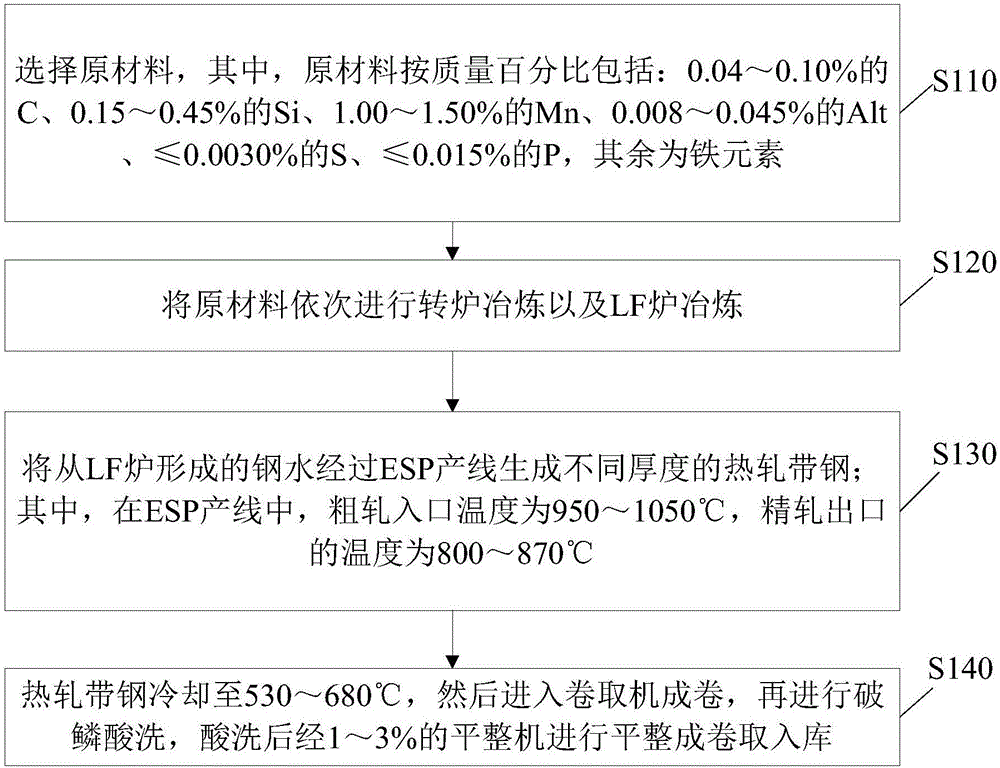

Method for producing thin-specification SAPH440 steel based on ESP thin slab continuous casting and rolling process

A thin-slab continuous casting and thin-gauge technology, which is applied in metal rolling, metal rolling, rolling mill control devices, etc., to achieve the effects of short production process, cost reduction and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

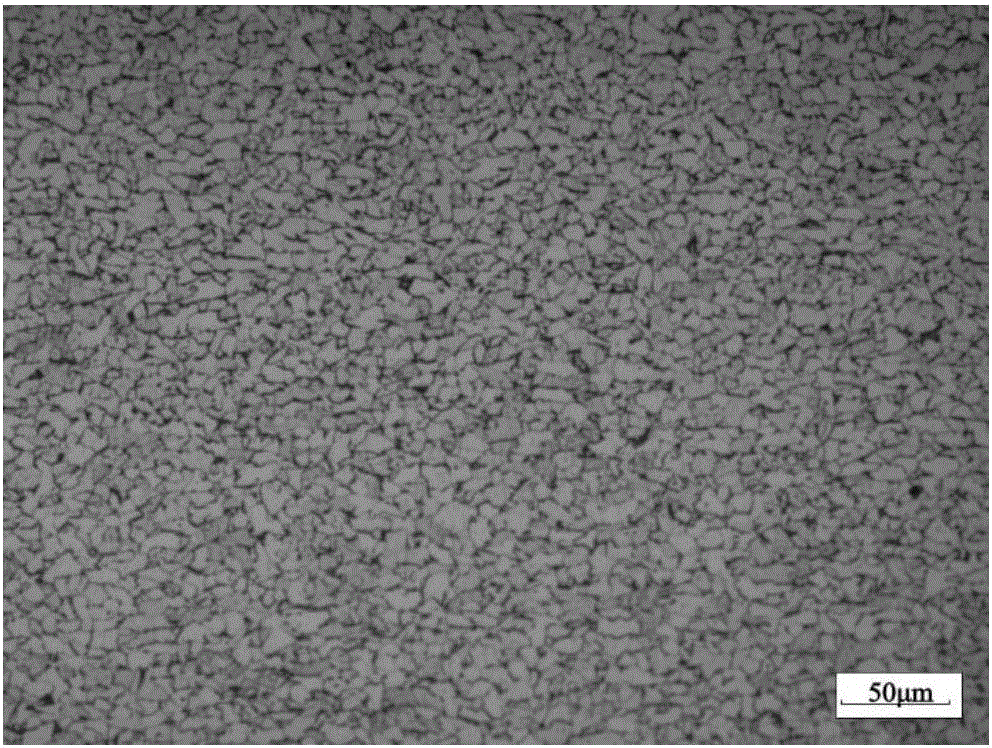

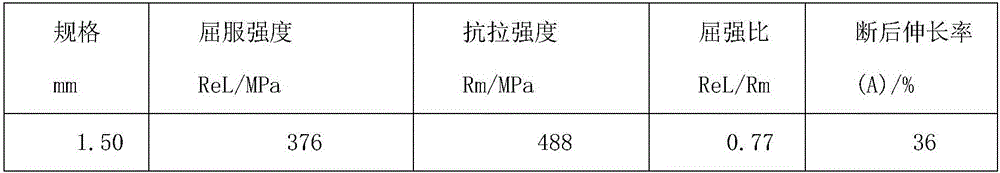

Embodiment 1

[0045] Select raw materials, wherein the raw materials include: 0.050% C, 0.25% Si, 1.25% Mn, 0.012% P, 0.0020% S, 0.028% Alt, and the rest are iron elements by mass percentage;

[0046] The raw materials are sequentially smelted in converter and LF furnace;

[0047] The molten steel refined by LF goes through ESP production line continuous casting, rough rolling, induction heating, finishing rolling, laminar cooling, coiling, pickling, and skin-passing processes to produce hot-rolled steel strips of different thicknesses.

[0048] Among them, in the ESP production line, the continuous casting process controls the superheat of the tundish to 18°C, the casting speed is 5.3m / min, and the thickness of the slab is 95mm;

[0049] The cast slab is rolled through three passes of rough rolling, the rough rolling inlet temperature is 1020°C, and the rough rolling exit temperature is 980°C;

[0050] The rough-rolled intermediate billet product is heated by an induction furnace, and the...

Embodiment 2

[0058] Select raw materials, wherein the raw materials include: 0.051% C, 0.25% Si, 1.28% Mn, 0.012% P, 0.0025% S, 0.030% Alt, and the rest are iron elements by mass percentage;

[0059] The raw materials are sequentially smelted in converter and LF furnace;

[0060] The molten steel refined by LF goes through ESP production line continuous casting, rough rolling, induction heating, finishing rolling, laminar cooling, coiling, pickling, and skin-passing processes to produce hot-rolled steel strips of different thicknesses.

[0061] Among them, in the ESP production line, the continuous casting process controls the superheat of the tundish to 20°C, the casting speed is 5.3m / min, and the thickness of the slab is 95mm;

[0062] The slab is rolled through three passes of rough rolling, the rough rolling inlet temperature is 1010°C, and the rough rolling exit temperature is 980°C;

[0063] The rough-rolled intermediate billet product is heated by an induction furnace, and the outl...

Embodiment 3

[0071] Select raw materials, wherein the raw materials include: 0.049% C, 0.26% Si, 1.33% Mn, 0.012% P, 0.0020% S, 0.030% Alt, and the rest are iron elements by mass percentage;

[0072] The raw materials are sequentially smelted in converter and LF furnace;

[0073] The molten steel refined by LF goes through ESP production line continuous casting, rough rolling, induction heating, finishing rolling, laminar cooling, coiling, pickling, and skin-passing processes to produce hot-rolled steel strips of different thicknesses.

[0074] Among them, in the ESP production line, the continuous casting process controls the superheat of the tundish to 21°C, the casting speed is 5.2m / min, and the thickness of the slab is 95mm;

[0075] The slab is rolled through three passes of rough rolling, the rough rolling inlet temperature is 1010°C, and the rough rolling exit temperature is 980°C;

[0076] The rough-rolled intermediate billet product is heated by an induction furnace, and the outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com