Preparation method of aluminum alloy casting with cavity filled with foamed aluminum

A foamed aluminum and aluminum alloy technology, applied in the field of aluminum alloy casting, can solve the problems of large investment, difficulty in mass production, and large pollution, and achieve the effects of improving overall strength, improving production efficiency, and reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of aluminum foam filled aluminum alloy cavity casting according to the present invention generally comprises the following steps:

[0034] (1) Preparation and pretreatment of foamed aluminum: process the foamed aluminum into the shape of the core by sawing or machining, preheat to 160-180°C, spray flux, and then heat-preserve and dry at about 200°C , and then spraying, repeated three times, and finally heat the molded aluminum foam to 600-660 ℃ and keep it warm for use;

[0035] (2) Preparation of aluminum alloy liquid: sequentially including melting, refining, composition adjustment, refinement and modification, and slag and hydrogen measurement steps, and finally keep the aluminum alloy liquid at 660-700°C for use;

[0036] (3) Mold preparation: preheat the mold to 260-300°C, spray a layer of paint, put the shaped aluminum foam with flux on the surface into the mold for fixing, and make the mold fit in place;

[0037] (4) Casting molding: After...

Embodiment 1

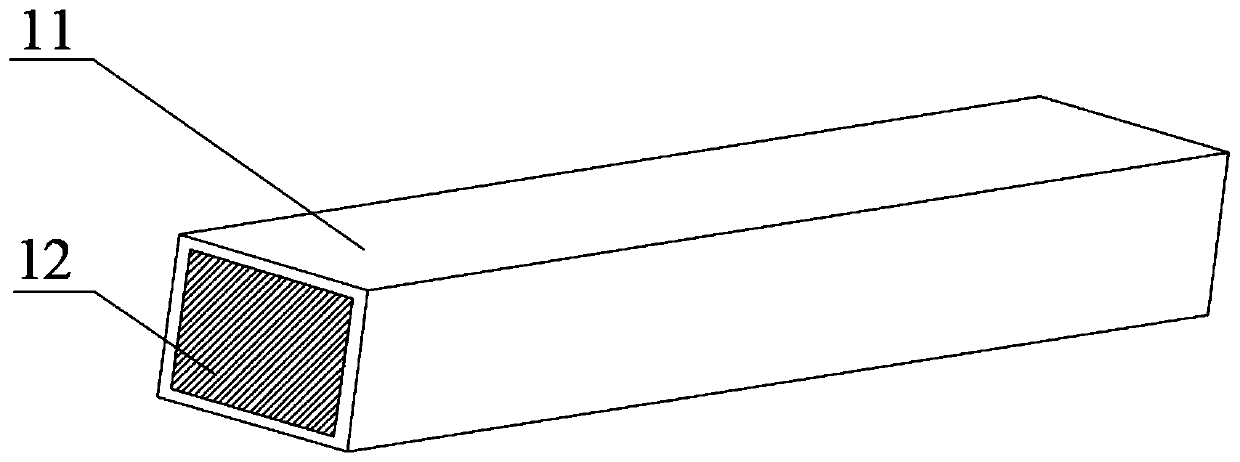

[0040] A certain type of automobile cab beam: the casting dimensions are 100×70×600mm, the alloy used is A356, the weight is 2.98kg, and the basic wall thickness is 7mm. Among them, the automobile cab beam includes its aluminum alloy cavity casting part and the foam aluminum part filled inside the cavity casting, such as figure 1 As shown, specifically, the beam 11 and the aluminum foam 12 filled in the beam are respectively. The dimensions of the filled aluminum foam are 86×60×600mm, the material is pure aluminum, the weight is 1.51kg, and the equivalent volume density is 0.2~0.5g / mm 3 . Casting process: low pressure casting.

[0041] The specific steps are:

[0042] (1) Preparation and pretreatment of foamed aluminum: process the foamed aluminum into a core shape by sawing and machining, spray a layer of flux on the surface after preheating, heat and keep it warm, and set aside;

[0043] (2) Preparation of aluminum alloy liquid: melting, refining (degassing and slag remo...

Embodiment 2

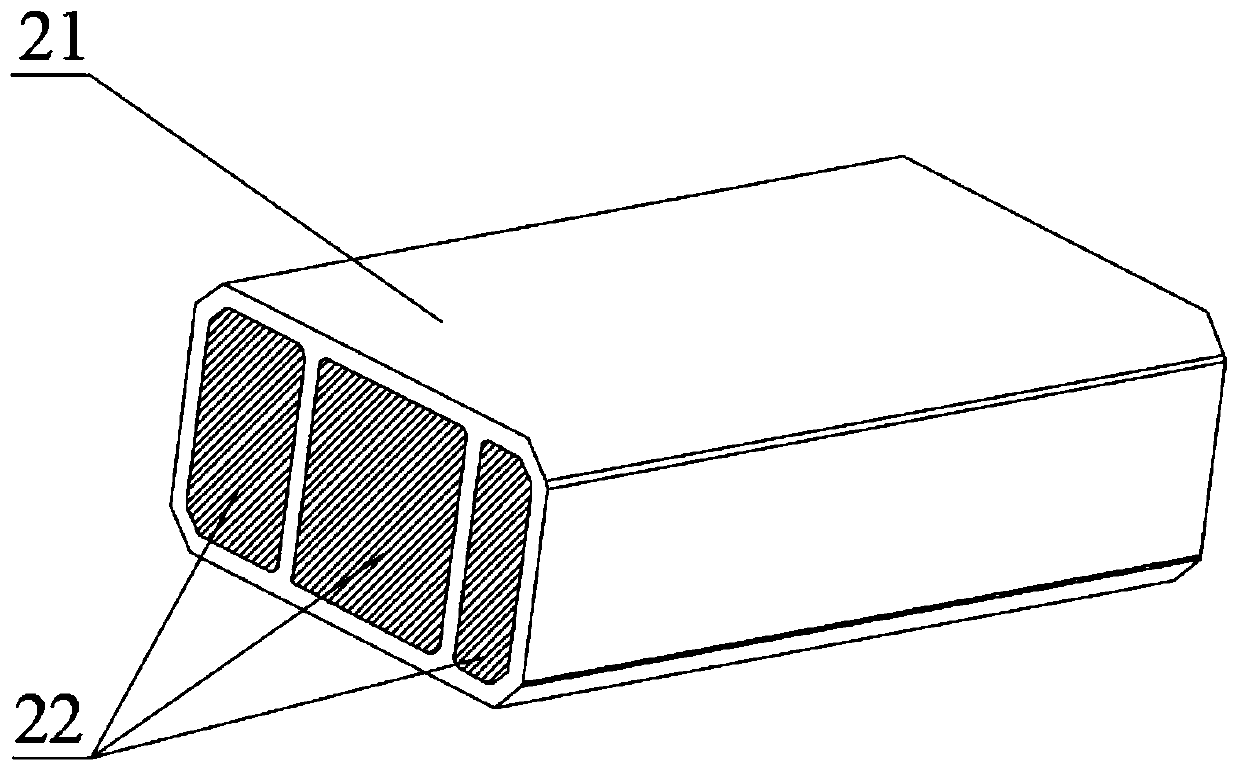

[0052] A certain type of automobile crash box: the dimensions of the casting are 120×64×200mm, the alloy used is A356, the weight is 1.2kg, and the basic wall thickness is 5mm. Among them, the automobile crash box includes its aluminum alloy cavity casting part, and the foam aluminum part filled inside the cavity casting, such as figure 2 As shown, specifically, the crash box 21 and the foamed aluminum 22 filled in the crash box. The dimensions of the filled aluminum foam are (32, 50, 18) × 54 × 600mm, the material is pure aluminum, the weight is 0.27kg, and the equivalent volume density is 0.2-0.5g / mm 3 . Casting process: low pressure casting.

[0053] The specific steps are:

[0054] (1) Preparation and pretreatment of foamed aluminum: process the foamed aluminum into a core shape by sawing and machining, spray a layer of flux on the surface after preheating, heat and keep it warm, and set aside;

[0055] (2) Preparation of aluminum alloy liquid: melting, refining (dega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com