Automobile collision energy absorbing box capable of achieving high-efficiency and stable energy absorption

A collision energy absorption, automobile technology, applied to vehicle parts, vehicle safety arrangements, bumpers, etc., can solve the problems of unstable energy absorption, discontinuous efficiency, poor adaptability to multi-angle impact, etc., to achieve good continuous energy absorption effect, Good effect and high energy absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The description will be further elaborated below in conjunction with specific embodiments.

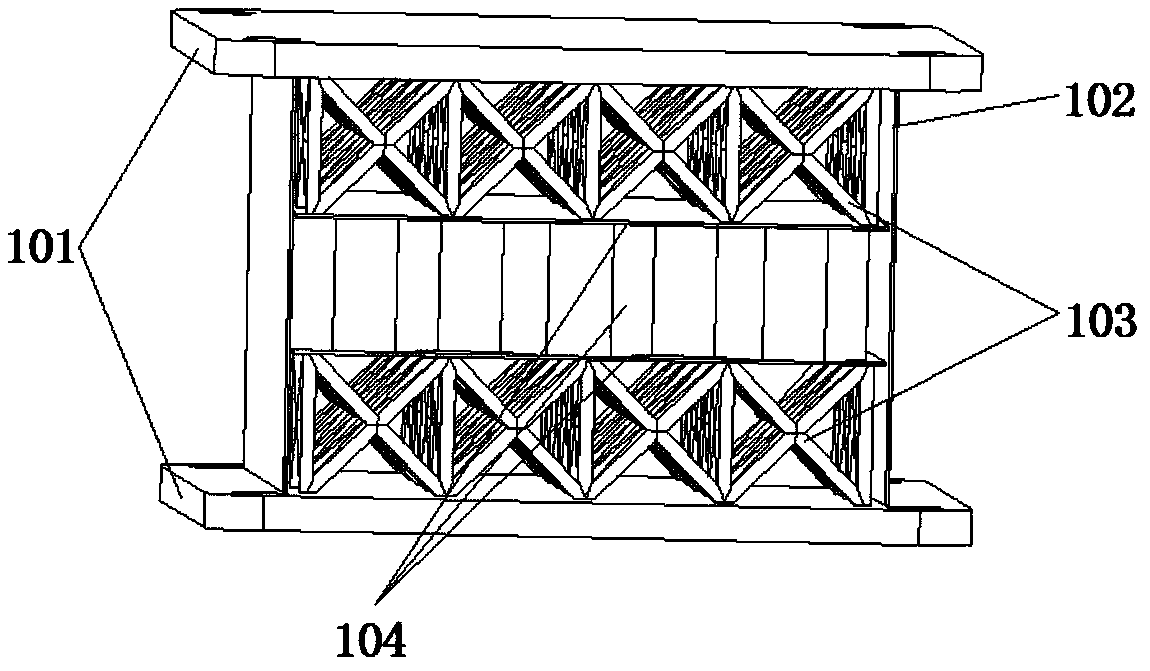

[0024] A kind of highly efficient and stable energy-absorbing automobile collision energy-absorbing box provided by this embodiment, such as figure 1 As shown, it includes a flange 101 , a square thin-walled shell 102 , a lattice structure 103 and a sandwich plate 104 . The flange 101 is arranged on the upper and lower ends of the square thin-walled shell 102, the lattice structure 103 is arranged on the upper and lower ends of the sandwich plate 104, and the lattice structure 103 and the sandwich plate 104 are placed in the square thin-walled shell 102 as a whole .

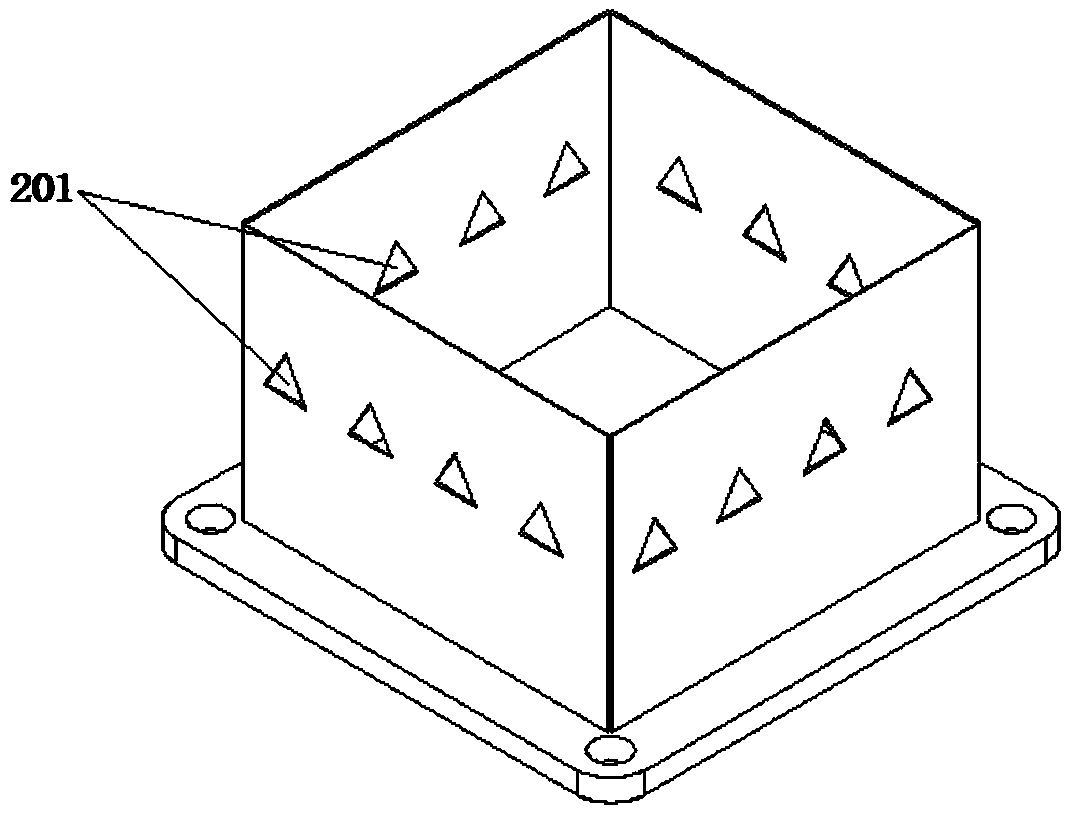

[0025] Wherein, the square thin-walled shell 102 such as figure 2 As shown, the material is light aluminum alloy, and the wall is provided with triangular defect holes 201 at intervals along the circumferential direction. Since the initial peak force of the square cross-section is small, it can effectively absor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com