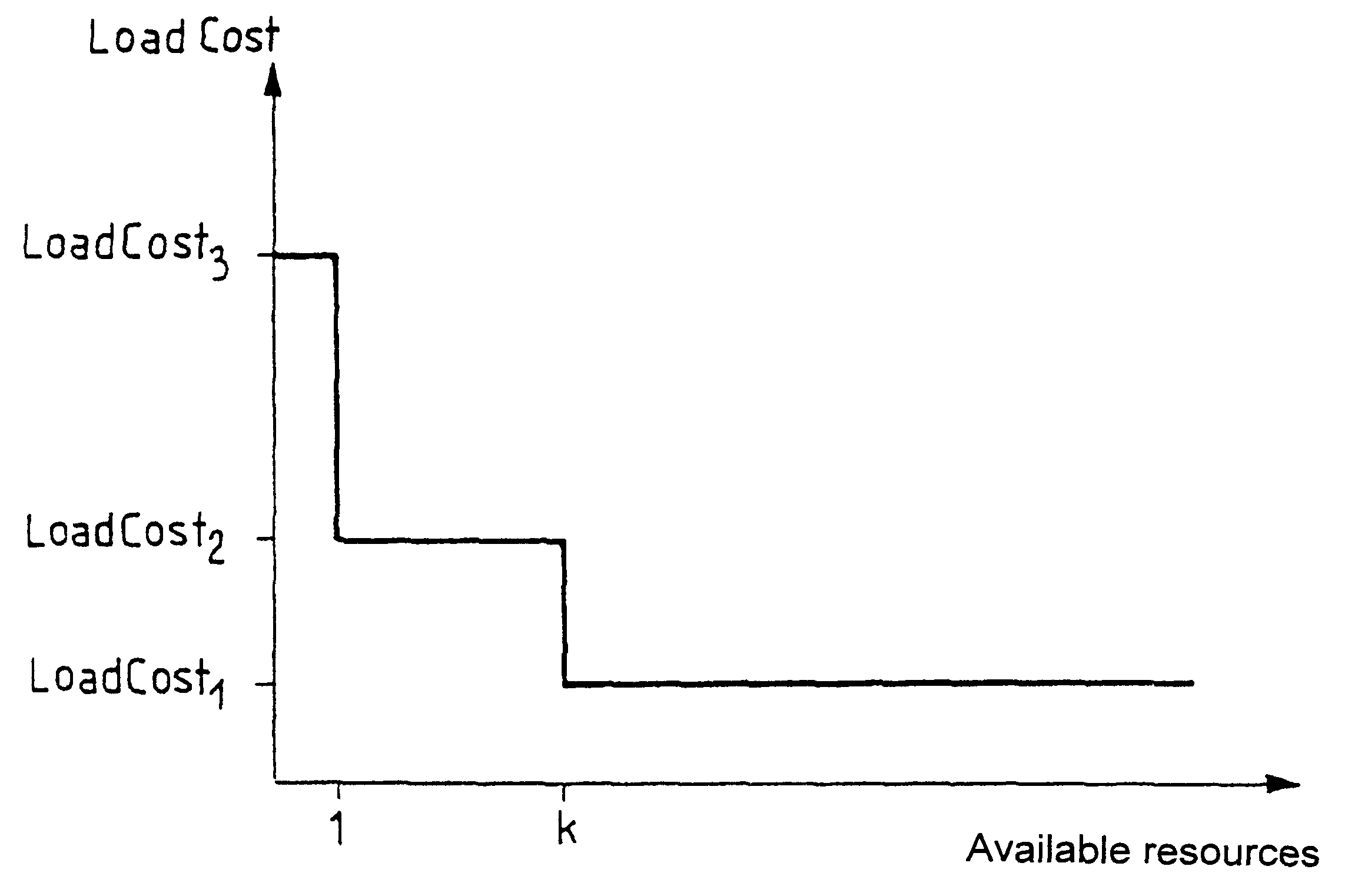

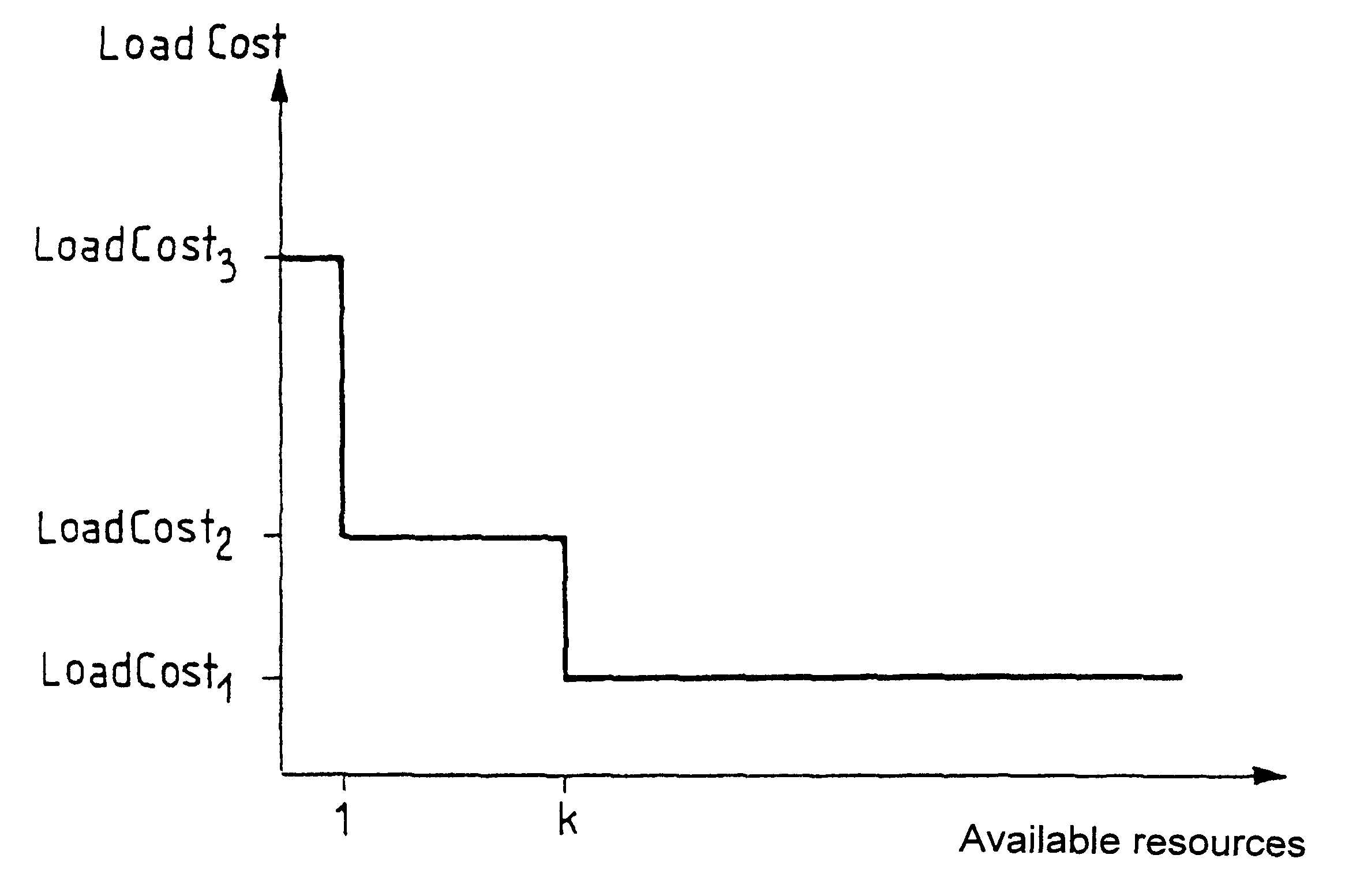

Routing calls in a telecommunications network on the basis of passband

InactiveUS6600722B1Cost minimizationLimit frequencyMultiplex system selection arrangementsError preventionTelecommunications linkTelecommunications service

The invention relates to a method of routing a call in a network having a plurality of nodes interconnected by trunks, the method including calculating the costs of different routes for taking the call, and selecting a route as a function of cost. According to the invention, the cost of a route is a function of the bandwidth available on the trunks making up the route, of the resources available on said trunks, and of the bandwidth required for the call. The cost of a trunk can be represented in the form of a vector whose first component is a decreasing function of the available bandwidth, and whose second component is a decreasing function of available resources. The invention makes it possible, when routing a call, to take account of quality of service in terms of bandwidth. If the second component is a function that has a value that is constant above some quantity of available resources, then the invention makes it possible to limit the number of routing calculations performed, and to avoid making new routing calculations so long as the topology of the network remains unchanged.

Owner:ALCATEL LUCENT SAS

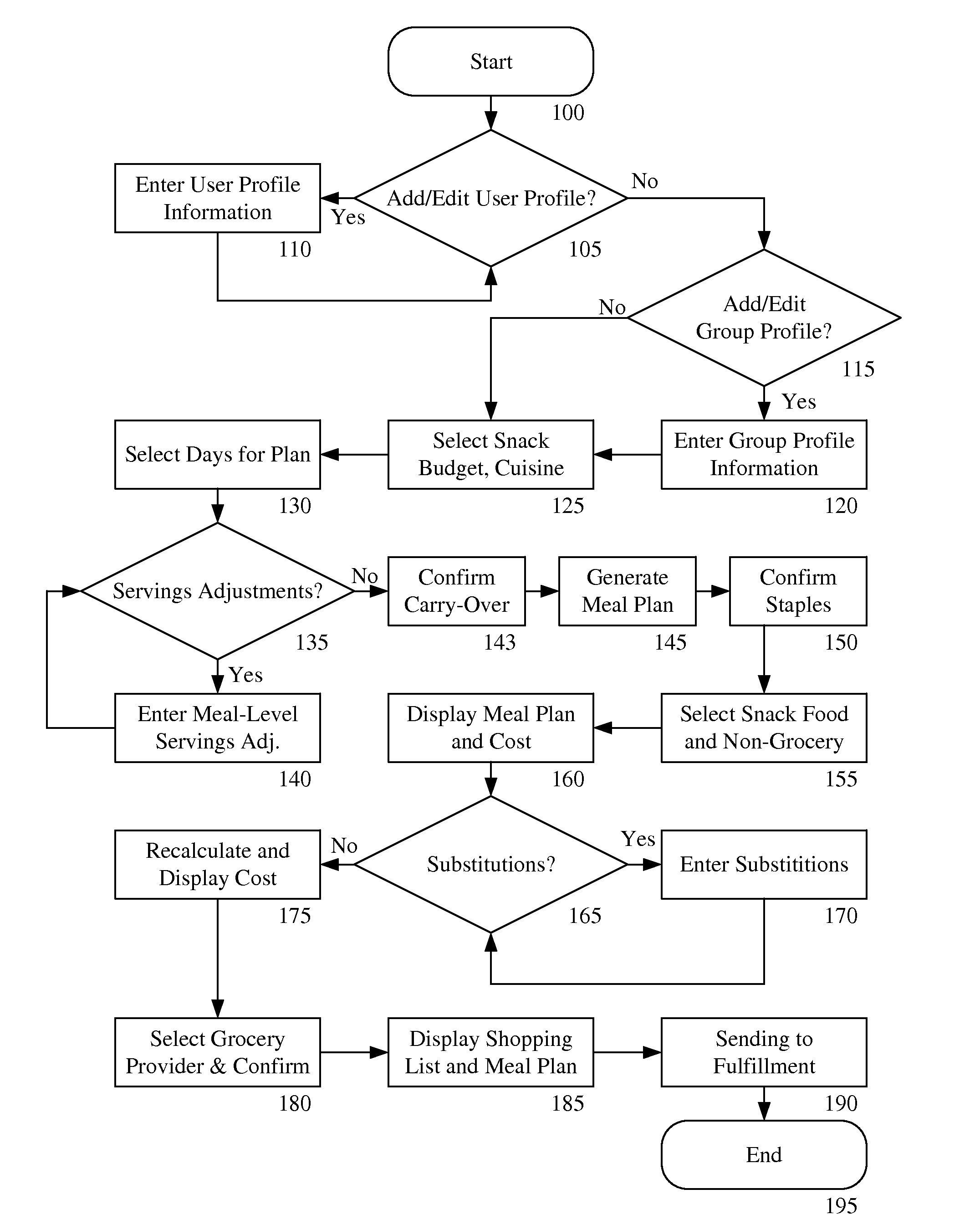

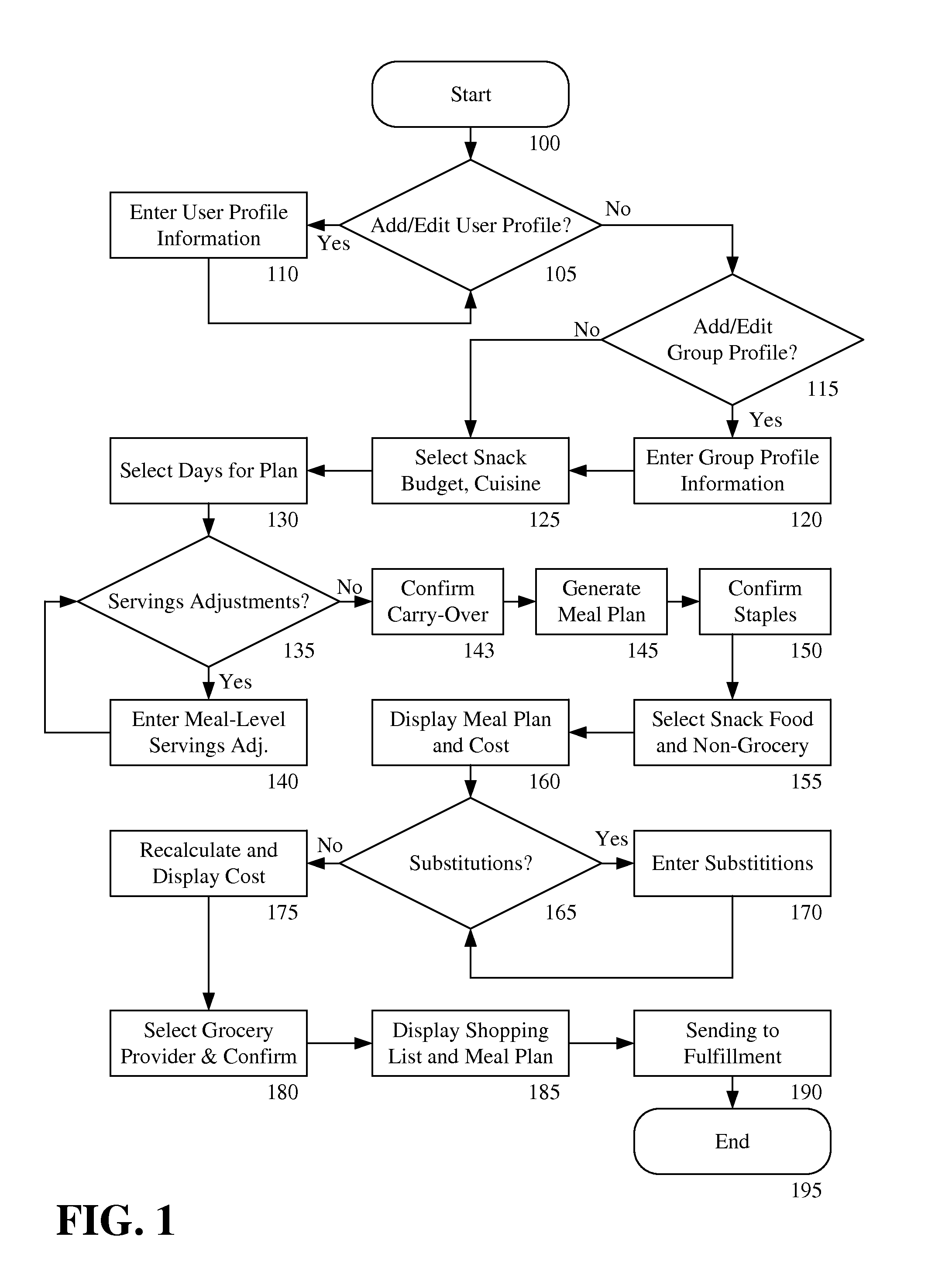

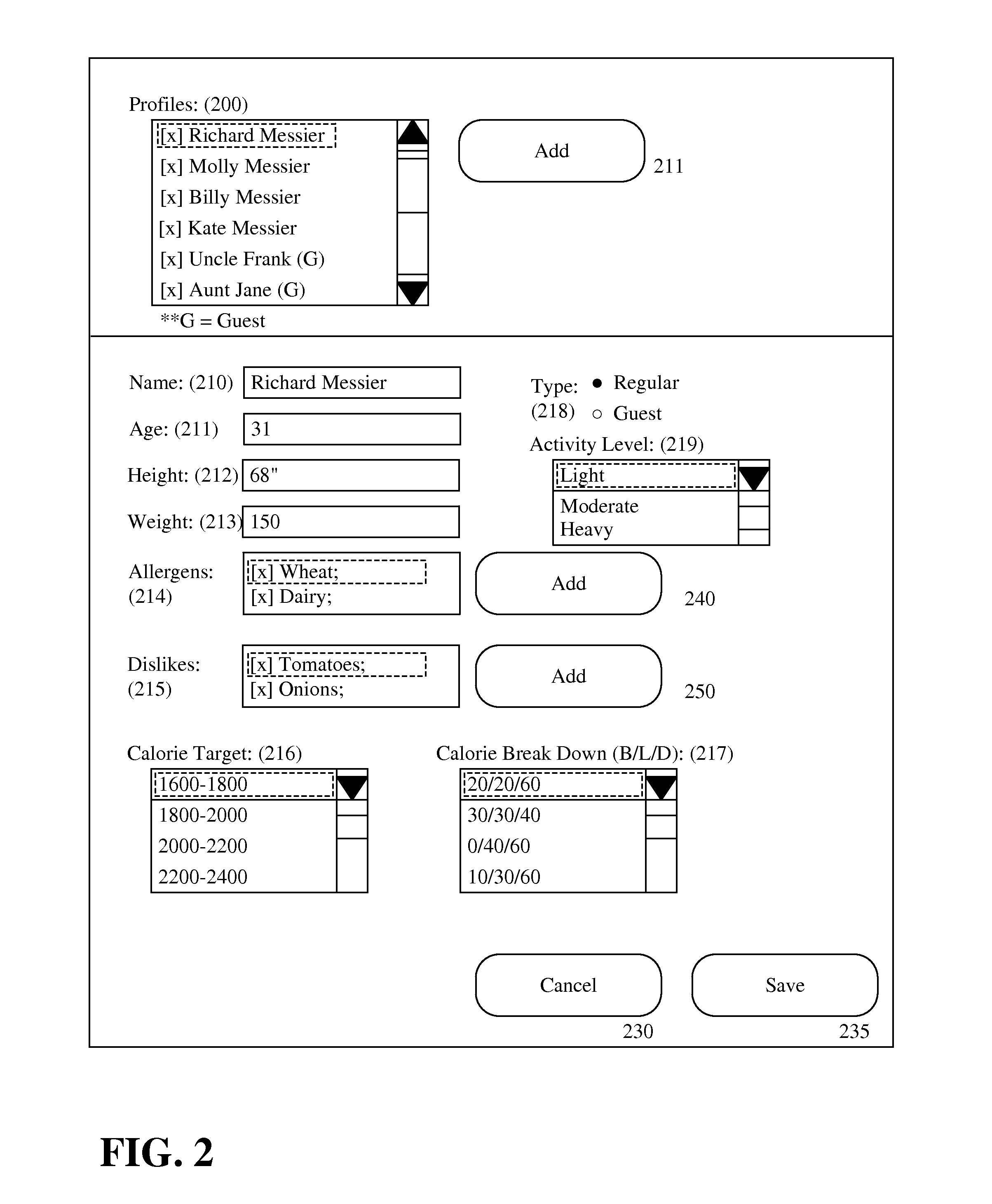

Method for Generating Low-Waste Personalized Meal Plans within a Budget

InactiveUS20160098942A1Cost minimizationReduce wasteElectrical appliancesTeaching apparatusMeal planUser profile

Disclosed is a method for generating a meal plan including receiving a plurality of user profiles, receiving a cuisine selection, receiving a budget selection, displaying a meal plan in accordance with the cuisine selection and the budget selection, the meal plan including a plurality of meals wherein at least one of the plurality of meals is scaled in accordance with the plurality of user profiles, displaying a first cost associated with the meal plan, displaying a shopping list in accordance with the meal plan, the shopping list including a plurality of ingredients associated with the plurality of meals.

Owner:MESSIER RICHARD THOMAS

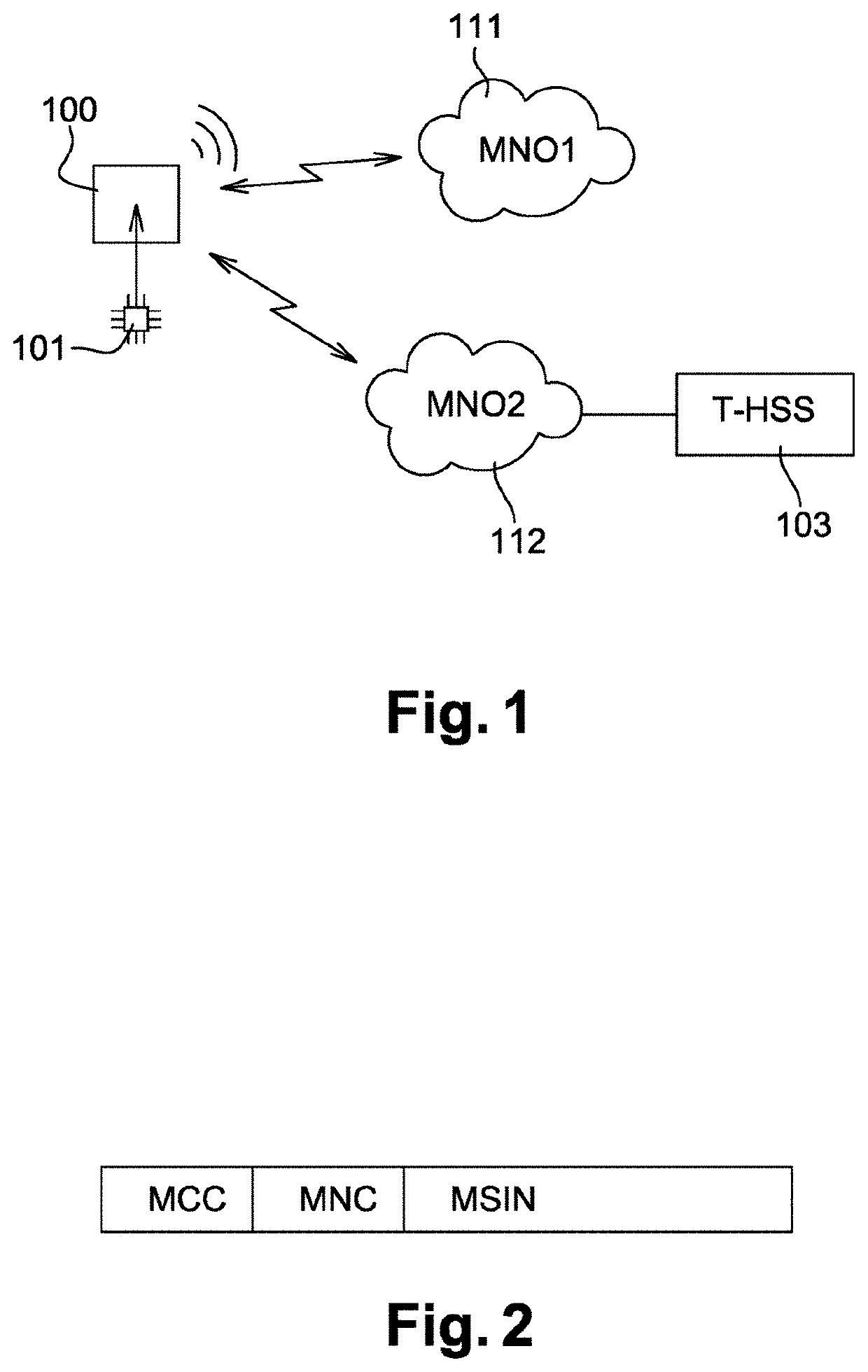

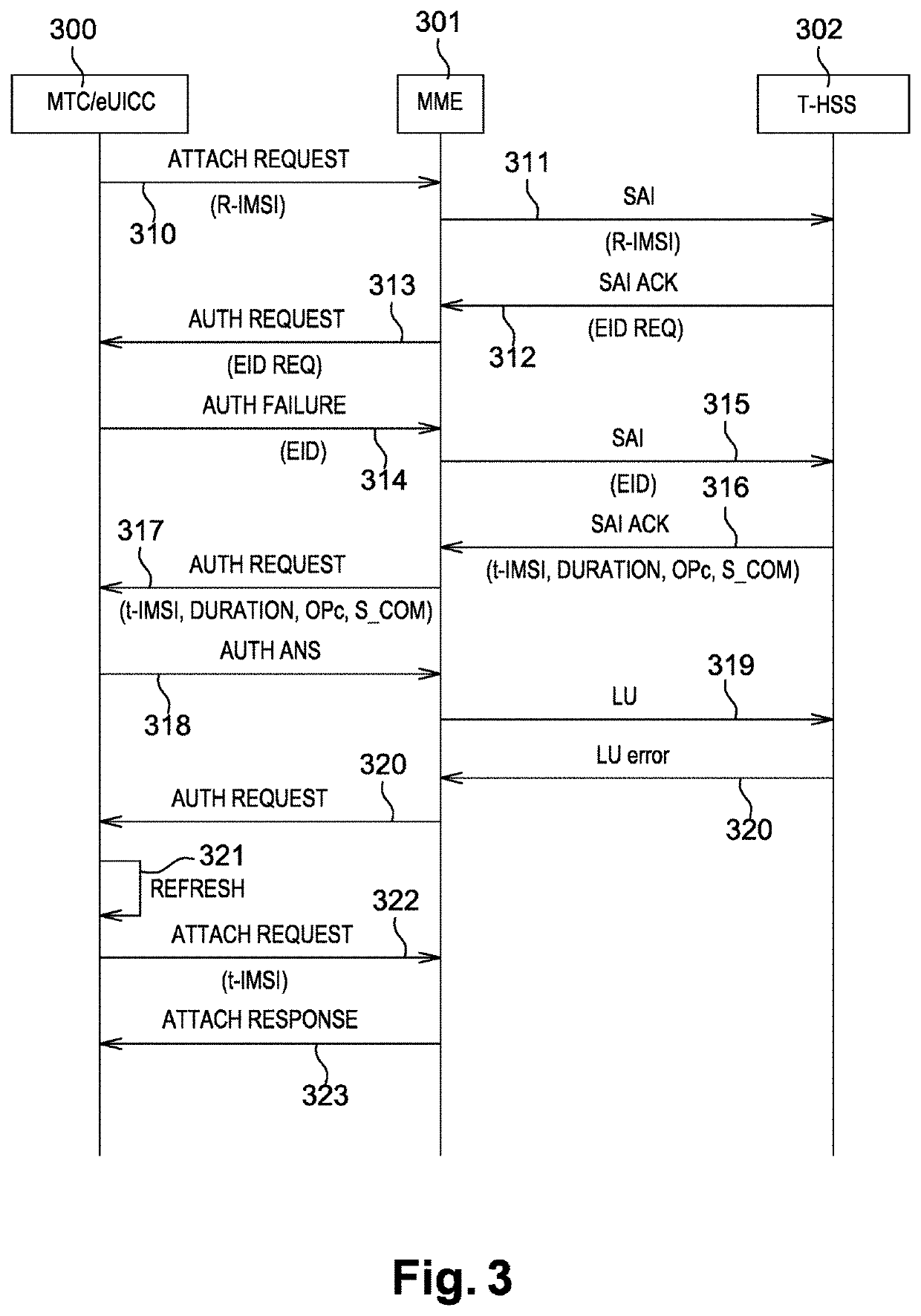

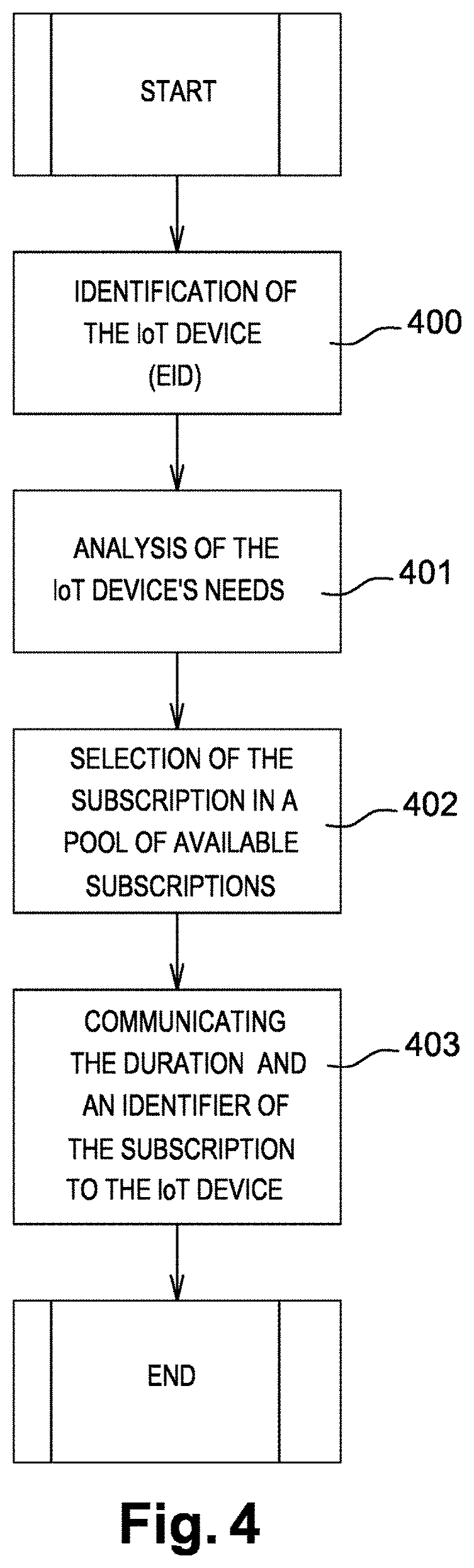

A method for allocating temporarily a subscription to a credential container

ActiveUS20200236529A1Cost minimizationLow costSecurity arrangementNetwork data managementComputer securityEngineering

A method for a credential container embedded into a wireless communication device to obtain a temporary wireless connectivity through a first wireless network, the credential container being provisioned with an identifier ID identifying the wireless communication device or the credential container and a pre-loaded subscription profile comprising a range of International Mobile Subscription Identifiers associated to a second network operator.

Owner:THALES DIS FRANCE SA

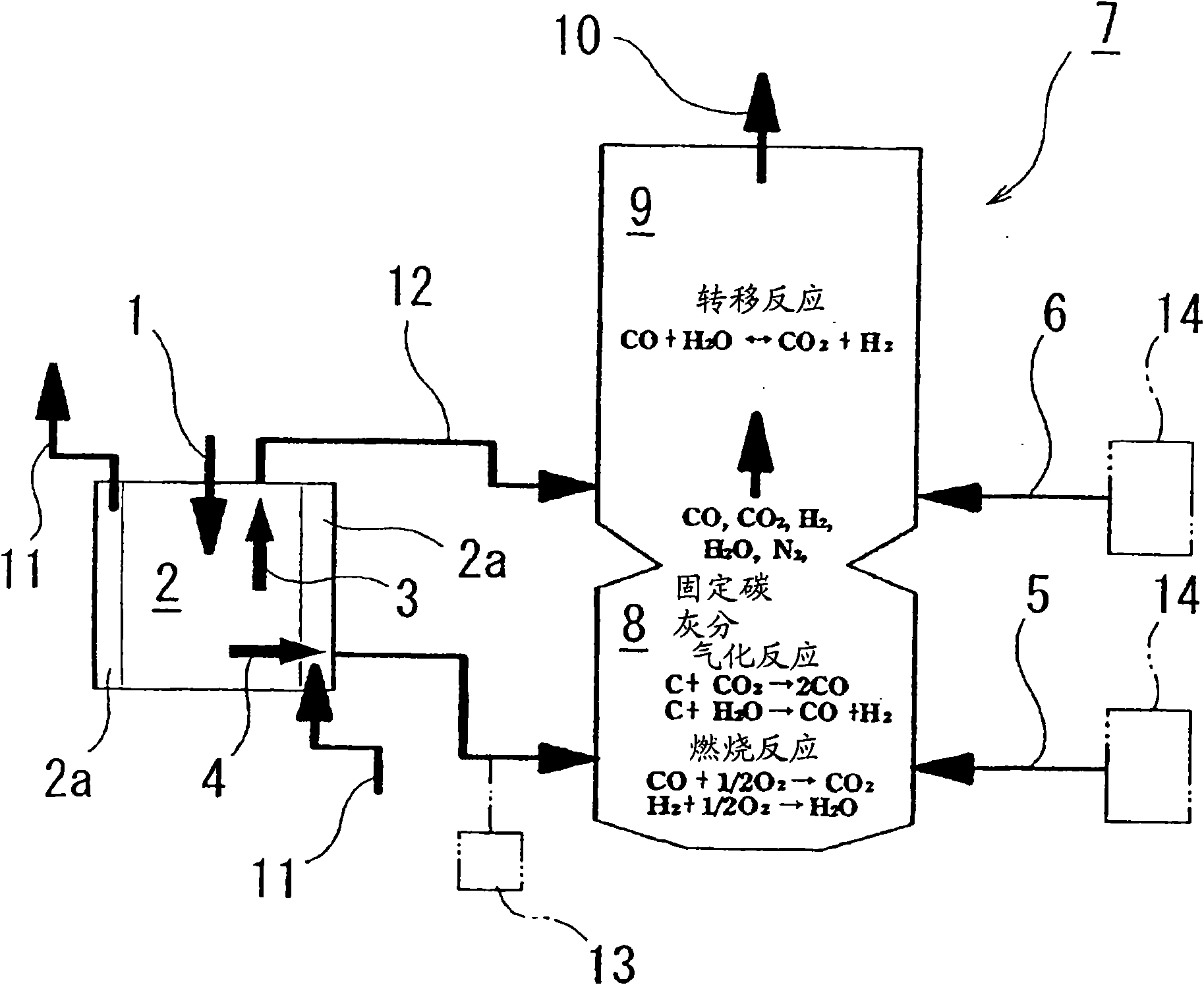

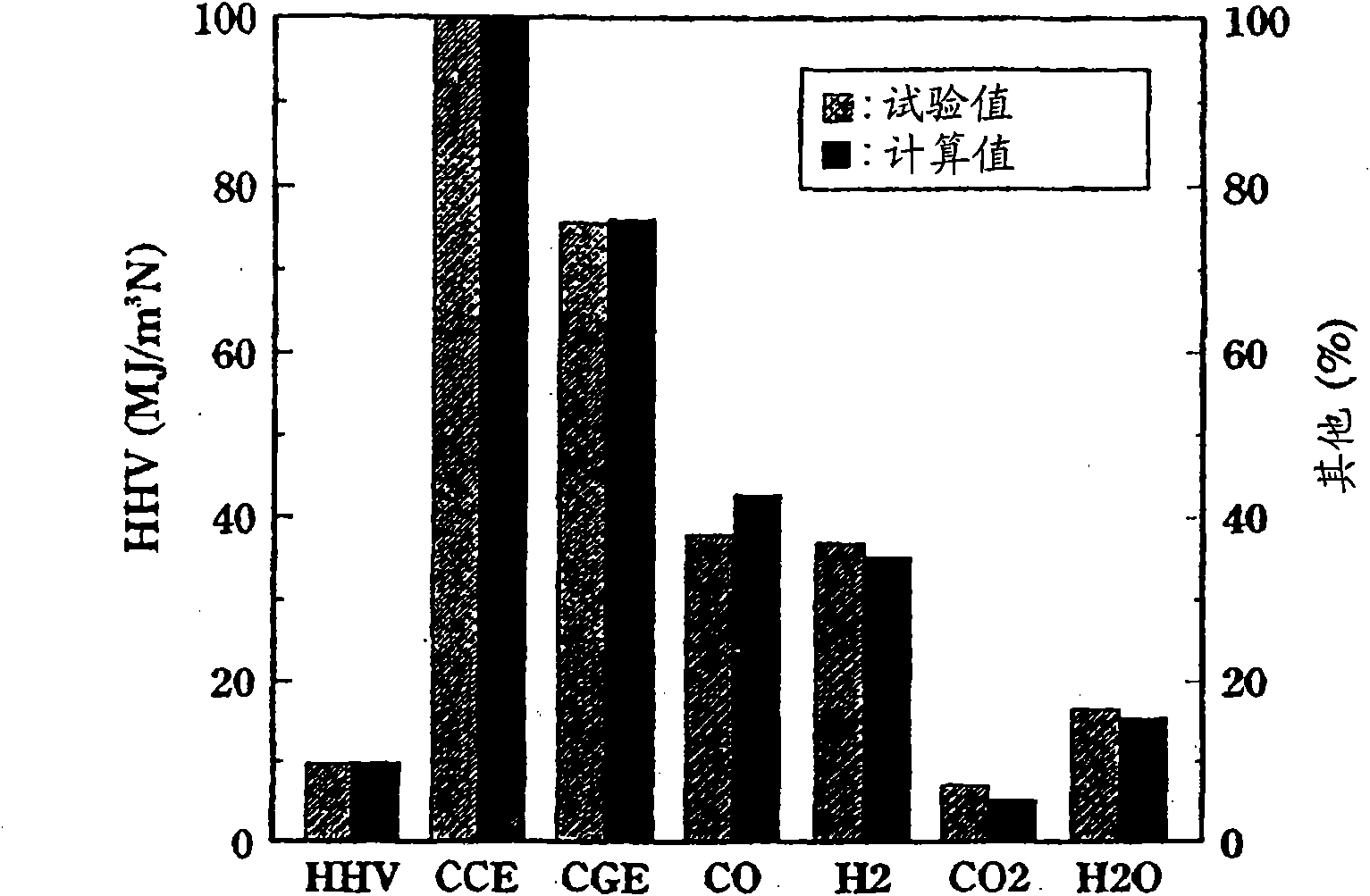

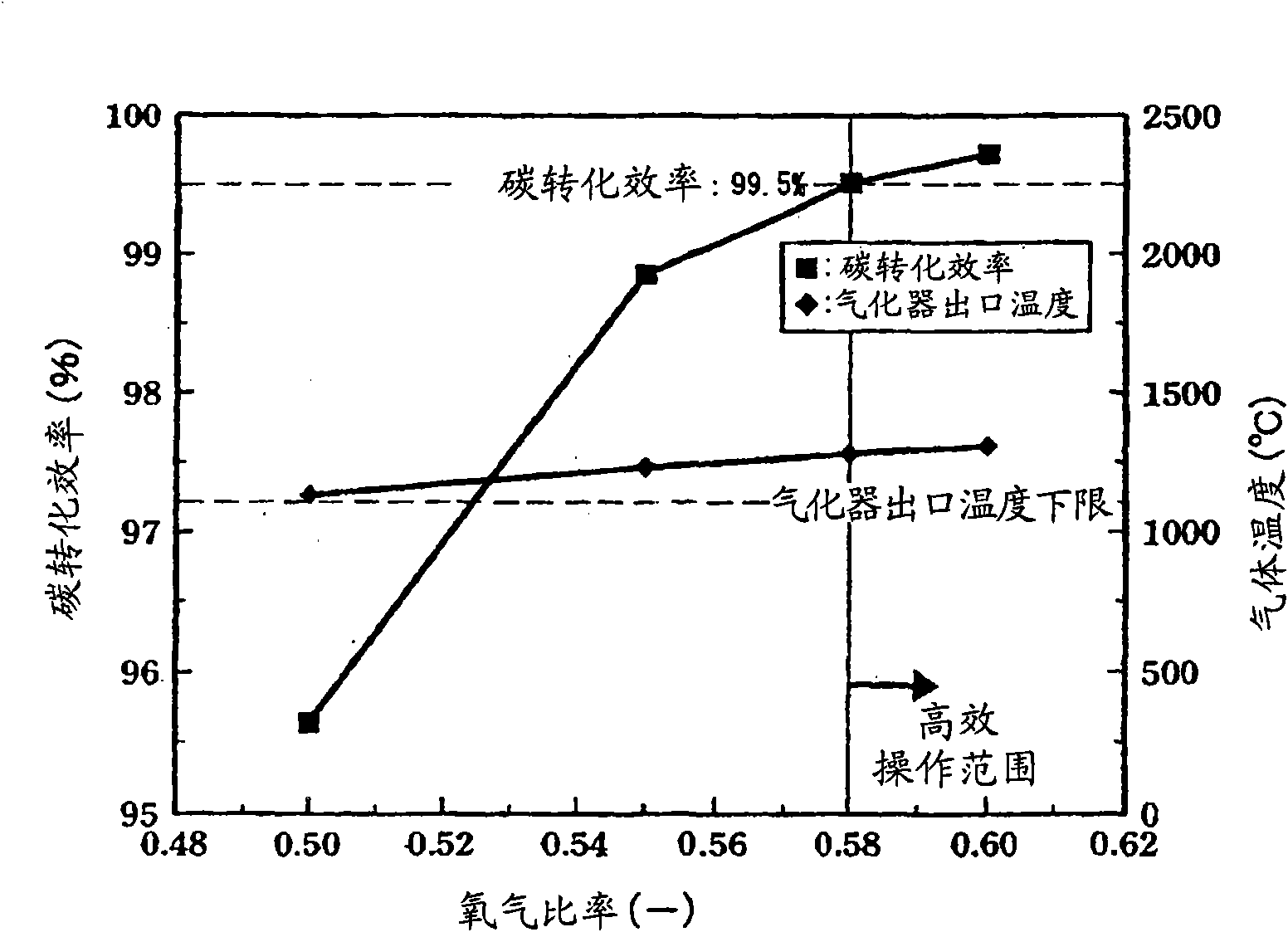

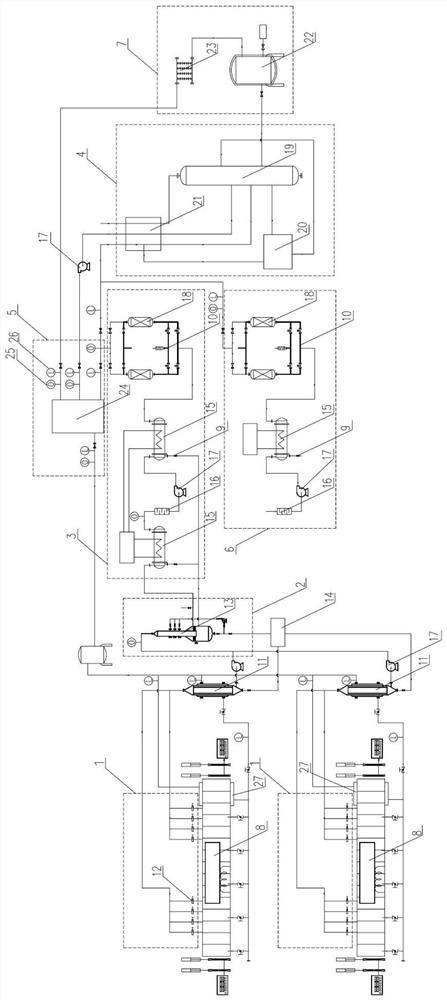

Carbonization and gasification of biomass and power generation system

InactiveCN101614154AImprove gasification efficiencyCost minimizationInternal combustion piston enginesSolid waste disposalTarBiomass

The invention provides a process for carbonization and gasification of biomass. Biomass, including waste biomass, is gasified by a process in which the biomass is first carbonized, and the char and pyrolysis gas from the carbonizer are respectively fed to a high temperature gasifying part and a gas reformer part of a two-stage gasifier. A gasifying agent is continuously fed to the gasifying part, and intermittently fed to the gas reformer, to maintain the temperature required to avoid tar formation in the gas reformer stage. Multiple carbonization chambers are operated in rotation. When the carbonization / gasification apparatus is used to provide fuel to an electric power generator set, exhaust heat from the generator power plant is fed back to the carbonizer, and can be supplemented by exchange of heat from the gas delivered to generator power plant from the outlet of the gasifier.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

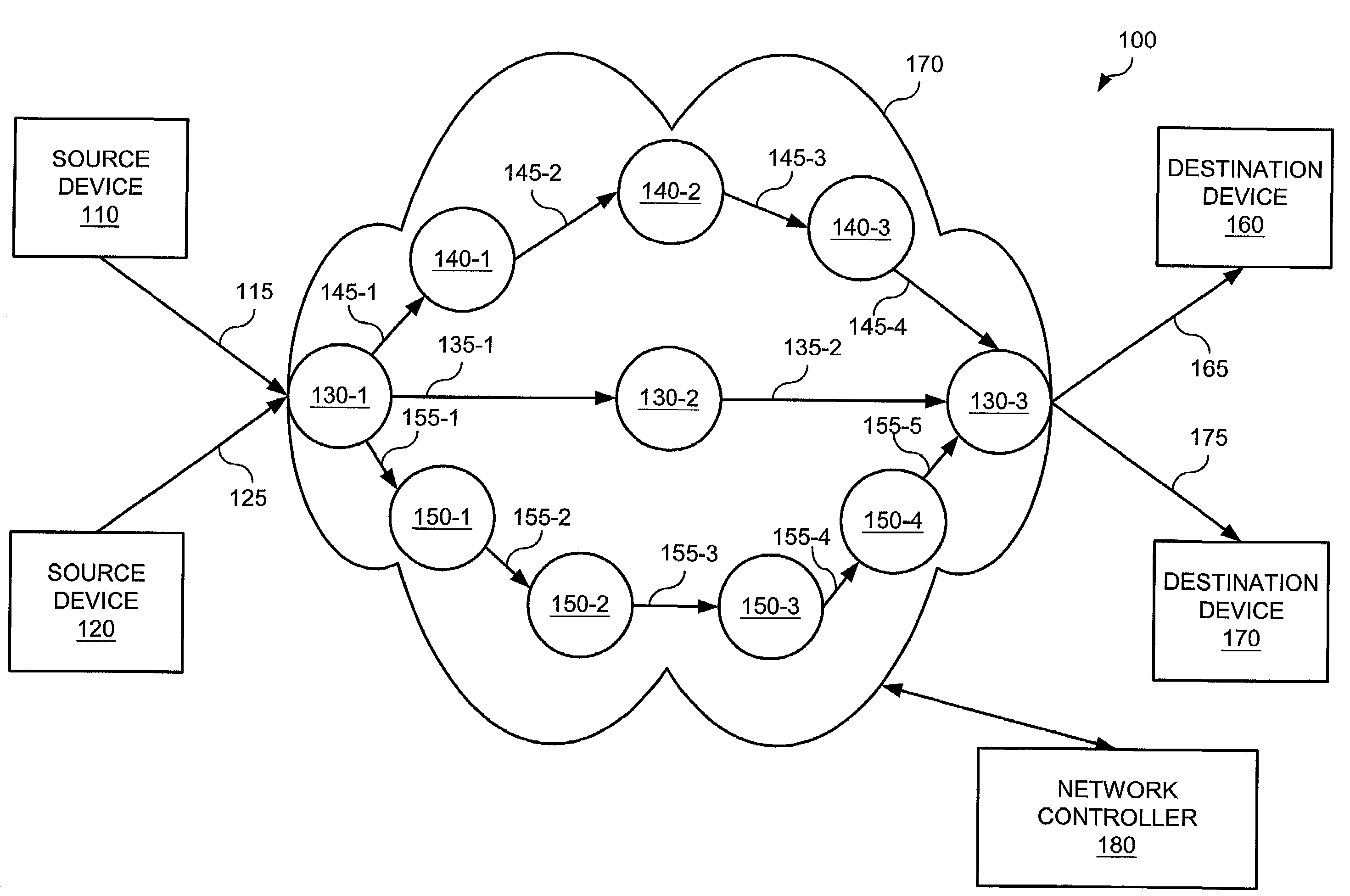

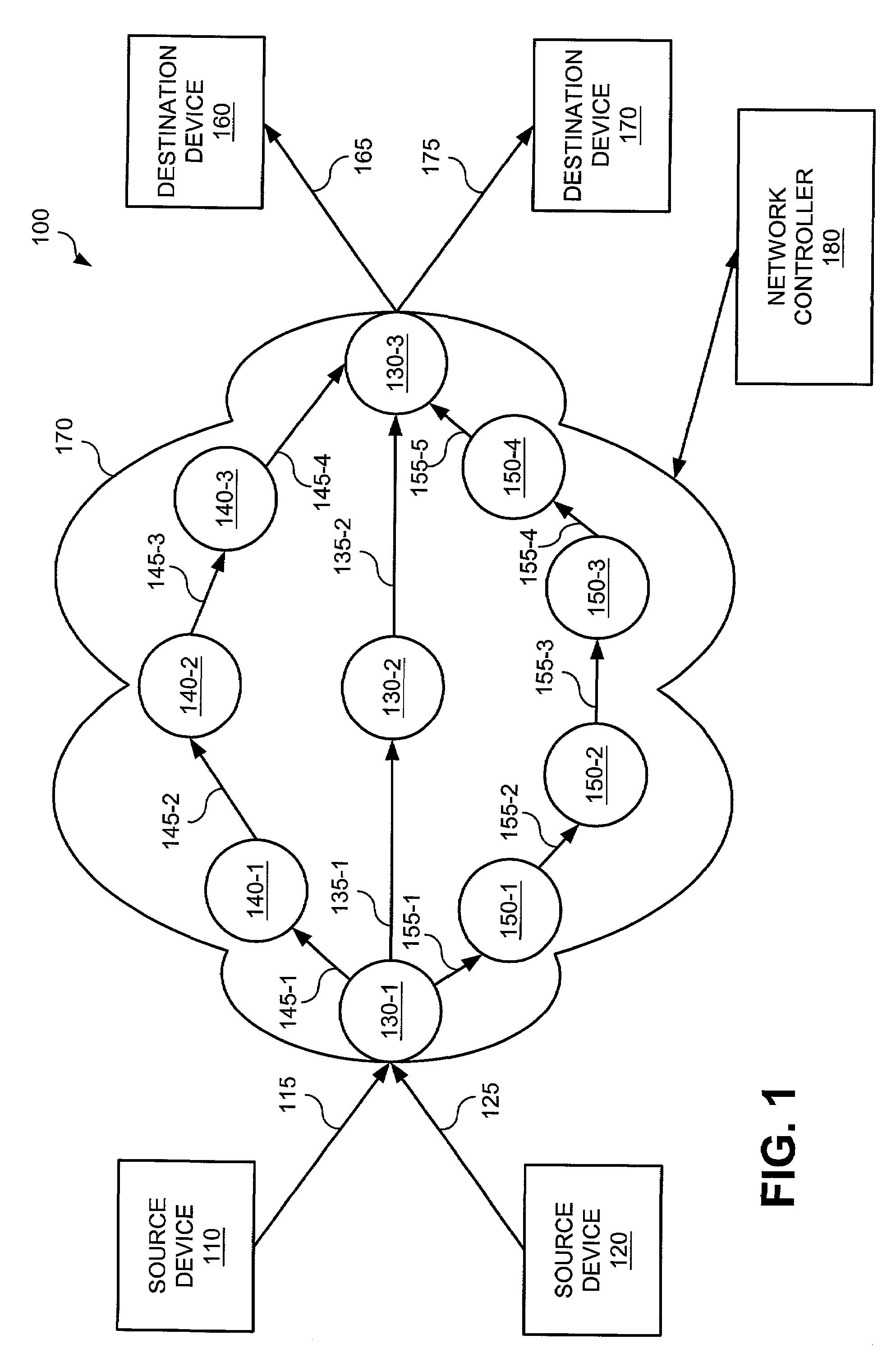

Fast and scalable approximation methods for finding minimum cost flows with shared recovery strategies, and system using same

InactiveUS7280526B2Cost minimizationEasily computedMultiplex system selection arrangementsError preventionTraffic volumeMajor and minor

Broadly, techniques for solving network routing within a predetermined error are disclosed. These techniques may be applied to networks supporting dedicated reserve capacity, where reserved capacity on links in the network is dedicated for a particular commodity (generally, a source and sink pair of computers), and shared recovery, where reserved capacity on links is shared amongst two or more commodities. These techniques use an iterative process to determine flows on each of the links in a network. Costs are set for each commodity, and primary and secondary (i.e., backup) flows are initialized. A commodity is selected and demand for the commodity is routed through the shortest path. Costs are updated for each potential failure mode. For each commodity, the flows and costs are updated. Once all flows and costs are updated, then it is determined if a function is less than a predetermined value. If the function is less than a predetermined value, then the commodity selection, and flow and cost adjustments are again performed. If the function is greater than the predetermined amount, then the network routing problem is solved to within a predetermined amount from an optimal network routing.

Owner:LUCENT TECH INC

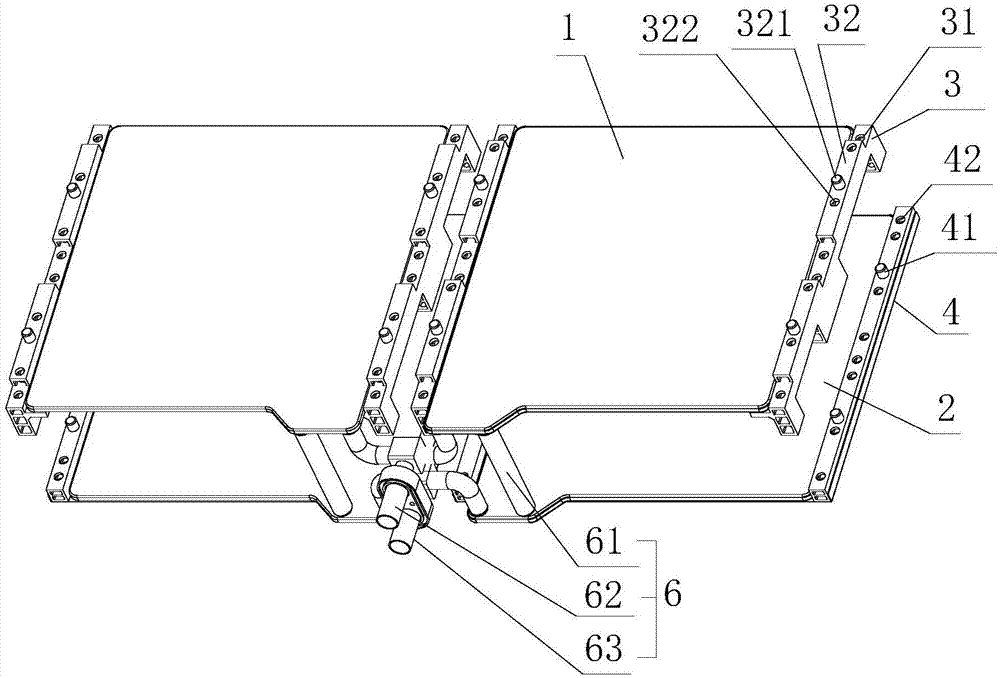

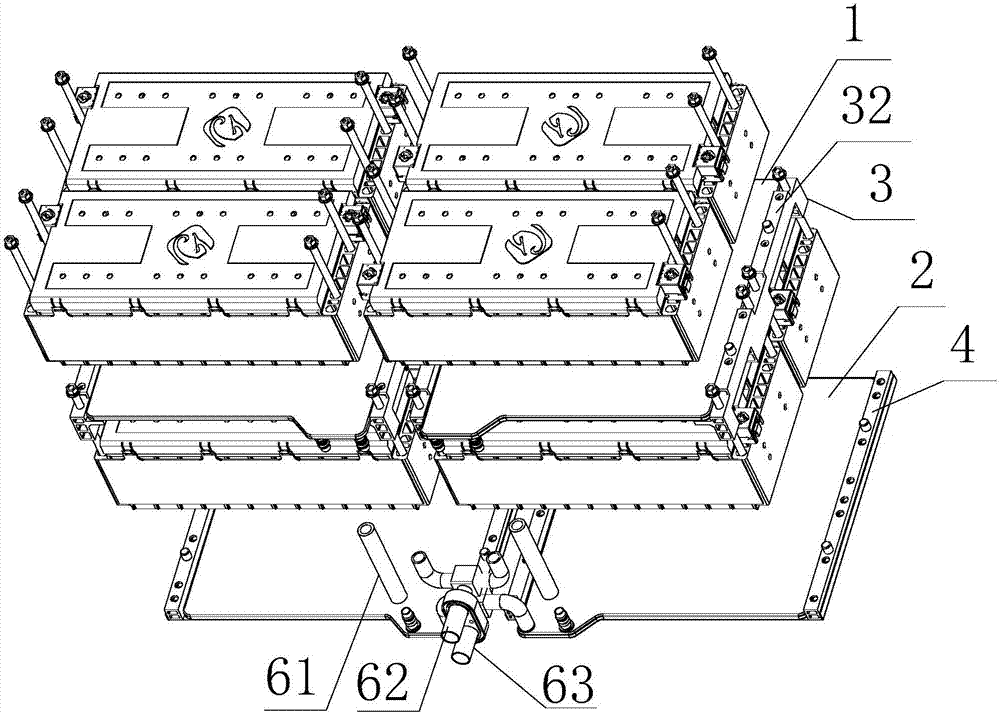

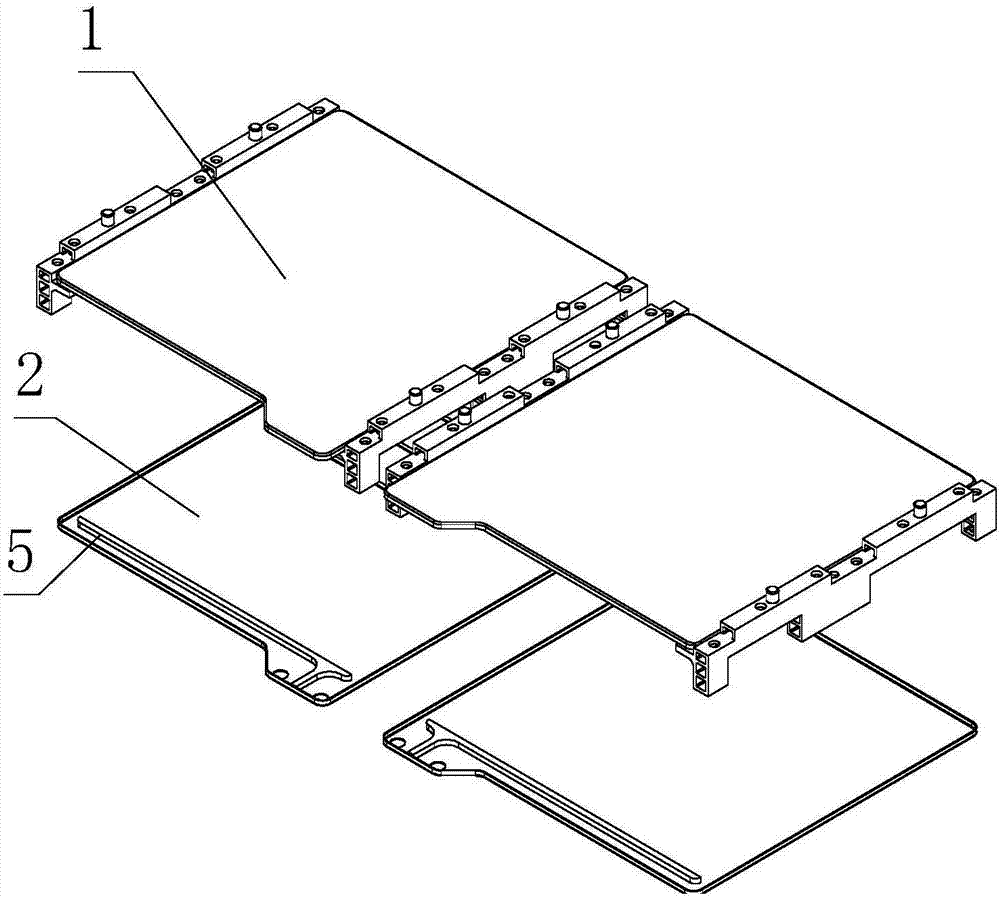

Liquid-cooled fixing structure for battery system

ActiveCN107359292ACost minimizationLow costSecondary cellsCell component detailsEngineeringCooling medium

The invention discloses a liquid-cooled fixing structure for a battery system. The liquid-cooled fixing structure comprises an upper water cooling plate and a lower water cooling plate, wherein the upper water cooling plate and the lower water cooling plate are arranged up and down and are connected with each other, each of the interior of the upper water cooling plate and the interior of the lower water cooling plate is provided with a medium flow passage for a cooling medium to flow, and the medium flow passage inside the upper water cooling plate communicates with the medium flow passage inside the lower water cooling plate to form a circuit; lower installation bases fixed to two sides of the lower water cooling plate are arranged on two sides of the lower water cooling plate, the lower installation bases on the two sides are matched with each other, a lower installation surface for a battery module to install is formed above the lower water cooling plate, and a lower fixing mechanism for fixing the battery module is arranged on the lower installation surface. According to the liquid-cooled fixing structure, a fixing device and a cooling device of the battery module are combined into one, the maximum utilization of system inner space is realized, the lightweight requirement of the system is met, and simultaneously the reliability requirement of the structure is further met.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

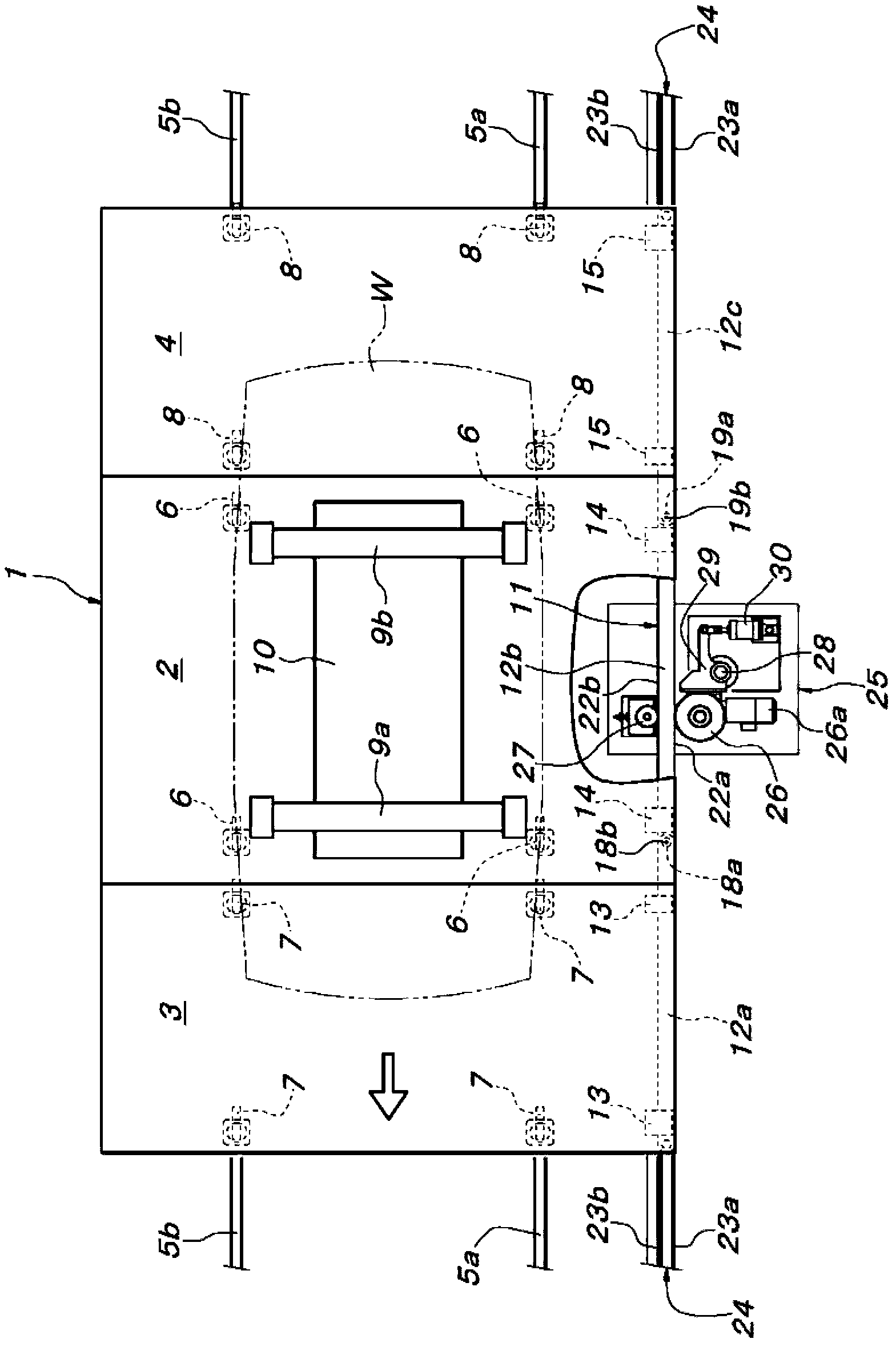

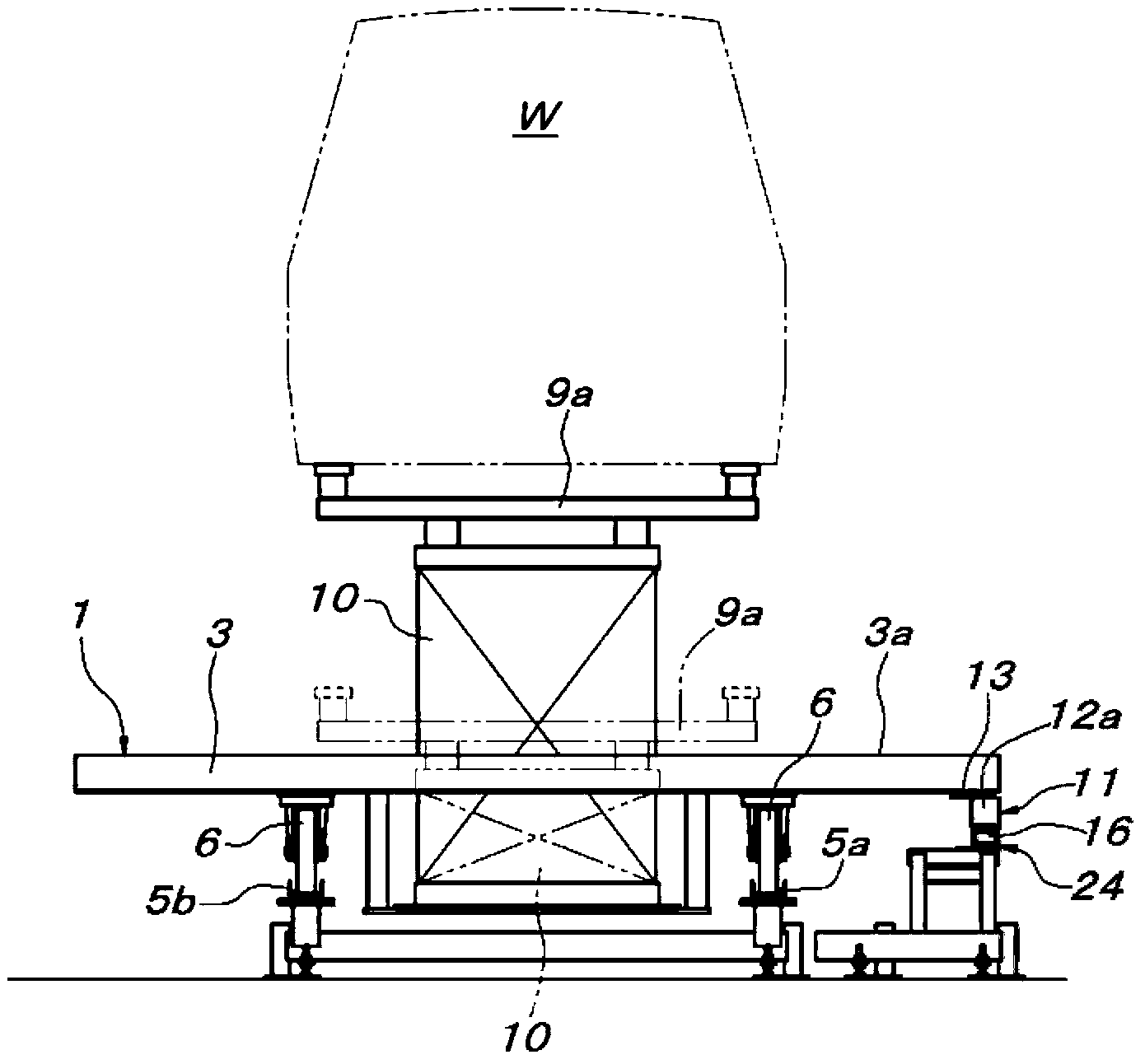

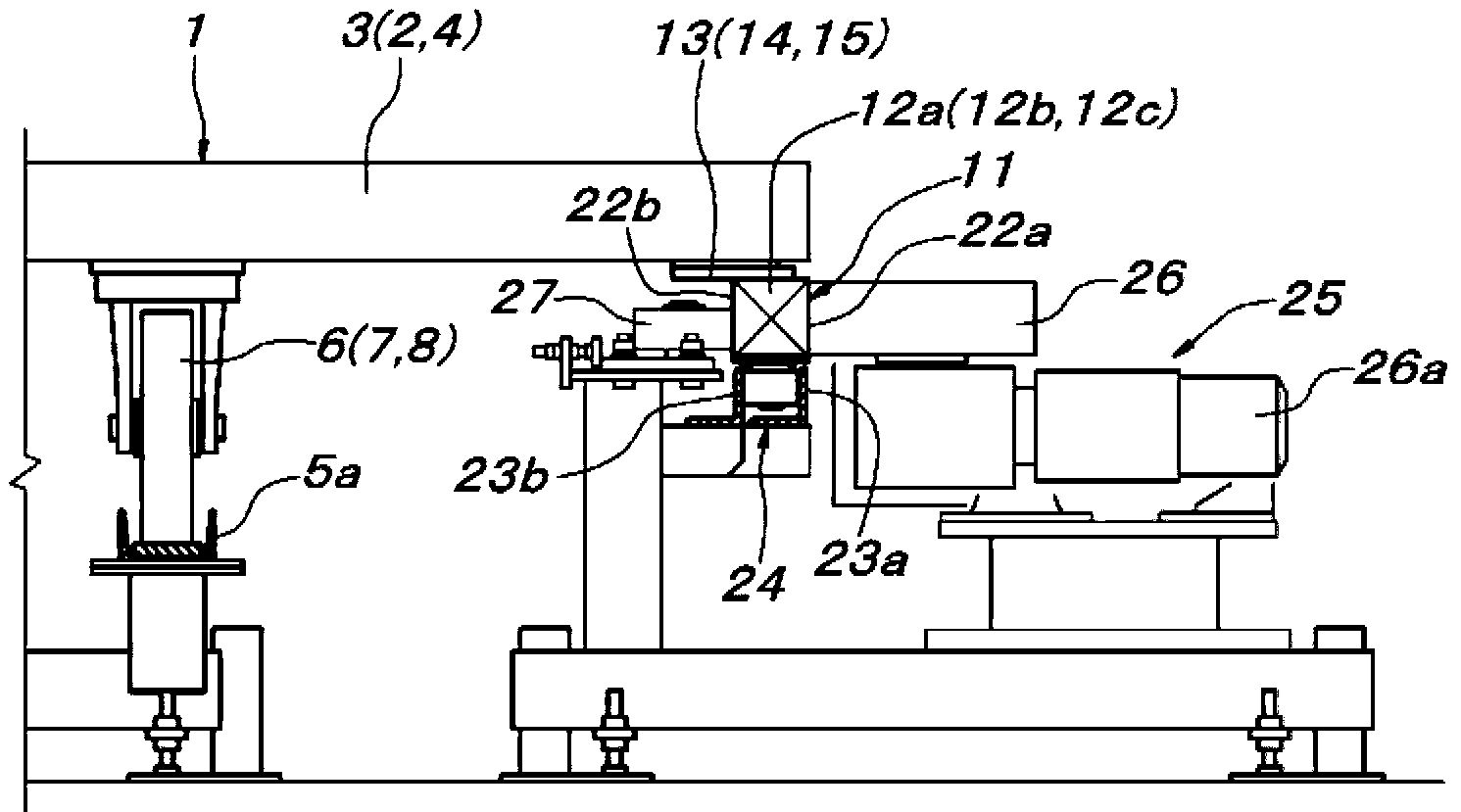

Friction-driving trolley type conveying device

ActiveCN102837943ACost minimizationDon't worry about security implicationsMechanical conveyorsFriction driveAssembly line

The invention discloses a friction-driving trolley type conveying device, which can be used for the operator of the vehicle assembly line to take the conveying trolley for the vehicle assembly operation. The conveying trolley 1 is constituted by a plurality of serially connected trolley single bodies 2-4 along the walking direction. One of a left side and a right side of the conveying trolley 1 having the trolley single bodies 2-4 under the forwarding state is connected with the periphery of the vertical joint axial central 18b, 19b of the straight line position parallel to the walking direction in a freely bendable manner. The friction driving rod 11 is disposed on each of the trolley bodies single bodies 2-4, and is constituted by a plurality of rod single bodies 12a-12c disposed the straight line position, besides, the rod single bodies 12a-12c can be freely bent around the joint axial center 18b,19b in the horizontal direction.

Owner:DAIFUKU CO LTD

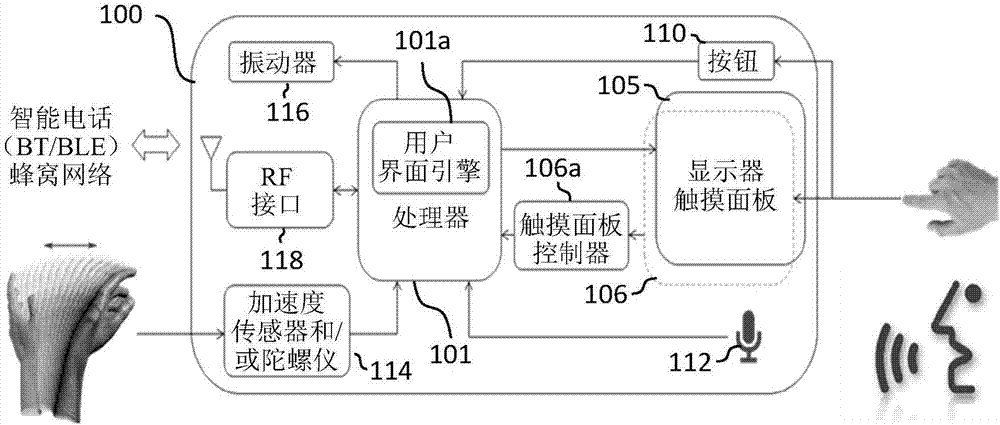

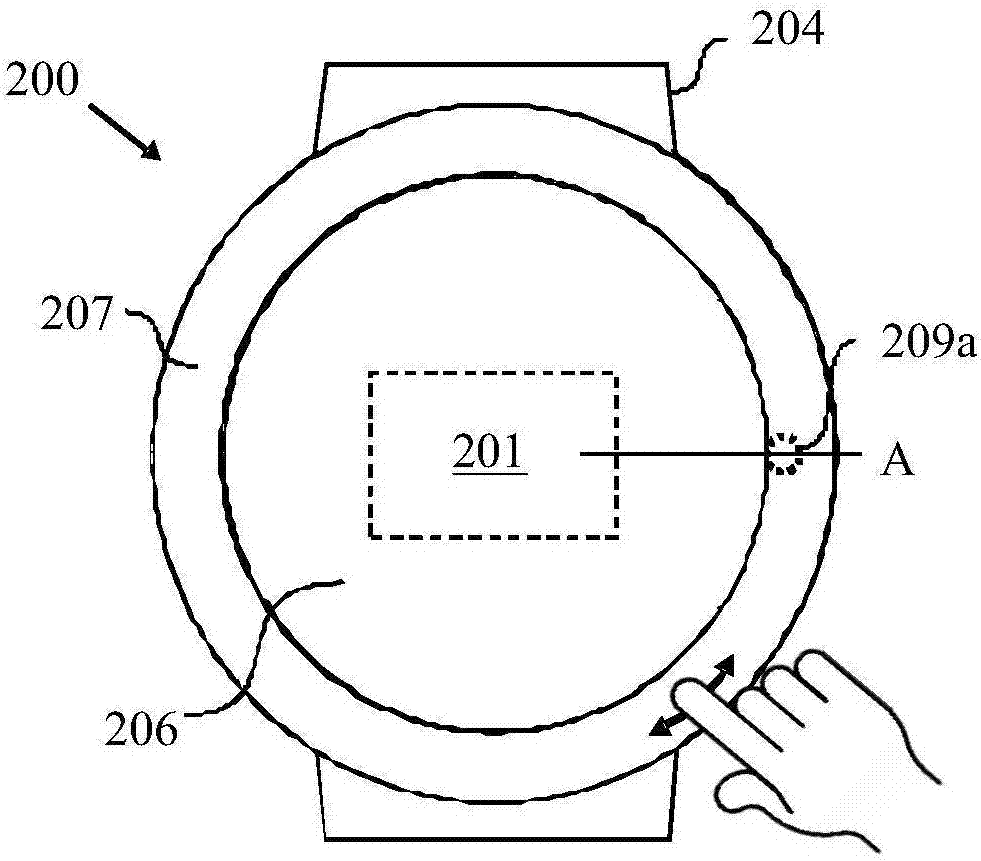

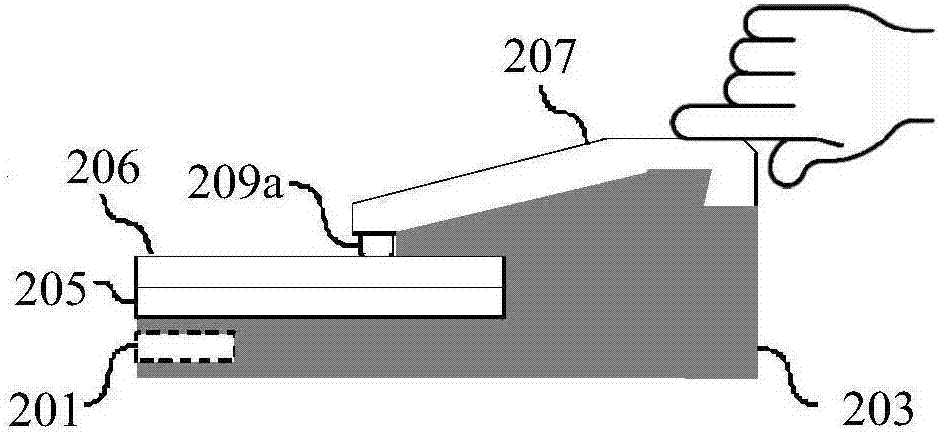

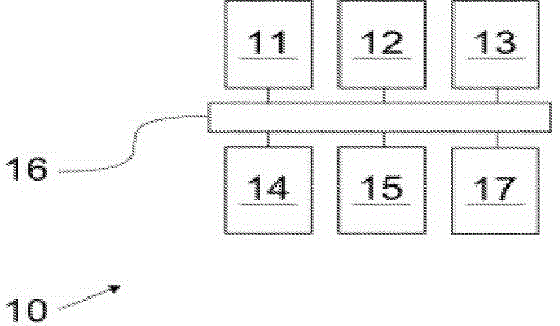

Electronic device with rotatably mounted bezel for interaction and method of operating such an electronic device

ActiveCN107003788ACost minimizationImproved Mechanical DesignInput/output for user-computer interactionElectric windingTouch panelDisplay device

The invention relates to an electronic device (200), in particular a smartwatch (200), comprising a processor (201) configured to implement a user interface for allowing a user to interact with the electronic device (200), a display and a touch panel (206) in communication with the processor (201), wherein the display and the touch panel (206) provide a touch-sensitive display configured to allow a user to interact with the electronic device (200) on the basis of the user interface by touching the touch panel (206), and a bezel (207) rotatably mounted on a housing of the electronic device (200), wherein the bezel (207) comprises a pointing element (209a) configured to activate the touch panel (206) at a plurality of different locations of the touch panel (206) and wherein the plurality of different locations of the touch panel (206) define a plurality of different positions of the bezel (207) relative to the housing allowing the user to interact with the electronic device (200) by using the bezel (207). Moreover, the invention relates to a method of operating such an electronic device (200).

Owner:HUAWEI TECH CO LTD

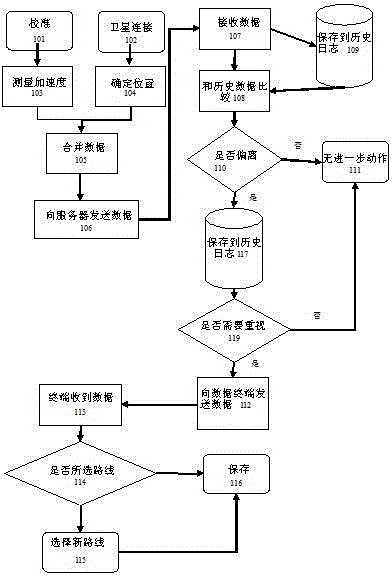

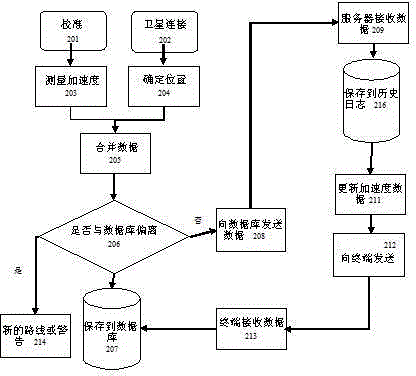

Method and system for surveying road condition through terminal

The invention relates to a method of surveying a road surface condition, a server with a computer software product and a system. Particularly, a road surface friction condition is surveyed. In the method, the acceleration of a vehicle is measured by an acceleration sensor, the position of the vehicle is monitored through a positioning device, and the acceleration value is measured when the position data for measuring the position are combined. The method compares the measured acceleration value at the specific position and the value for a corresponding area on the server, and if the acceleration value exceeds the value on the server, the measured acceleration value at the specific position is sent to the server.

Owner:TRANSCEND COMM BEIJING

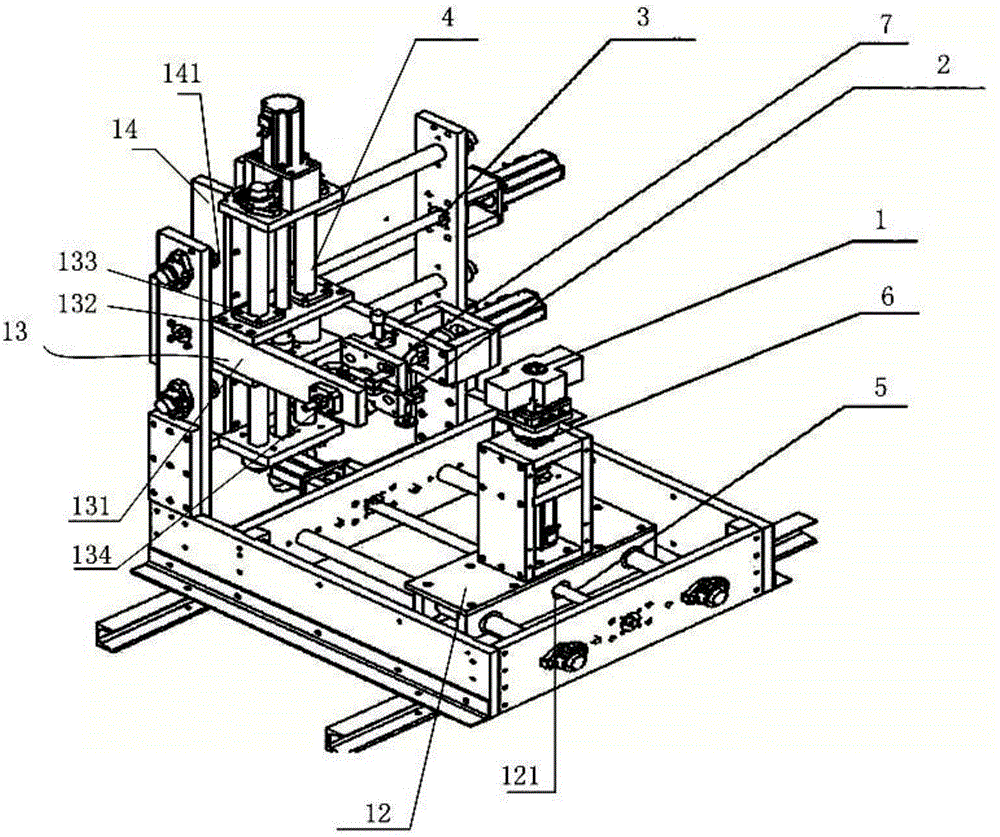

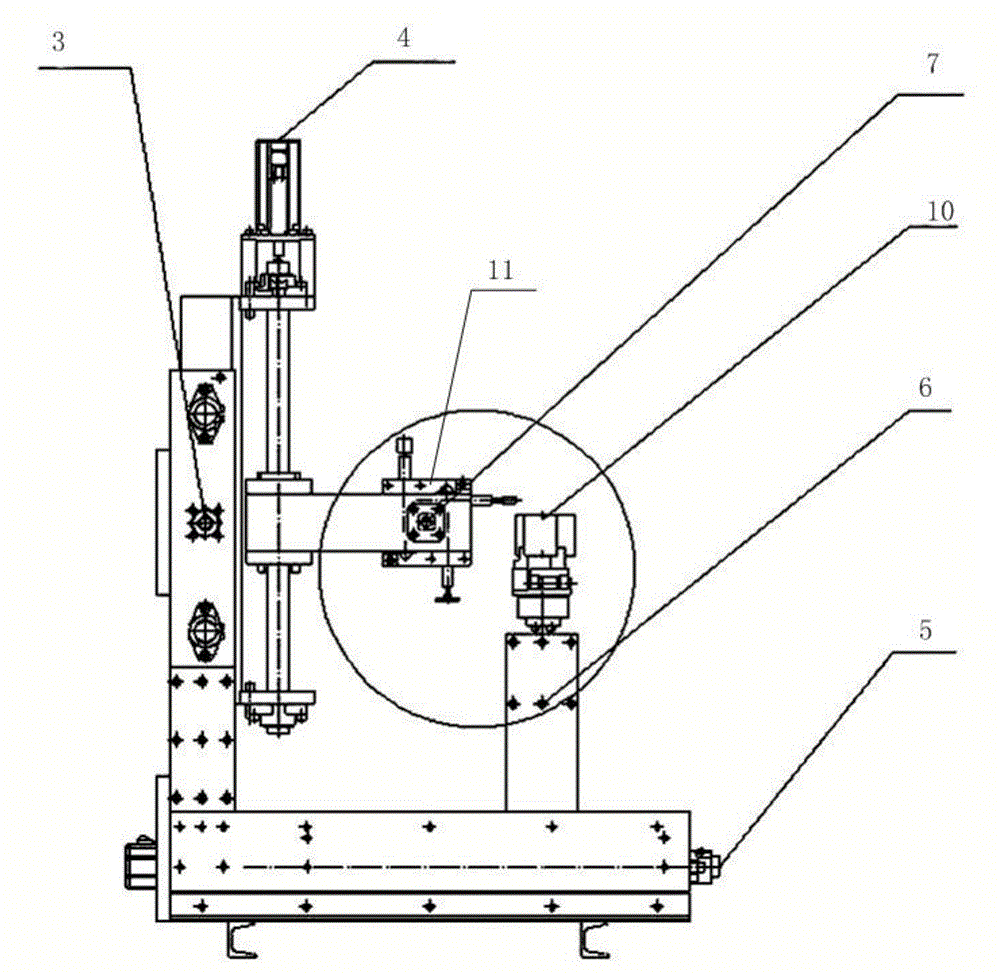

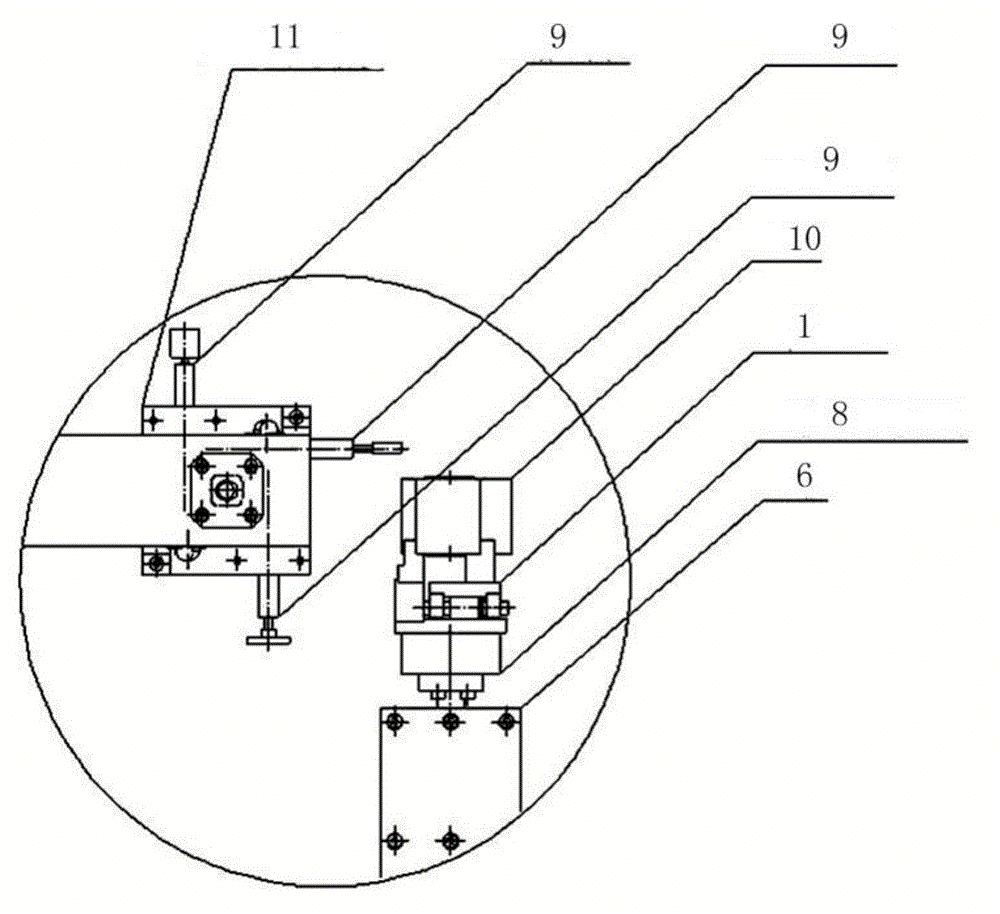

Workpiece deburring device

ActiveCN104625911AThe tool is less stressedCost minimizationEdge grinding machinesEngineeringMachining

The invention discloses a workpiece deburring device which comprises a workpiece frame and a tool frame. The workpiece deburring device further comprises a first horizontal shaft, a first vertical shaft, a second horizontal shaft, a second vertical shaft and a third horizontal shaft. The first horizontal shaft and the third horizontal shaft are parallel to each other. The second horizontal shaft is perpendicular to the first horizontal shaft and the third horizontal shaft. The workpiece frame is installed on the second vertical shaft which is installed on the second horizontal shaft through a first connecting box body. The tool frame is installed on the third horizontal shaft and rotates around the third horizontal shaft. The third horizontal shaft is installed on the first vertical shaft through a second connecting box body. The first vertical shaft is installed on the first horizontal shaft through a third connecting box body. According to the workpiece deburring device, on the basis of low cost, the multi-freedom-degree flexible machining requirements are met, different grinding tools can be switched for a single workpiece, different workpieces can be switched as well, multiple purposes can be achieved through one device, and the investment efficiency is maximized.

Owner:SMC (BEIJING) MFG CO LTD +1

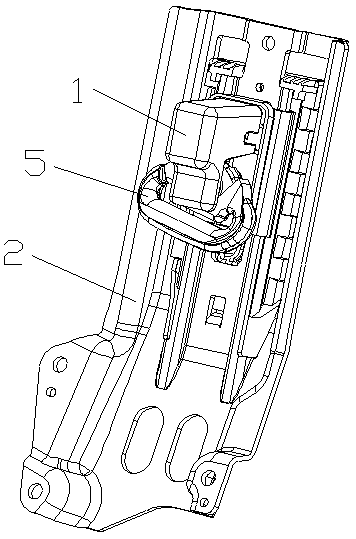

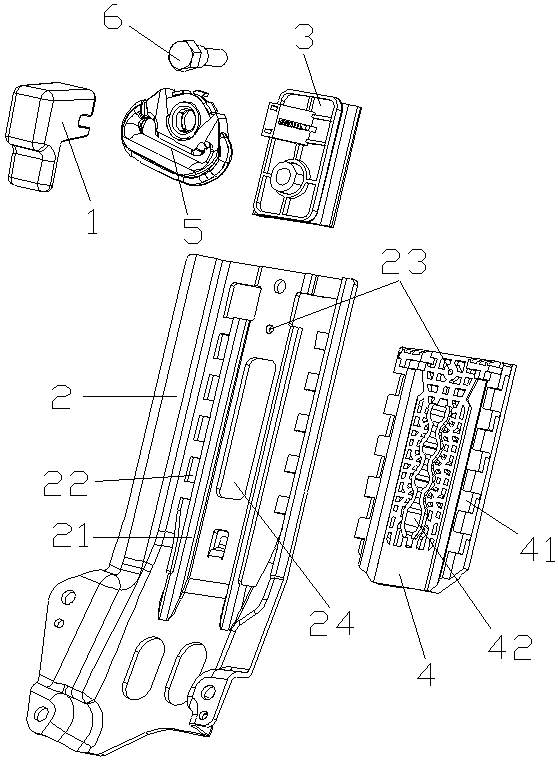

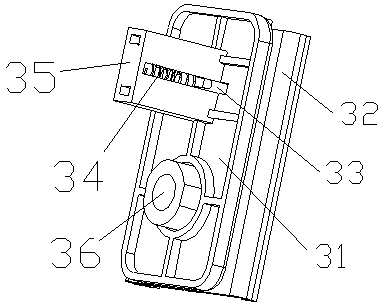

Safety belt height adjusting mechanism

PendingCN108275112AReduce Design RedundancyCost minimizationBelt anchoring devicesHeight increasedBelt safety

Owner:CHANGCHUN FAWAY ADIENT AUTOMOTIVE SYST CO LTD

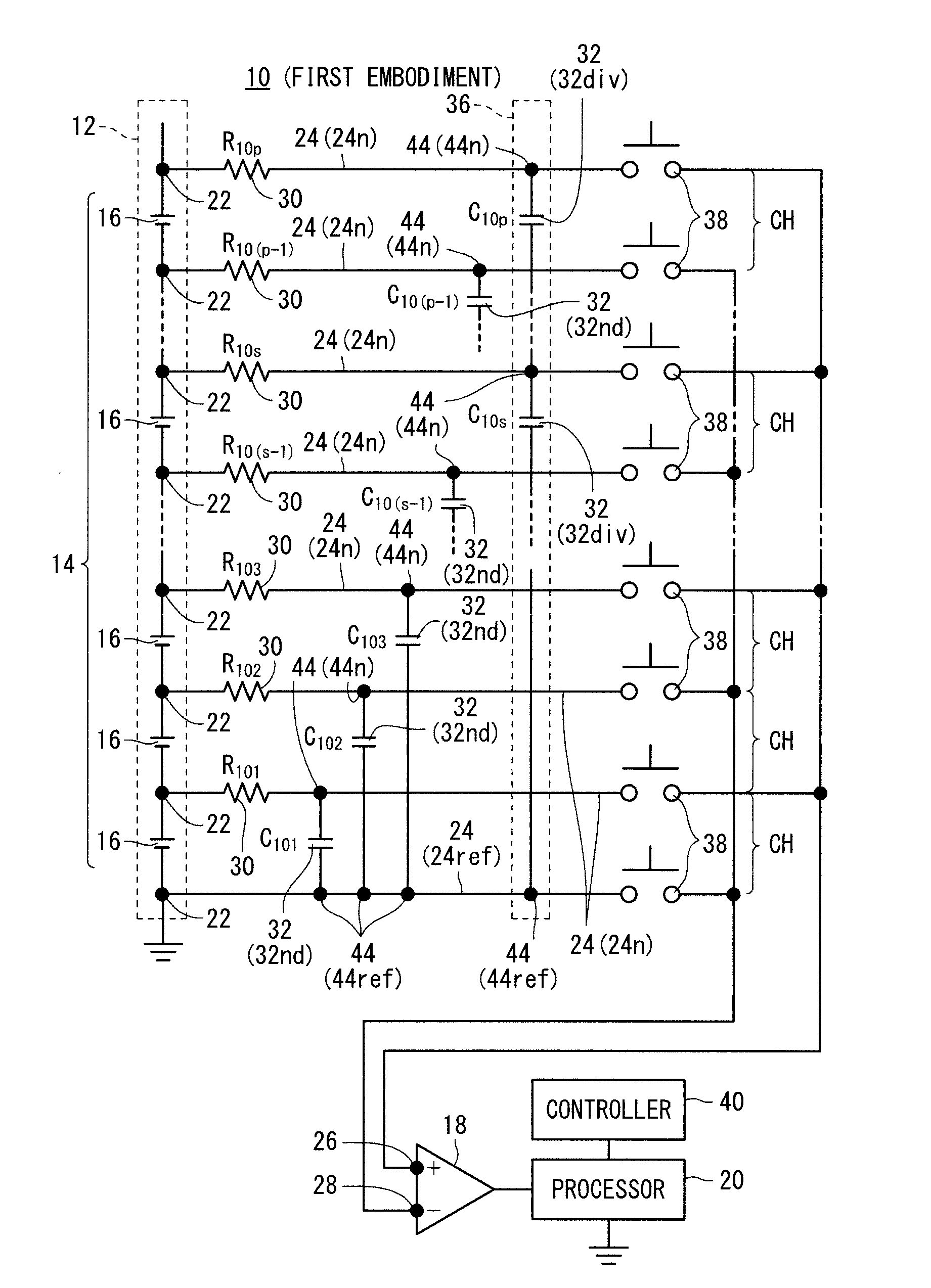

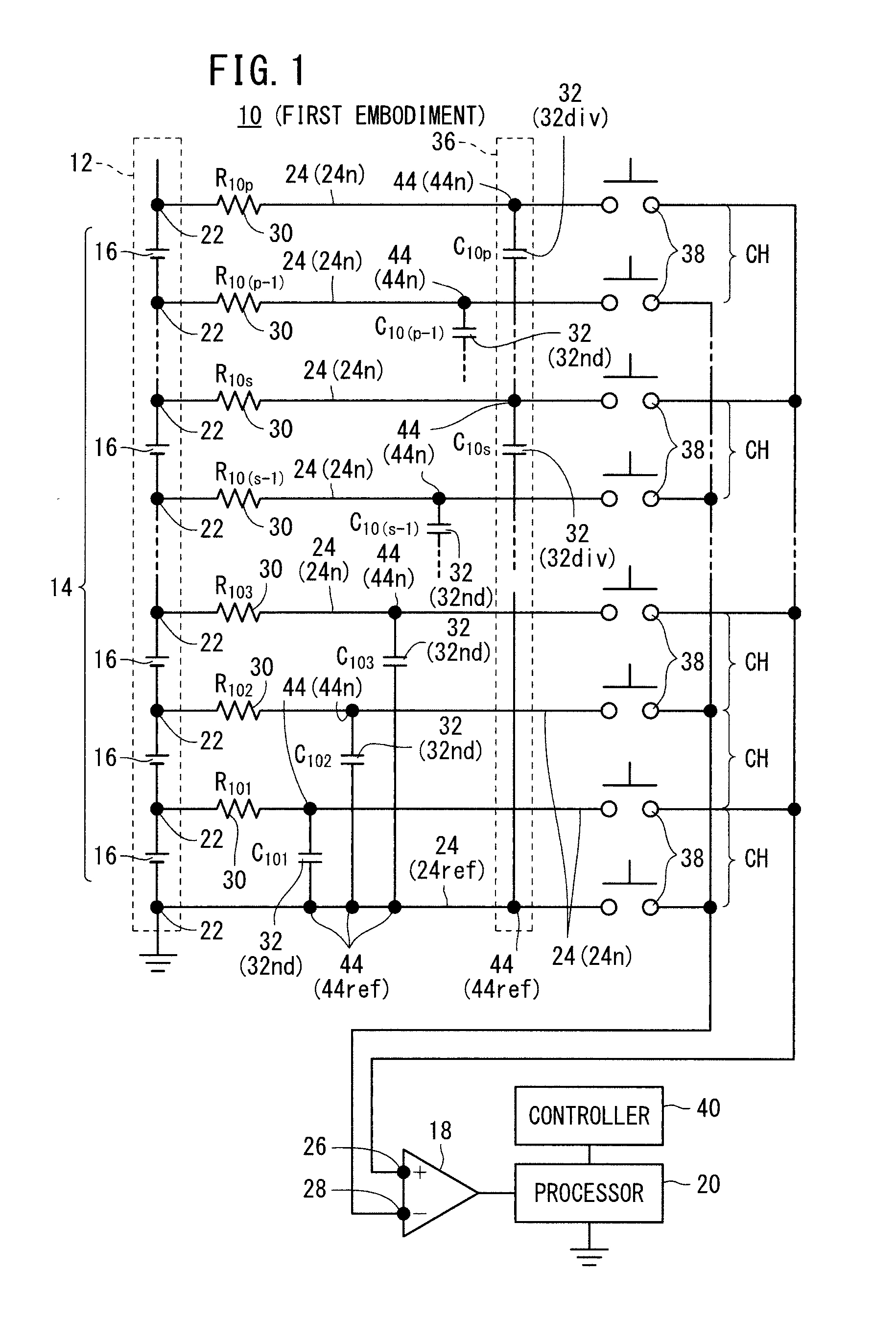

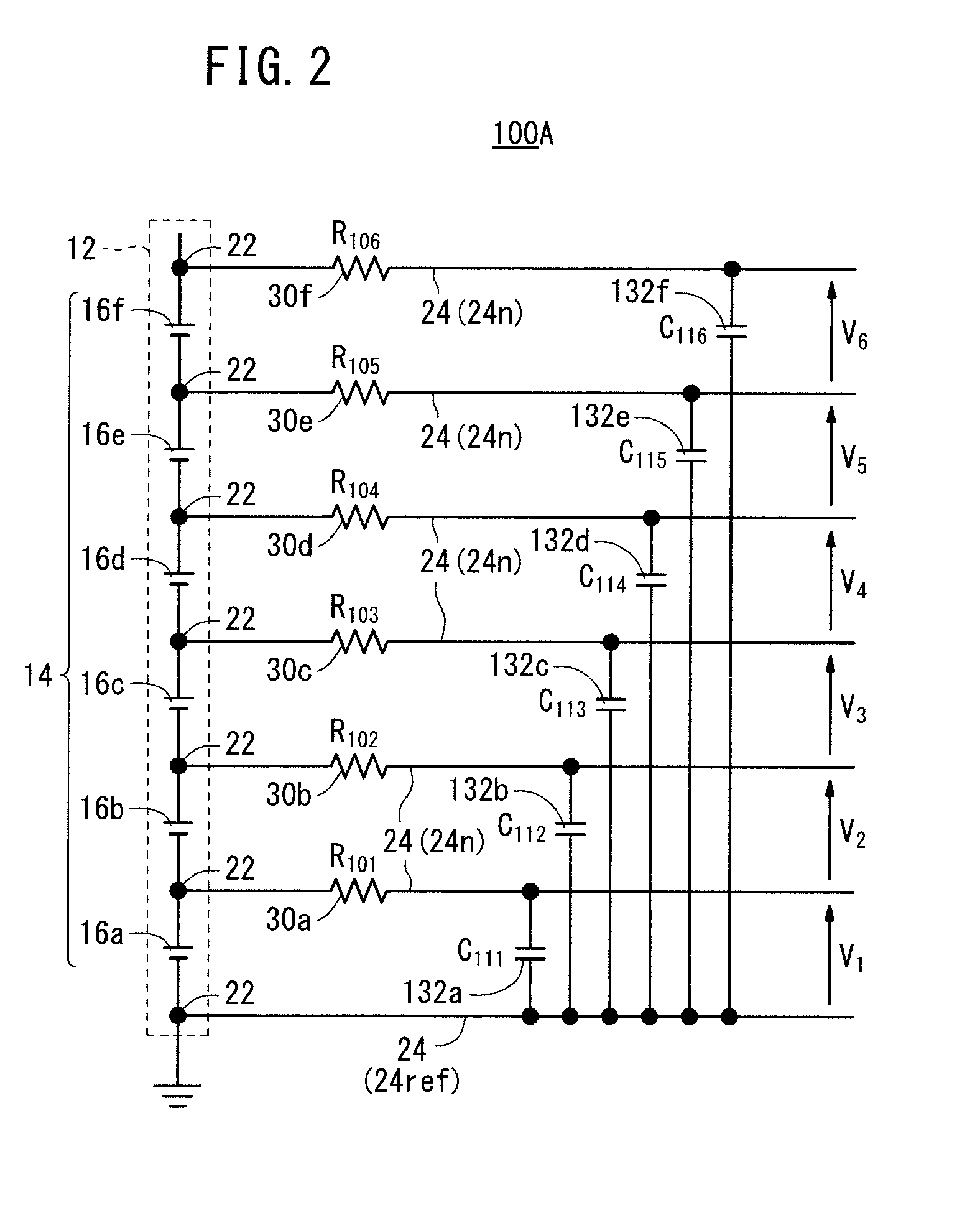

Voltage measuring device

ActiveUS20140350878A1Easy to adjust resistance valueCost minimizationBatteries circuit arrangementsElectrical testingEngineeringLow-pass filter

Provided is a voltage measuring device capable of increasing the degree of freedom in the design of an RC filter (low-pass filter) while suppressing the withstand voltage limit of a capacitor. The voltage measuring device comprises: at least one divided capacitor group having a plurality of divided capacitors connected in series through measurement nodes and having one end connected to a reference node and the other end connected to a non-reference node; and at least one non-divided capacitor having one end connected to the reference node and the other end connected to a non-reference node to which the divided capacitors are not connected.

Owner:HONDA MOTOR CO LTD

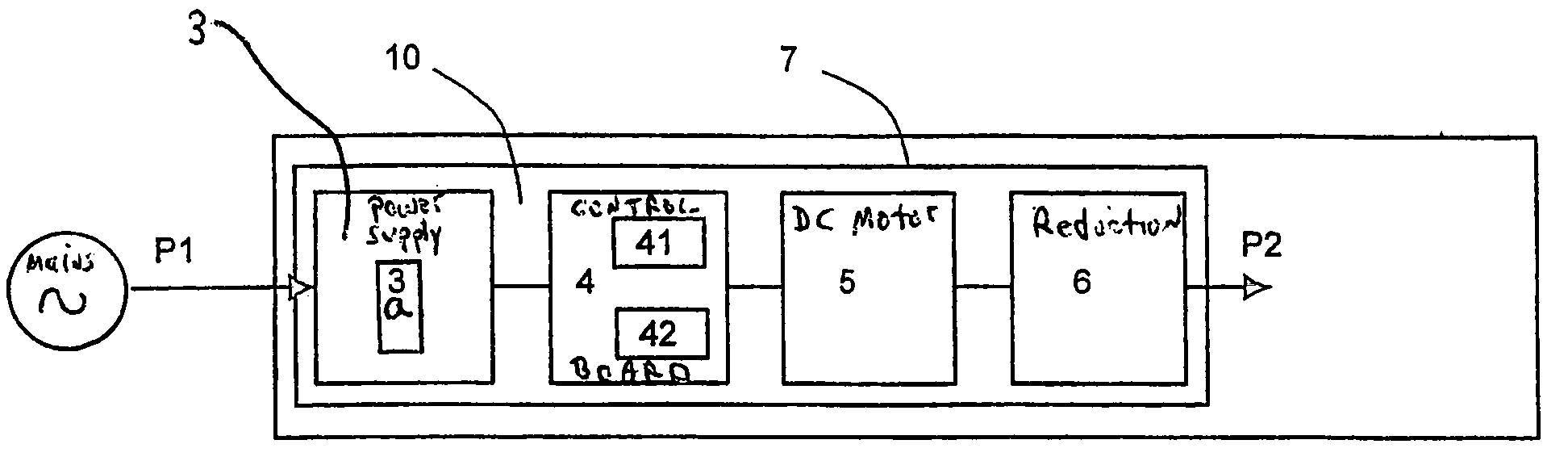

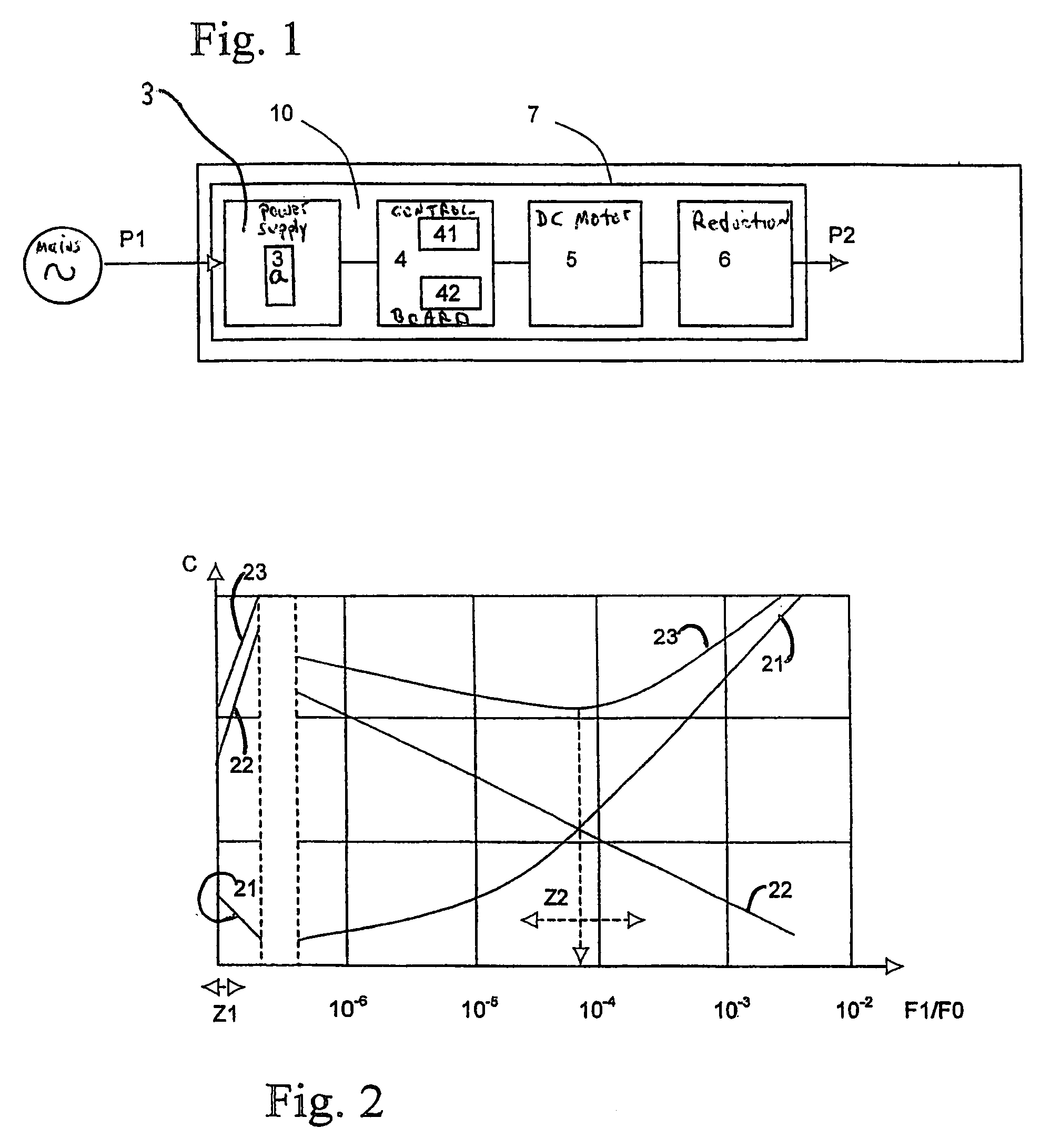

Electrical actuator having a direct current motor

ActiveUS7081724B2Cost minimizationSatisfy thermal performanceAssociation with control/drive circuitsMotor/generator/converter stoppersVoltage converterRadio wave

An electrical mains-powered actuator designed to operate a closing, darkening or solar protection element, having in a common enclosure, a direct current motor, a board controlling the motor power supply and an AC / DC voltage converter, the control board including a radio-wave receiver, such that the voltage converter enables lowering of the voltage and includes at least one switch controlled at a frequency (F1) such that it is at most equal to twice the mains sector frequency or such that its ratio to the radio-wave receiver frequency (F0) ranges between 2.2 10−5 to 2.2 10−4.

Owner:SOMFY ACTIVITES SA

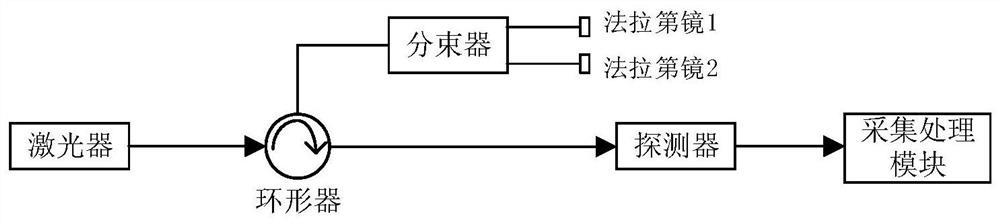

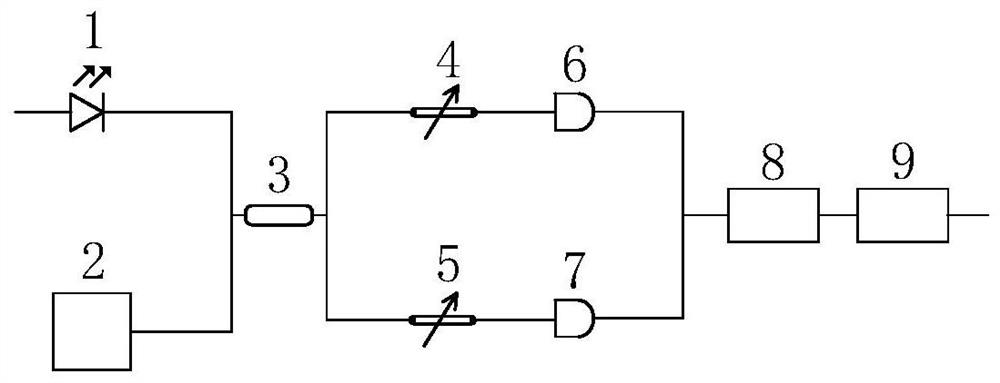

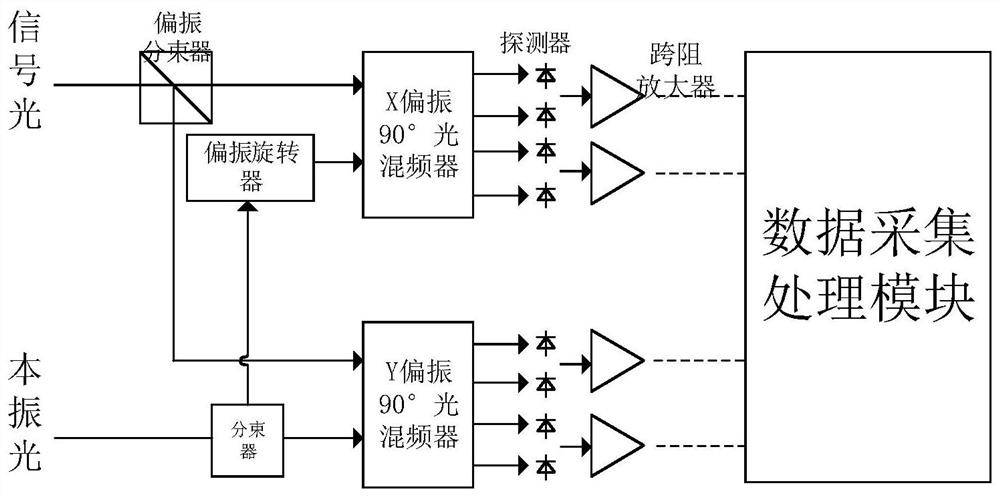

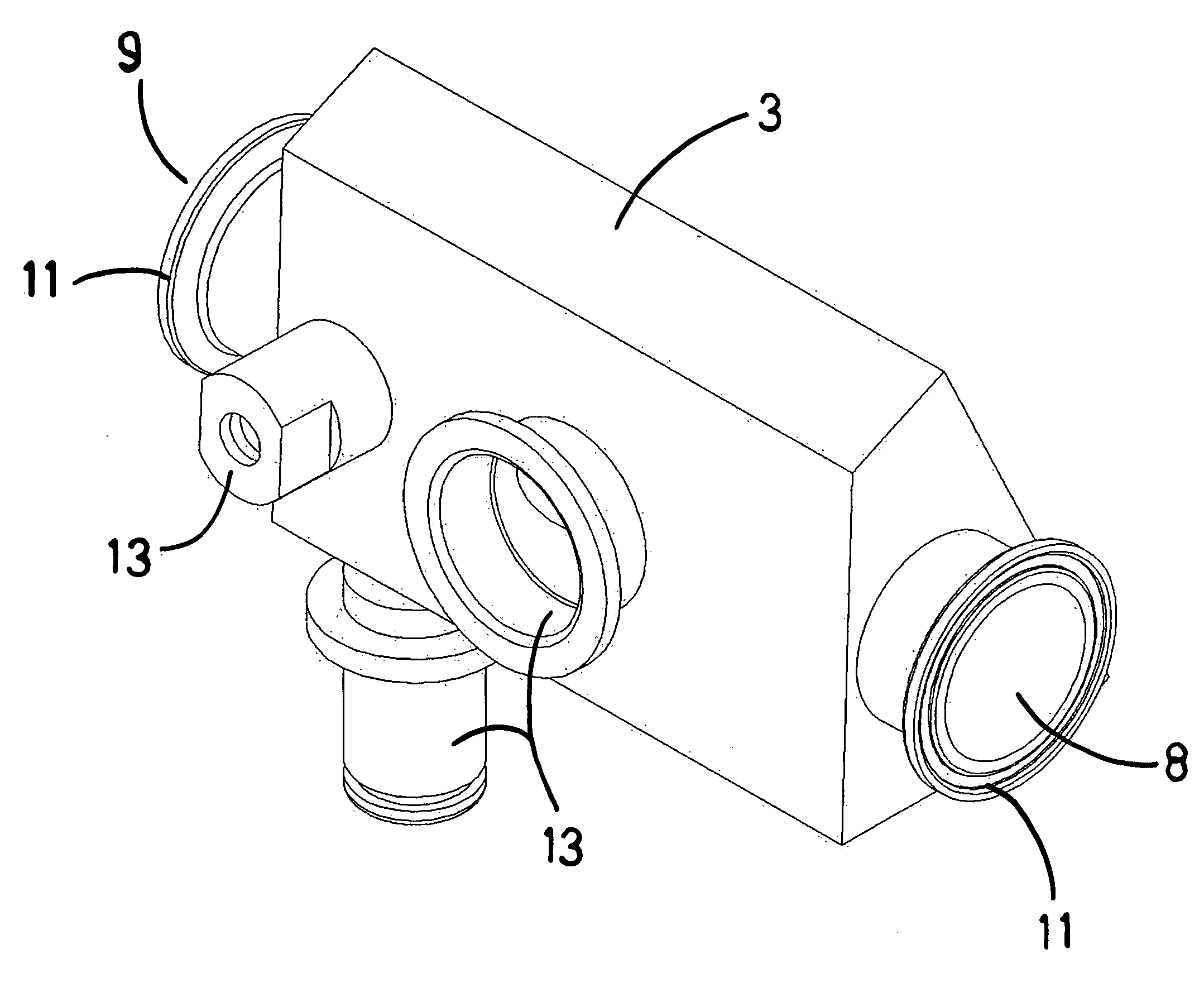

Quantum random number generation device, method and equipment based on coherent optical receiver

ActiveCN113031919ACost minimizationLow costQuantum computersRandom number generatorsOptical receiversLight source

The invention provides a quantum random number generation device, method and equipment based on a coherent light receiver. The quantum random number generation device comprises a local oscillator light source, the coherent light receiver and a data acquisition and processing module, wherein the local oscillator light source is connected to one input end of the coherent light receiver, and the other input end of the coherent light receiver has no light input and is used as a vacuum state input end; the coherent optical receiver is configured to perform beam splitting, polarization, interference and conversion on input light to obtain a voltage signal; the output end of the coherent optical receiver is connected with a data acquisition and processing module, and the data acquisition and processing module is configured to perform data acquisition on the voltage signal output by the coherent optical receiver and quantify the voltage signal to generate analysis data, and then process the analysis data through a random number post-processing method to generate a random number. The device, the method and the equipment have the advantages of high stability, miniaturization and low cost, and multi-channel random number generation can be realized.

Owner:山东国迅量子芯科技有限公司

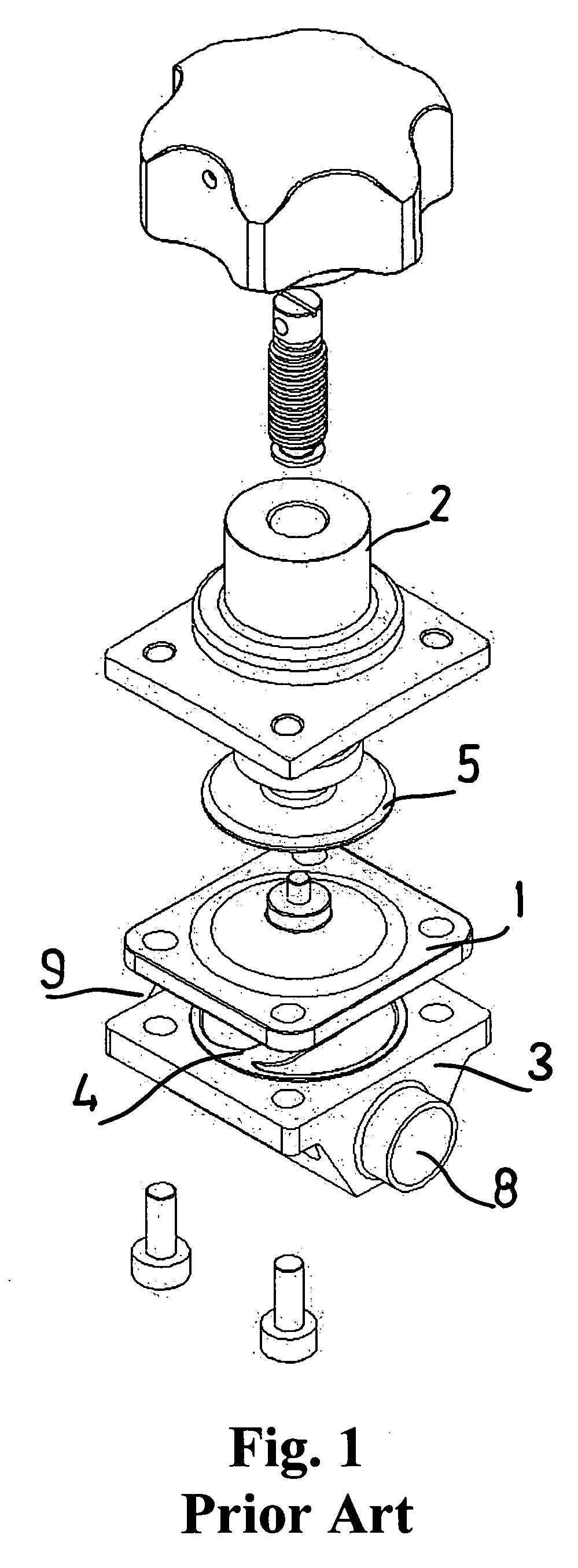

Versatile valve

InactiveUS20060237066A1Cost minimizationThe test result is accuratePipeline systemsService pipe systemsEngineeringInstrumentation

A valve comprising a bonnet, an actuator for controlling the movement of a diaphragm situated between the bonnet and a valve body having an inlet port, an outlet port, a passageway connecting the inlet port and the outlet port for fluid flow, the valve body having an access receiving port for accommodating a device. The access receiving port is designed to accommodate any type of devices especially a test instrument which is usually a measuring or a sensing device. The access receiving port may be one or more than one. The proposed valve body can replace an existing valve body thereby avoiding the need to replace the entire valve. The access receiving port can have the same design or different designs. It is located either above the passageway of the valve body for a weir type valve or into the passageway of the valve body for a radial style valve.

Owner:GAGNE MICHAEL C +2

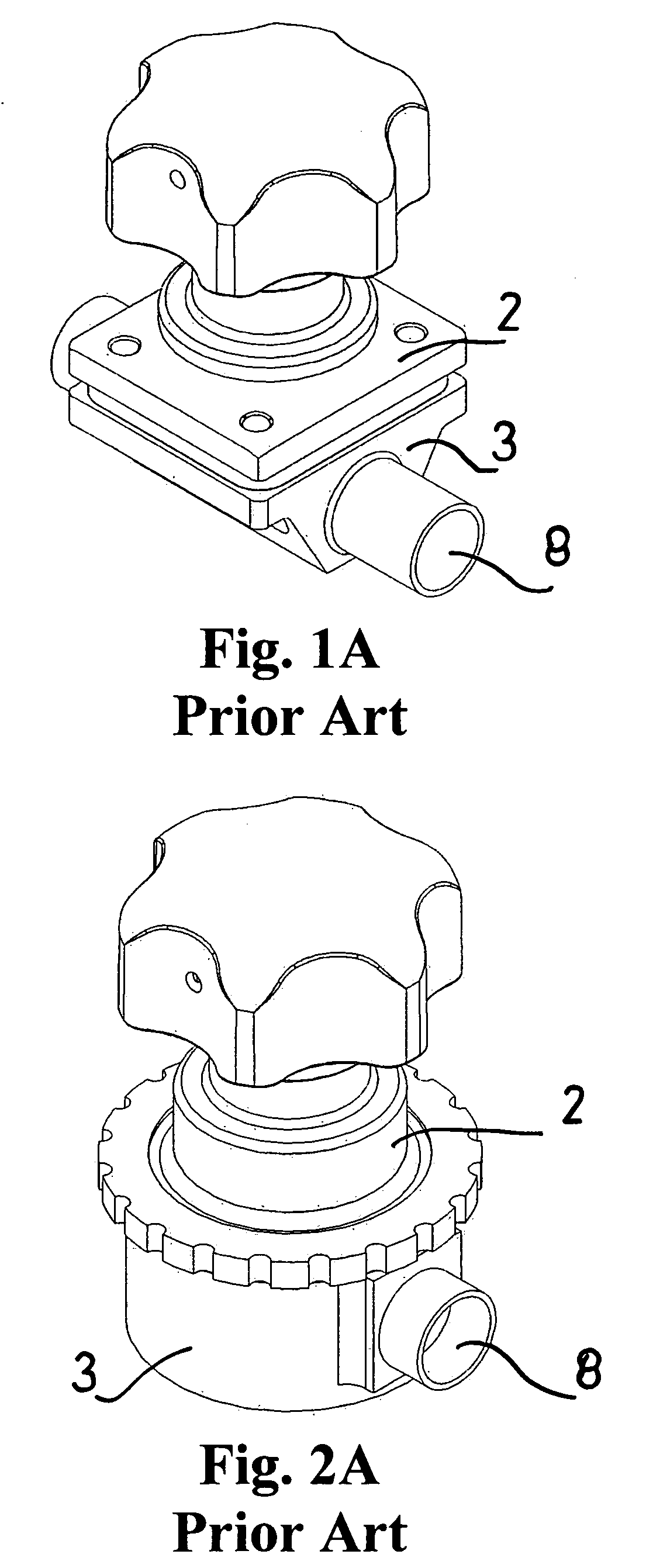

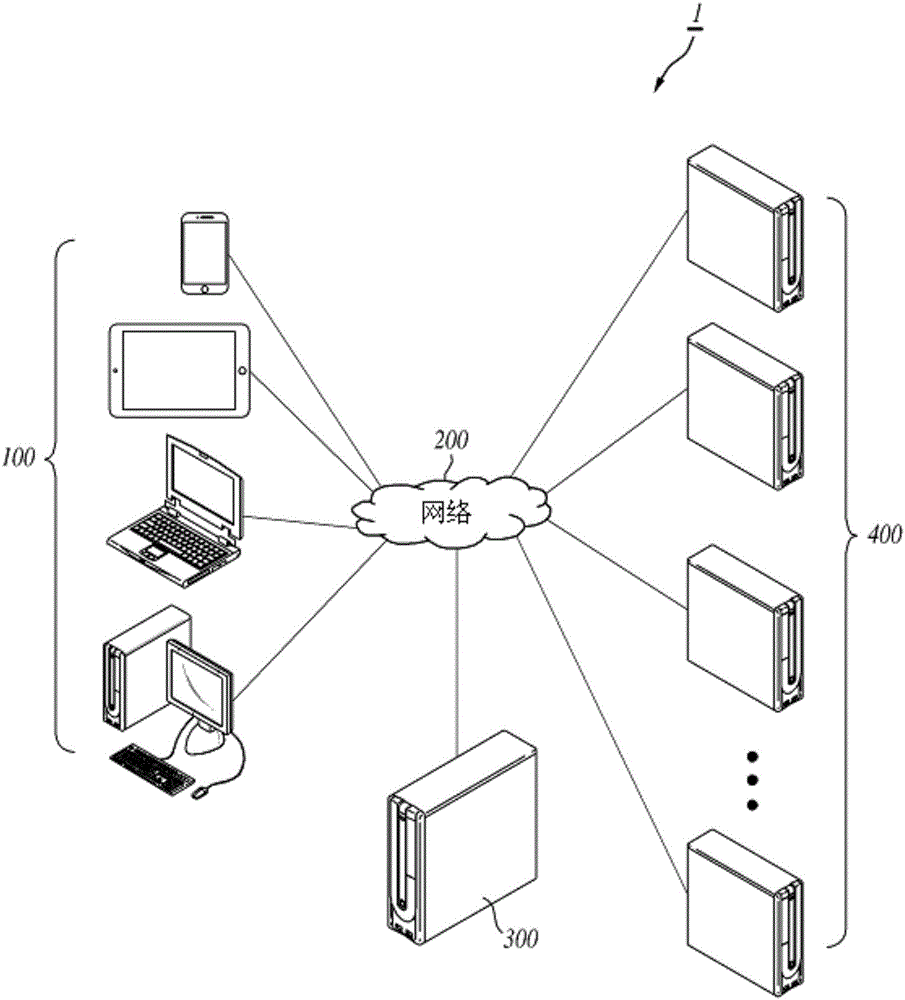

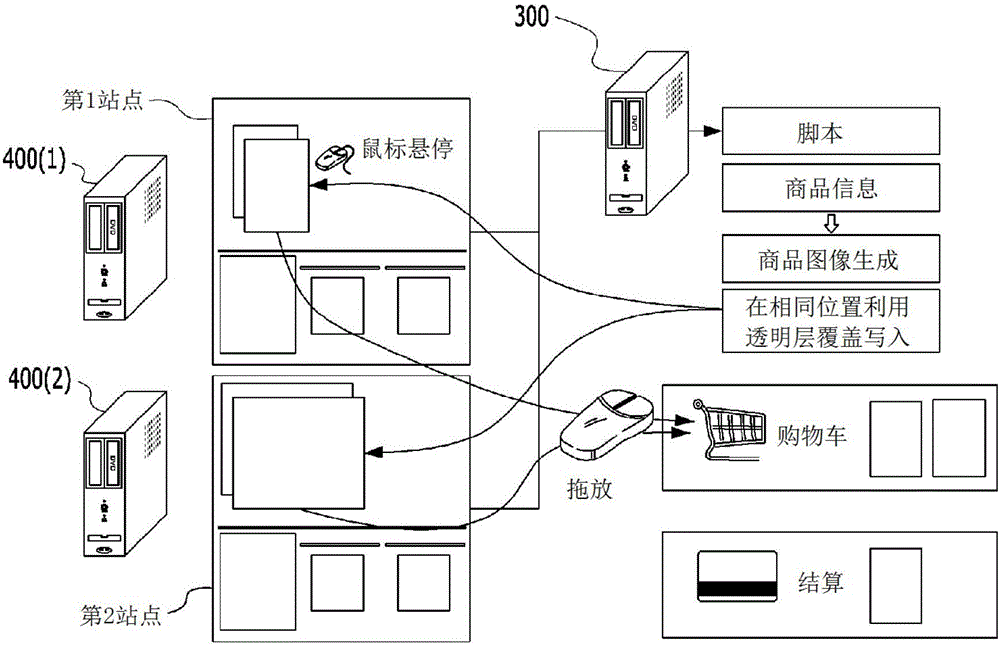

Product-purchase interworking service providing method

ActiveCN106462887ACost minimizationEasy to cooperatePayment architectureBuying/selling/leasing transactionsProduct dataDatabase

The present invention relates to a product-purchase interworking service providing method. An embodiment of the present invention may provide a product-purchase interworking service providing method capable of sharing product information in a way of providing at least one script to another affiliated shopping mall server, receiving product data of another shopping mall using the script, transparent-layer-processing the product data, and overwriting the product data on the website of a corresponding shopping mall. According to the present invention, it is possible to remove traffic generated in maintaining the latest information in a product database and minimize a cost accrued in operating a database on product information, and there is no waste of costs and resources for providing product information. Therefore, the affiliation with another shopping mall can become much easier.

Owner:韩国基加株式会社

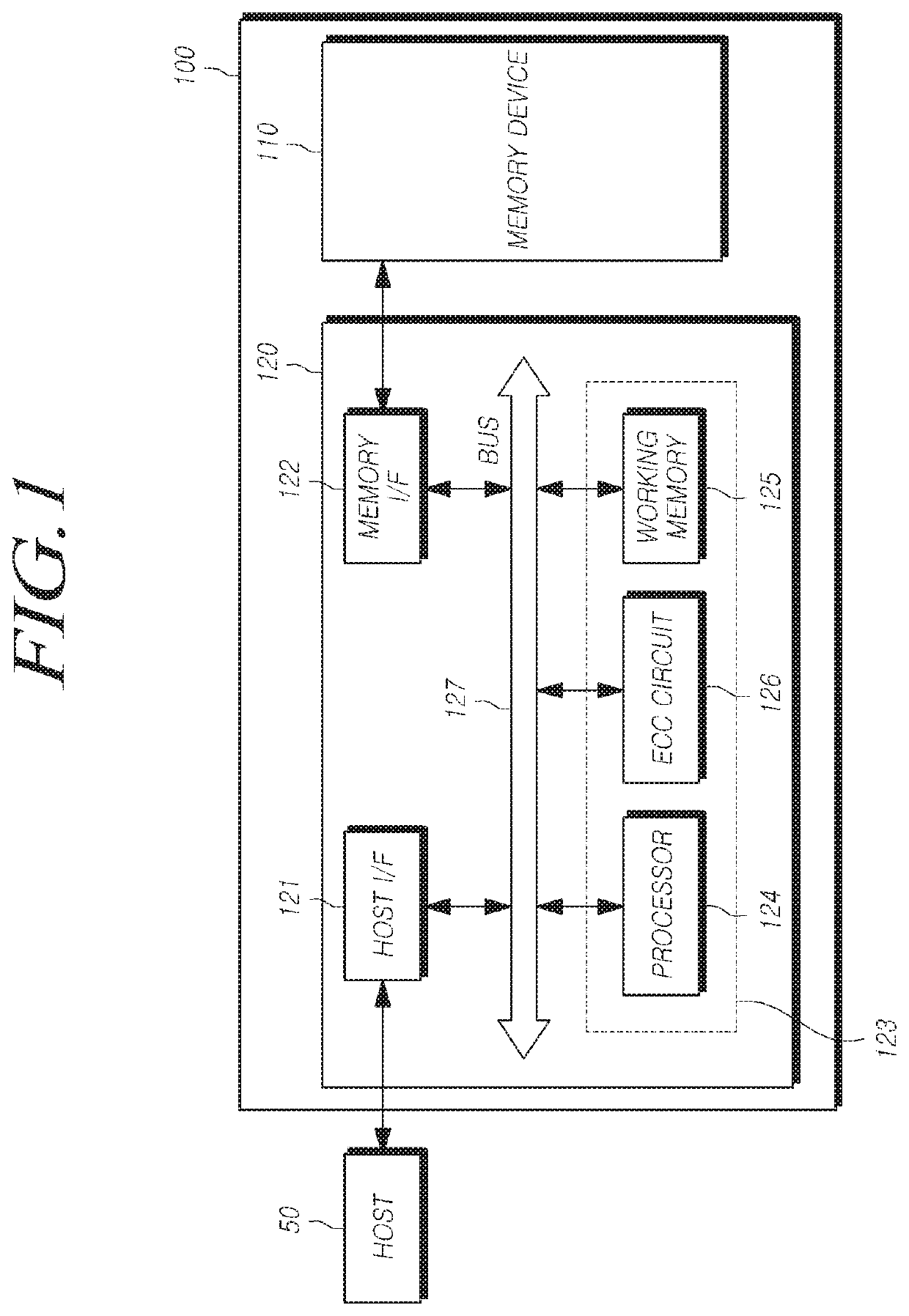

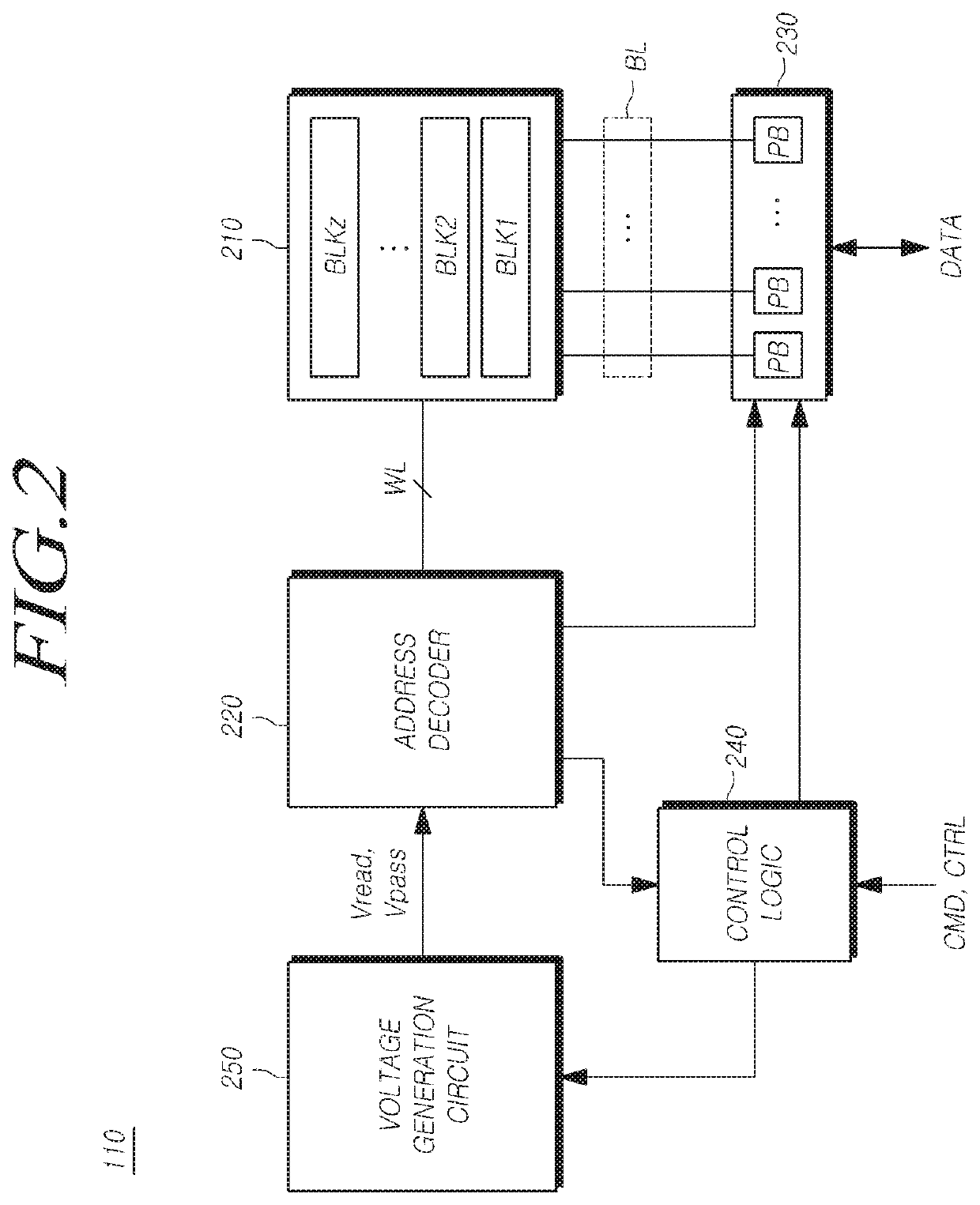

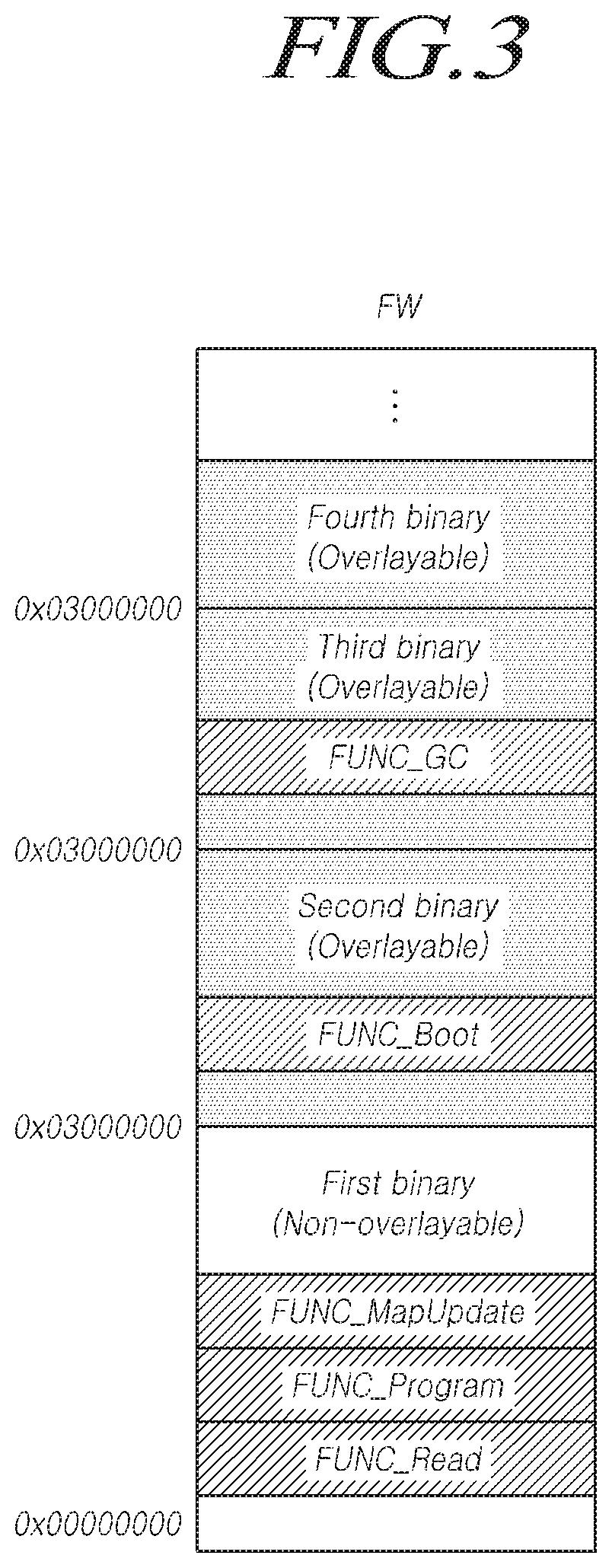

Memory system, memory controller and operating method of memory controller

ActiveUS20200310692A1Cost minimizationLow costMemory architecture accessing/allocationInput/output to record carriersMemory controllerEngineering

A memory system includes a memory device including memory blocks and a memory controller configured to control the memory device. The memory device stores a firmware which includes binaries, and the binaries include a first binary and a second binary. The memory controller loads the firmware to a first region in a working memory, loads the first binary to a second region which is included in the first region, and loads the second binary to a third region which is included in the first region and is different from the second region. The memory controller stores information on an entry function corresponding to a target function included in the second binary, in a fourth region which is different from the first region. A start address of the second region is determined as a fixed value, and a start address of the third region is dynamically determined.

Owner:SK HYNIX INC

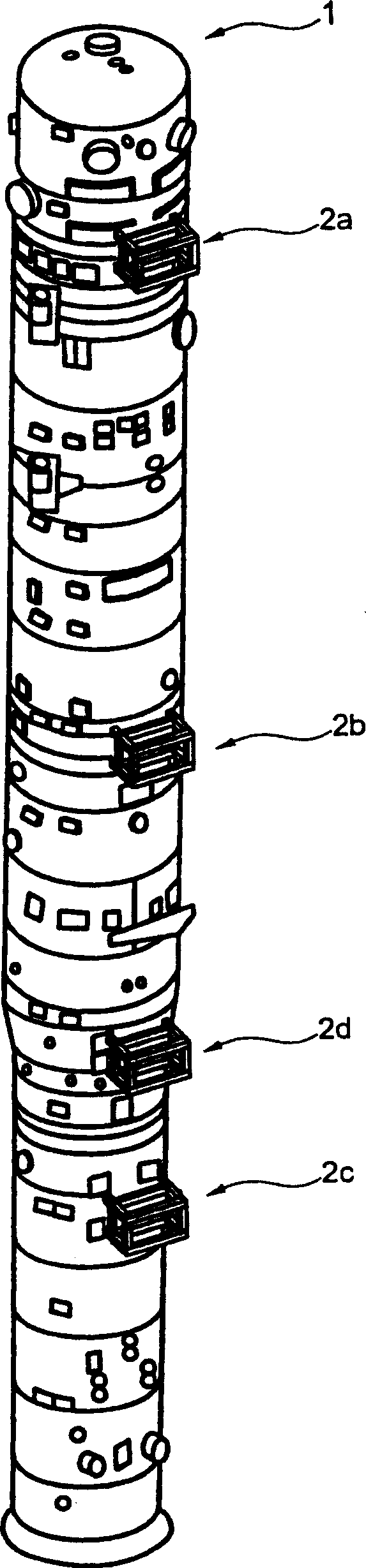

Assembly of a plant for gas separation

InactiveCN101430160AReduce material costsCost minimizationSolidificationLiquefactionManufacturing FactoriesGas separation

The invention relates to an assembly method of a gas separation device comprising at least a separating column (1) and a casing device for bounding the separation column (1). The separation column (1) is manufactured in advance in a manufacturing factory and is equipped with a pipe bridge module. The column (1) is horizontally supported on a construction site so that the pipe bridge module (2a-2d) is mounted on an upper part of an outer casing along a parallel axis to a preferable axis of the separation column (1). Thus the pipe bridge module (2a-2d) can be fully or partially mounted on the peripheral surface of the separation column and accessory portions are mounted in the manufacturing factory or on the construction site. Accessories are at least partially assembled on the pipe bridge module (2a-2d) when the separation column (1) is horizontally supported. Only a small scaffold in the separation column (1) diameter height is needed by assembling the accessories in the horizontal orientation. Almost all the work is done in a plain place. In parallel with the horizontal assembly of the accessories on the separation column (1), the casing device is processed to half of the height in vertical direction, wherein the upper part is kept open. After the separation column (1) is pricked as a vertical orientation and is guided in the casting device from above, the assembly is finished and the casing device is closed.

Owner:LINDE AG

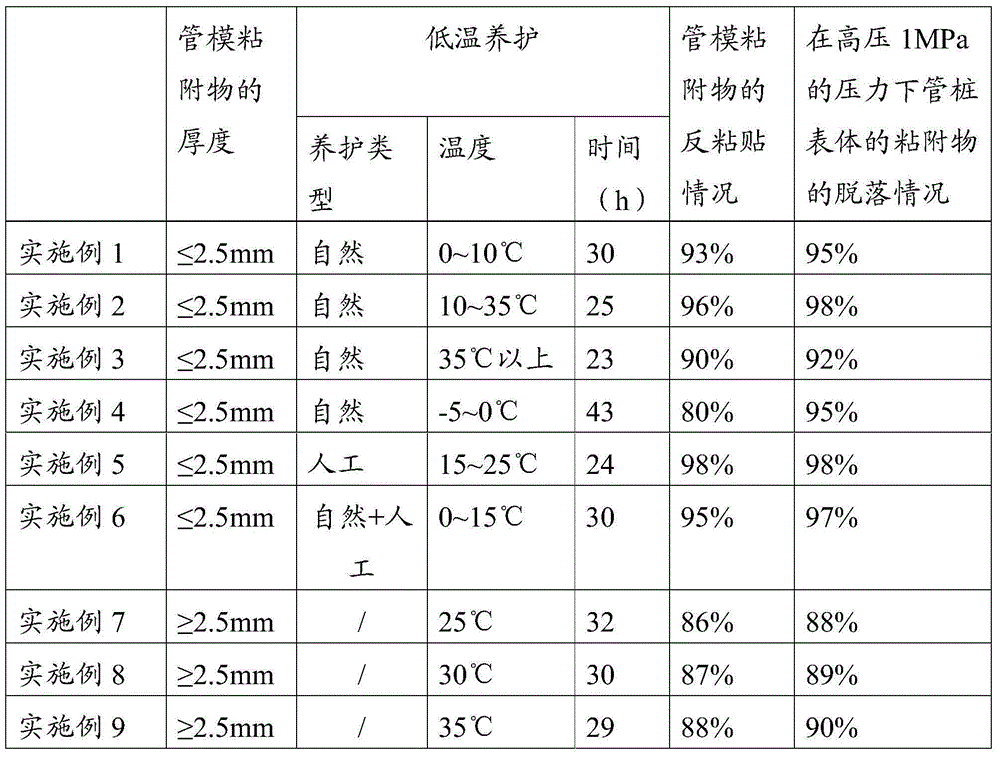

Adhesion resisting handling method for burrs adhered to inner wall of pipe die for concrete tubular pile

The invention provides an adhesion resisting handling method for burrs adhered to the inner wall of a pipe die for a concrete tubular pile. The method comprises the steps that step 10, whether the pipe die has burrs is examined before pipe pile preparation; step 20, after the pipe die is adopted to prepare the pipe pile, the pipe die with burrs is placed into a steam maintenance pool for low-temperature maintenance: if the thickness of the burrs of the pipe die is less than 2.5 mm, the maintenance temperature is controlled to be under the natural temperature and no less than minus 5 DEG C, and the maintenance time is controlled to be in the range of 20-44 hours; if the thickness of the burrs of the pipe die is more than 2.5 mm, the maintenance temperature is controlled to be in the range of 25-35 DEG C, and the maintenance time is controlled to be 30 minus and plus 2 hours. According to the adhesion resisting handling method, the relationship between the concrete setting time and temperature is utilized, the burrs of the pipe die is re-adsorbed to the surface of the pipe pile under the control state, so that the burrs can fall off easily and can be disposed radically, and the cost minimization is realized.

Owner:FUJIAN DADI CONCRETE PILE

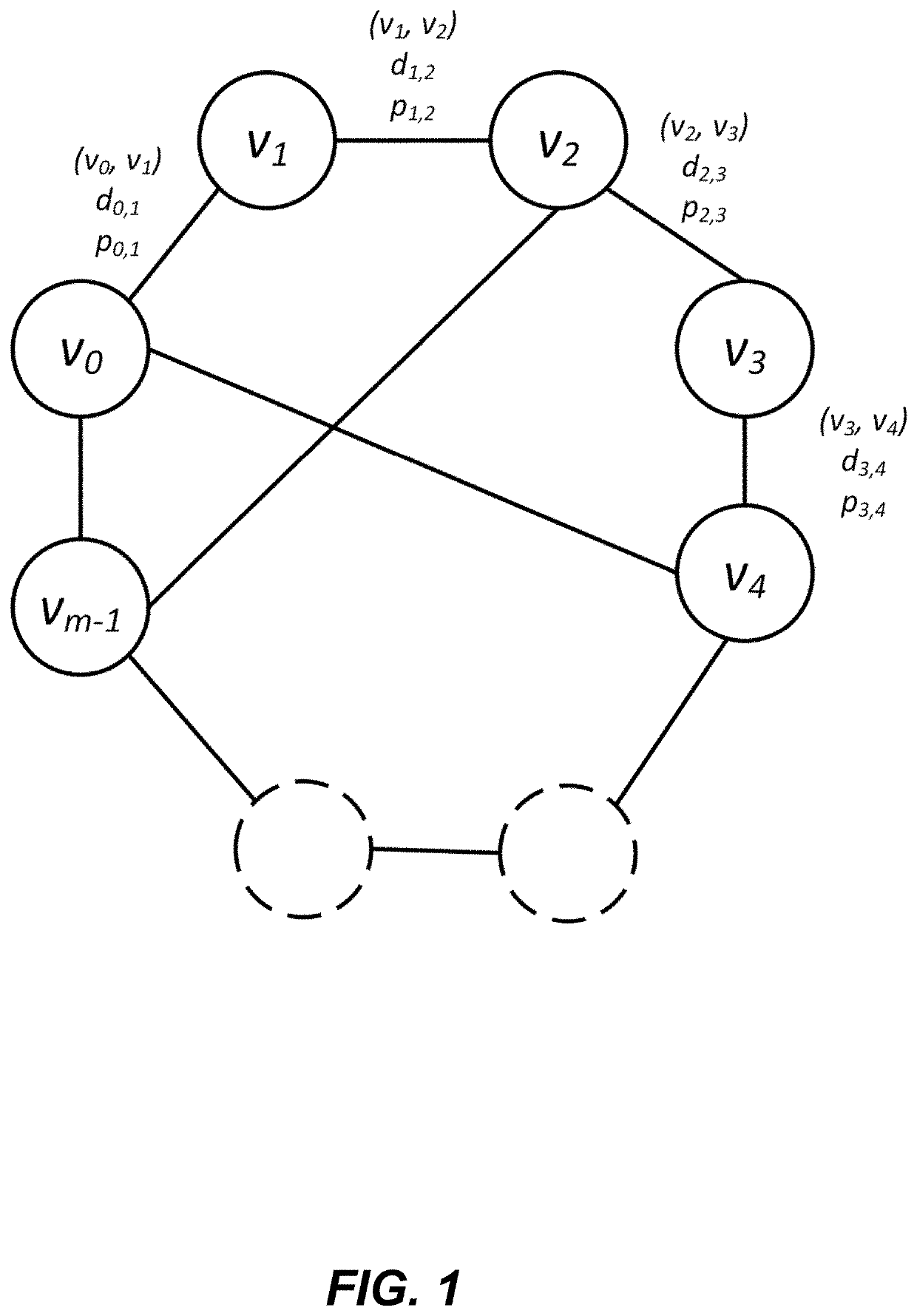

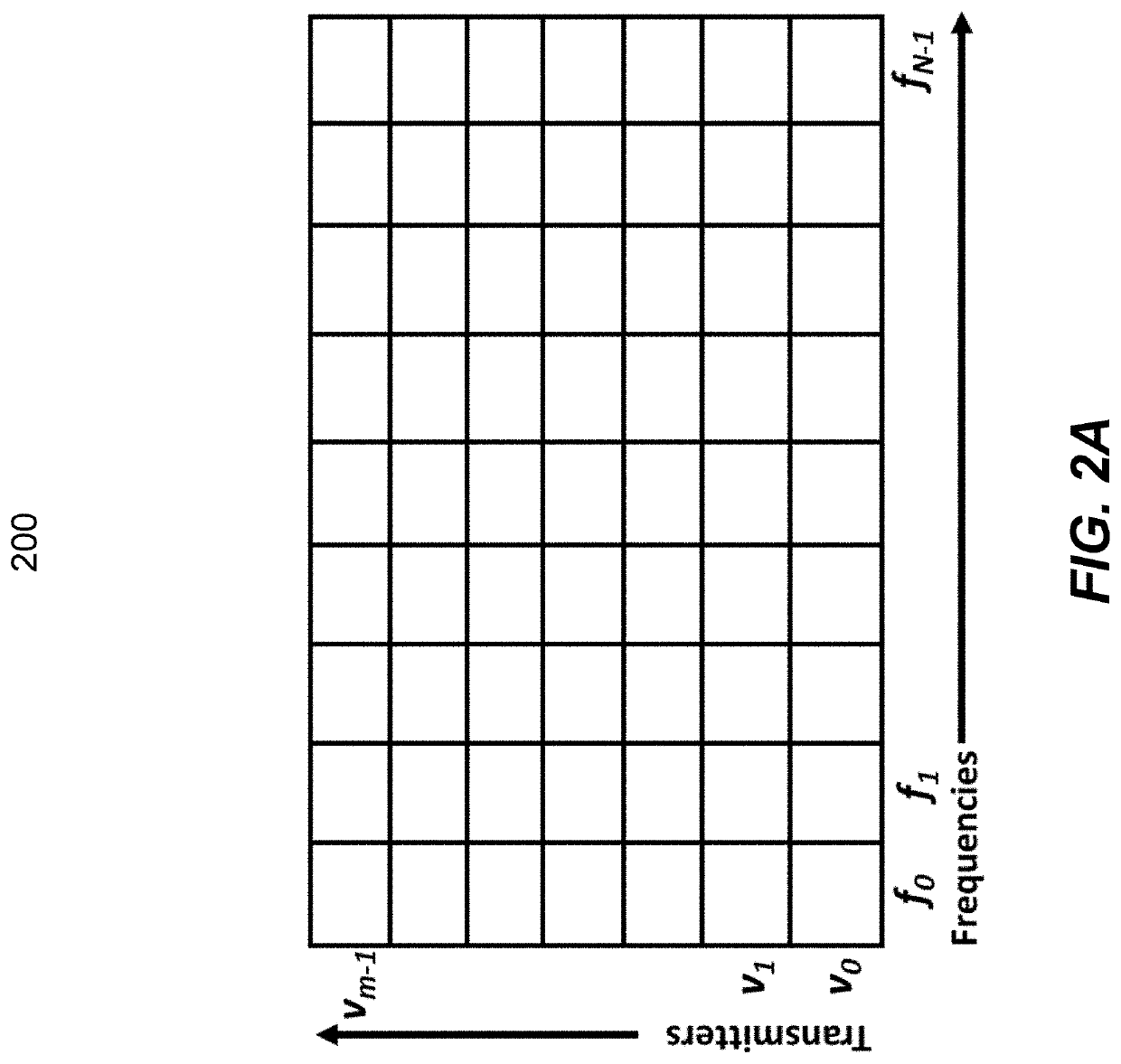

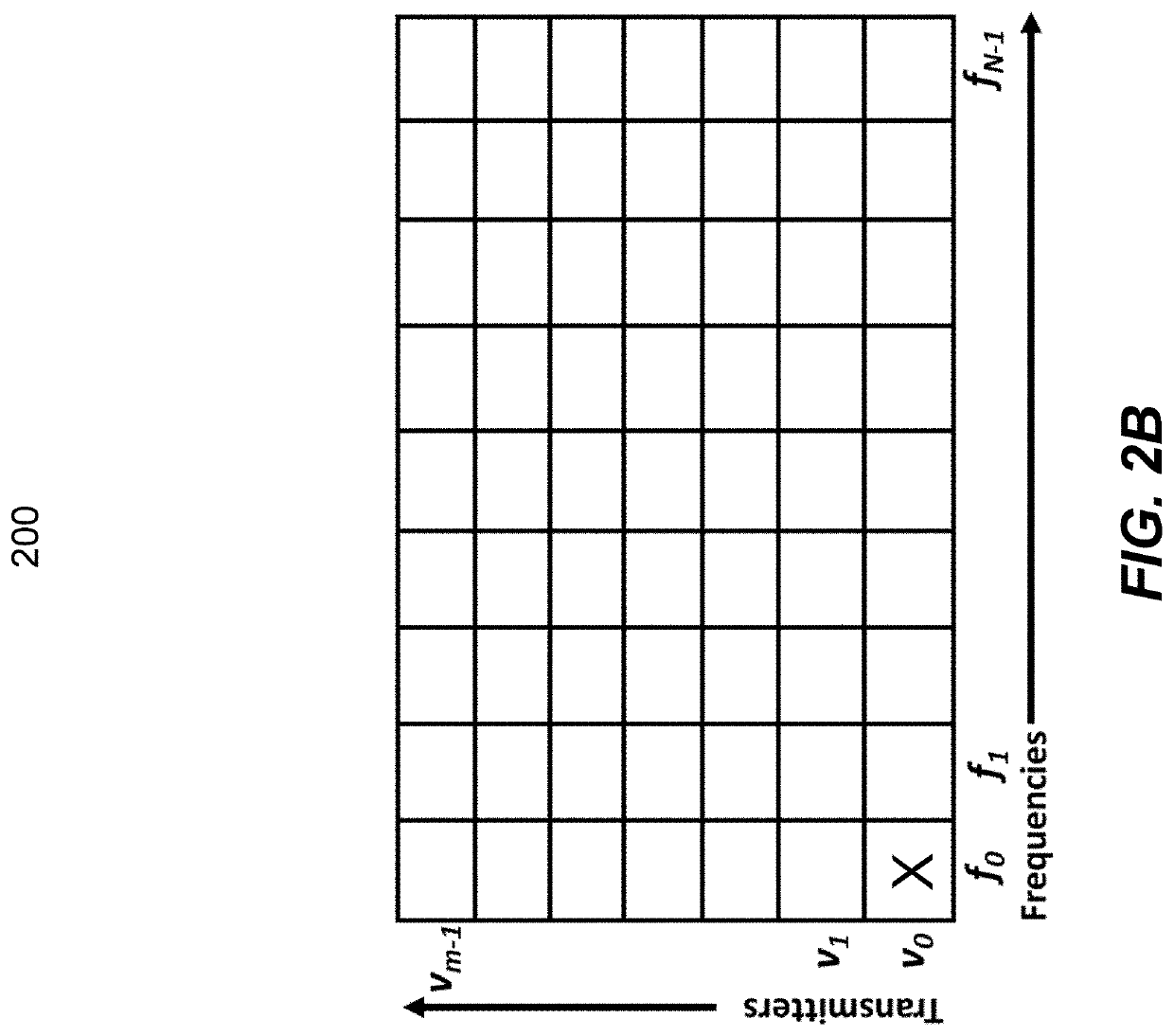

Search-based heuristic for fixed spectrum frequency assignment

PendingUS20200359227A1Interference costCost minimizationSignal allocationMulti-frequency code systemsEngineeringTransposer

A search-based heuristic for assigning frequencies to transmitters in a fixed spectrum frequency assignment (FS-FA) telecommunications network in order to satisfy a set of frequency constraints is described. Each connection in a network must have a frequency assigned from the spectrum which satisfies the set of constraints, which specify the frequency separation which is necessary between frequencies assigned to different transmitters. Violation of these constraints creates interference, which must be minimized. The exemplary heuristic has two main components: a local search heuristic and a compound move. The local search heuristic employs one-change moves and a lookup table that classifies all possible one-change moves as positive or negative, which are chosen until a locally minimal solution is found. The compound move operation shifts the local search to a new location in the search space. The local search and compound move are iterated until a total interference cost function is minimized.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Tail gas recovery system of kiln

PendingCN112957883AEasy to useCost minimizationCombination devicesSolidificationProcess engineeringEnvironmental geology

The invention discloses a tail gas recovery system of a kiln. The tail gas recovery system comprises a tail gas collection system, a dust treatment system, a first purification system, a fractionation system and a gas mixing system which are sequentially connected through pipelines; and a gas inlet of the tail gas absorption system is communicated with an exhaust port of the kiln, and a gas outlet of the gas mixing system is communicated with a gas inlet of the kiln. The system can meet the requirement of part of materials for the high oxygen content in the kiln, the problem that in the prior art, the product quality is unqualified due to the fact that the oxygen concentration required by the process cannot be met after tail gas is recycled is solved, good overall sealing performance is achieved, the problem that the oxygen concentration is reduced due to air entering is solved, use is flexible, adjustment can be carried out according to different situations, the cost of recycling and oxygen using is minimized, waste heat of all positions is fully utilized, and the production cost when the system is started is further reduced.

Owner:HUNAN SHANSHAN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com