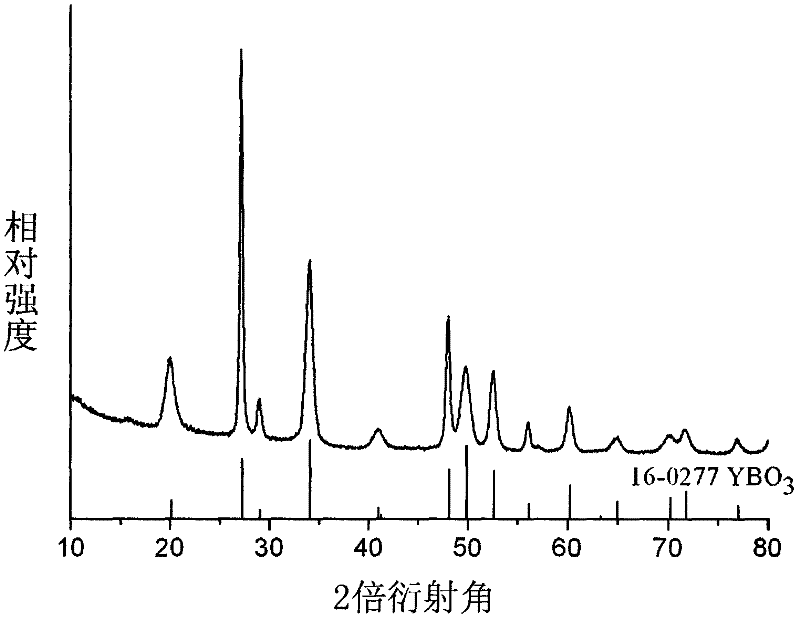

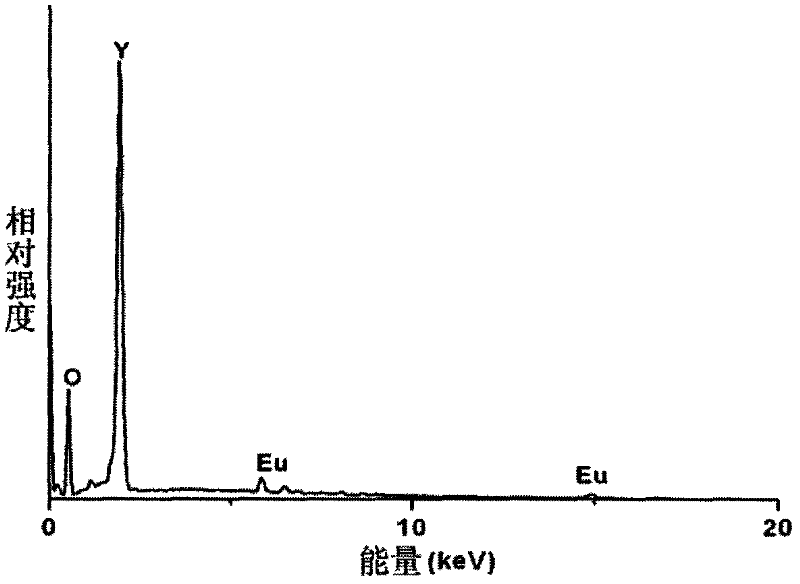

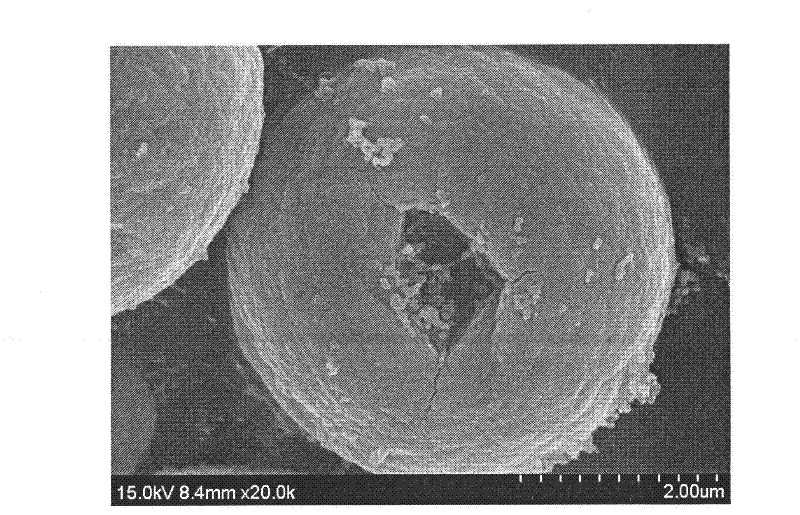

Hydro-thermal preparation method for spherical boric acid yttrium doped europium fluorescent powder in hollow structure

A hollow structure and fluorescent powder technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as difficult spherical structures, and achieve the effect of facilitating transfer, meeting light weight requirements, and uniform luminous effect in all directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation embodiment of nucleating reagent:

[0029] Configure glucose into a 0.5 mol / liter solution, take 80 milliliters of the solution and put it into a 100 milliliter reactor for hydrothermal reaction, the hydrothermal reaction temperature is 160°C, and the hydrothermal reaction time is 12 hours; after the reaction, the product obtained is centrifuged, and then Wash three times with ethanol, then wash three times with deionized water, put the prepared carbon spheres into a nitric acid solution with a volume ratio of nitric acid and deionized water of 1:5 for ultrasonic dispersion, soak at room temperature for 10 hours, wash with water until neutral, and collect by centrifugation , and dry to obtain carbon spheres with a diameter of 1-5 microns. Add 10.0 mL of deionized water to the obtained carbon spheres to form a suspension, and sonicate for 15 to 30 minutes. is the nucleating reagent.

Embodiment 1

[0031] Dissolve 0.7280 g of yttrium nitrate hexahydrate in 19.0 mL of deionized water; dissolve 0.0446 g of europium nitrate hexahydrate in 1.0 mL of deionized water; dissolve 0.1200 g of boric acid in 20.0 mL of deionized water. Stir separately to obtain a homogeneous solution, the concentrations of yttrium ion, europium ion and boric acid are all 0.1 mol / L. The above three solutions are mixed, and in the mixed solution, the molar concentration ratio of yttrium ion, europium ion and boric acid is 19:1:20. The mixed solution was stirred for 15 minutes. Add 4.0 mL of nucleating reagent followed by 0.3100 g of malonic acid. After the pH of the solution was stabilized, the pH of the solution was adjusted to 9.0 with 2.0 mol / L ammonia water. The above solution was transferred into a 100mL reactor for hydrothermal reaction, the hydrothermal temperature was 220°C, and the hydrothermal time was 24 hours. After the hydrothermal reaction, the obtained product is centrifuged and drie...

Embodiment 2

[0033] Dissolve 7.2800g of yttrium nitrate hexahydrate in 19.0mL of deionized water; dissolve 0.4460g of europium nitrate hexahydrate in 1.0mL of deionized water; dissolve 1.2000g of boric acid in 20.0mL of deionized water. Stir separately to obtain a homogeneous solution, the concentrations of yttrium ion, europium ion and boric acid are all 1.0 mol / liter. The above three solutions are mixed, and in the mixed solution, the molar concentration ratio of yttrium ion, europium ion and boric acid is 19:1:20. The mixed solution was stirred for 15 minutes. Add 8.0 mL of nucleating reagent, and then add 3.1000 g of malonic acid, and after stirring for 15 minutes, adjust the pH of the solution to 10.0 with 2.0 mol / liter of ammonia water. The above solution was transferred into a 100mL reactor for hydrothermal reaction, the hydrothermal temperature was 160°C, and the hydrothermal time was 48 hours. After the hydrothermal reaction, the obtained product is centrifuged and dried to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com