Assembly of a plant for gas separation

A gas separation and assembly method technology, which is applied in cold treatment separation, lighting and heating equipment, industrial buildings, etc., can solve the problems of large separation column size and transportation trouble, and achieve the effect of saving material cost and minimizing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

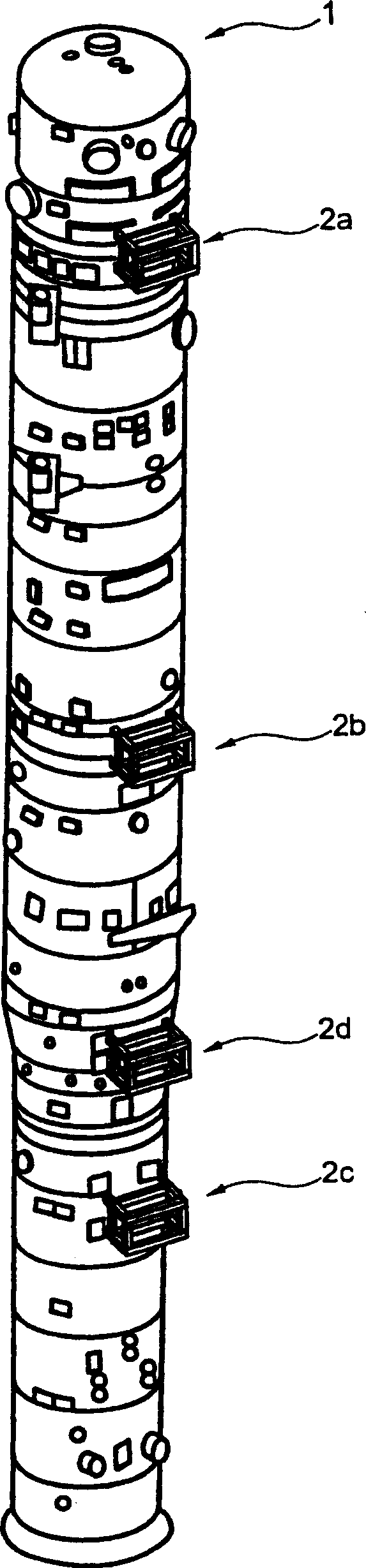

[0029] figure 1A separation column 1 with tube bridge modules 2a-2d is shown, which is installed in a gas separation device according to the assembly method of the present invention. The separation column 1 is prefabricated in a workshop and equipped with pipe bridge modules 2a-2d. On the construction site, the separation column 1 is supported horizontally, so that the pipe bridge modules 2a-2d are located on the upper half of the jacket along an axis parallel to the preferred axis of the separation column 1. Here, the installation of these tube bridge modules 2a-2d can be carried out completely or partially in the workshop or on the construction site. The assembly of the accessories is at least partially carried out on the tube bridge modules 2a-2d with the separation column 1 being horizontally supported. By assembling the accessories in a horizontal orientation, only a small scaffold at the height of the diameter of the separation column 1 is required. Almost all work is carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com