Carbonization and gasification of biomass and power generation system

A biomass power generation and biomass technology, applied in the direction of gas turbine devices, biofuels, gaseous engine fuels, etc., can solve the problems of consistent fuel assurance, high collection costs, and difficulty in high-efficiency power generation, and achieve miniaturization costs, high gas The effect of maximizing efficiency and high-efficiency power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

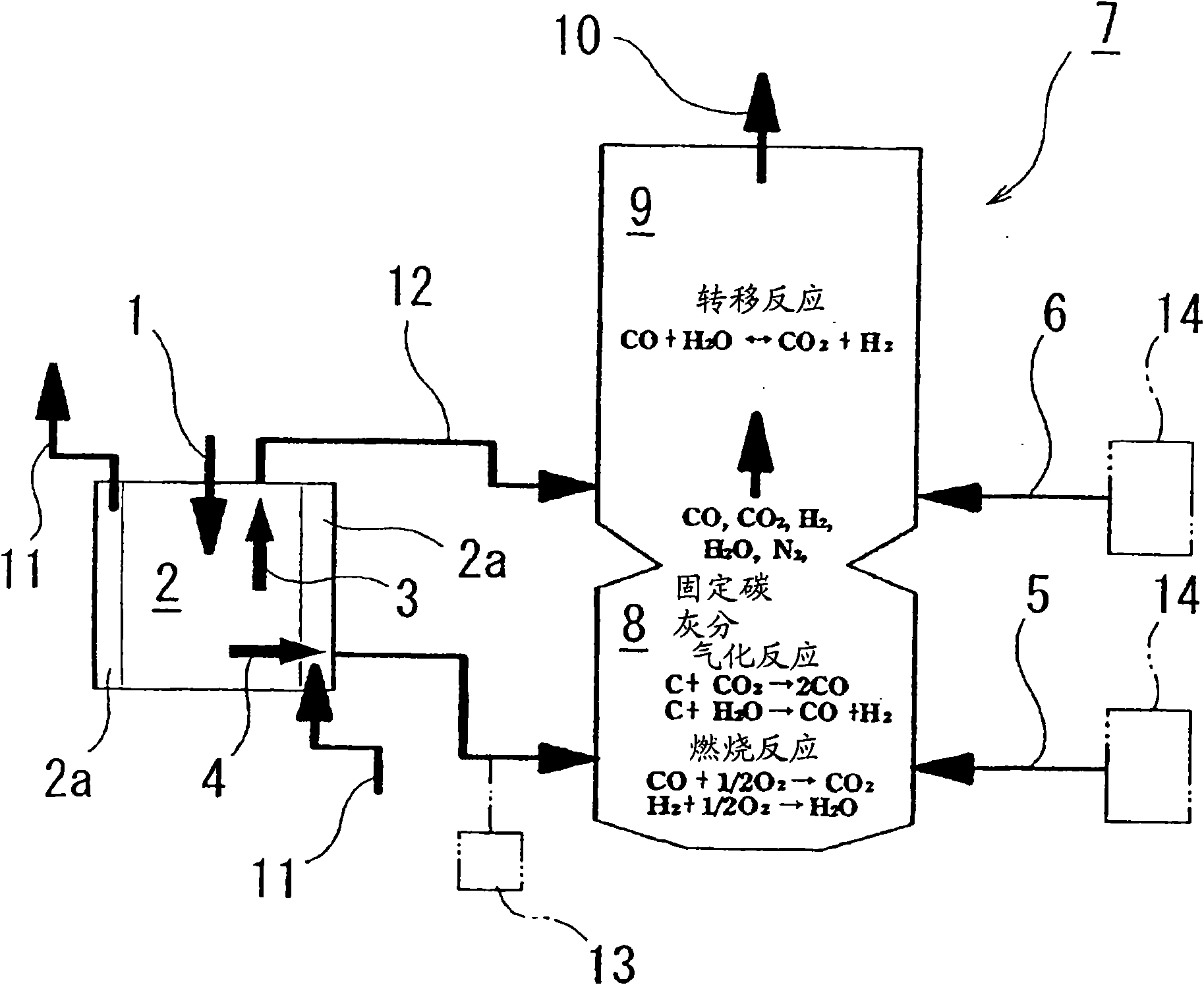

[0056] figure 1The specific embodiment of the invention shown is a biomass carbonization-gasification plant for pyrolysis of biomass fuels 1 such as wood-based biomass, waste-based biomass including municipal solid waste, and such mixture of biomass. The biomass carbonization-gasification device includes: a carbonization chamber 2 for receiving and heating a biomass fuel 1 to produce a carbonized material 4; Composed of a gas converter 9 for converting combustible cracked gas 3; carbonized material feeder 13, used to send carbonized material 4 to the high-temperature gasification part 8 of gasifier 7; The cracked gas 3 is sent to the gas converter 9 of the gasifier 7; and the gasification agent feeding device 14 is used to send the gasification agent 5 to the high-temperature gasification part 8 of the gasifier, and the oxygen-containing gasification agent 6 sent to the gas converter 9.

[0057] The cracked gas 3 contains tar volatilized during the generation of the carboni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com