Water-proof LED flexible light stripe and its manufacturing method

A light strip, flexible technology, applied in the field of decoration, can solve the problems of poor colloid strength, increased product unit price, not too long, etc., and achieve the effect of improved soft strip strength, high quality reliability, and good use safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In the following, specific embodiments are described in detail with the attached drawings, so that it is easier to understand the purpose, technical content, characteristics and effects of the present invention.

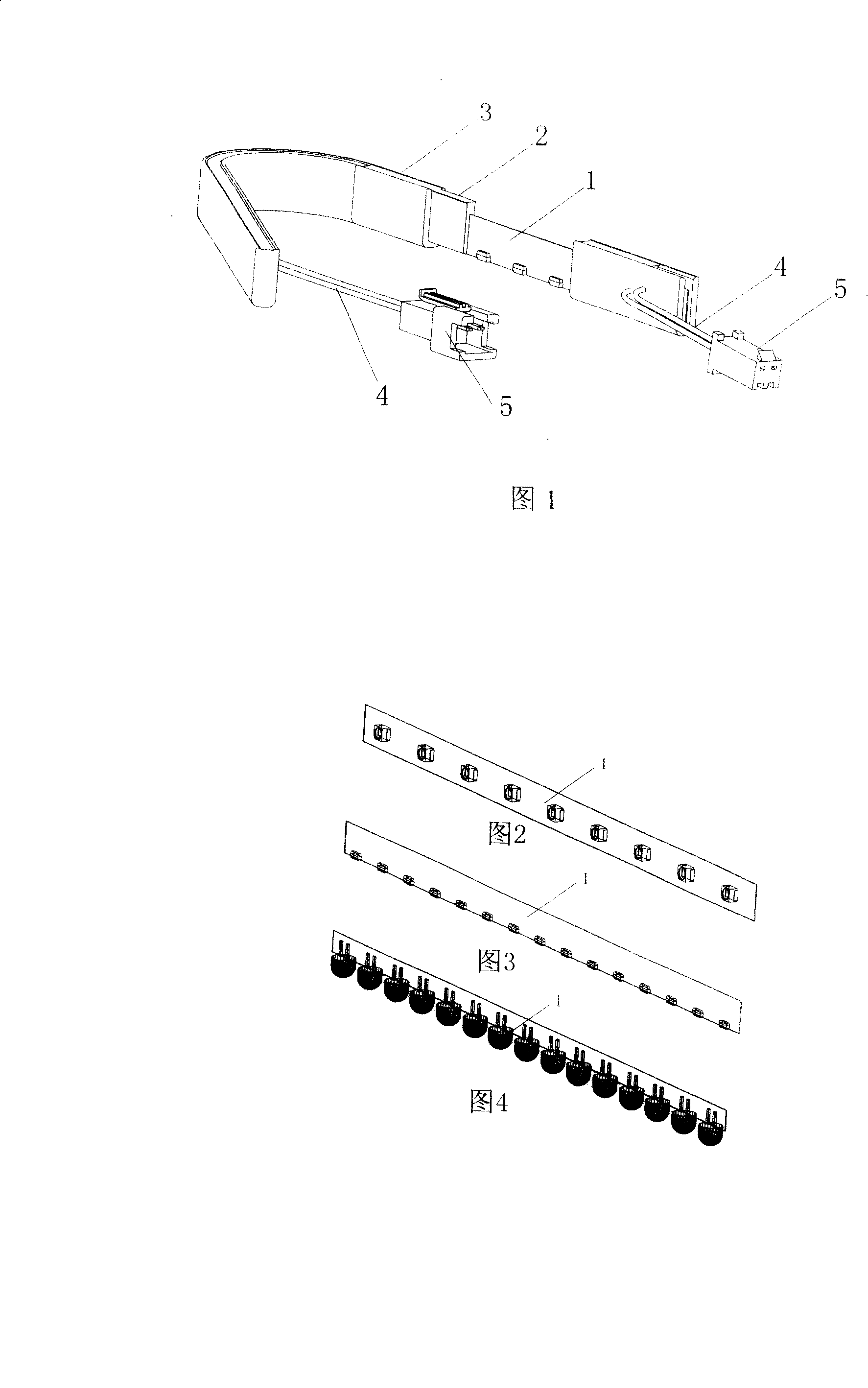

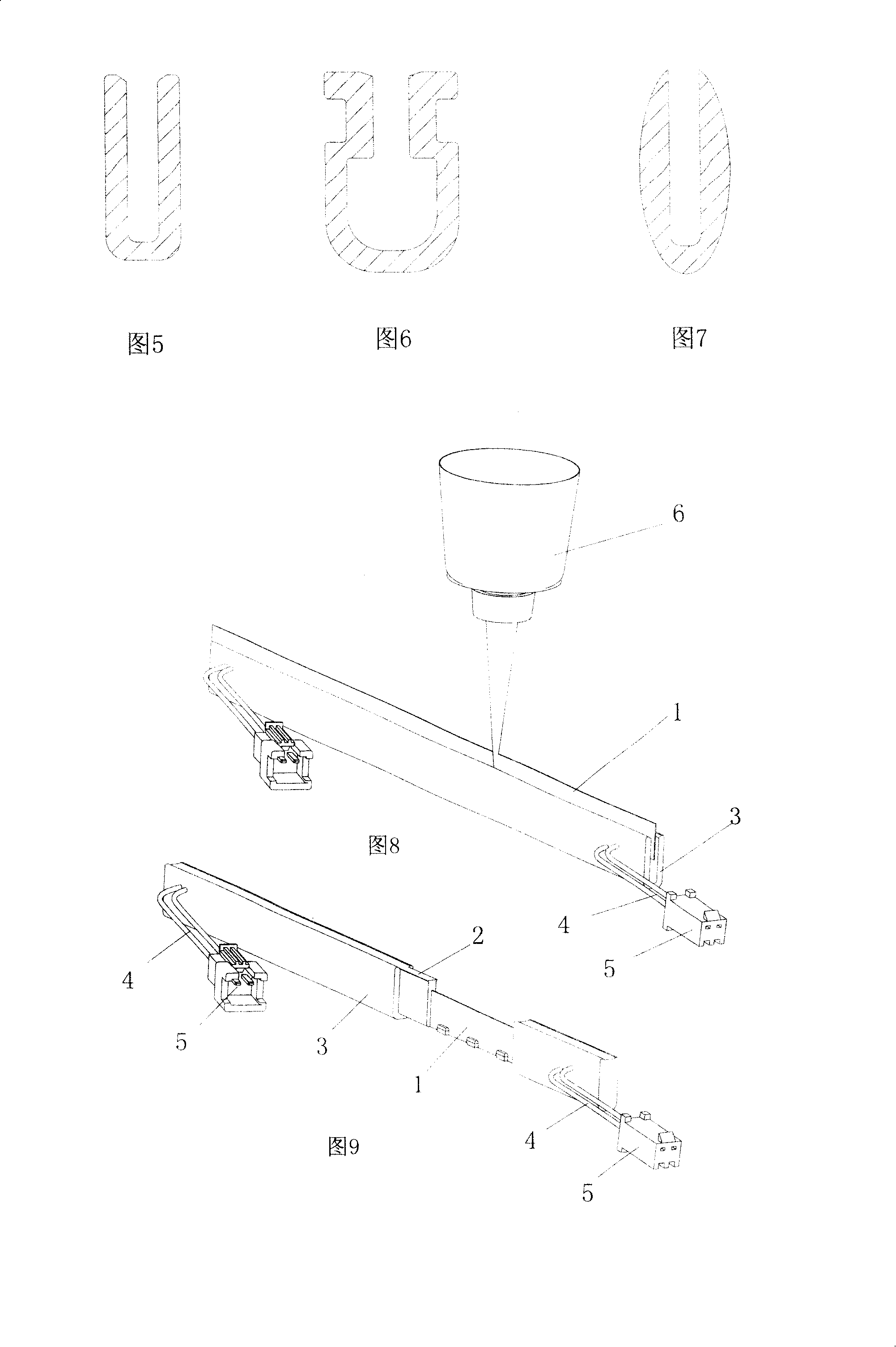

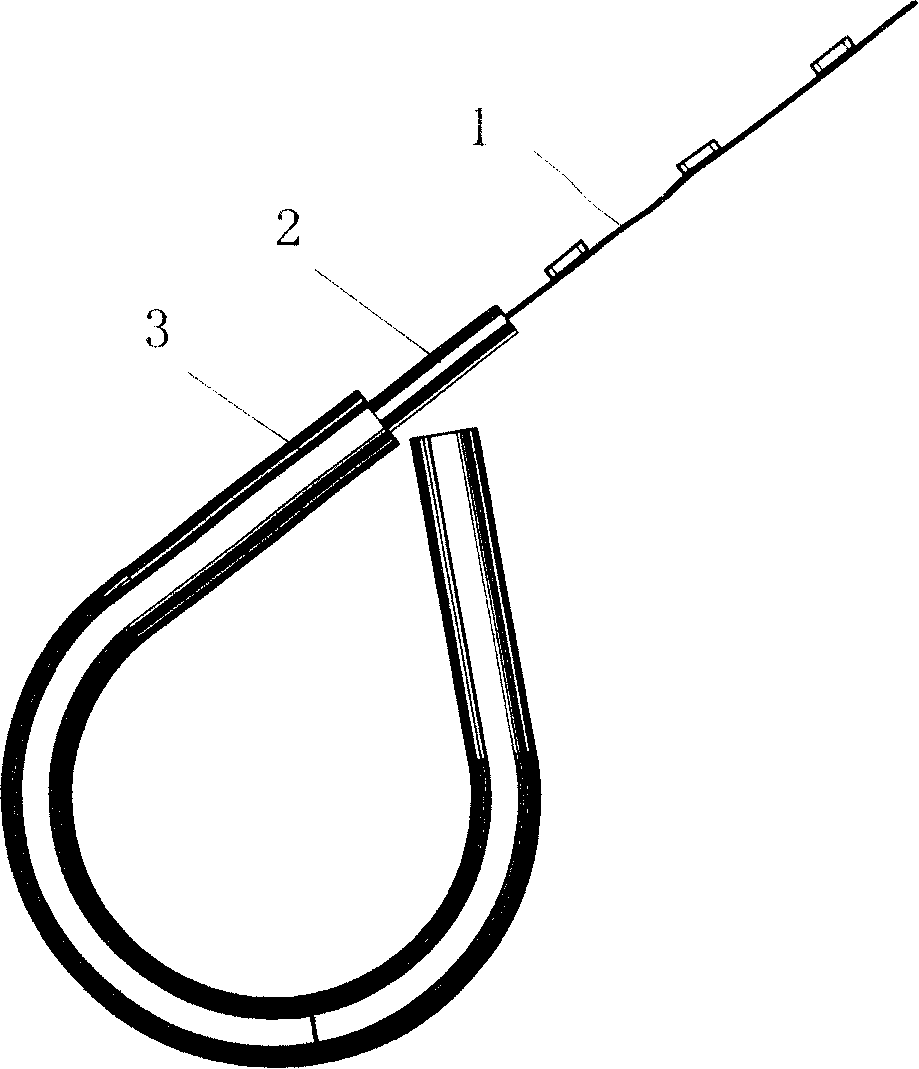

[0053]Fig. 1 is a structural schematic diagram of the waterproof LED flexible light strip according to the present invention. The waterproof LED flexible light strip includes a LED flexible light strip 1 , the LED flexible light strip 1 is covered with a colloid layer 2 , and the colloid layer 2 is bonded to the outer skin 3 .

[0054] The length of LED flexible light strip 1 can be determined according to production needs, which includes a very soft PCB board, soldering multiple LEDs on the flexible PCB board, and welding multiple electronic components on the flexible PCB board, LED flexible light strip 1 Data lines 4 and power connectors 5 can also be connected to the sides of both ends.

[0055] The LEDs can be SMD LEDs, full-color SMD LEDs or other LEDs t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com