Integral bursting type composite material launching box cover and manufacturing method thereof

A composite material and bursting technology, which is applied in the field of integral bursting composite launch box cover and its production, can solve the problems of no delay in opening the box cover, unfavorable storage, complicated maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with the accompanying drawings, the present invention will be described in further detail:

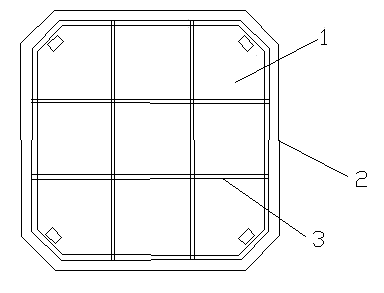

[0038] As shown in the figure: the overall burst type composite material launch box cover, including the frame body; the frame body is octagonal, the frame bodies are separated from each other into a frame 1, a cover plate 2, the frame 1 is octagonal, the cover The plate 2 matches the shape of the frame 1 and is mounted on the frame 1 .

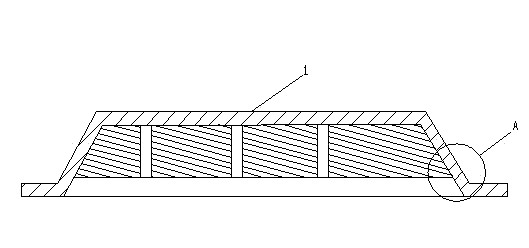

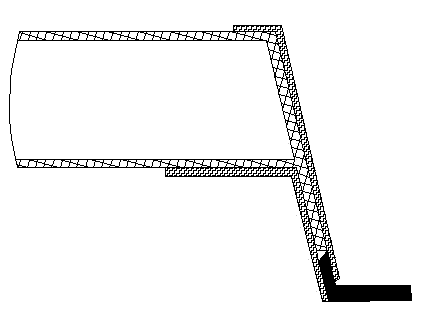

[0039] The main body of the cover plate 2 is made of polyurethane foam, the inner and outer surfaces of the polyurethane foam are fitted with a composite material layer, and the composite material layer extends downward with a support angle, and the support angle is connected with the frame 1 .

[0040] The reinforcing ribs 3 are installed in the cover plate 2, and the reinforcing ribs 3 are arranged in a well-shaped shape and are made of paulownia. The inner and outer sides of the contact surface between the support angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com