Skirt plate structure of rail traffic vehicle body and forming method of skirt plate structure

A rail transit vehicle and molding method technology, applied in the field of composite material structure molding technology, can solve problems such as easy deformation, unstable size, and difficult molding, and achieve the effects of weight reduction, saving molding time and cost, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

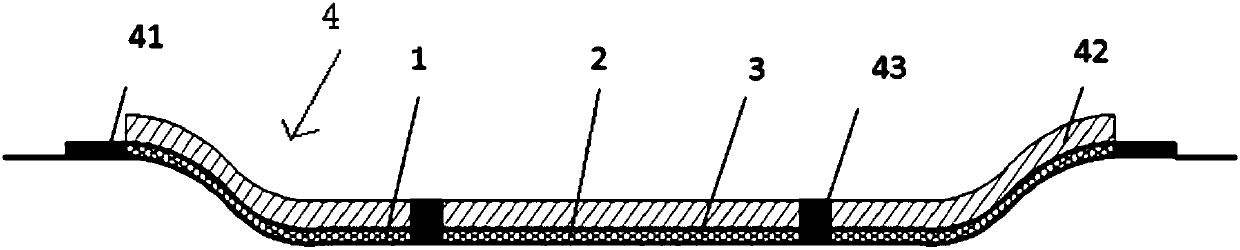

[0112] The embodiment of the present invention provides a method for forming the skirt plate of a sandwich structure of a monorail vehicle, such as figure 1 As shown, the overall size of the sandwich structure skirt plate is 1400×2400mm, and the section is bow-shaped, and the method includes:

[0113] Step (1), making a formwork according to the design size of the skirt plate of the sandwich structure;

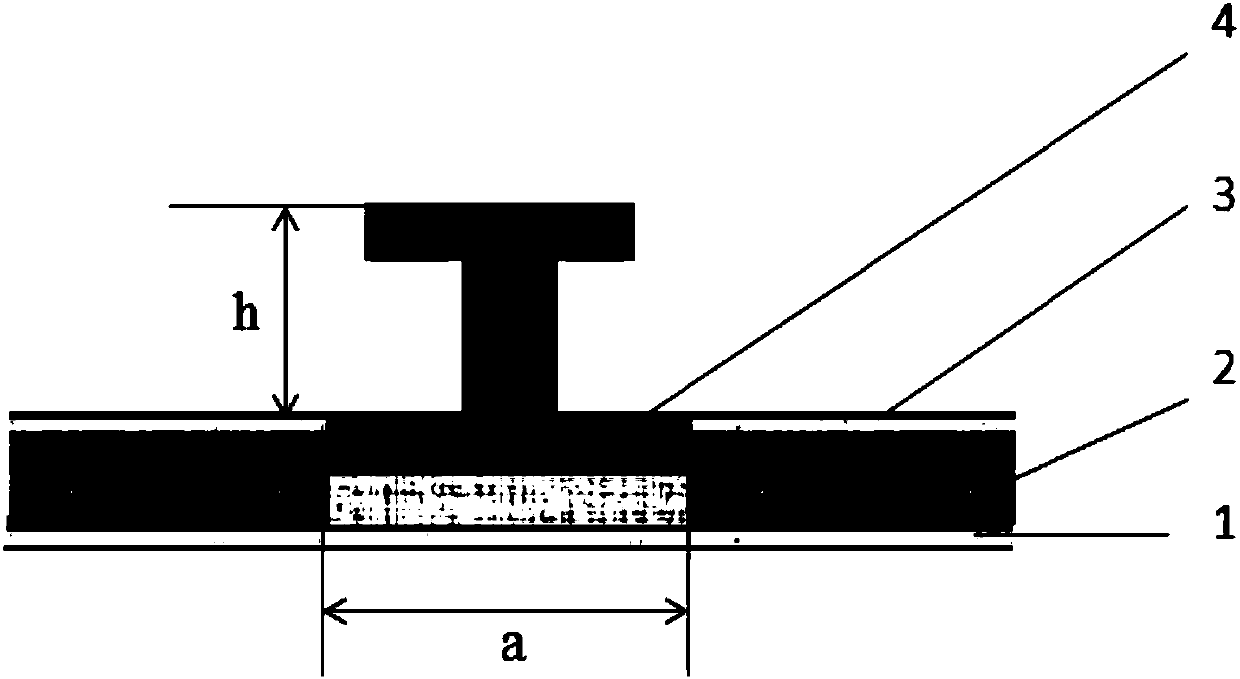

[0114] Step (2), use a surface density of 300g / m 2 The prepreg is laminated on the mould, the thickness of the laminate is 40mm, and it is cured in an autoclave to obtain a reinforcing rib block, which is cut into a curved reinforcing rib with a width of 80mm. The prepreg uses halogen-free flame-retardant epoxy resin as the resin matrix, with a density of 200g / m 2 The glass cloth is used as the reinforcing fiber, and the performance of the composite material meets the HL3 grade of the EN45545 standard; there are 3 reinforcing ribs obtained, and the accuracy of the shape and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com