Method for producing thin REH380LA steel based on ESP thin slab continuous casting and rolling process

A thin slab continuous casting, thin gauge technology, applied in the field of metal material processing and forming, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

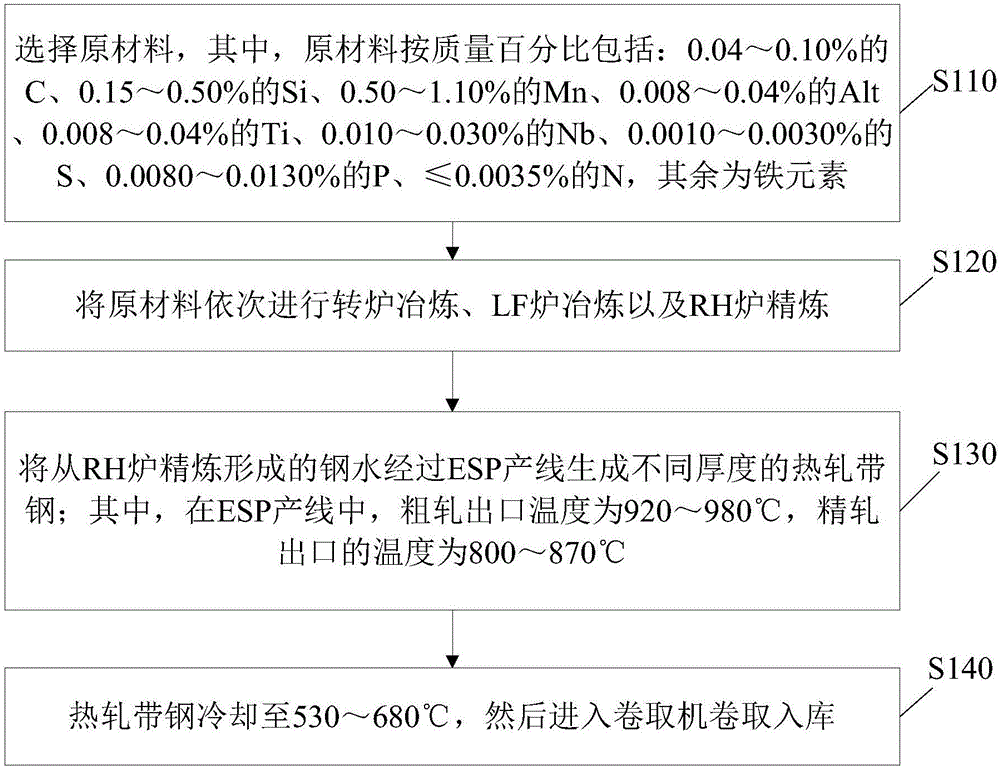

Method used

Image

Examples

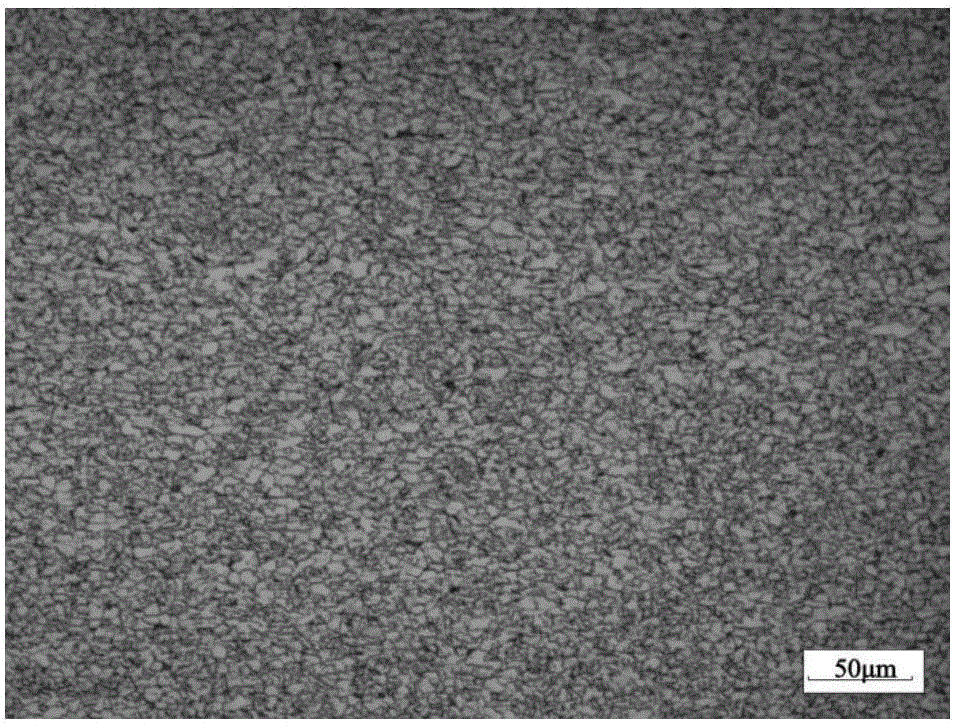

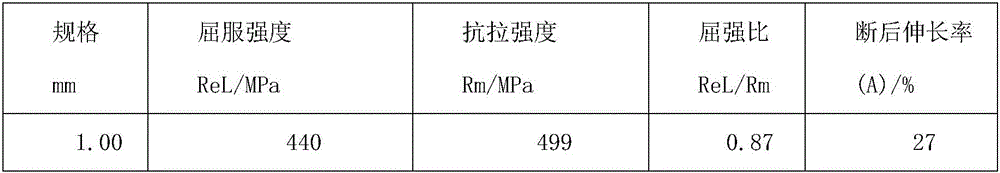

Embodiment 1

[0048] Select raw materials, wherein the raw materials include: 0.045% C, 0.21% Si, 0.80% Mn, 0.012% P, 0.0020% S, 0.028% Alt, 0.013% Ti, 0.020% Nb by mass percentage , 0.0025% N, the rest is iron and unavoidable impurities;

[0049] The raw materials are sequentially smelted in converter, LF furnace and RH furnace;

[0050] The molten steel refined by LF and RH passes through ESP production line continuous casting, rough rolling, finish rolling, laminar cooling, coiling and pickling process to produce hot-rolled strip steel of different thickness;

[0051] Among them, in the ESP production line, the continuous casting process controls the superheat of the tundish to 18°C, the casting speed to 5.6m / min, and the thickness of the slab to 95mm;

[0052] The cast slab is rolled through three passes of rough rolling, the rough rolling inlet temperature is 1020°C, and the rough rolling exit temperature is 980°C;

[0053] The rough-rolled intermediate billet product is heated by an...

Embodiment 2

[0060] Select the raw materials, wherein the raw materials include: 0.048% C, 0.20% Si, 0.79% Mn, 0.010% P, 0.0020% S, 0.028% Alt, 0.012% Ti, 0.019% Nb by mass percentage , 0.0028% N, the rest is iron and unavoidable impurities;

[0061] The raw materials are sequentially smelted in converter, LF furnace and RH furnace;

[0062] The molten steel refined by LF and RH passes through ESP production line continuous casting, rough rolling, finish rolling, laminar cooling, coiling and pickling process to produce hot-rolled strip steel of different thickness;

[0063] Among them, in the ESP production line, the continuous casting process controls the superheat of the tundish to 20°C, the casting speed is 5.6m / min, and the thickness of the slab is 95mm;

[0064] The cast slab is rolled through three passes of rough rolling, the rough rolling inlet temperature is 1000°C, and the rough rolling exit temperature is 980°C;

[0065] The rough-rolled intermediate billet product is heated b...

Embodiment 3

[0072] Select raw materials, wherein the raw materials include: 0.046% C, 0.20% Si, 0.81% Mn, 0.011% P, 0.0022% S, 0.030% Alt, 0.012% Ti, 0.020% Nb by mass percentage , 0.0025% N, the rest is iron and unavoidable impurities;

[0073] The raw materials are sequentially smelted in converter, LF furnace and RH furnace;

[0074] The molten steel refined by LF and RH passes through ESP production line continuous casting, rough rolling, finish rolling, laminar cooling, coiling and pickling process to produce hot-rolled strip steel of different thickness;

[0075] Among them, in the ESP production line, the continuous casting process controls the superheat of the tundish to 18°C, the casting speed is 5.5m / min, and the thickness of the slab is 95mm;

[0076] The cast slab is rolled through three passes of rough rolling, the rough rolling inlet temperature is 980°C, and the rough rolling exit temperature is 960°C;

[0077] The rough-rolled intermediate billet product is heated by an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com