Wind resistance braking device applied to high-speed train

A high-speed train, wind resistance braking technology, applied in the field of wind resistance braking, high-speed train wind resistance braking device, to achieve the effect of simple structure, lower maintenance cost and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

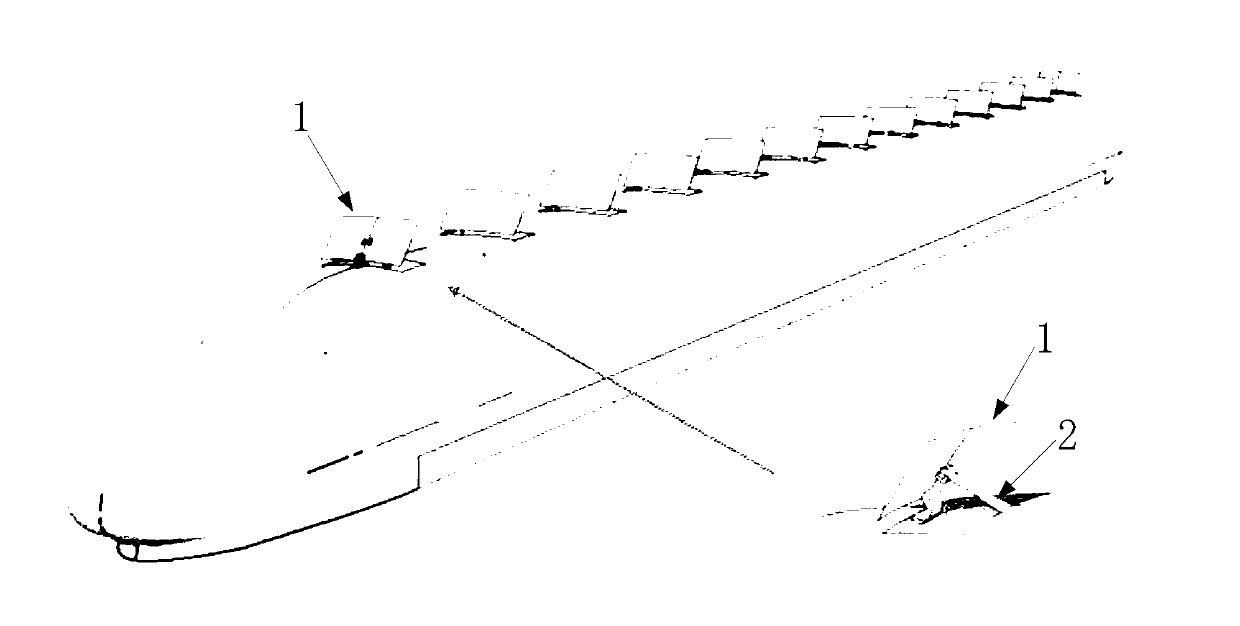

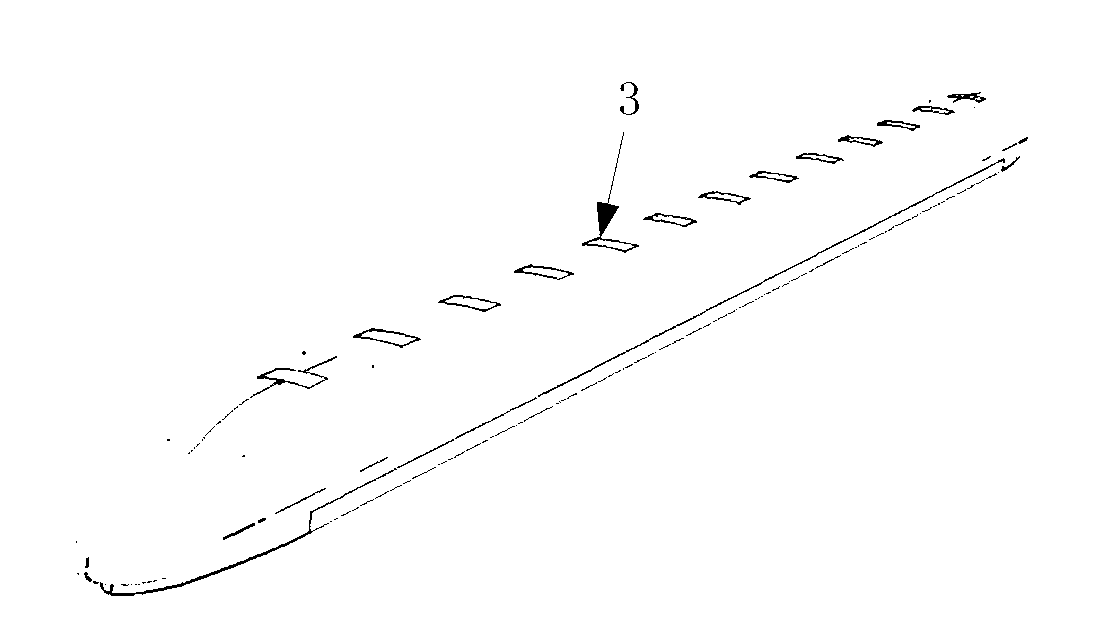

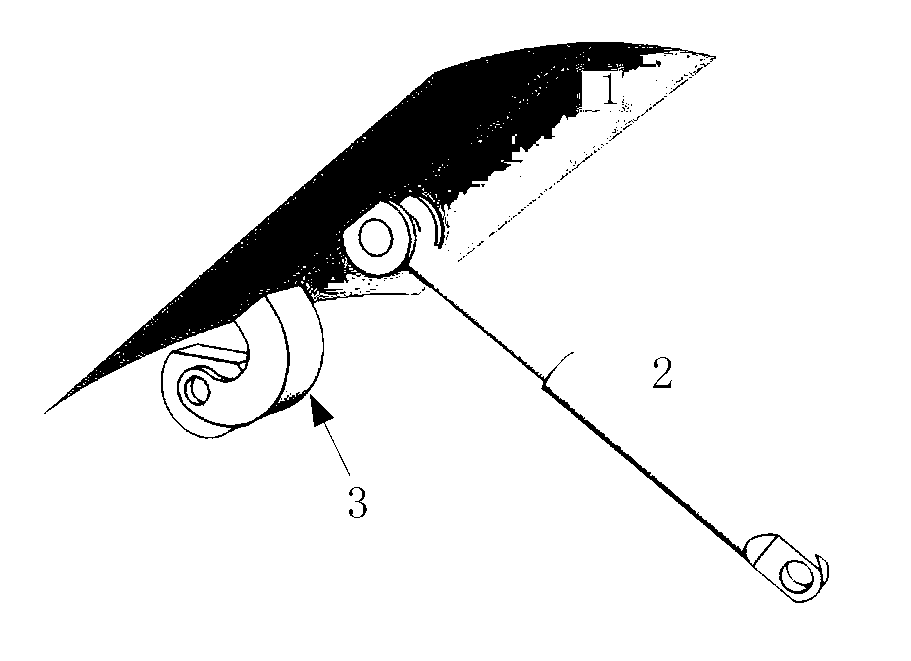

[0035] Taking the shape of the CRH2 motor car, the total weight of the 3 cars (the front + middle car + the rear) is 150t, the total length is 75m, the width is 3.38m, and the height is 3.7m. The length of the speed brake is 1.5m and the longitudinal length is 1m. The straight section of the whole vehicle is about 58m. In order to determine the optimal spacing for speed brake installation, CFD numerical simulation is carried out for the three situations of spacing 2.5m (24 pieces), 5m (12 pieces), and 10m (6 pieces). The resistance coefficient of speed brake under the condition of 80m / s is as follows:

[0036] Installation spacing (quantity)

Total drag coefficient of airbrake

2.5m (24 pieces)

0.67

5m (12 pieces)

0.77

[0037] 10m (6 pieces)

0.66

[0038] Take the spacing of 5m and the installation quantity of 12 as the scheme implemented by the distance.

[0039] According to the above-mentioned implementation pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com