drive system for vehicles

A drive system, vehicle technology, applied in vehicle components, fluid drive clutches, non-mechanical drive clutches, etc., can solve the problems affecting the operation responsiveness of the clutch mechanism, the influence of the operation responsiveness, the influence of centrifugal hydraulic pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

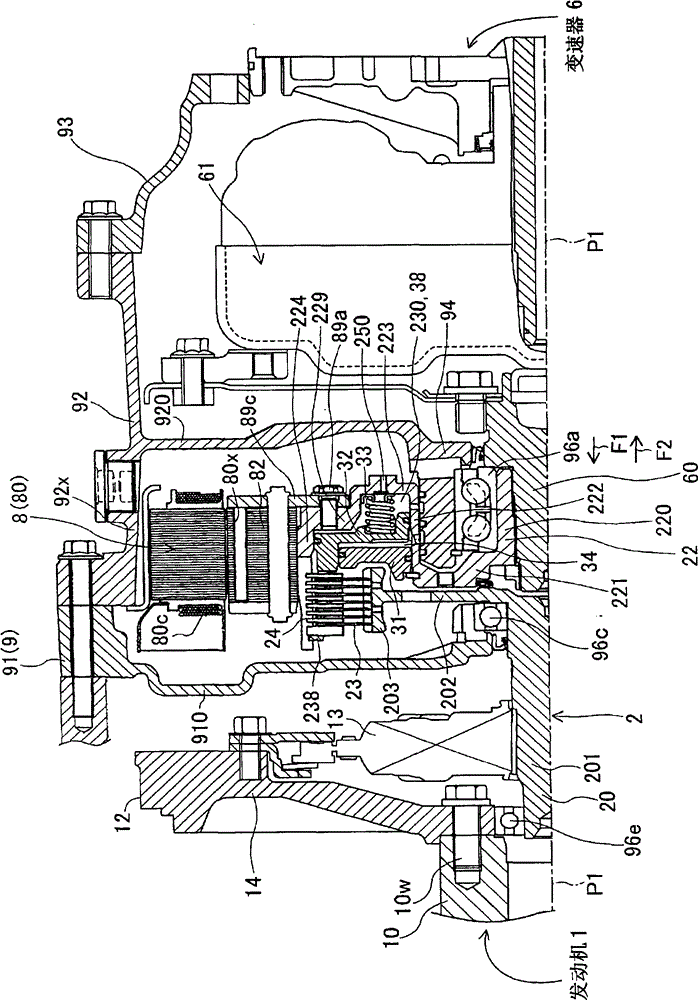

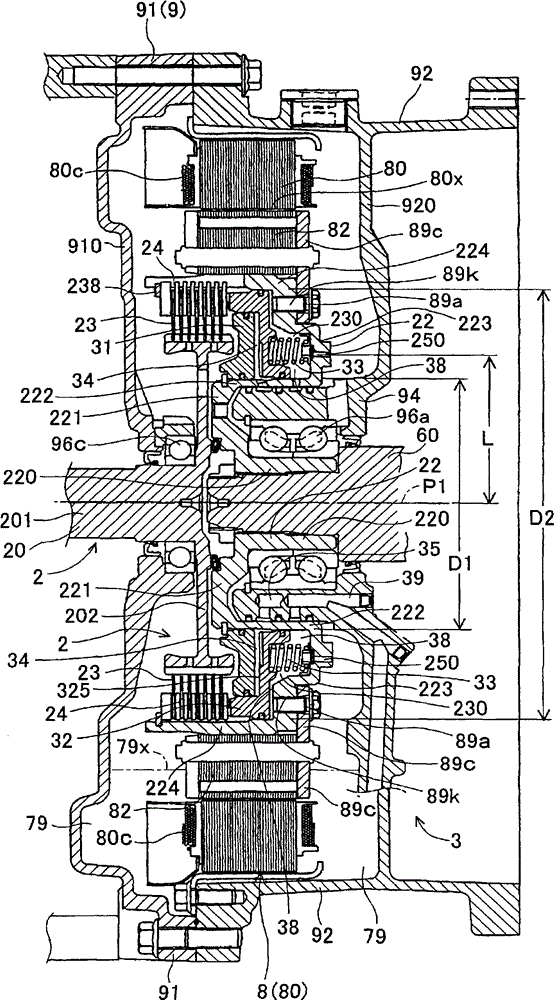

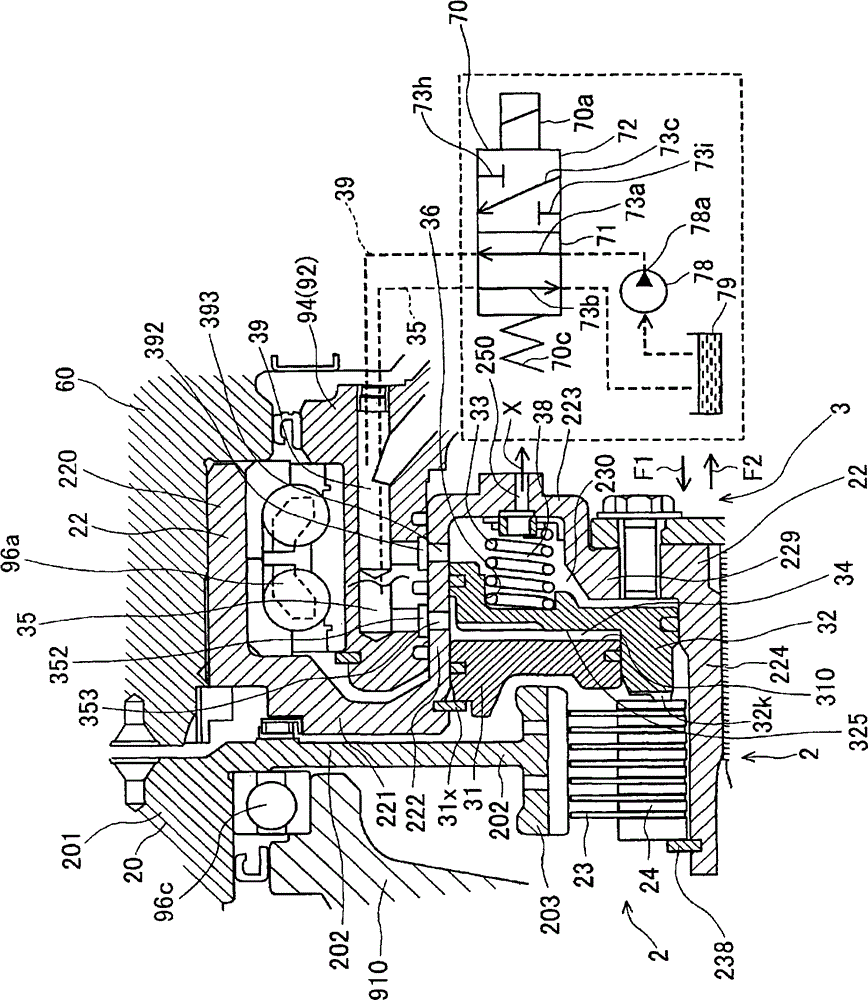

[0026] The first embodiment of the present invention is applied to a hybrid vehicle, for example, a hybrid passenger vehicle, a large hybrid vehicle, and the like. Next, a first embodiment of the present invention will be described with reference to the drawings. figure 1 is a sectional view illustrating the upper half of the drive system for a vehicle according to the first embodiment. figure 2 is a sectional view illustrating a portion near the clutch mechanism 2 in the drive system according to the first embodiment. image 3 and Figure 4 Each is an enlarged view illustrating a main part of the lower half of the drive system according to the first embodiment. Figure 5 is a block diagram of the drive system according to the first embodiment. Such as Figure 5As shown in , the drive system includes: an engine 1 as a drive source, a clutch mechanism 2, a drive motor 8 (hereinafter referred to as an electric motor) formed by an electric motor (electric motor) for driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com