Lightweight flame retardant modified polyamide material and its preparation method

A polyamide modification technology, which is applied in the field of lightweight modified polyamide materials and its preparation, can solve the problems of high density, poor surface quality, and large addition amount of flame-retardant products, and achieve excellent material performance, lower density, and low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] PA66 (viscosity 2.4) 100 parts,

[0035] Flame retardant (brominated polystyrene: antimony trioxide = 4 / 1) 16 parts,

[0036] Hollow glass microspheres (density 0.32g / cm 3 ) 5 copies,

[0037] Compatibilizer (PP-g-MAH) 5 parts,

[0038] Antioxidant (1098 / 168=1 / 2) 0.3 part,

[0039] Lubricant (ethylene-acrylic acid copolymer) 0.3 part;

[0040] According to the above weight content, PA66, flame retardant, hollow glass beads, compatibilizer, and other additives are put into a high-speed mixer and mixed at a high speed. The speed of the high-speed mixer is controlled at 700rmp, and the mixing temperature is 60°C. 3min; feed the mixture into the hopper of the extruder, control the temperature of each zone at 250-265°C, and cut the strands of the extruder into pellets to obtain the composition. The mechanical performance test is shown in Table 1.

Embodiment 2

[0042] PA66 (viscosity 2.8) 100 parts,

[0043] 30 parts of alkali-free glass fiber (7μm in diameter),

[0044] Flame retardant (decabromodiphenylethane: sodium antimonate = 3 / 1) 28 parts,

[0045] Hollow glass microspheres (density 0.48g / cm 3 ) 10 parts,

[0046] Compatibilizer (POE-g-MAH) 12 parts,

[0047] Antioxidant (1010 / 168=1 / 2) 1 part,

[0048] Lubricant (silicone powder) 0.8 parts;

[0049] According to the above weight content, PA66, flame retardant, hollow glass beads, compatibilizer, and other additives are put into a high-speed mixer and mixed at a high speed. The speed of the high-speed mixer is controlled to 500rmp, and the mixing temperature is 70°C. 6min; feed the mixed material to the hopper of the extruder, and add the glass fiber to the feeding port on the side of the glass fiber port of the extruder. The composition can be obtained, and its mechanical property test is shown in Table 1.

Embodiment 3

[0051] PA66 (viscosity 3.2) 100 parts,

[0052] 60 parts of alkali-free glass fiber (7μm in diameter),

[0053] Flame retardant (bromotriazine: melamine polyphosphate = 2 / 1) 20 parts,

[0054] Hollow glass microspheres (density 0.6g / cm 3 ) 15 copies,

[0055] Compatibilizer (EPDM-g-MAH) 18 parts,

[0056] Antioxidant (1098 / 168=1 / 2) 0.6 part,

[0057] Lubricant (TAF) 1.0 parts;

[0058] According to the above weight content, PA66, flame retardant, hollow glass beads, compatibilizer, and other additives are put into a high-speed mixer and mixed at a high speed. The speed of the high-speed mixer is controlled at 600rmp, and the mixing temperature is 80°C. 5min; feed the mixed material to the hopper of the extruder, and add the glass fiber to the feeding port on the side of the glass fiber port of the extruder. The composition can be obtained, and its mechanical property test is shown in Table 1.

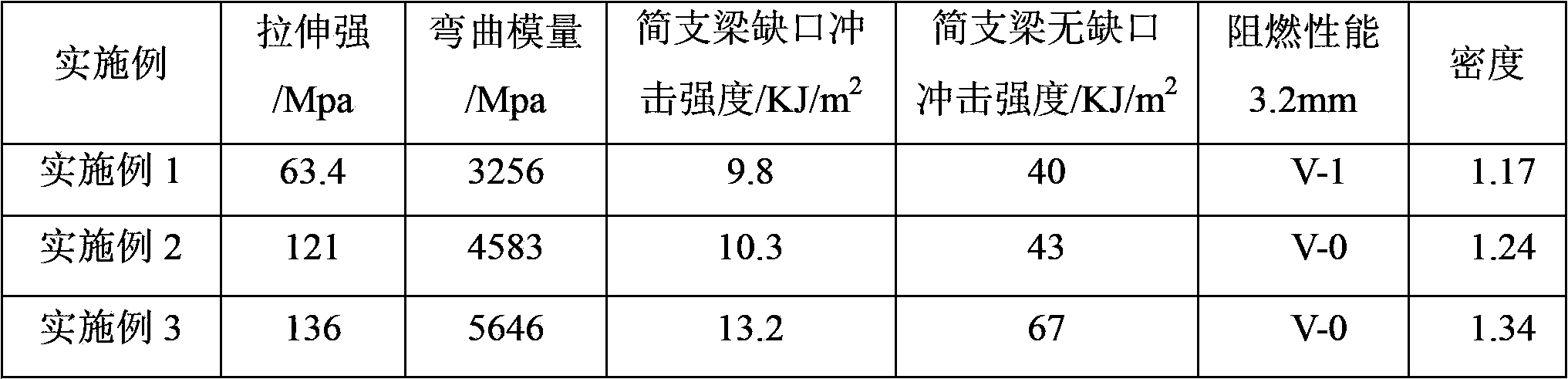

[0059] Table 1

[0060]

[0061] It can be seen from Table 1 that the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com