Traction bar ball assembly, and assembling tool and assembling method for traction bar ball assembly

A ball head assembly and thrust rod technology, which is applied in the field of vehicle balance suspension, can solve the problems of low assembly efficiency, many auxiliary tooling, low press-fitting efficiency, etc., so as to reduce the manufacturing cost, reduce the assembly time, and improve the assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

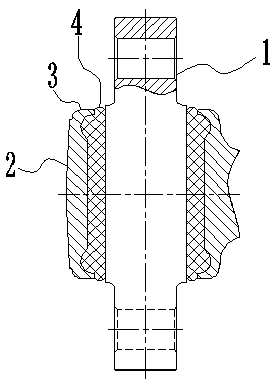

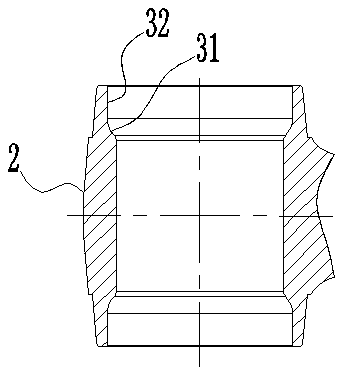

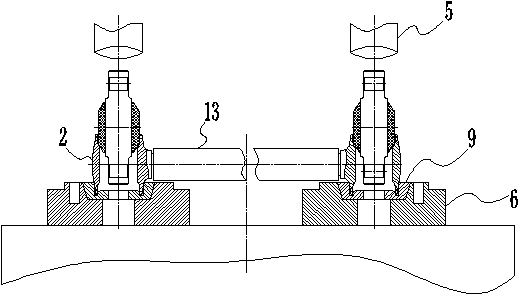

[0045] Embodiment 1: as figure 1 and figure 2 As shown, a thrust rod ball head assembly includes a thrust rod ball joint 1 and a thrust rod ball head, and the thrust rod ball head includes a thrust rod ball head body 2 and two ends of the thrust rod ball head body 2 The flanging structure 3, the flanging structure 3 and the thrust rod ball head body 2 are integrally formed; through the flanging structure 3 at both ends of the thrust rod ball head body 2 and the thrust rod ball hinge 1, the thrust Rod ball hinge 1 is limited in the ball head of the thrust rod.

[0046] The thrust rod ball joint 1 is a radially pre-compressed elastic ball joint of an integral rubber body; the flanging structure 3 of the thrust rod ball head includes arc flanged parts 31 and The straight-line flanging portion 32 provided on the arc flanging portion 31; the arc flanging portion 31 and the straight-line flanging portion 32 at both ends of the ball head of the thrust rod are buckled in the radial...

Embodiment 2

[0061] Embodiment 2: as Figure 17 As shown, compared with Example 1, the difference is that: the thrust rod ball joint 1 is a radially pre-compressed elastic ball joint with an integral metal jacket; The metal jacket 15 of the radially precompressed elastic ball hinge of the integral metal jacket is buckled with the straight-line flanging part to limit the thrust rod ball hinge 1 in the thrust rod ball head.

Embodiment 3

[0062] Embodiment 3: as Figure 18 As shown, compared with Embodiment 1, the difference is that: the thrust rod ball joint 1 is an axially pre-compressed elastic ball joint with metal outer end caps 16 at both ends; The line flanging part and the linear flanging part are buckled on the metal outer end cap 16 of the axially precompressed elastic ball hinge of the outer casing at both ends, and the thrust rod ball hinge is limited in the thrust rod ball head.

[0063]To sum up, in the present invention, the flanging structure provided at both ends of the ball head of the thrust rod and integrated with the ball head of the thrust rod is buckled on the spherical hinge of the thrust rod, so that the spherical hinge of the thrust rod is limited to the position of the ball joint of the thrust rod. In the ball head, the structure of the thrust rod ball head assembly is simple and maintenance-free, which reduces the manufacturing cost of the thrust rod ball head assembly, and its weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com