Film coating source, vacuum film coating device and film coating process thereof

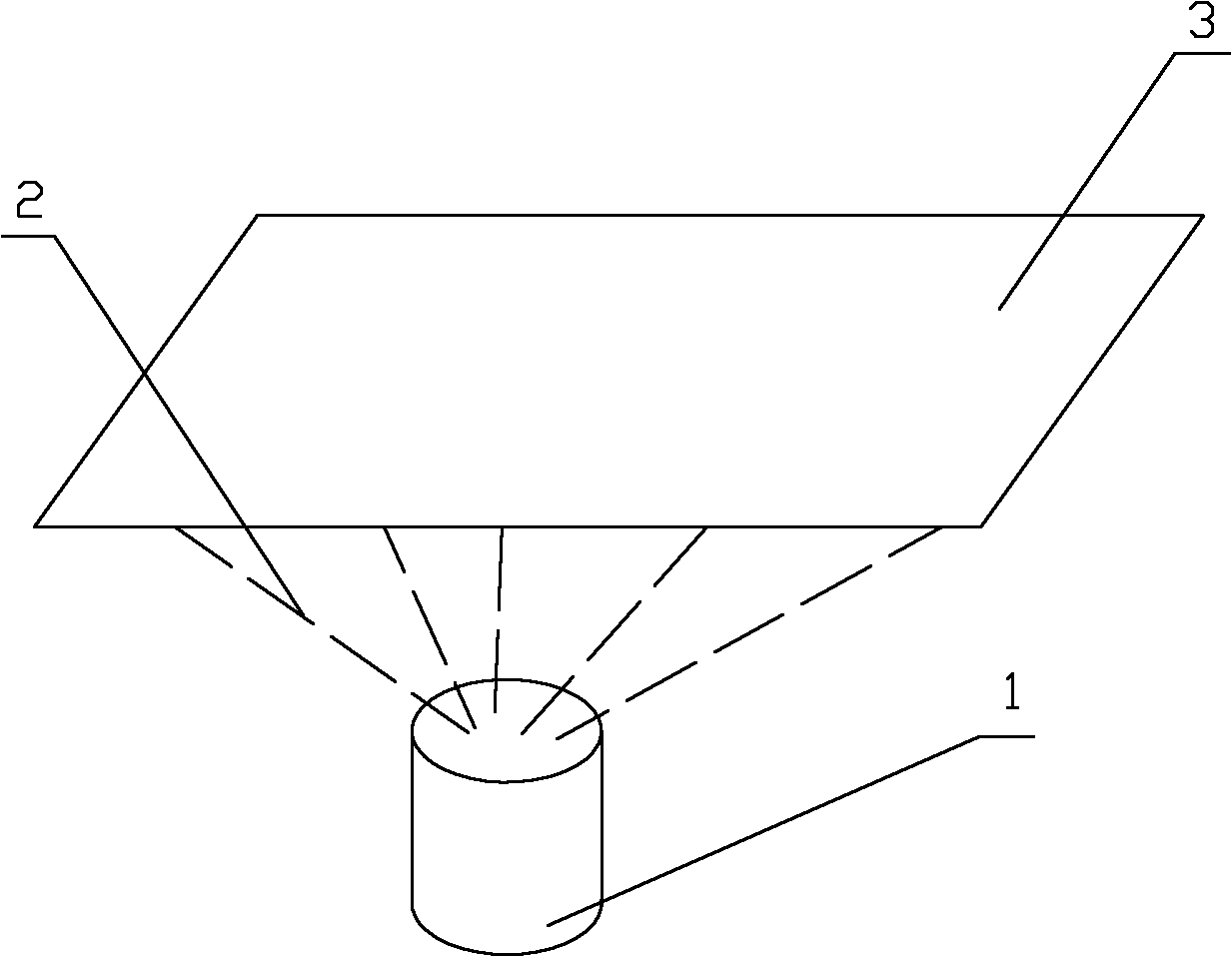

A vacuum coating and vacuum chamber technology, applied in the field of vacuum coating equipment and its coating process, can solve the problems of poor uniformity of film thickness distribution in the substrate plane, low material utilization rate, etc., and achieve good pattern accuracy, uniform light-emitting performance, good film Thick and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

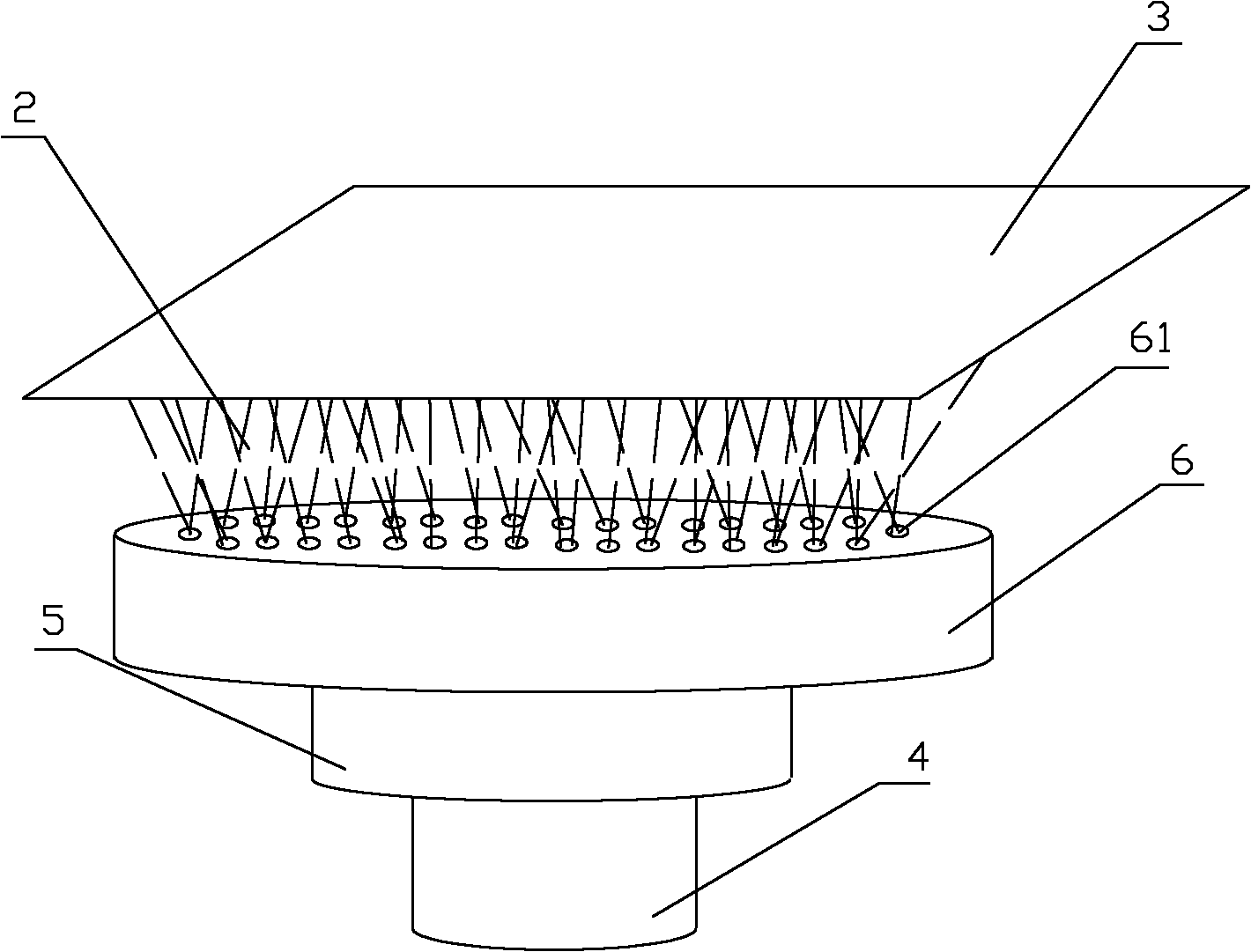

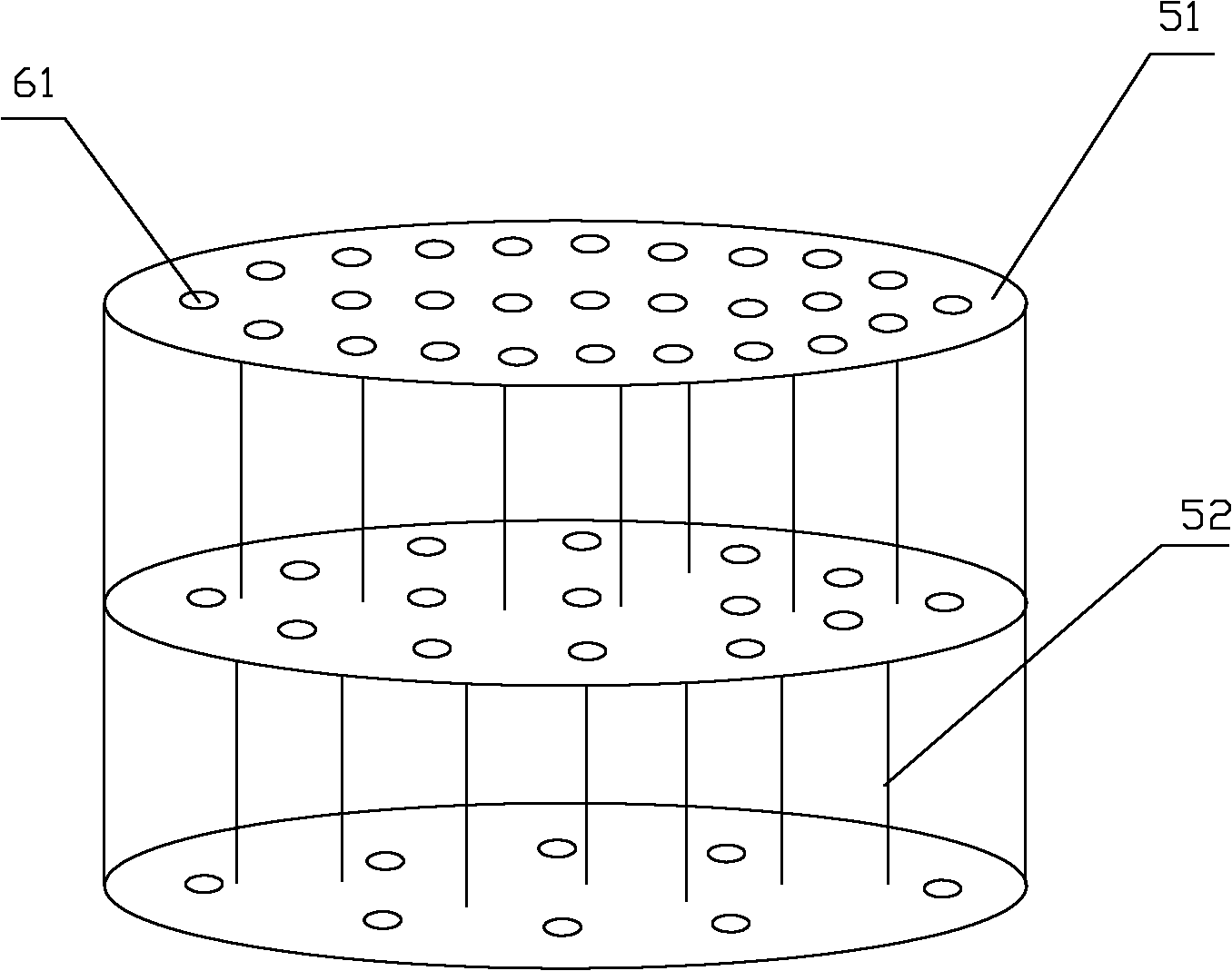

[0038] use figure 2 In the coating source structure shown, the container part 4 is made of copper, and a layer of nickel is plated on it to improve the uniformity of heat conduction. The evaporative airflow adjustment part 5 adopts the structure of two layers of injection plates 51, the first layer of injection plates 51 is seamlessly connected with the container part 4, the second layer of injection plates 51 is also seamlessly connected with the first layer of injection plates 51, and the second layer of injection plates 51 is also seamlessly connected with the first layer of injection plates 51. The distance between the spray plate 51 and the spray plate 51 of the first layer is 7 cm. The diameter of the injection port 61 on the first layer of injection plate 51 is 4cm, and 2 injection ports are evenly arranged on the first layer of injection plate 51, and 4 injection ports 61 are evenly arranged on the second layer of injection plate 51, and its diameter is 3cm. There a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com