Decoration strip structure and air conditioner

A technology for decorative strips and air conditioners, applied in decorative arts, instruments, lighting devices, etc., can solve problems such as failure to beautify products, dull surface gloss of decorative strips, etc., to improve competitiveness, improve aesthetic effects, and facilitate popularization and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

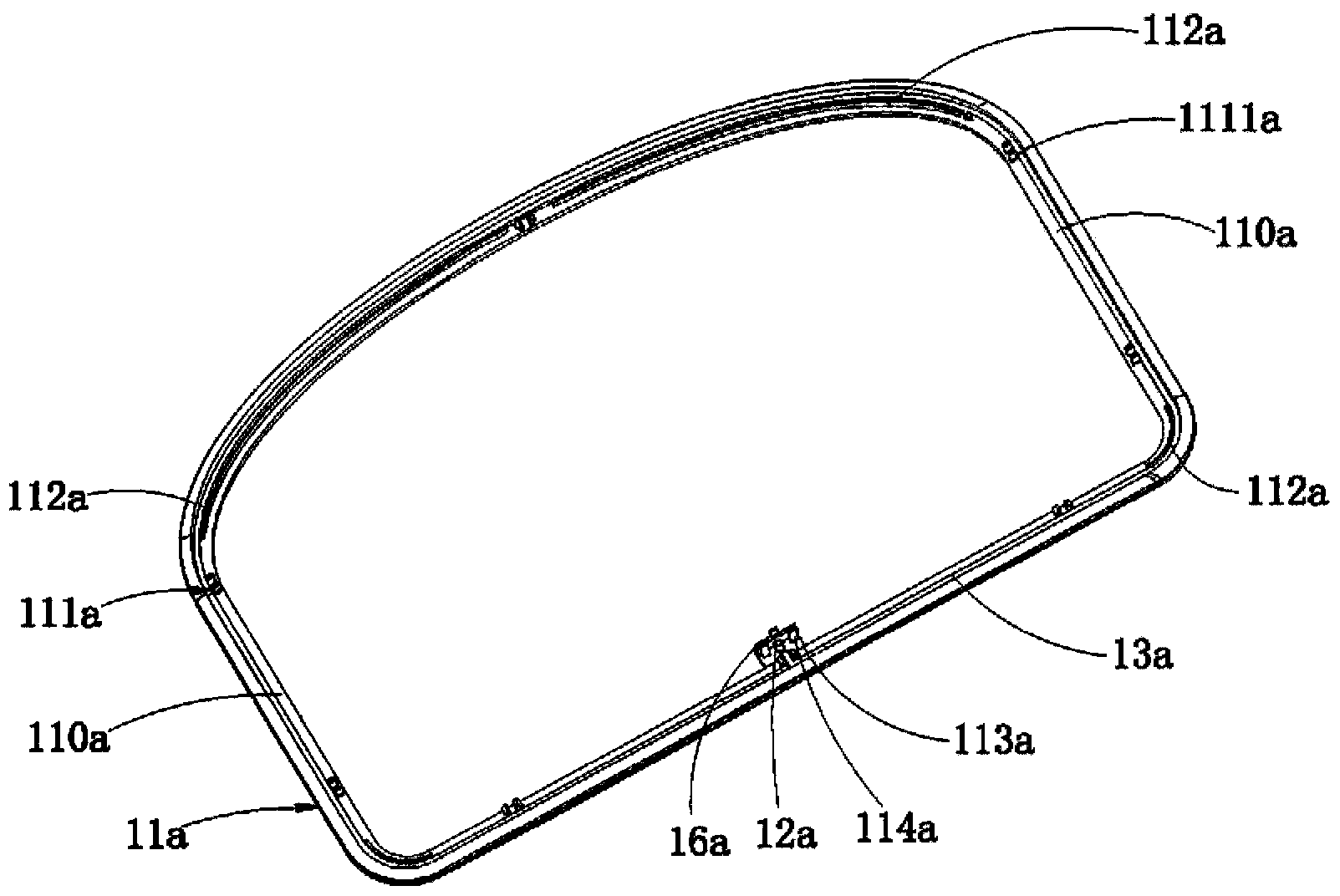

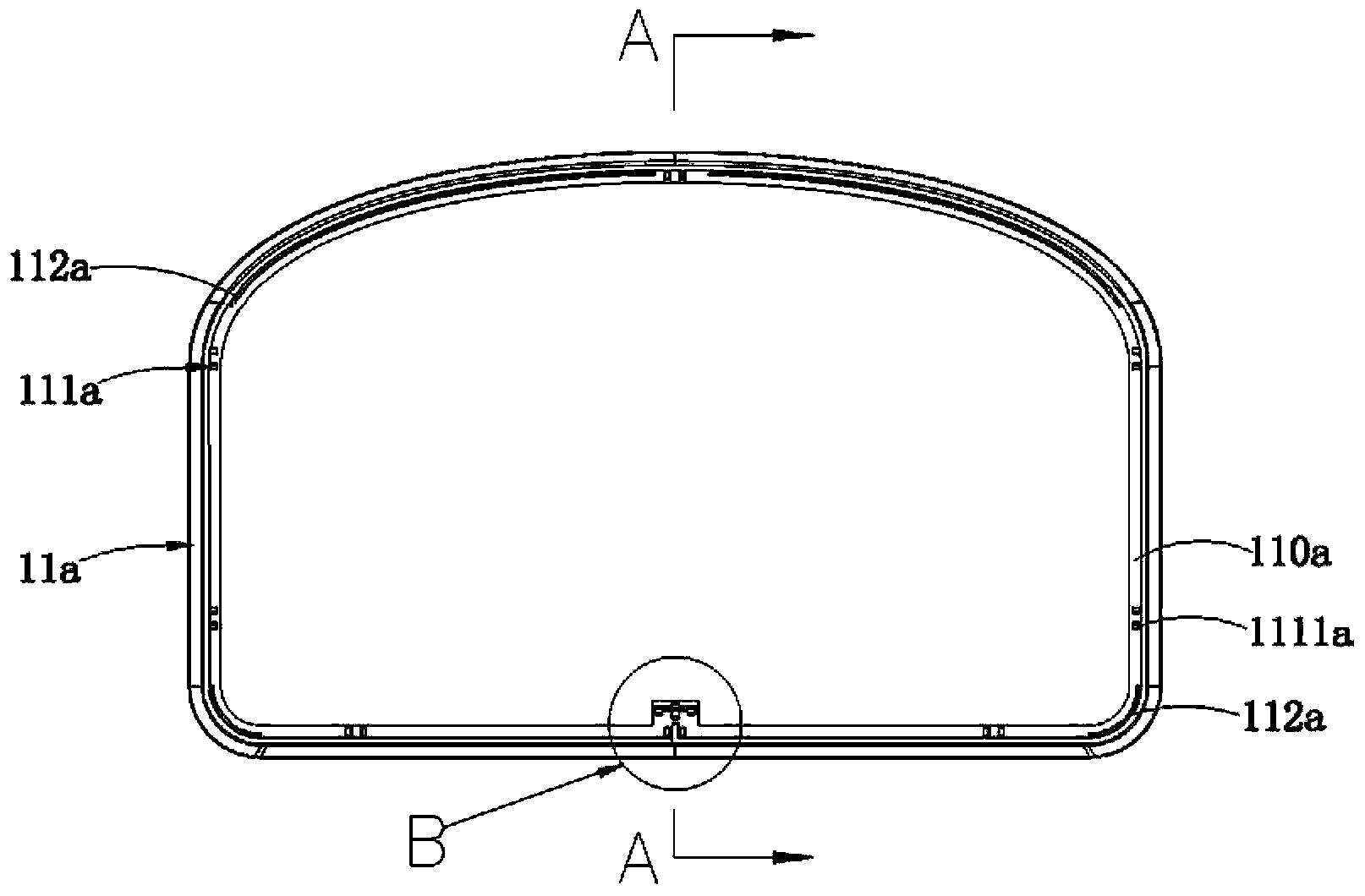

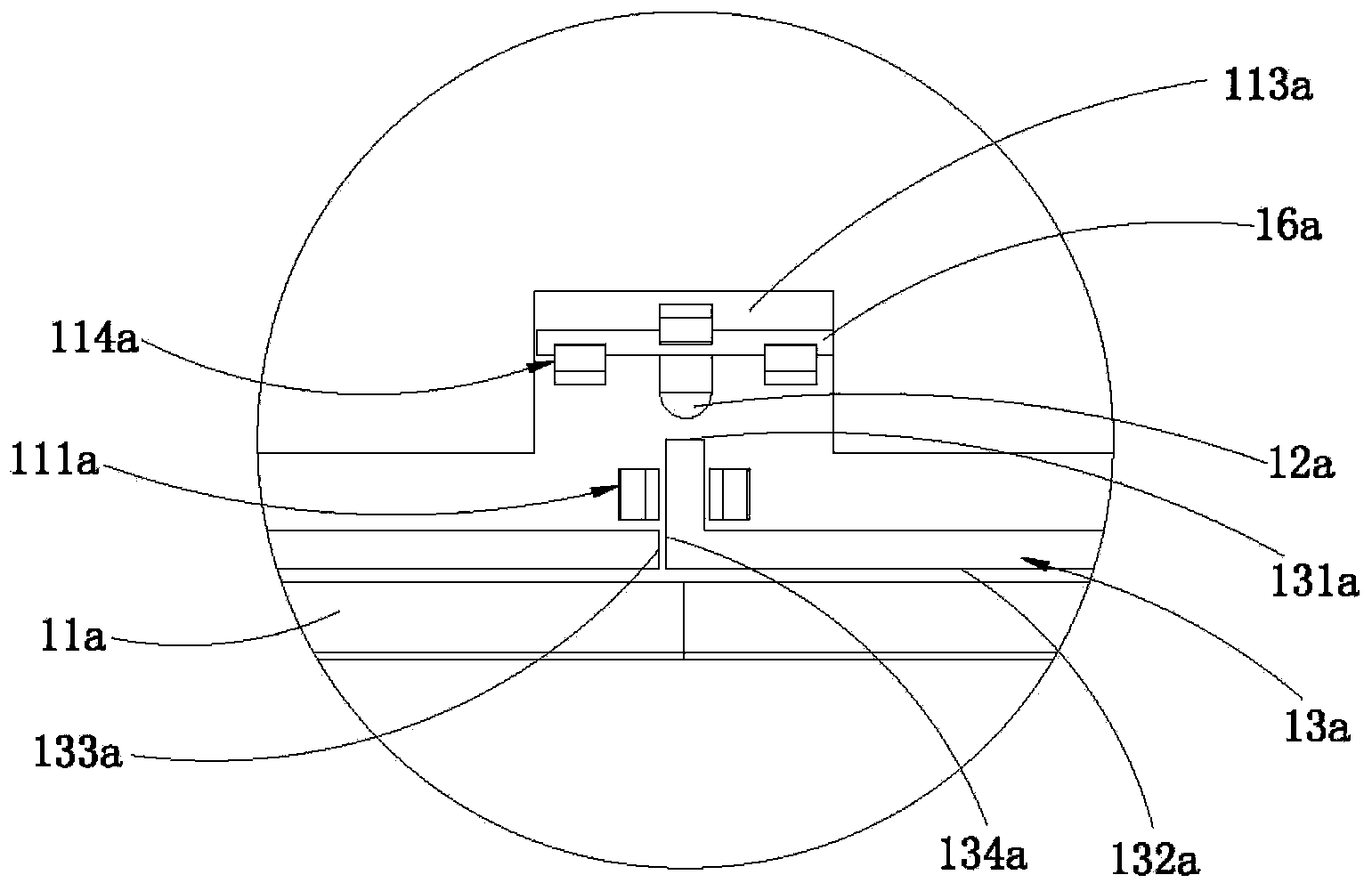

[0037] Such as Figure 1 ~ Figure 4 As shown, in this embodiment, the decorative strip body 11a is a solid light-transmitting member, which is made of a material with good light-transmitting properties, so that almost all the light irradiated on it can pass through it and emit; The inner side of the strip body 11a is dug downward to form a concave edge 110a, that is, the height of the concave edge 110a is smaller than the height of the outer side of the decorative strip body 11a. In specific processing, the decorative strip body 11a can be processed into a solid piece with the same inner and outer heights, and then the concave edge 110a can be processed by digging out a part of the material on the inner top; or the concave edge 110a can be directly molded. At least one set of limiting ribs 112a is provided on the concave edge 110a. The limiting ribs 112a can be integrally formed with the decorative strip body 11a, or can be fixed on the decorative strip body 11a by welding. Th...

Embodiment 2

[0041] Such as Figure 5 ~ Figure 8 As shown, in this embodiment, the decorative strip body 11b is a solid non-transparent member, which is made of a material with poor light transmission, so that the light irradiated on it can hardly pass through it and emit ; The inner side of the decorative strip body 11b is dug downward with a concave edge 110b, and a limiting rib 112b is provided on the concave edge 110b, and the light guide 13b is locked on the concave edge 110b through the limiting rib 112b; it is on the decorative strip body 11b The transparent part 14b is also embedded, and the side of the decorative strip body 11b is correspondingly provided with an embedding groove (not shown in the figure) for the transparent part 14b to be embedded in. The transparent part 14b includes a reflective part protruding from the concave edge 110b 141b, the conductive part 143b inserted in the embedding groove of the decorative strip body 11b and the light emitting part 142b attached to ...

Embodiment 3

[0046] Such as Figure 9 ~ Figure 11As shown, in this embodiment, the decorative strip body 11c is a non-transparent member, and the non-transparent member is made of a material with poor light transmittance, so that the light irradiated on it can hardly pass through it to be emitted; and The decorative strip body 11c is provided as a solid body. Of course, the decorative strip body 11c may also be hollow, and the light guide 13c is pasted on the outside of the decorative strip body 11c. The light guide 13c is bonded and fixed to the outside of the decorative strip body 11c by an adhesive (not shown in the figure), and the inherent viscosity of the adhesive can bond and fix the light guide 13c to the outside of the decorative strip body 11c, so as to The purpose of locking and fixing the light guide member 13c is achieved; and the bonding process is simple to operate and easy to implement, thus facilitating the disassembly and assembly of the light guide member 13c on the deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com