Small micro centrifugal compressor without radial bearing

A centrifugal compressor and radial bearing technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems such as the inability to achieve ultra-high speed, small and miniaturization of centrifugal compressors, and achieve the effect of simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

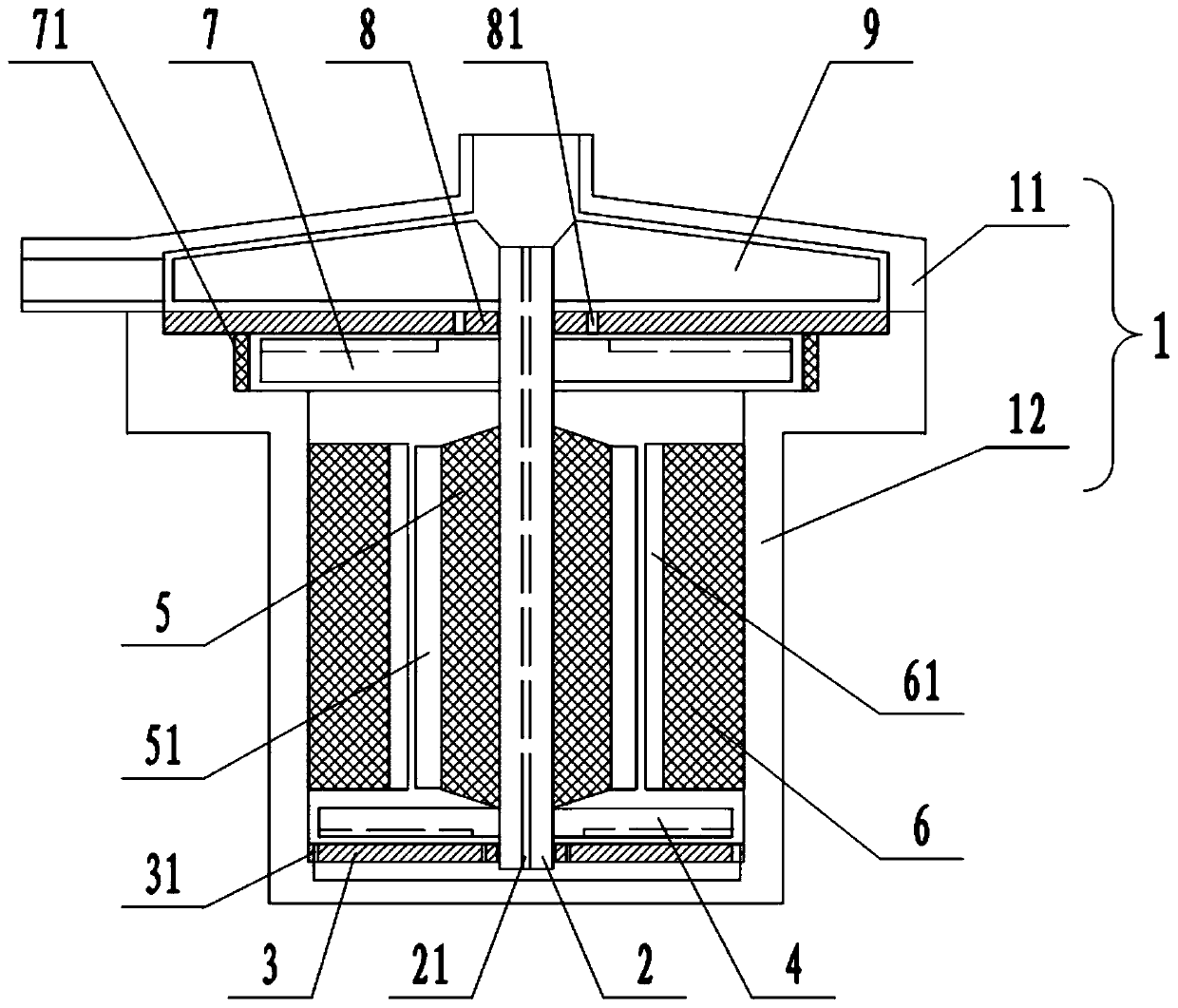

[0025] A small and micro centrifugal compressor without radial bearings, such as figure 1 As shown, it includes a housing 1, a main shaft 2, a first axial static ring 3, a first moving ring 4, a rotor 5, a rotating sleeve 51, a stator 6, a fixed sleeve 61, a second moving ring 7, and a second shaft To the static ring 8 and the centrifugal impeller 9.

[0026] The casing 1 of the compressor is provided with an air inlet and an air outlet. The main shaft 2 is rotatably installed in the housing 1 , and an air flow hole 21 is opened in the main shaft 2 . One end of the air flow hole 21 communicates with the exhaust port of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com