Adhesion resisting handling method for burrs adhered to inner wall of pipe die for concrete tubular pile

A technology of concrete pipe pile and treatment method, which is applied in ceramic molding machines, manufacturing tools and other directions, can solve the problems of inability to achieve the effect of reverse sticking, and achieve the effect of minimizing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

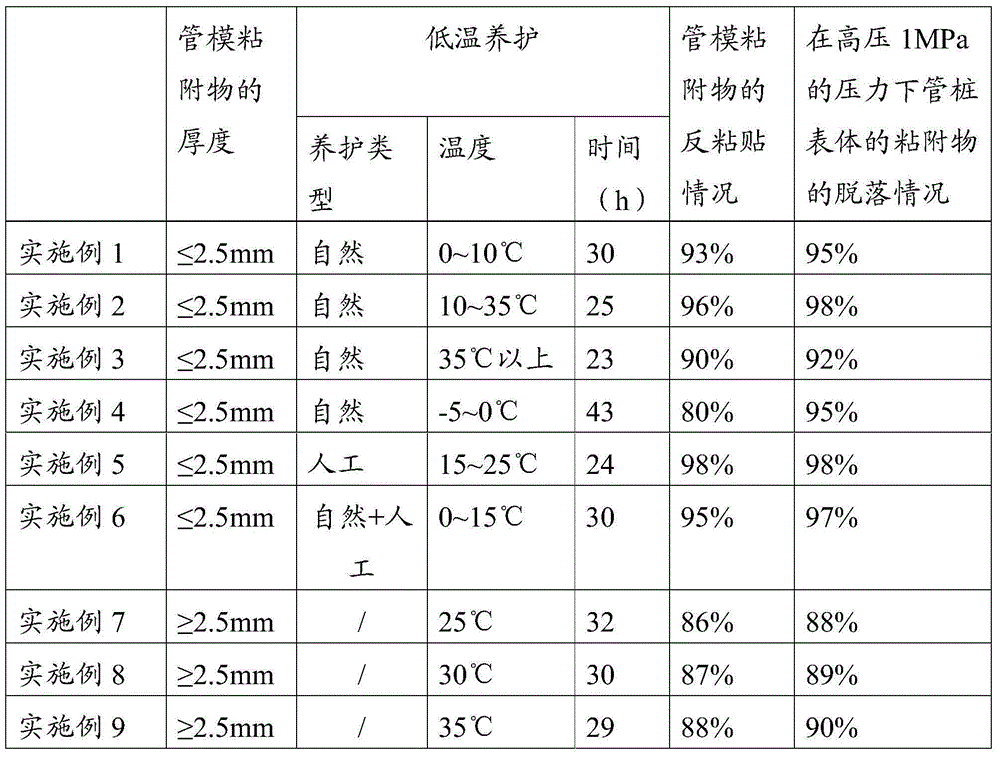

Examples

Embodiment Construction

[0018] The anti-pasting treatment method after the adhesive on the inner wall of the concrete pipe pile pipe mold of the present invention sticks to the mold comprises:

[0019] Step 10. With the prolongation of the use time of the pipe mold, it will be found that part of the inner wall of the pipe mold has a layer of film pasted on its surface. Therefore, before preparing the pipe pile, it is necessary to check the pipe mold to see if there is any adhesion; If the inner wall of the pipe mold is smooth and bright, it is judged that there is no adhesion. If the inner wall of the pipe mold is uneven and rough, it is judged that there is adhesion. If the adhesion on the inner wall of the pipe mold must be removed, it can be used continuously. There are flaws in the surface appearance.

[0020] Step 20. Place the pipe molds with adherents found in the inspection and place them in the steam curing pool for low-temperature curing after the pipe piles are prepared: this low-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com