Patents

Literature

35results about How to "Simple elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

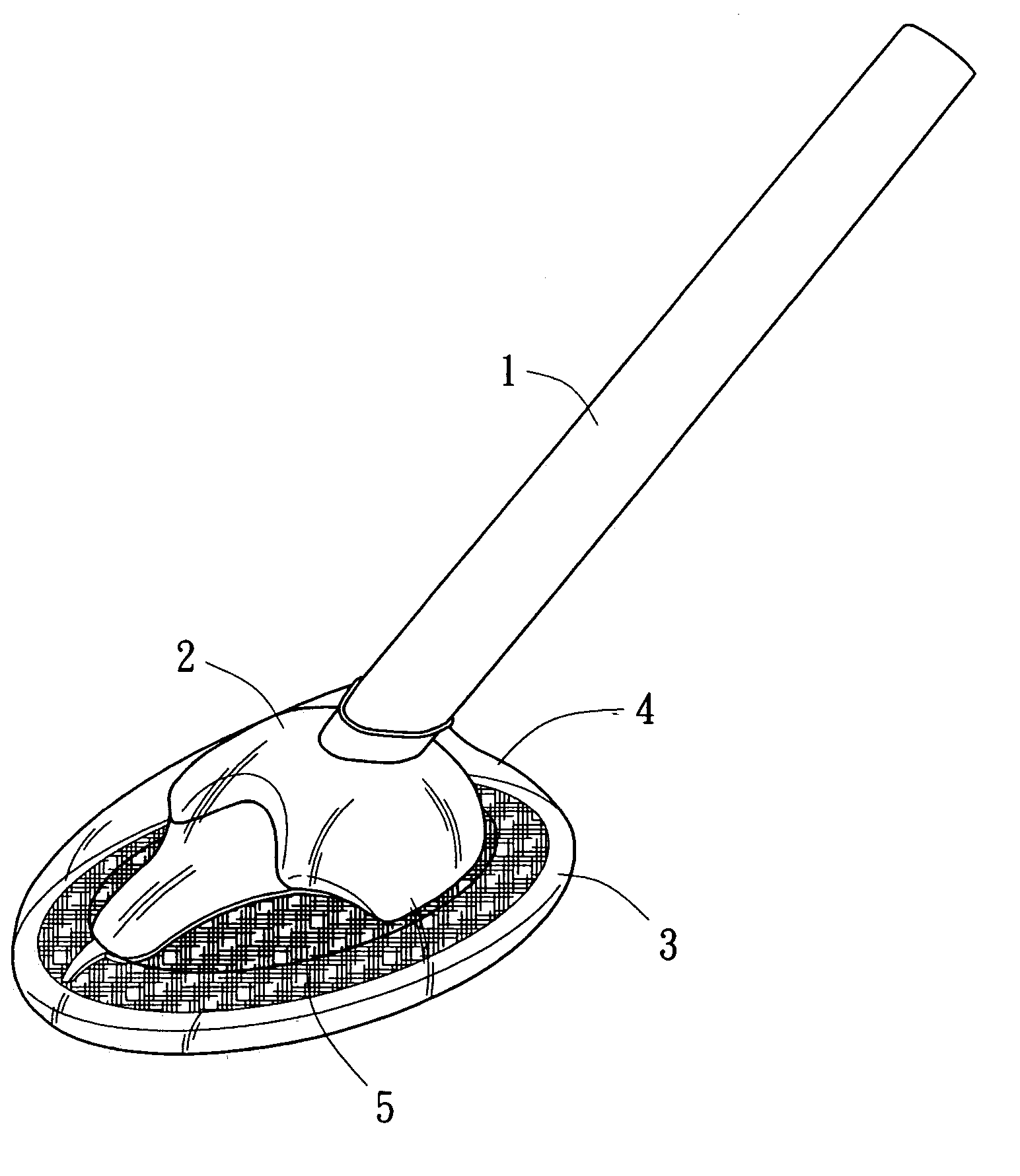

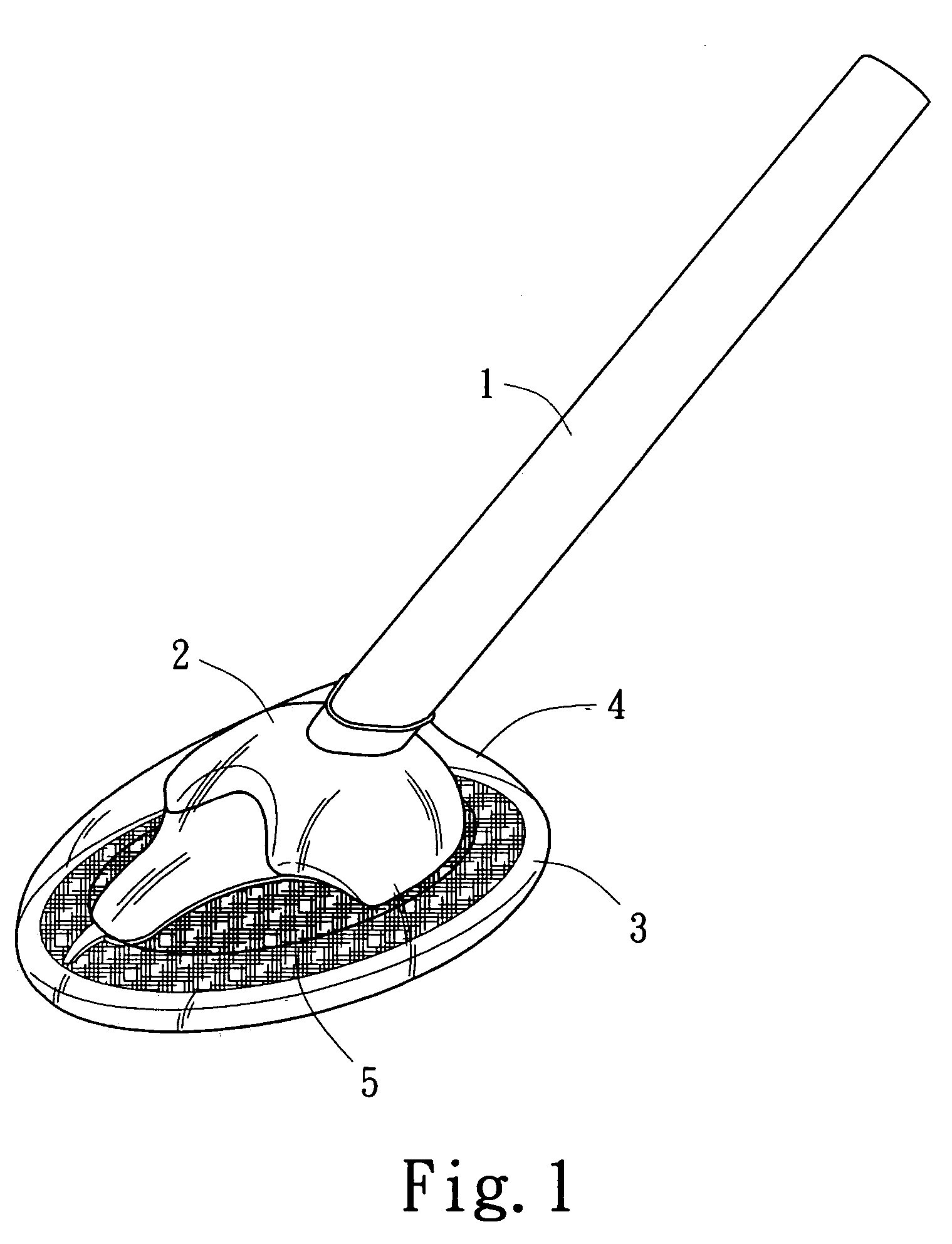

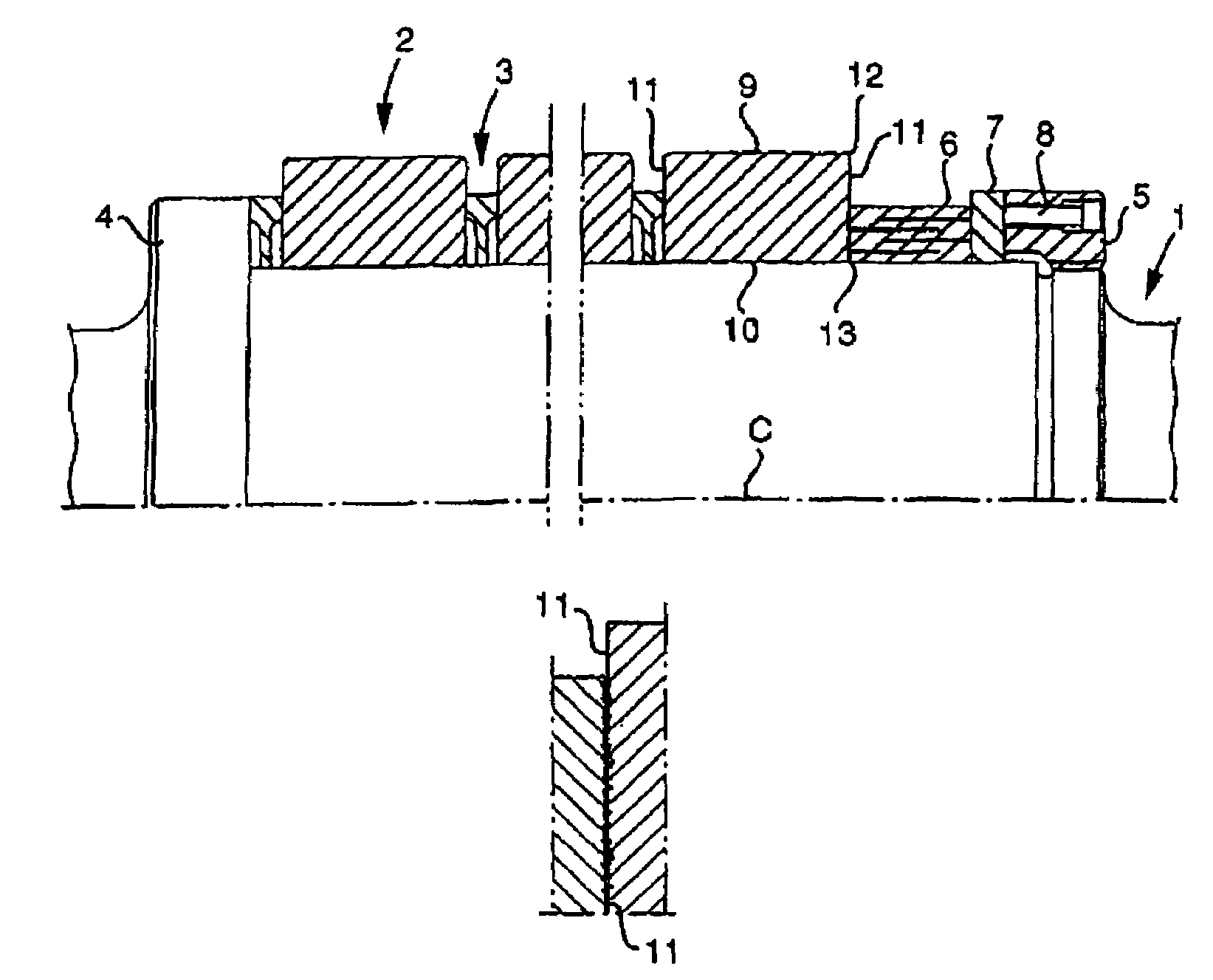

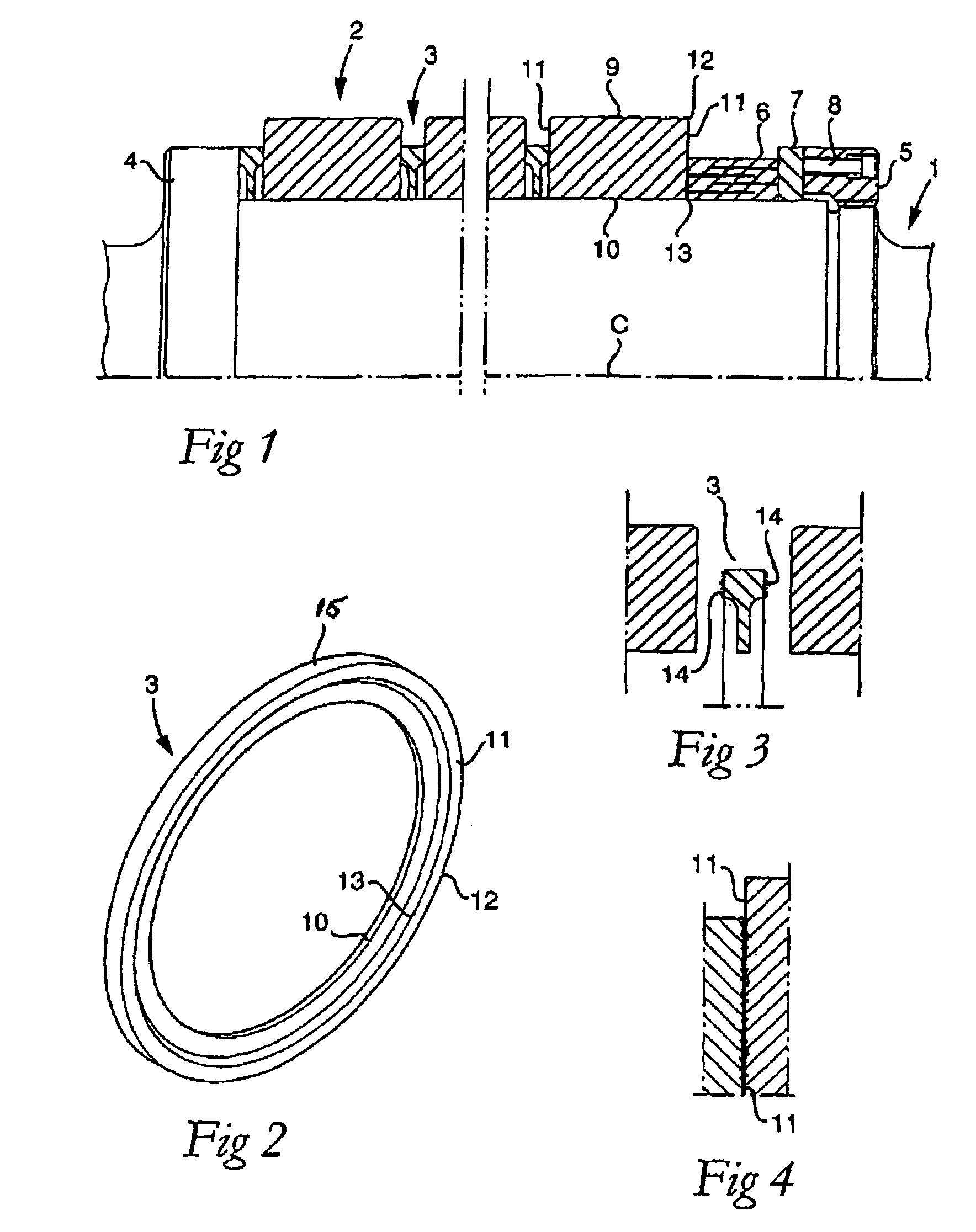

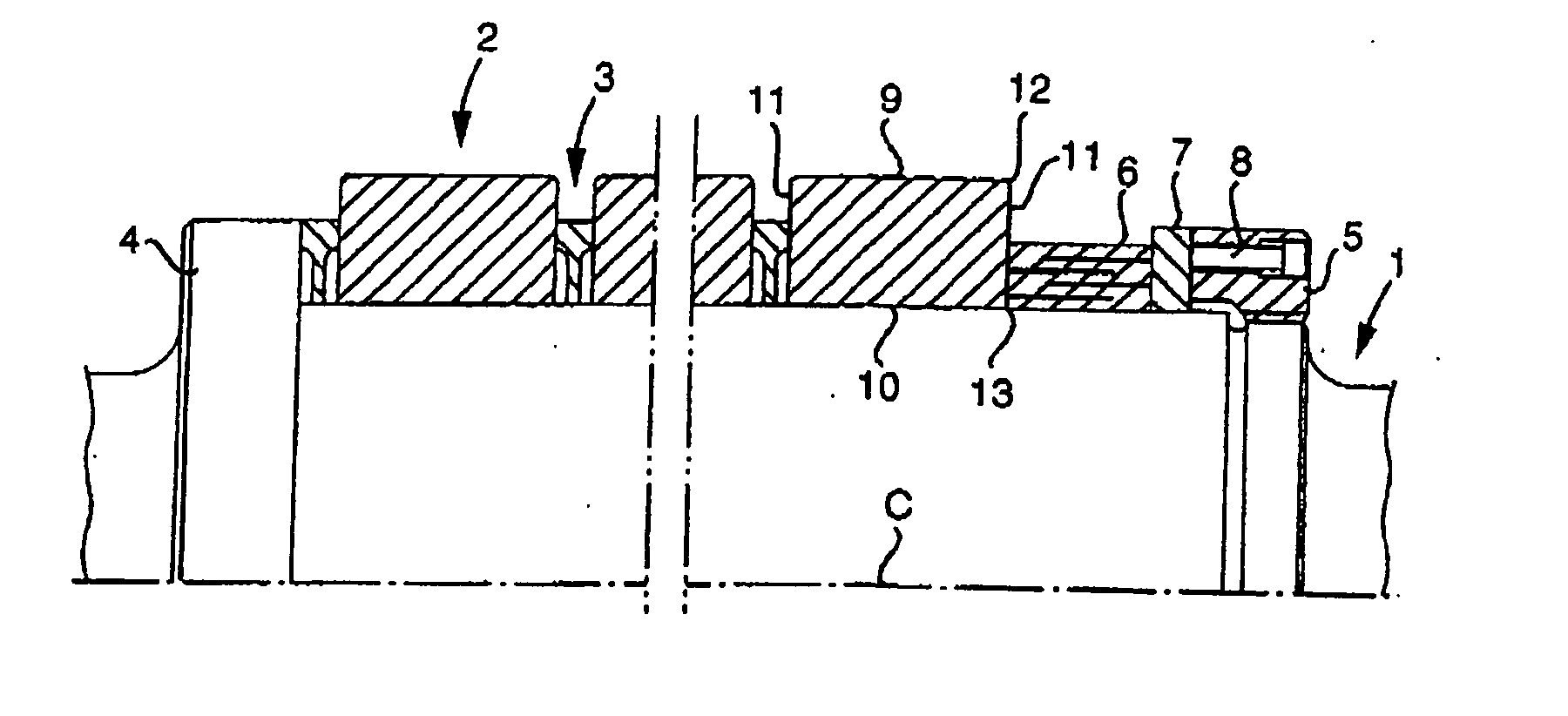

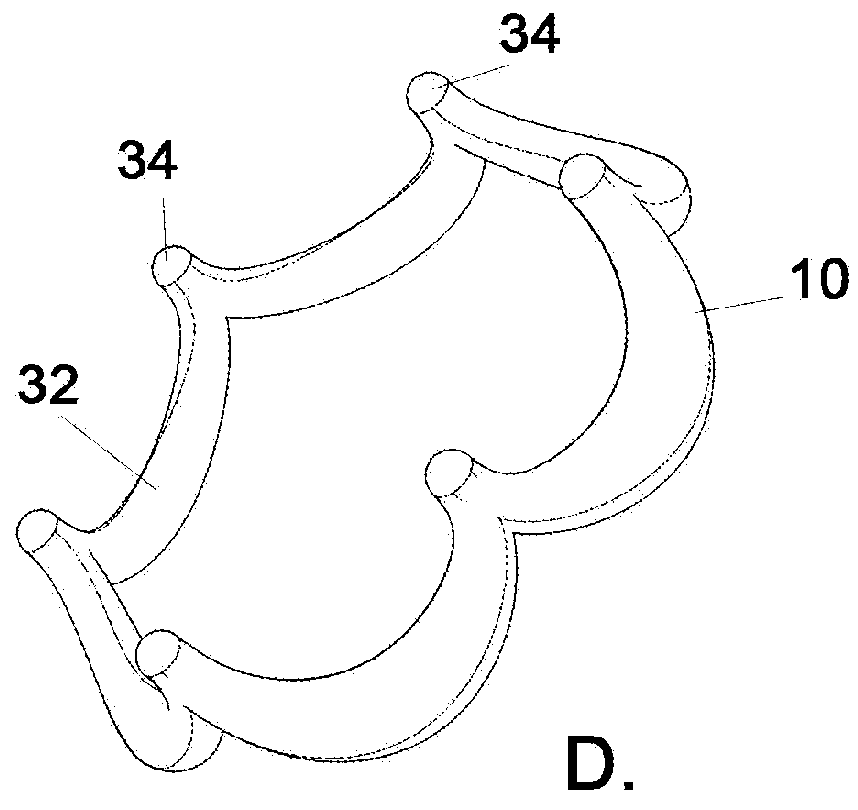

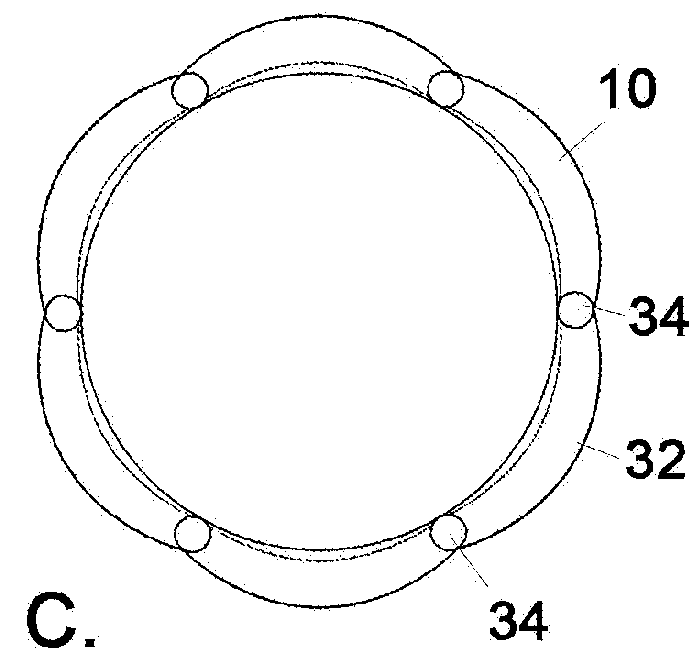

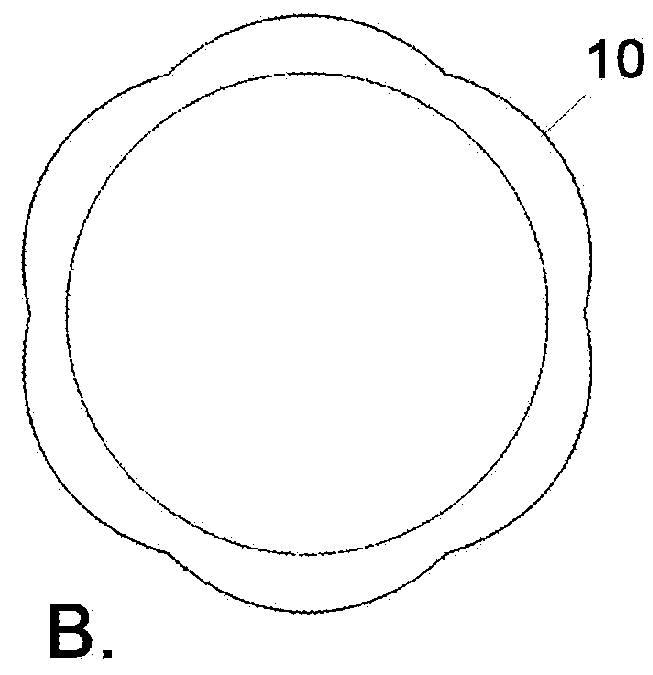

Laryngeal-mask construction

InactiveUS20060027238A1Simple elementsEasy to assembleTracheal tubesRespiratory masksHollow coreEngineering

A laryngeal-mask construction comprises a tube body, provided with an external expanding portion at its one end, wherein said external expanding portion has a shape like a cap with indentations at its front sides and is provided with a stud on its front end, while on the lower other end of said tube body, an extending tube end with a circular plate is formed by extending therefrom; a hollow annular resilient support, which is also supported by a horse-shoe shape fenestrated plate bridging between the said hollow annular resilient support and the groove in the extending tube provided for joining around said external expanding portion; a pliant elastomeric beret, being sticky and tensile, and used for enclosing said external expanding portion and said hollow annular resilient support to form integrally a laryngeal-mask construction that, after inserting into the oral cavity of a patient, can make the distal airway opening closer to the larynx of the patient for achieving an effective seal and lessening the risk of aspiration.

Owner:FUTURE TOP MEDICAL ENVIRONMENT TECHNIC

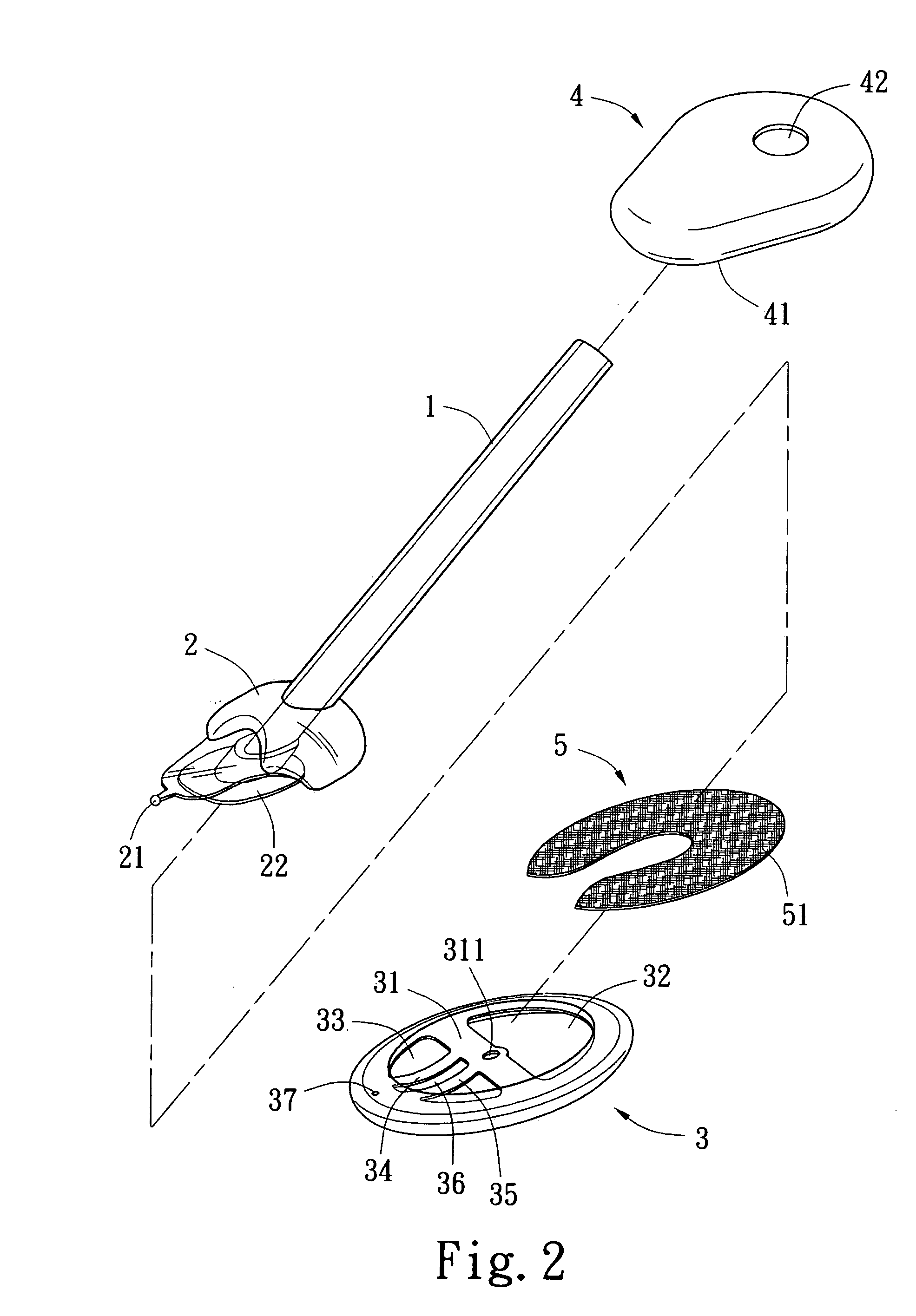

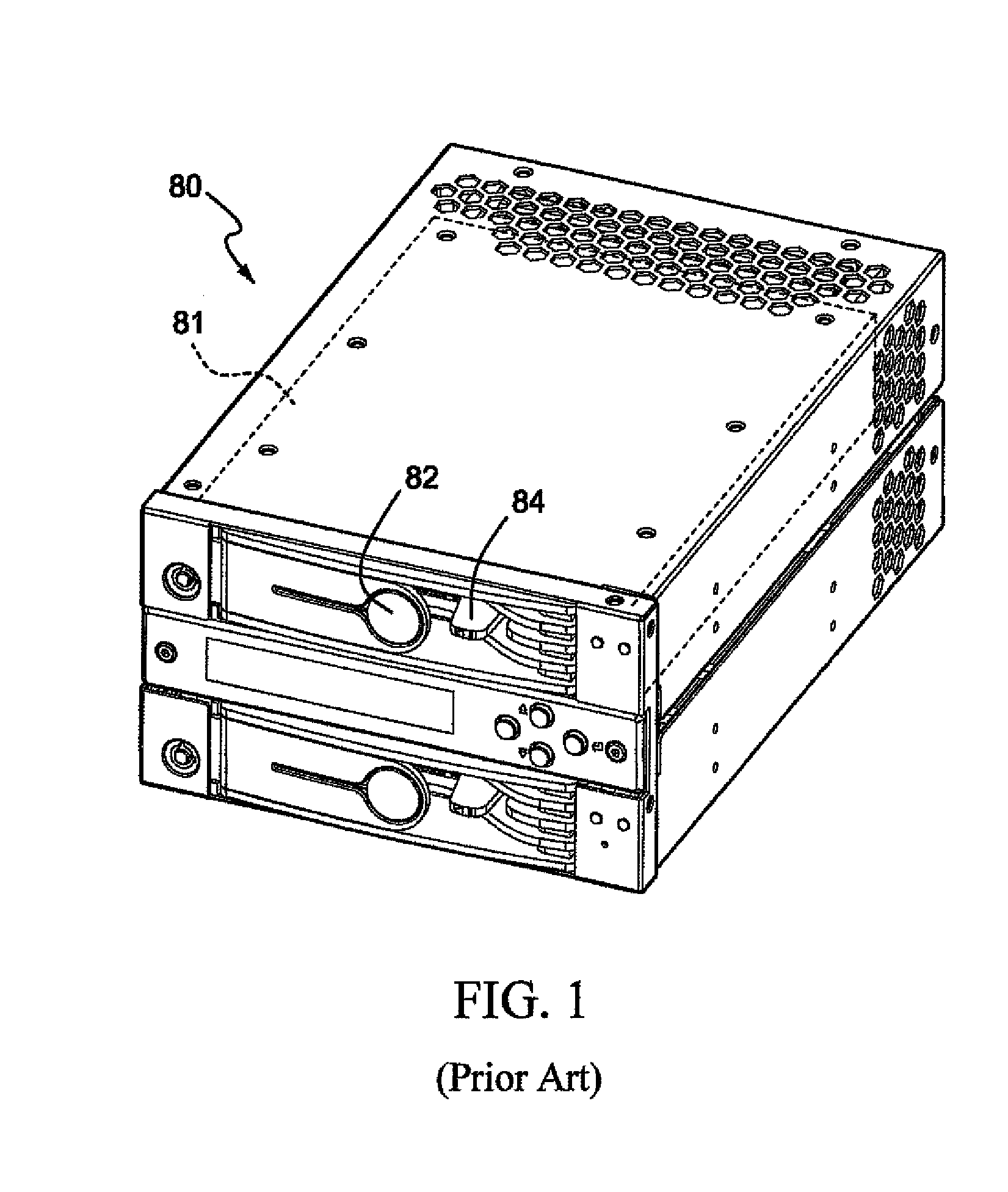

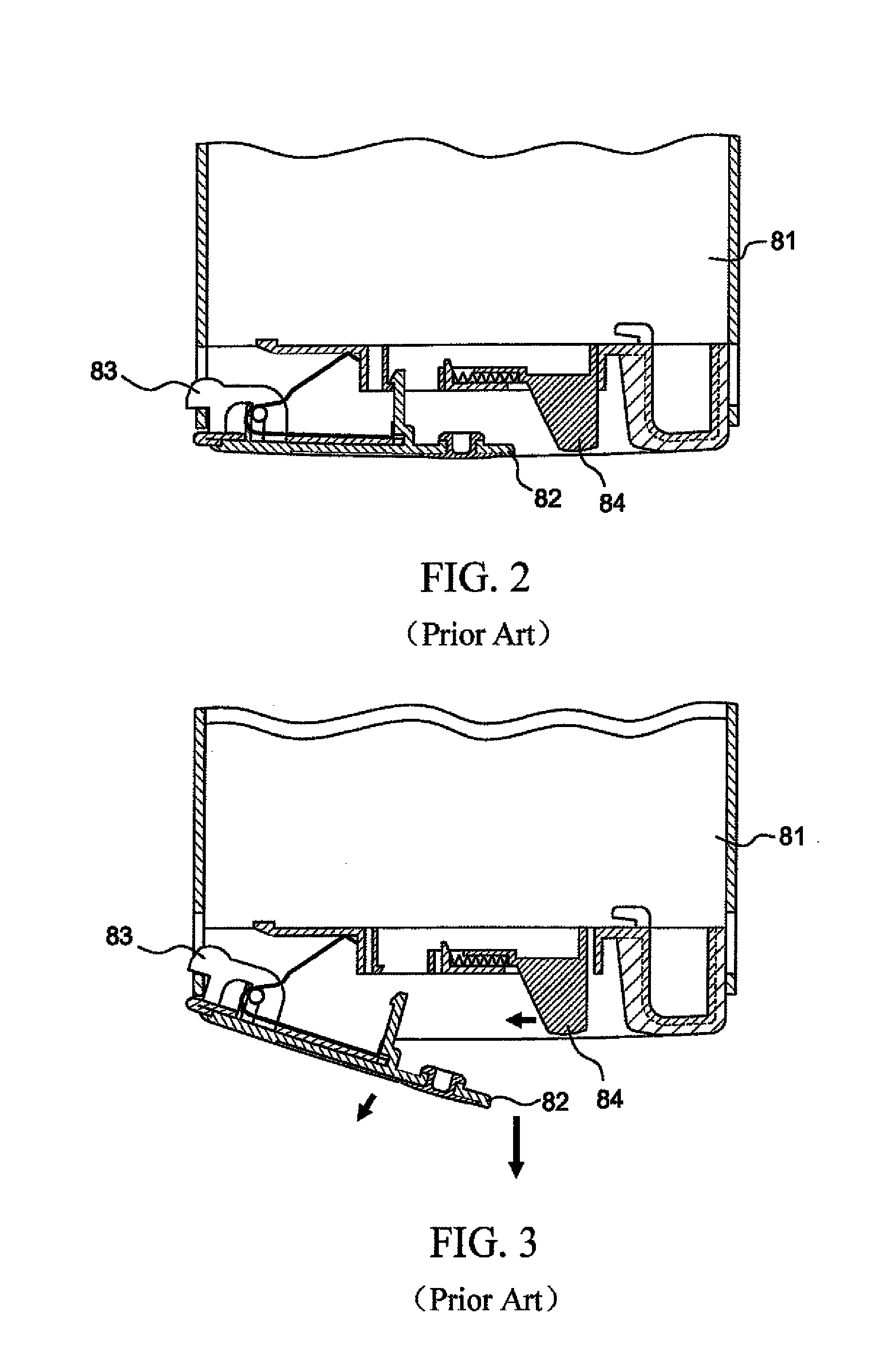

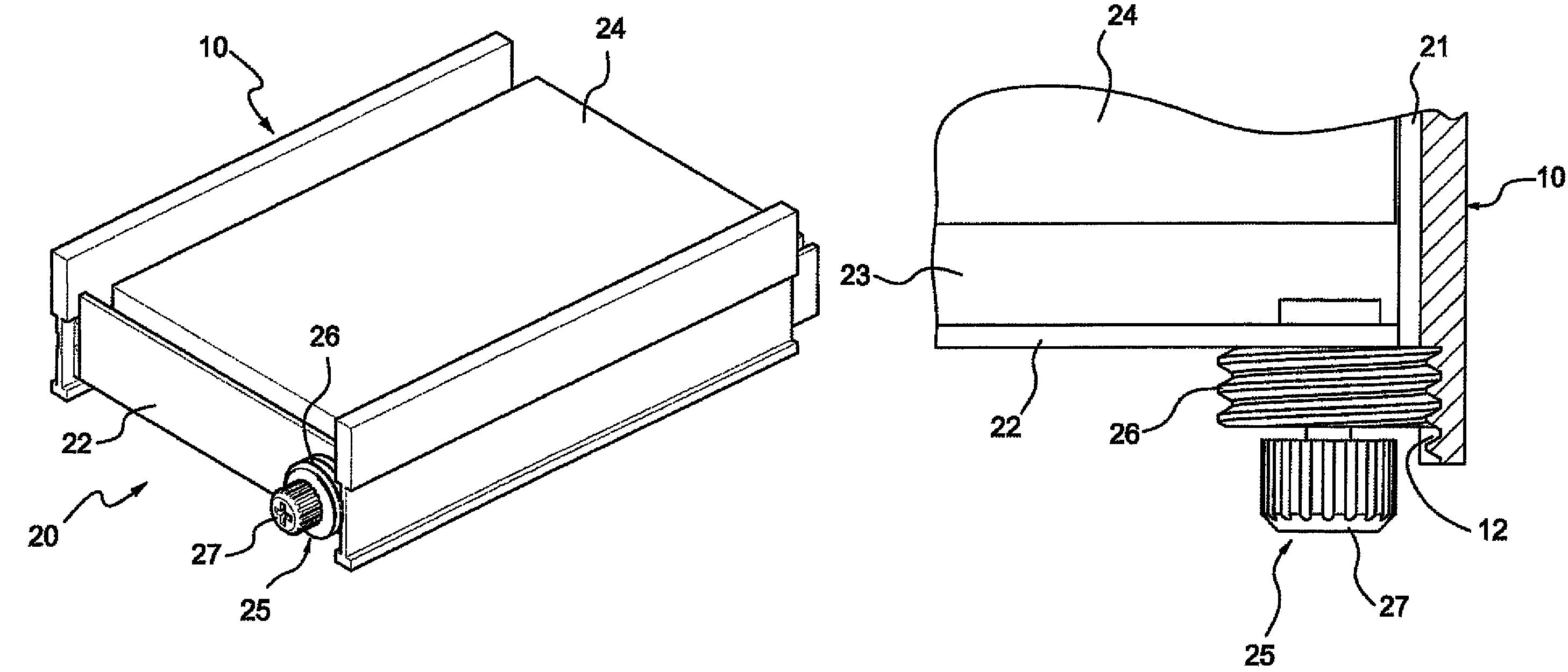

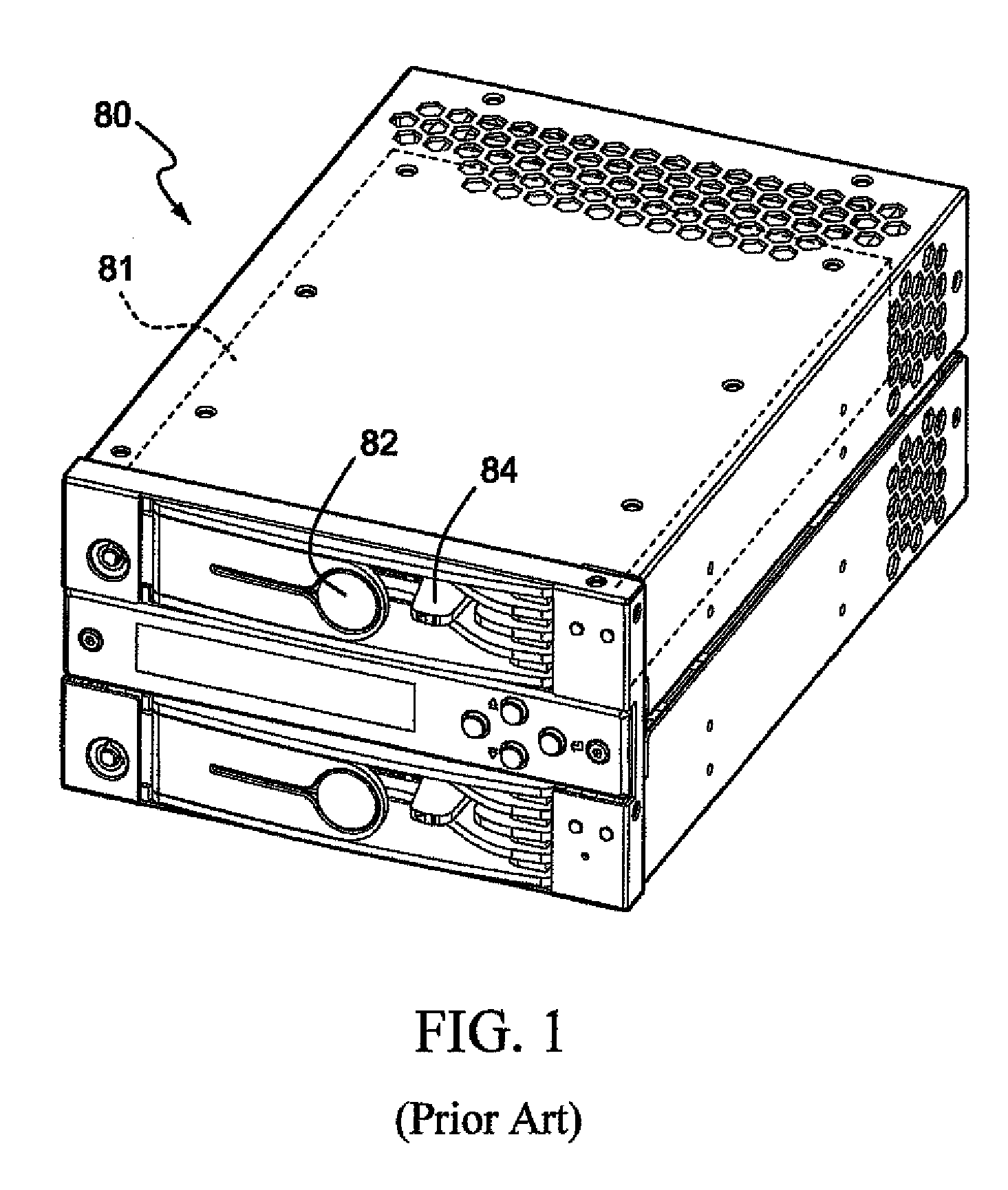

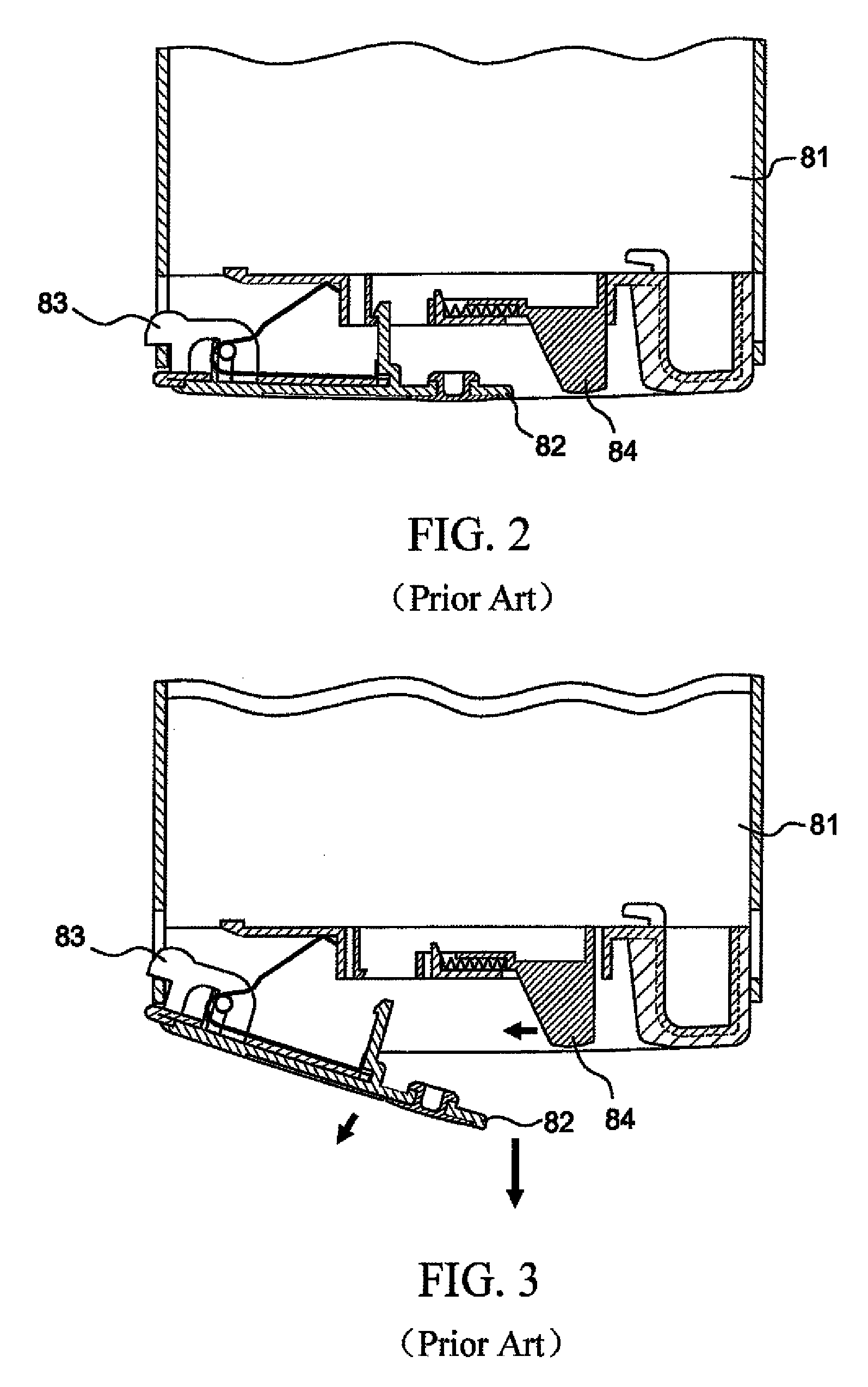

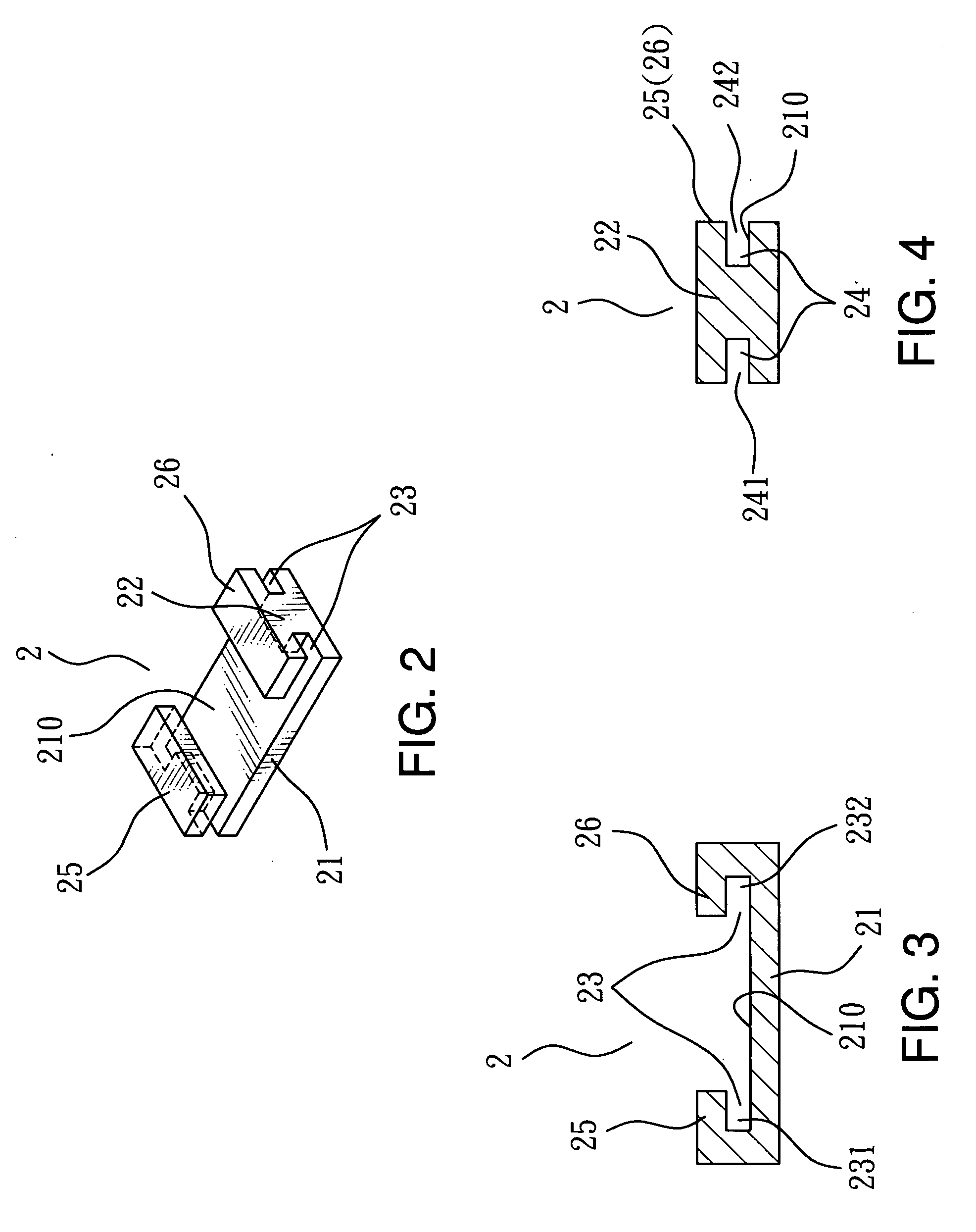

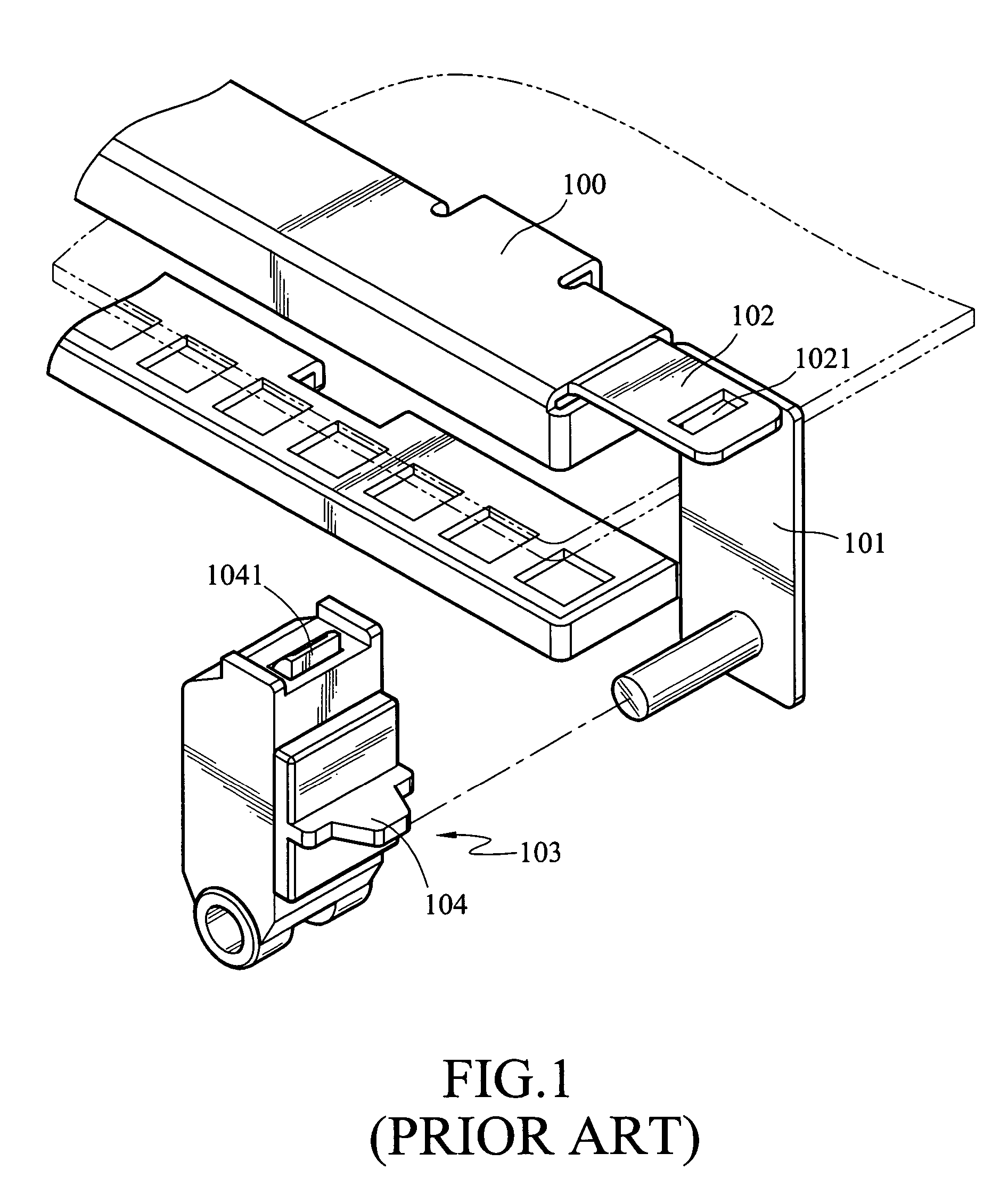

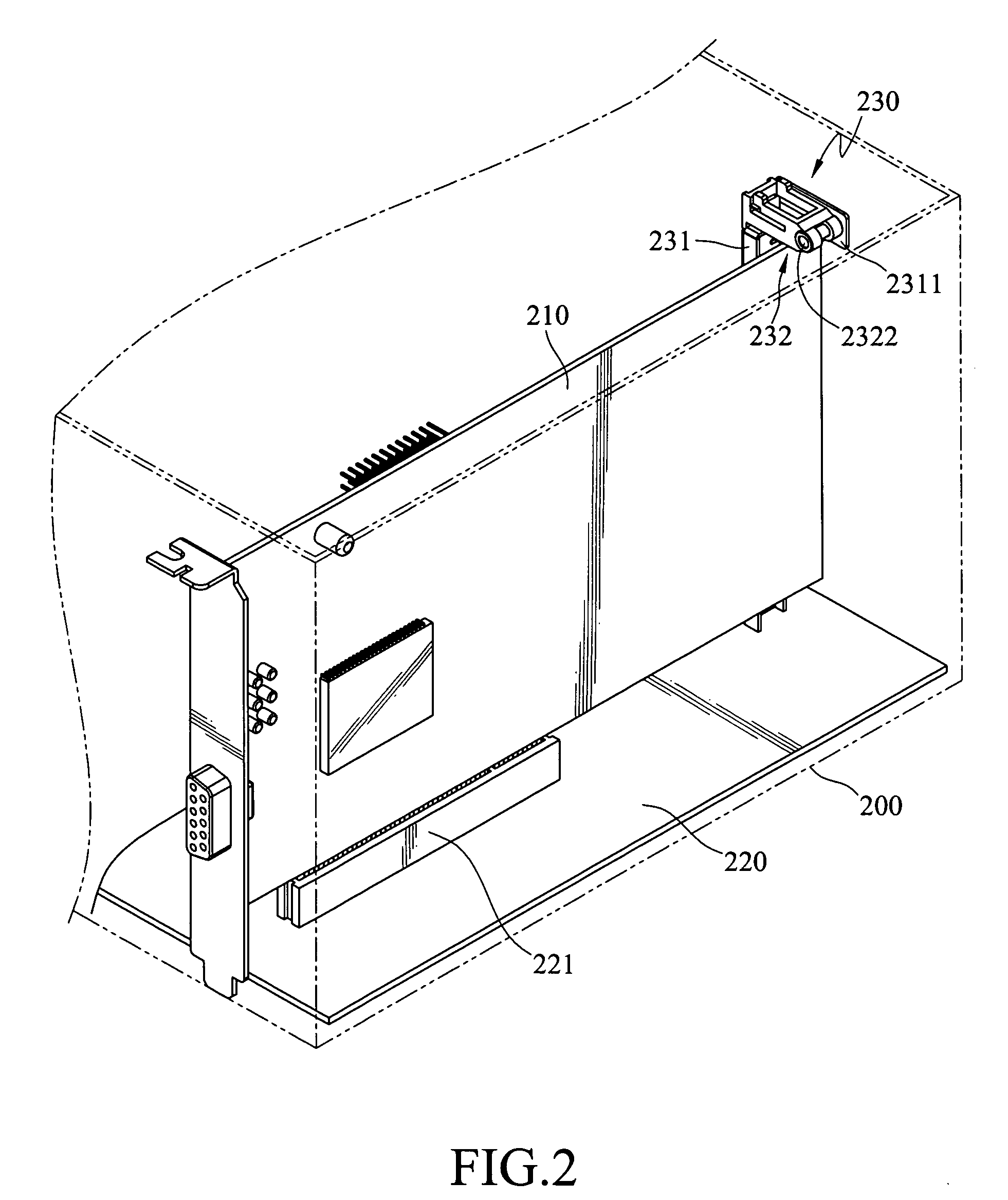

Removable hard disk module

InactiveUS20080298009A1Increase the use of spaceSimple elementsDigital data processing detailsFurniture partsComputer engineeringServer system

A removable hard disk module is provided which is mainly applicable to a server system. The removable hard disk module includes a server rack and a hard disk removable enclosure which is detachable form the server rack. The server rack has at least one pair of accommodation slots with threads formed on an inner wall thereof. The hard disk removable enclosure defines a space to accommodate a hard disk and has a threaded engagement portion disposed therein corresponding to the threads. When the hard disk removable enclosure is inserted into the accommodation slots, the threaded engagement portion is contacted with the threads, and the hard disk removable enclosure is moved alone to the threads through the threaded engagement portion, thereby the hard disk removable enclosure is moved into and fixed within the accommodation slots of the server rack.

Owner:ACARD TECH CORP

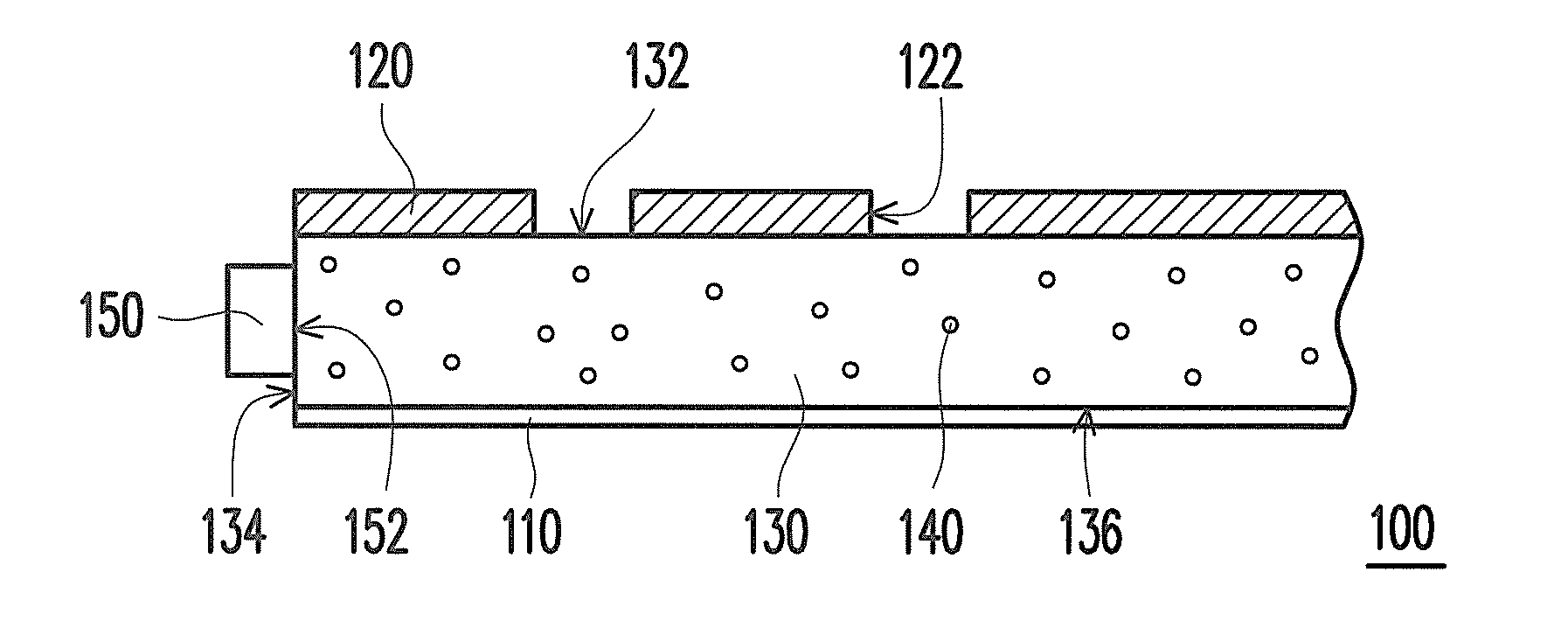

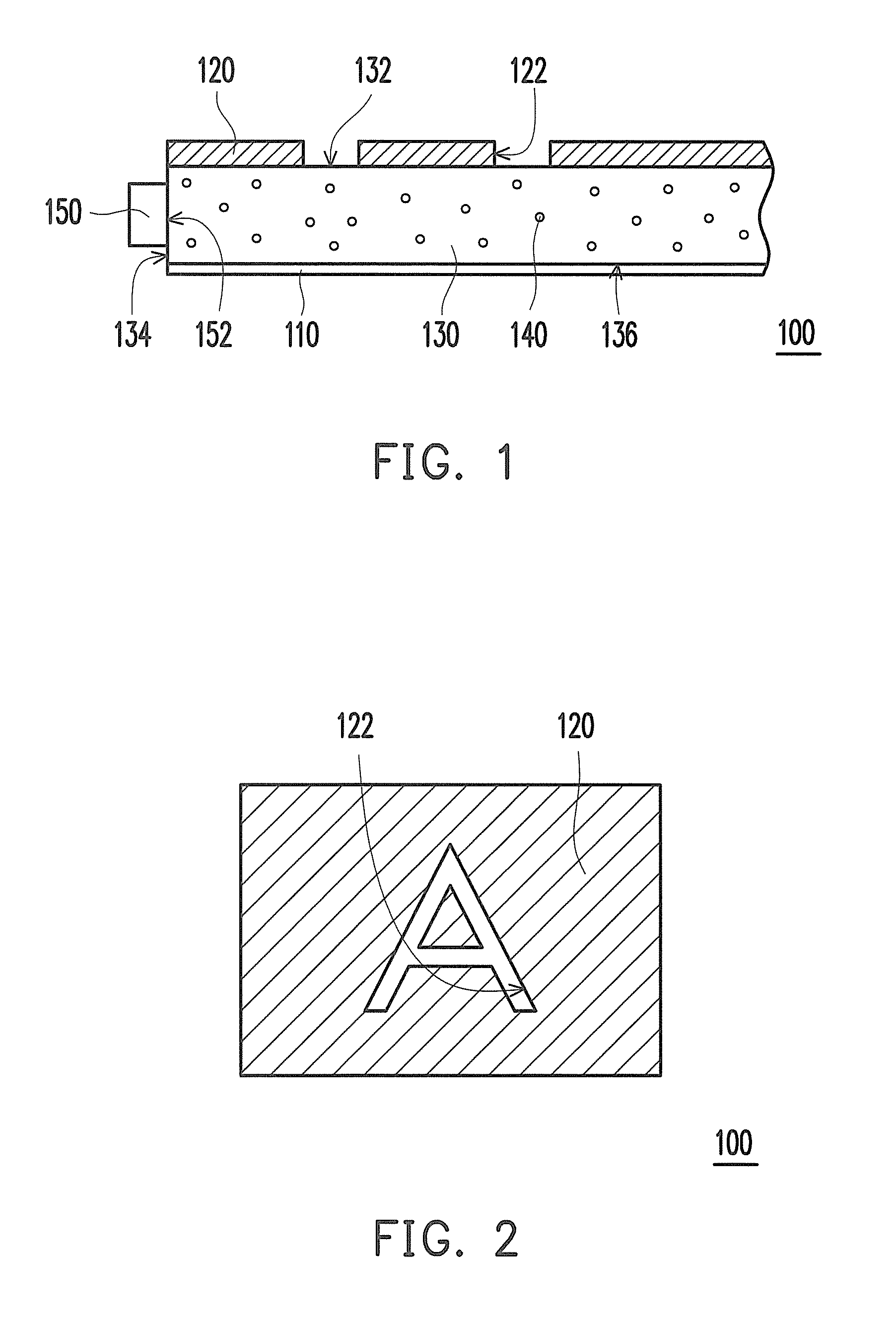

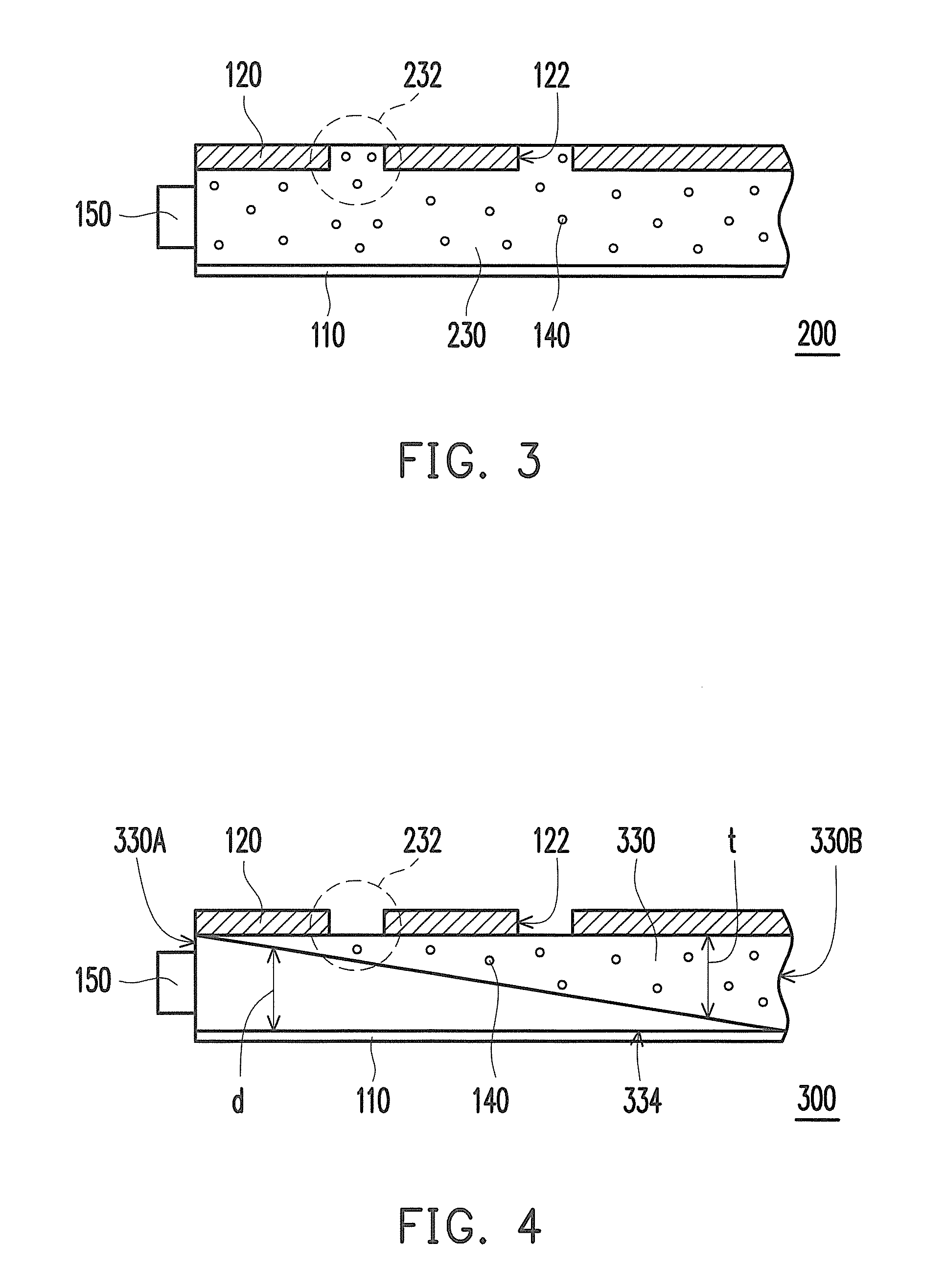

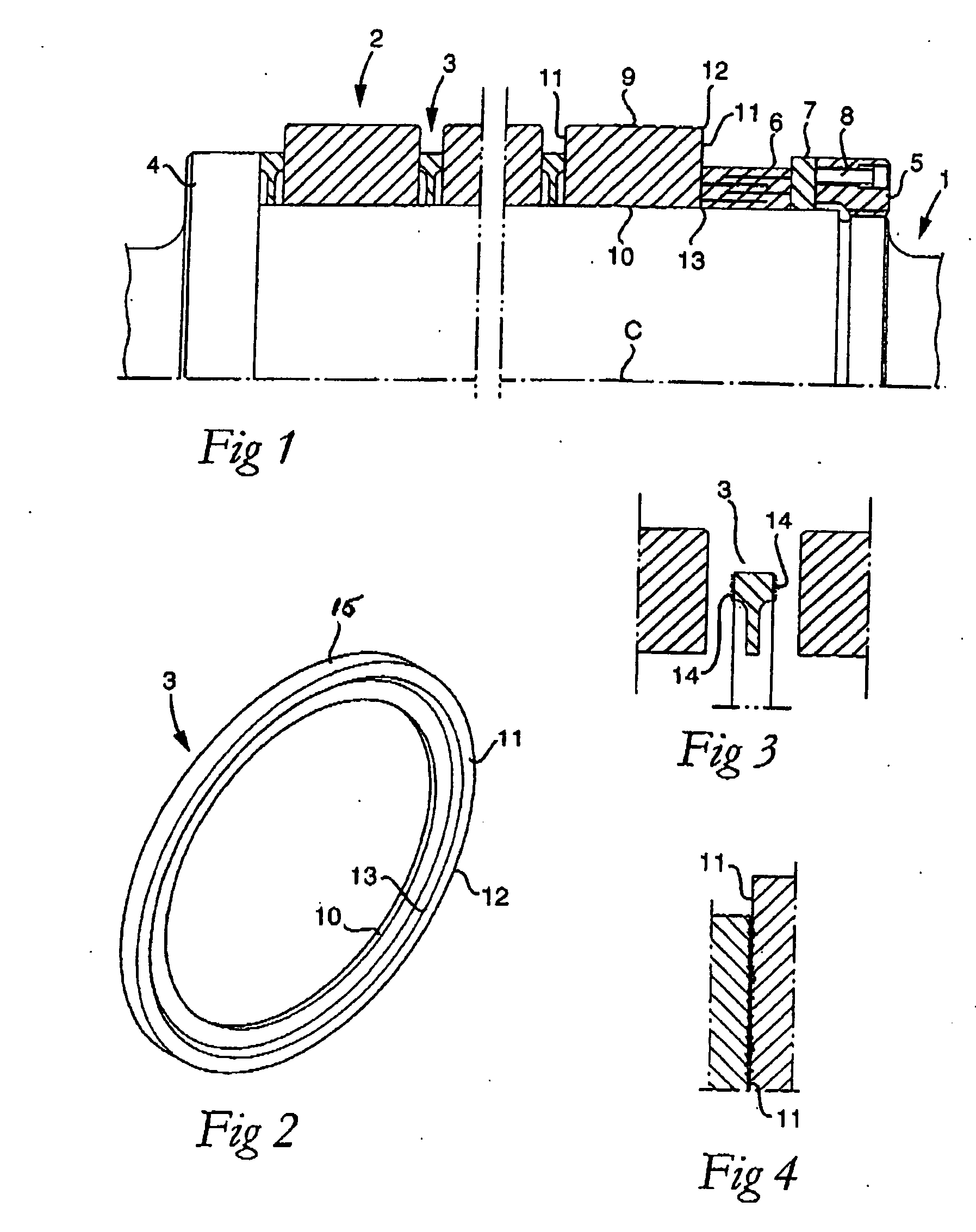

Decoration panel

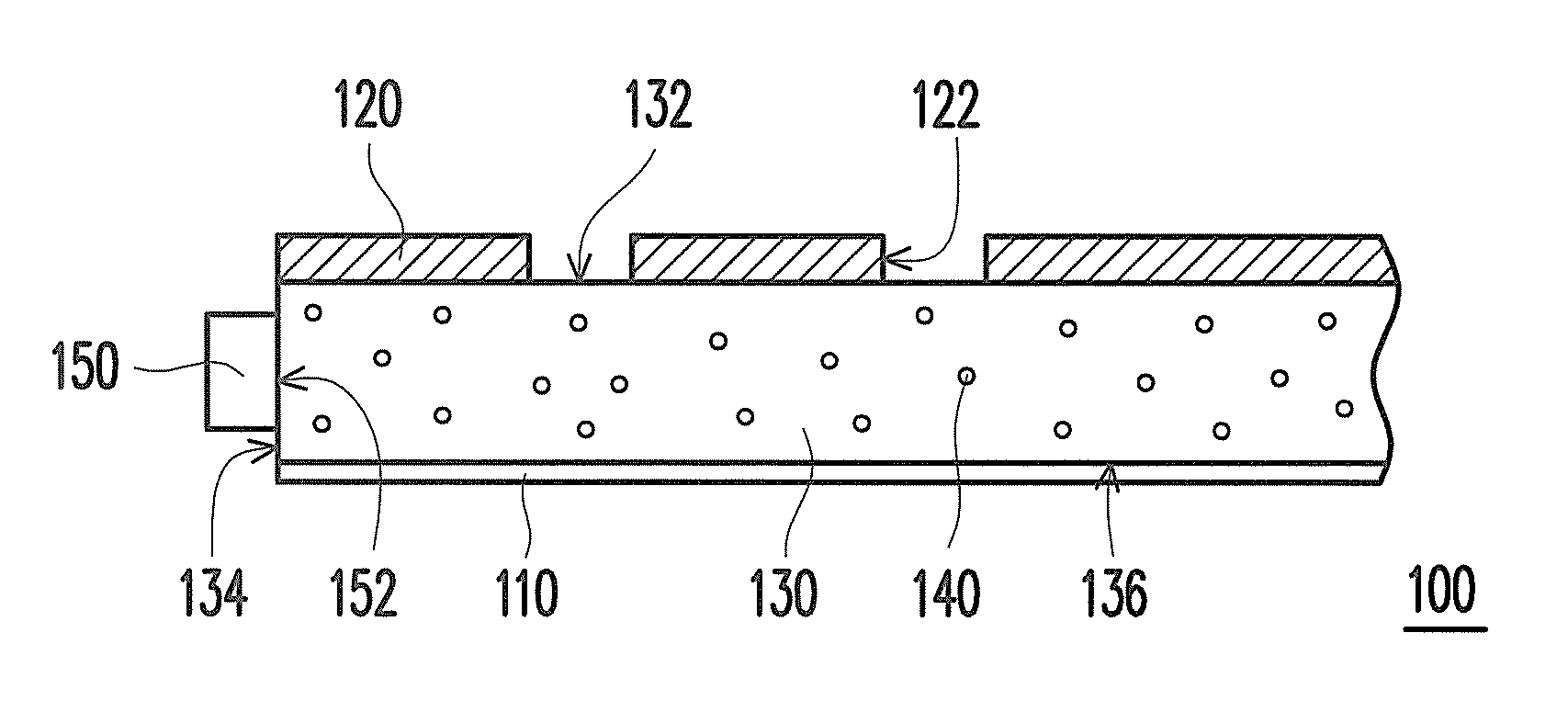

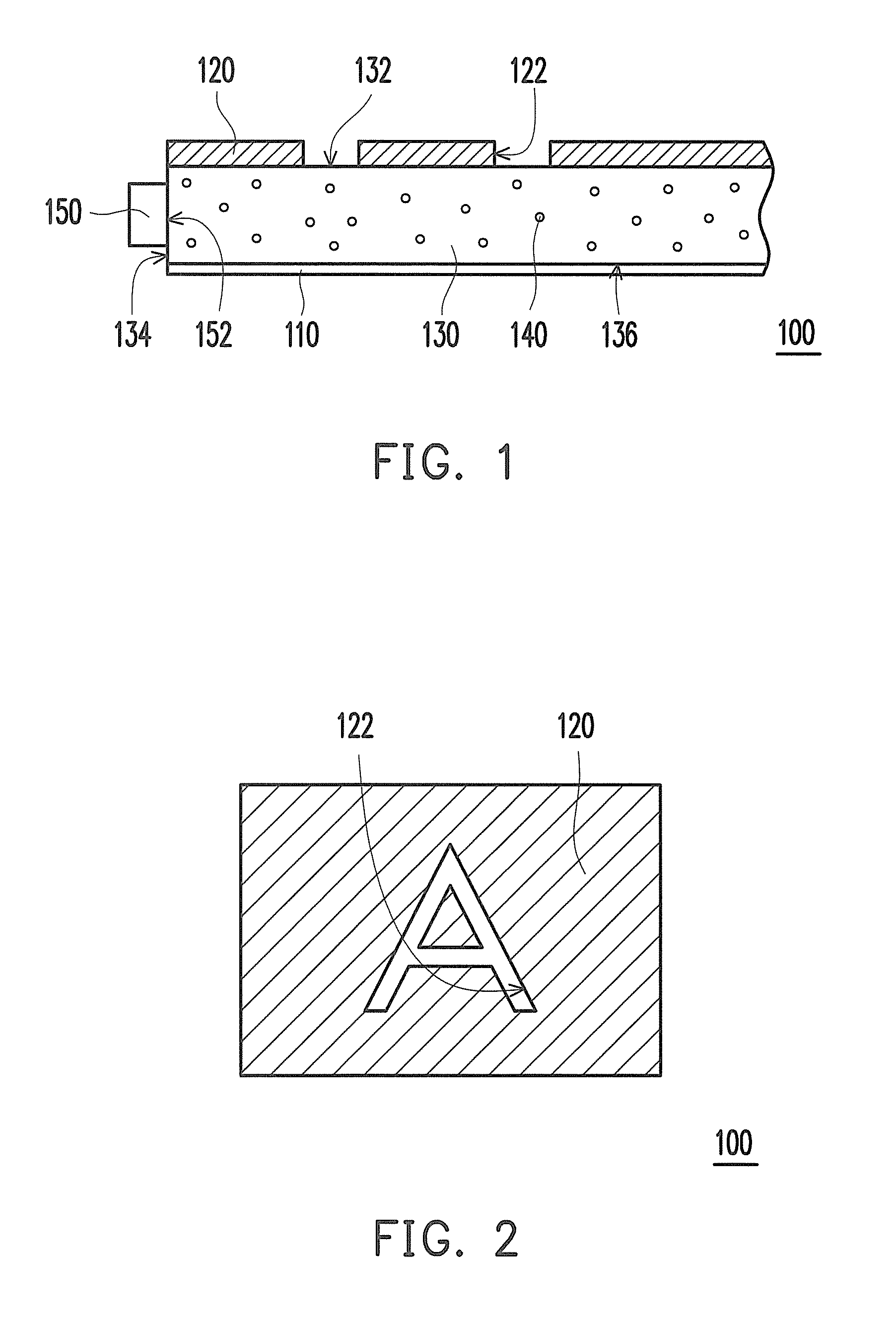

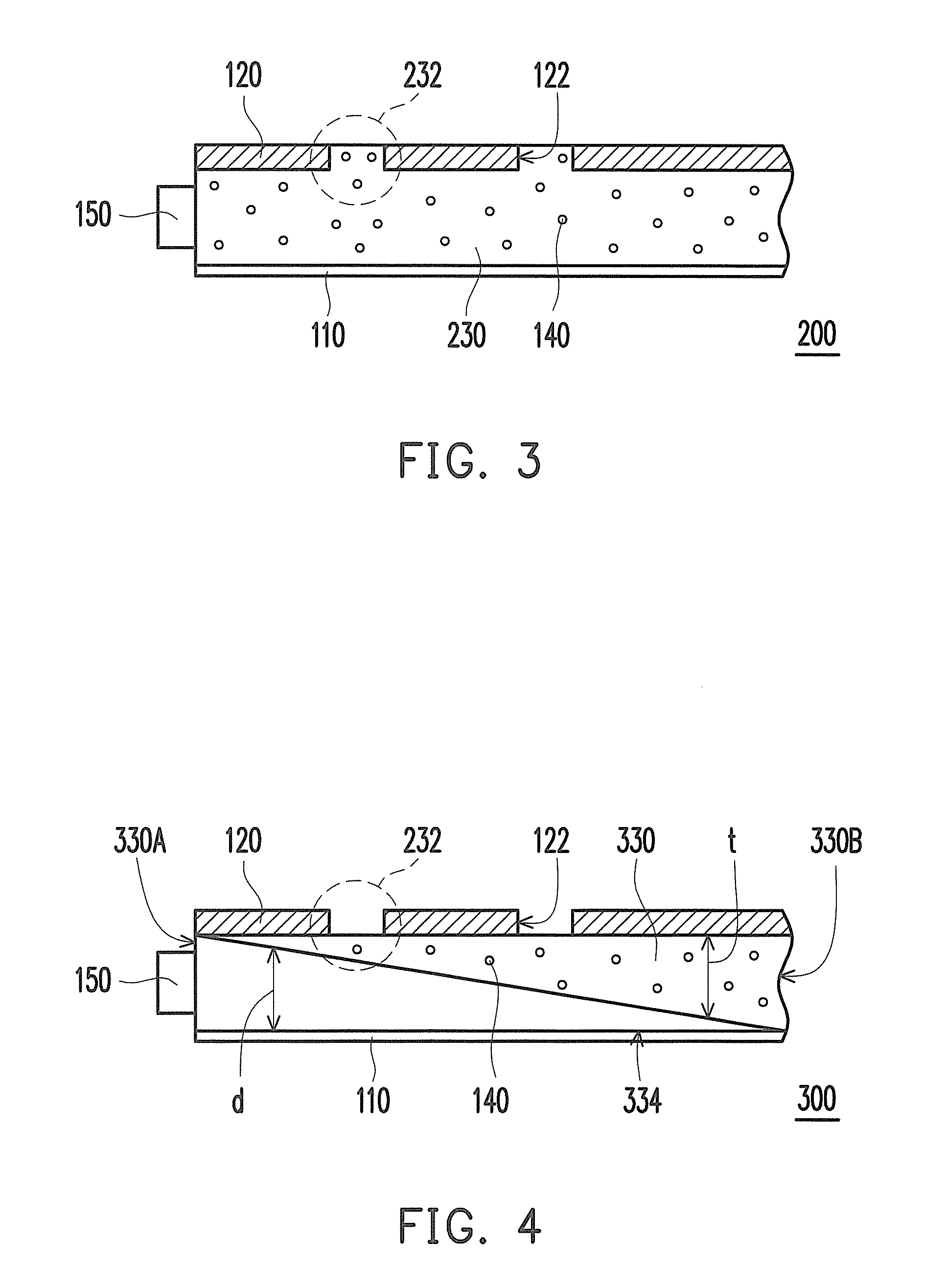

ActiveUS20110194305A1Simple elementsOverall small sizePlanar/plate-like light guidesIlluminated signsLight guideReflective layer

A light guide module capable of illuminating and being applied in a device for decoration is provided. The light guide module includes a reflective layer, a light guide with a plurality of diffusing particles, and a light source. The light guide has a side surface, a reflective surface and a light-exiting surface, thereby allowing a light from the light source to enter and reflect and exit the light guide respectively. The reflective layer is disposed on the reflective surface of the light guide for reflecting the light to the light-exiting surface. The light guide forms a portion of an outer surface of the device.

Owner:COMPAL ELECTRONICS INC

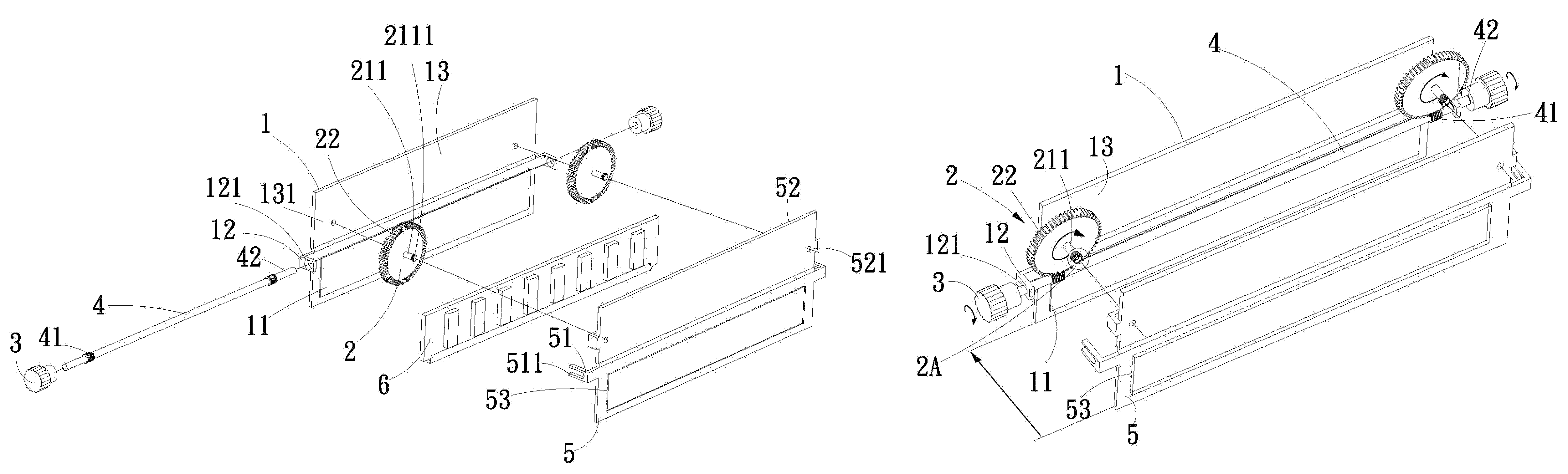

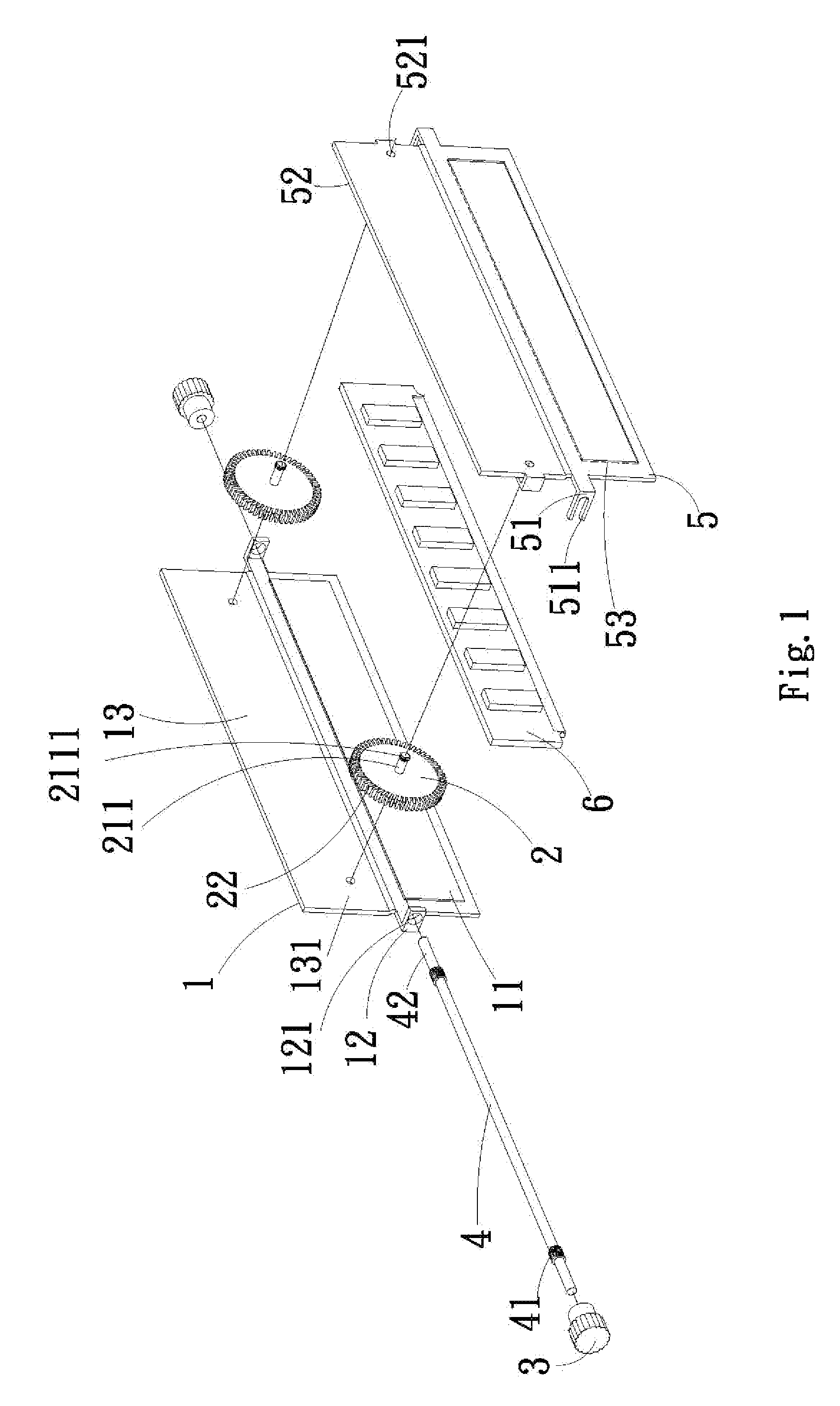

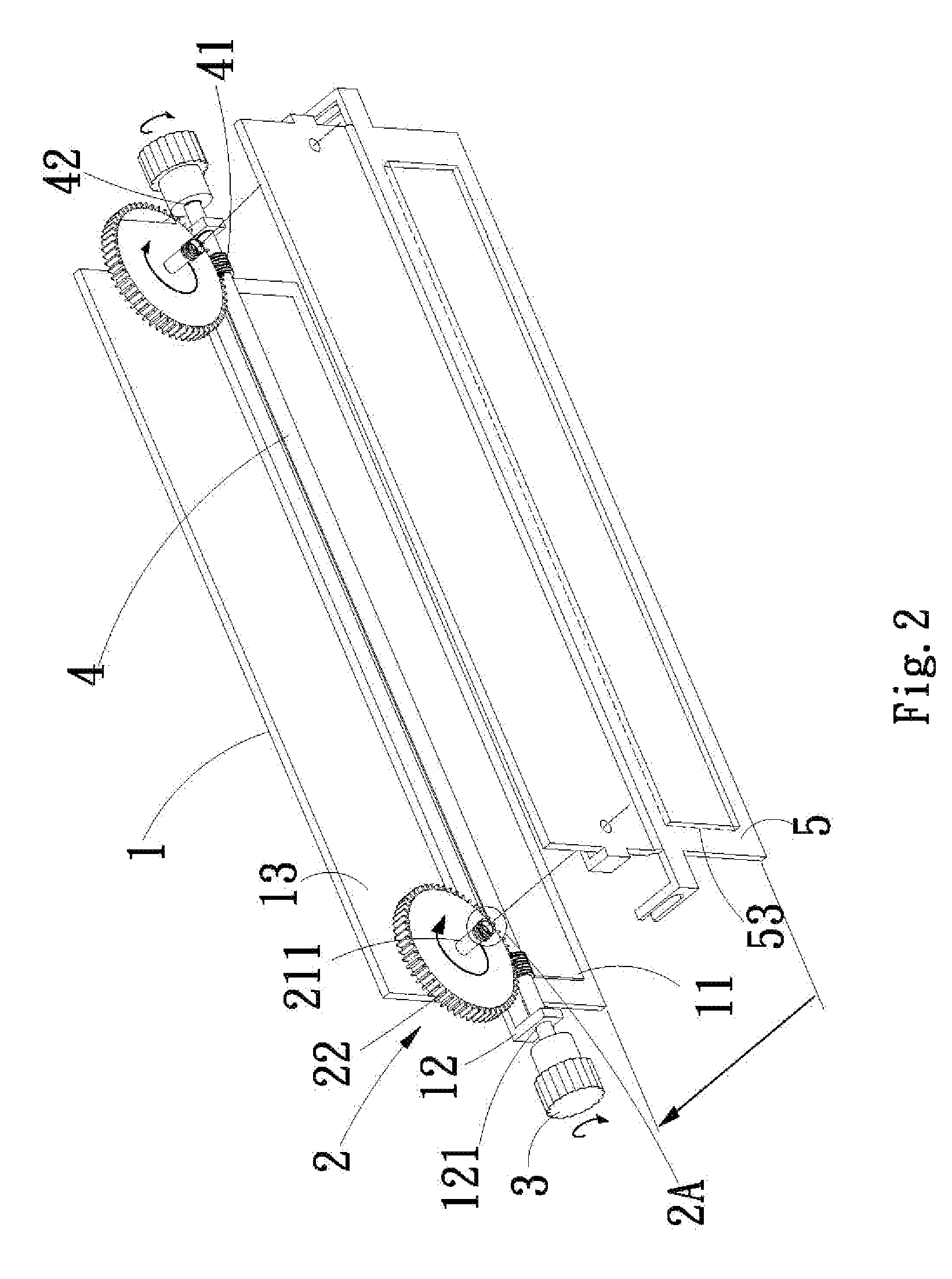

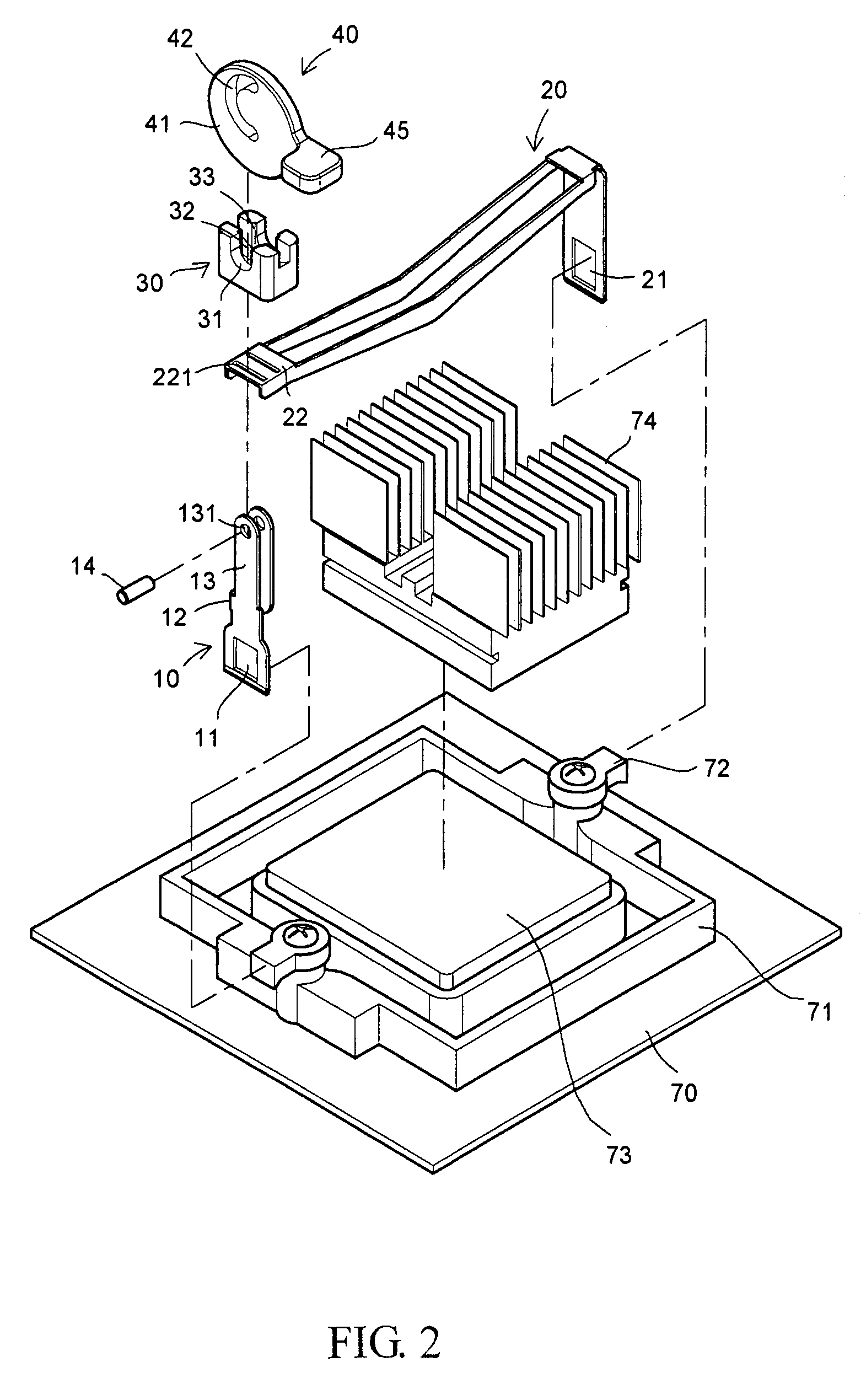

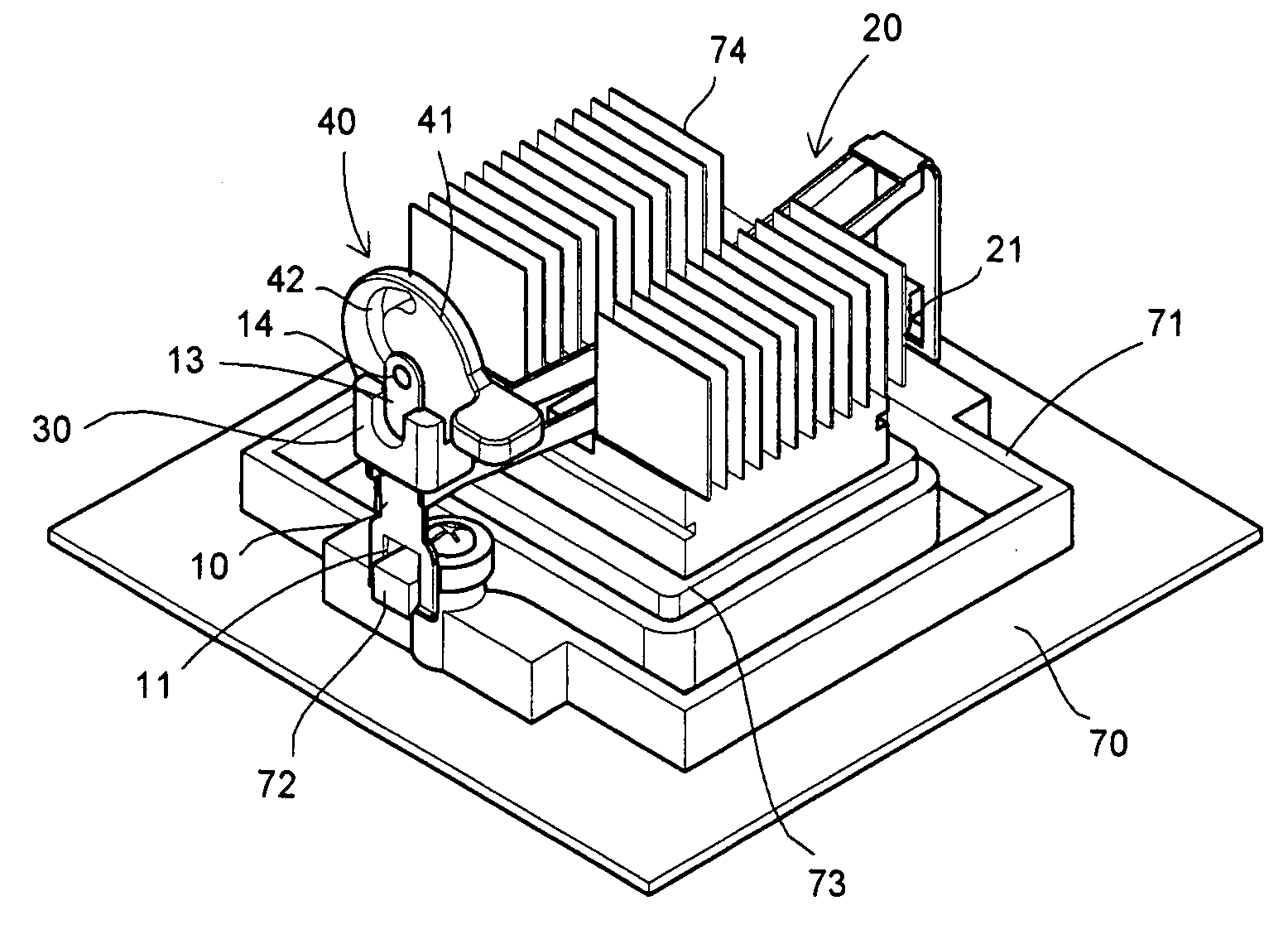

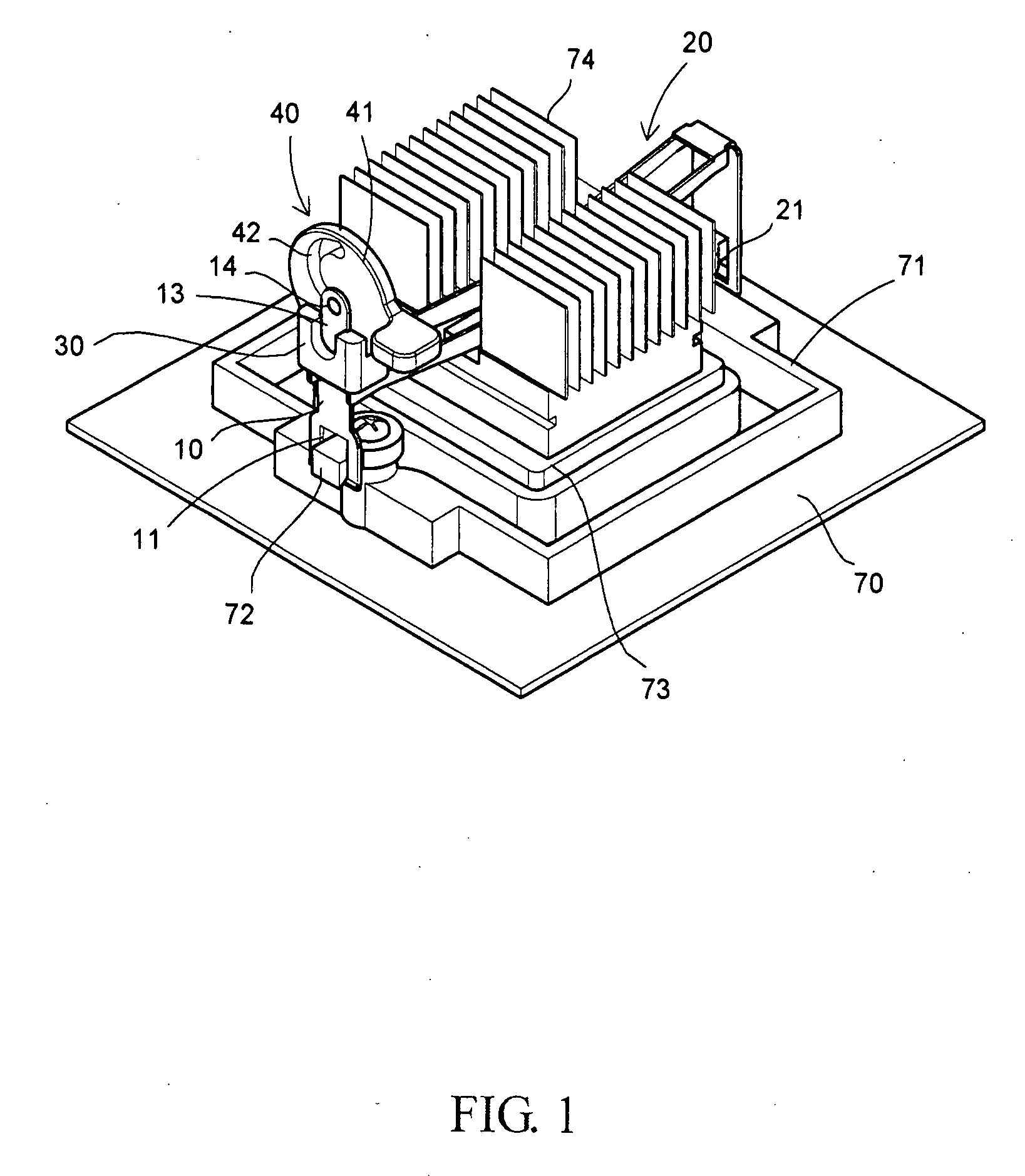

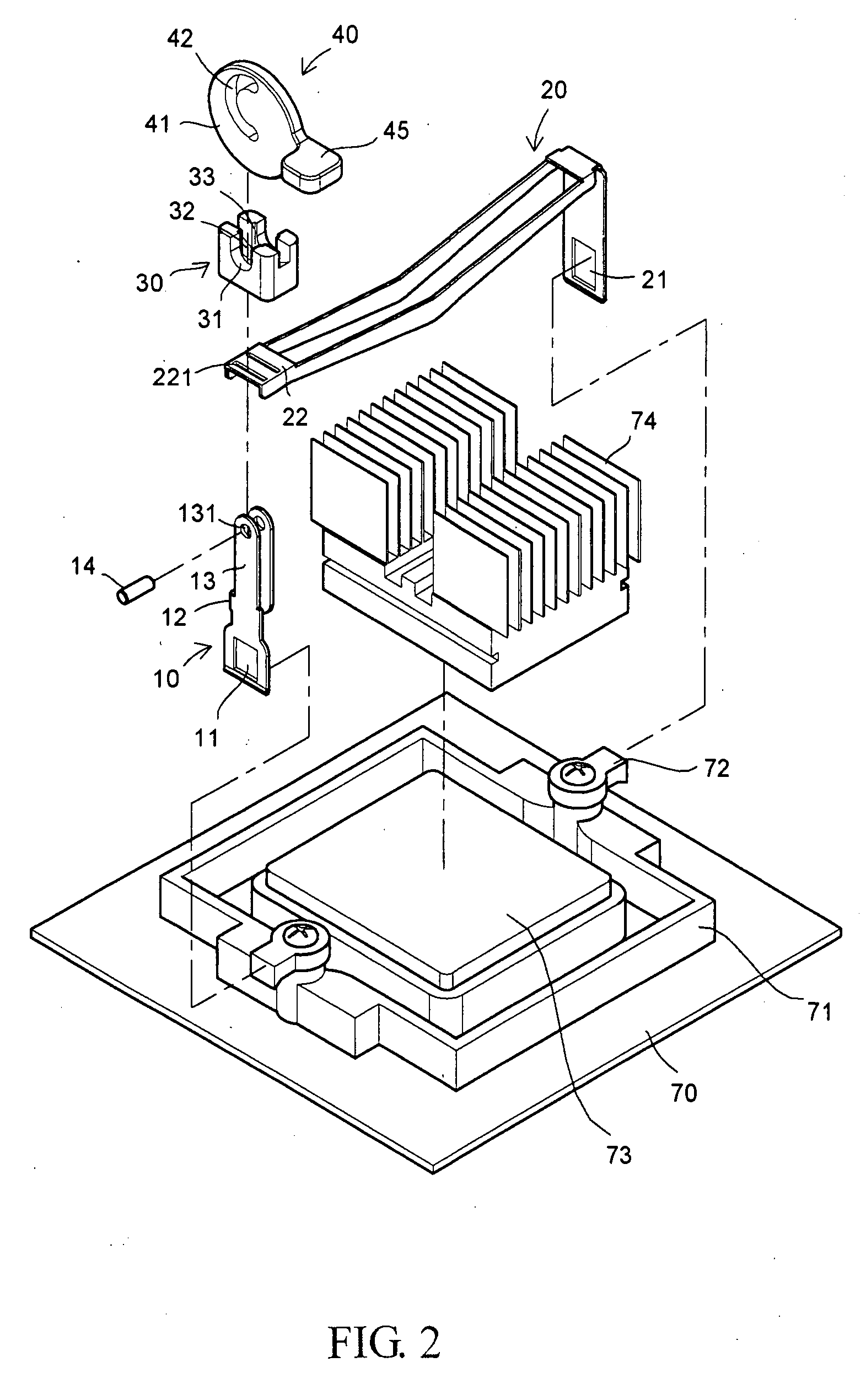

Heat sink mechanism

InactiveUS7600557B2Easily to dismountedSimple elementsControlling membersControlled membersEngineeringScrew thread

A heat sink mechanism includes a fixed and a movable clamping piece, at least one adjusting gearwheel rotatably mounted to and between the fixed and the movable clamping piece via a fixing shaft while an end of the fixing shaft is screwed to the movable clamping piece, and an adjusting worm shaft rotatably mounted to the fixed clamping piece for driving the adjusting gearwheel to rotate via meshed worm threads on the worm shaft and gear teeth on the adjusting gearwheel. When the adjusting worm shaft is rotated, the meshed worm threads and gear teeth bring the adjusting gearwheel and the fixing shaft thereof to rotate, so that the movable clamping piece screwed to the rotating fixing shaft is brought to move toward or away from the fixed clamping piece to thereby fix the heat sink mechanism to a heat-producing source to achieve the purpose of heat dissipation.

Owner:ASIA VITAL COMPONENTS SHENZHEN CO LTD

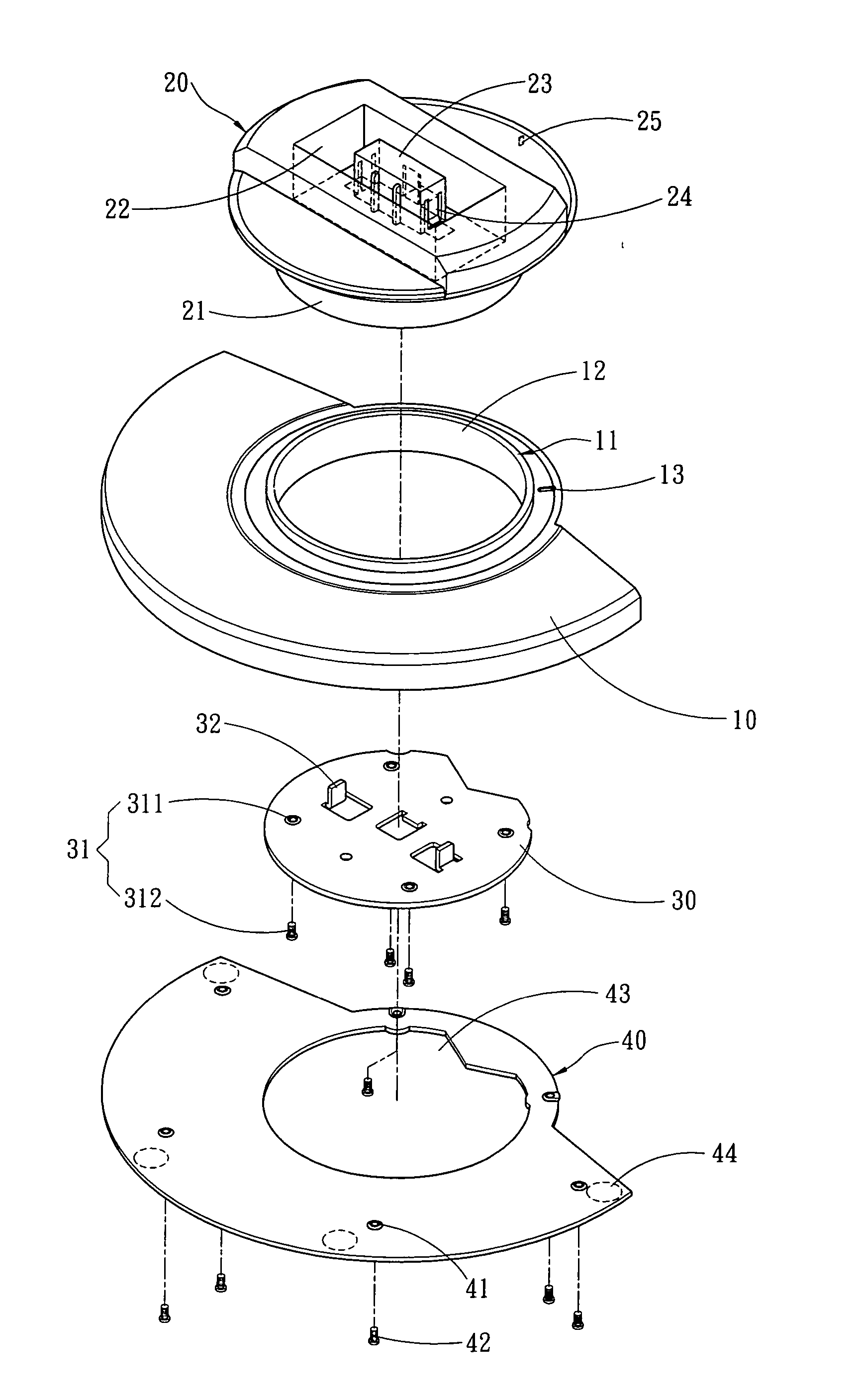

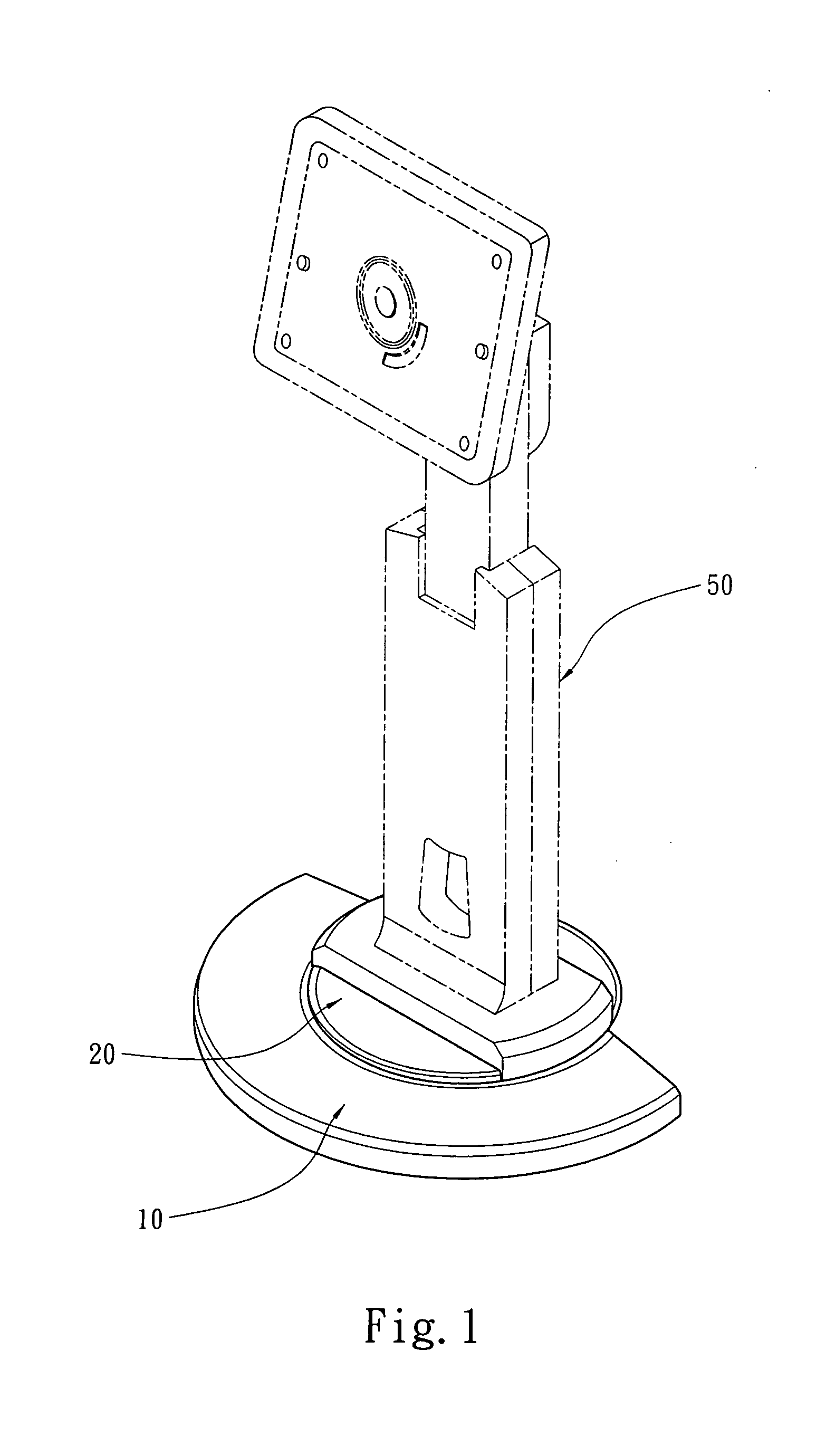

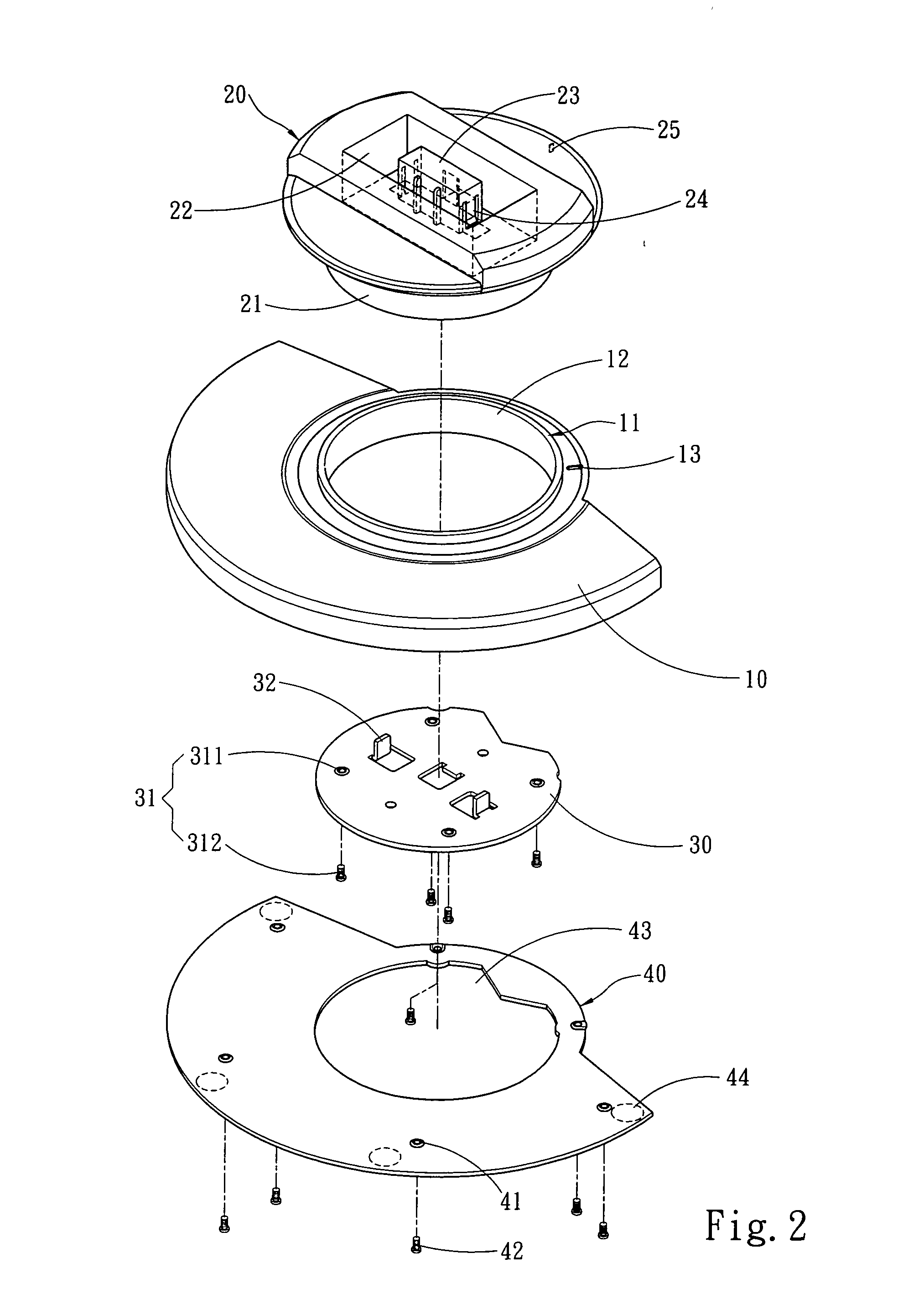

Rotary structure for display base docks

InactiveUS20070221798A1Save material consumptionLow production costDigital data processing detailsStands/trestlesCouplingDisplay device

A rotary structure for display base docks includes a bracing seat which has a confining zone and an opening on the confining zone, a rotary dock on one end of the opening that has a coupling portion corresponding to the opening and a confining plate on the other end of the opening. The confining plate has an anchor member to be fastened to the coupling portion. The confining plate is in contact with the rim of the opening to form a confining relationship between the rotary dock and the bracing seat. The coupling portion generates a swivel displacement relative to the bracing seat when the rotary dock is subject to a force. The invention contains fewer elements, can be fabricated and assembled easier, and is steadier.

Owner:TAIWAN THICK FILM IND

Roll

InactiveUS7572215B2Powerful and efficient friction jointIncrease frictionShaft and bearingsRollsEngineeringMechanical engineering

Owner:SANDVIK INTELLECTUAL PROPERTY AB

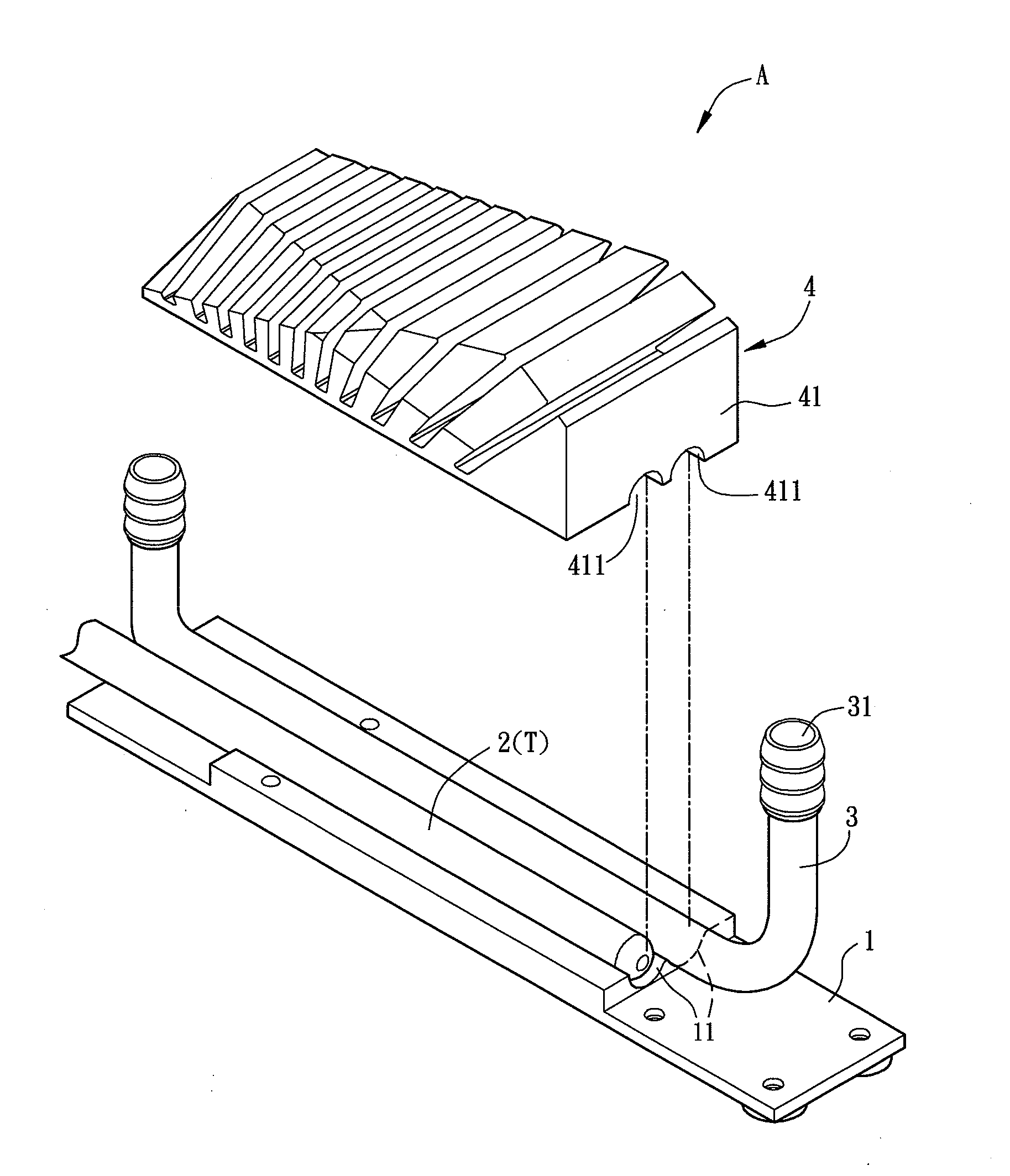

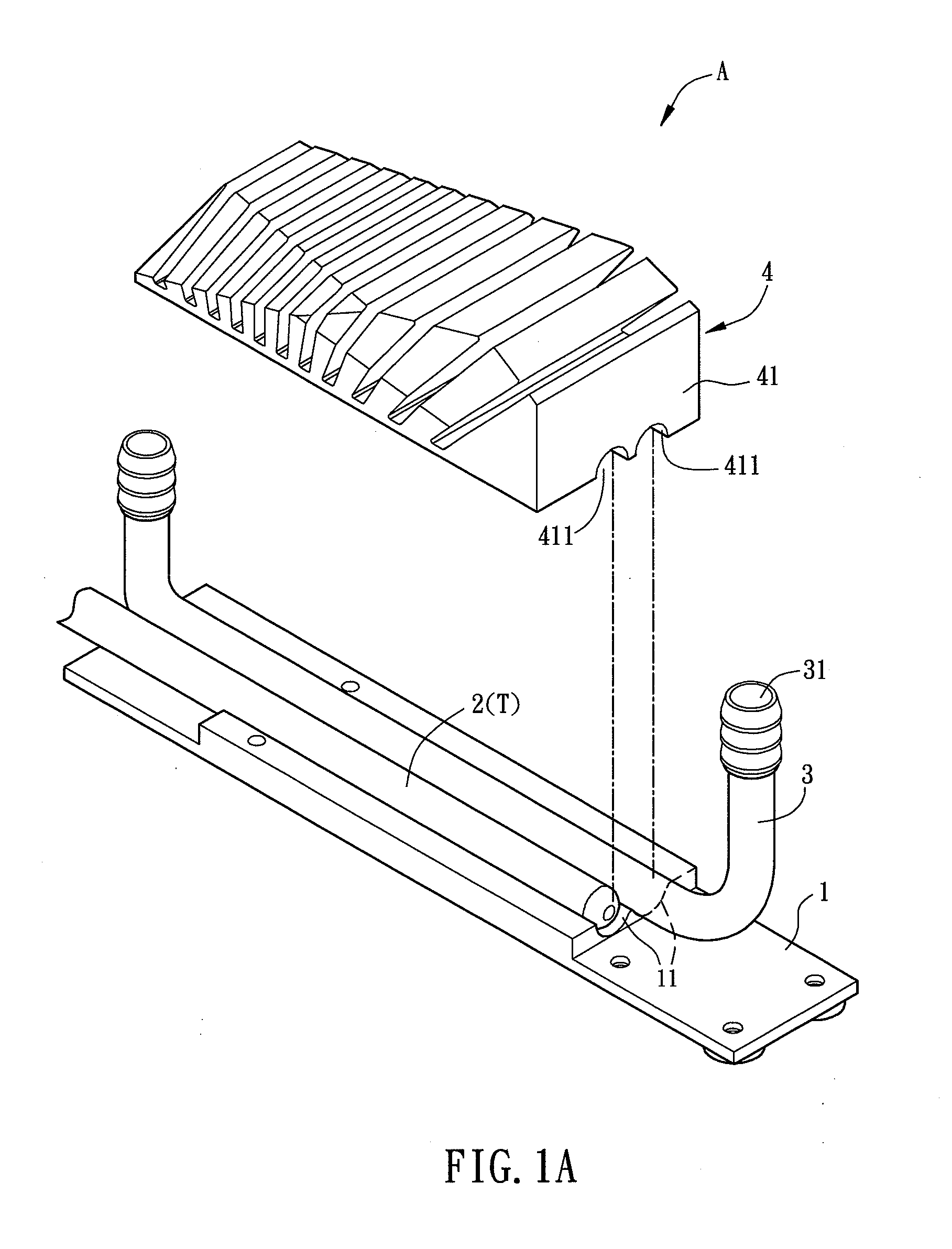

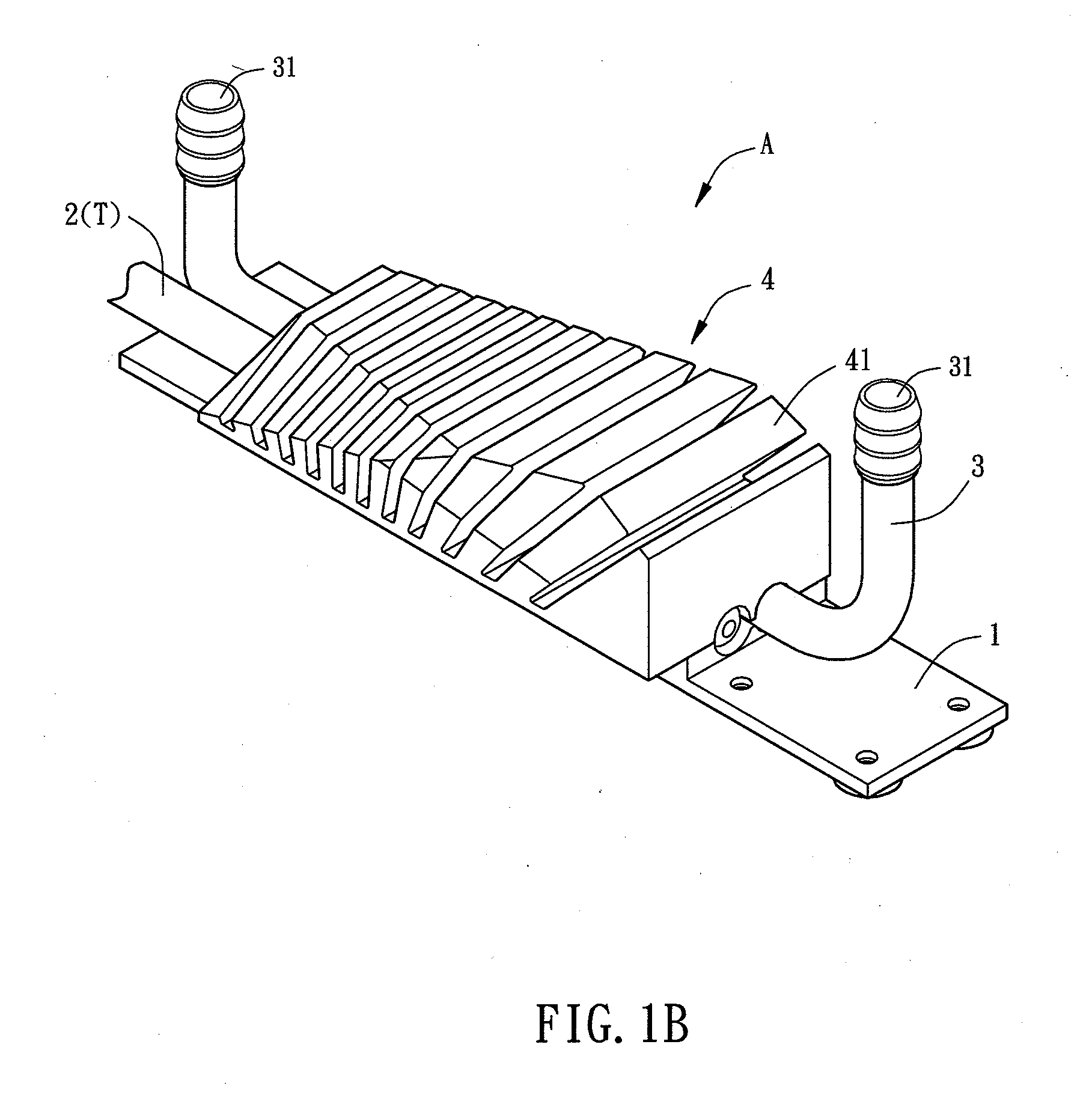

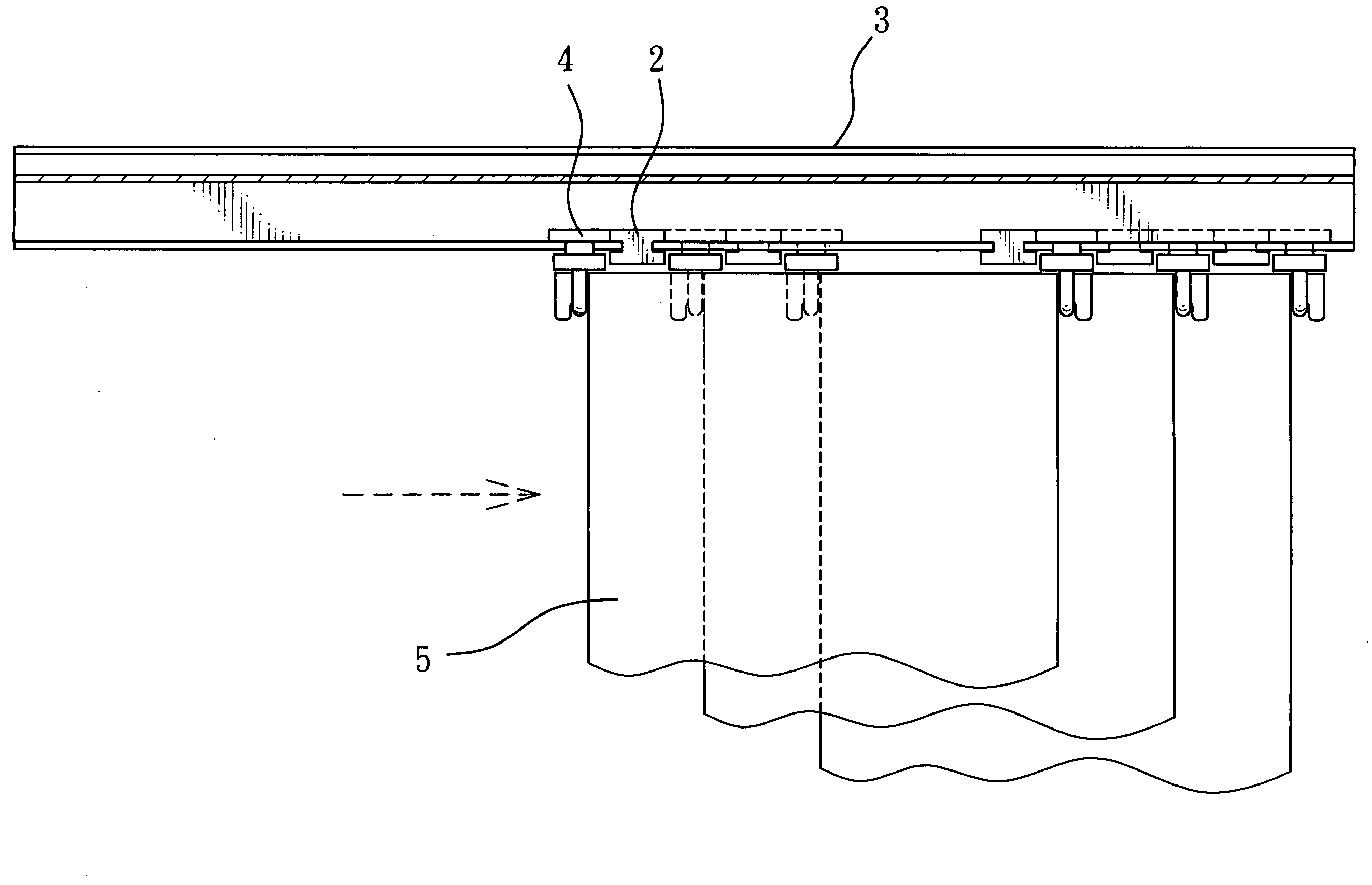

Heat dissipating module

InactiveUS20130206367A1Simple elementsImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesEngineeringWater cooling

A heat dissipating module includes a base, at least one thermal conductive element, at least one liquid-pipe and a heat sink. The thermal conductive element is disposed at the base. The liquid-pipe is disposed adjacent to the thermal conductive element. The liquid-pipe is disposed at the base. The heat sink covers the thermal conductive element and the liquid-pipe. A part of the heat sink is connected to the base. The heat sink includes a plurality of fins. The heat dissipating module combines air-cooling with water-cooling so as to enhance thermal conductivity.

Owner:ASUSTEK COMPUTER INC

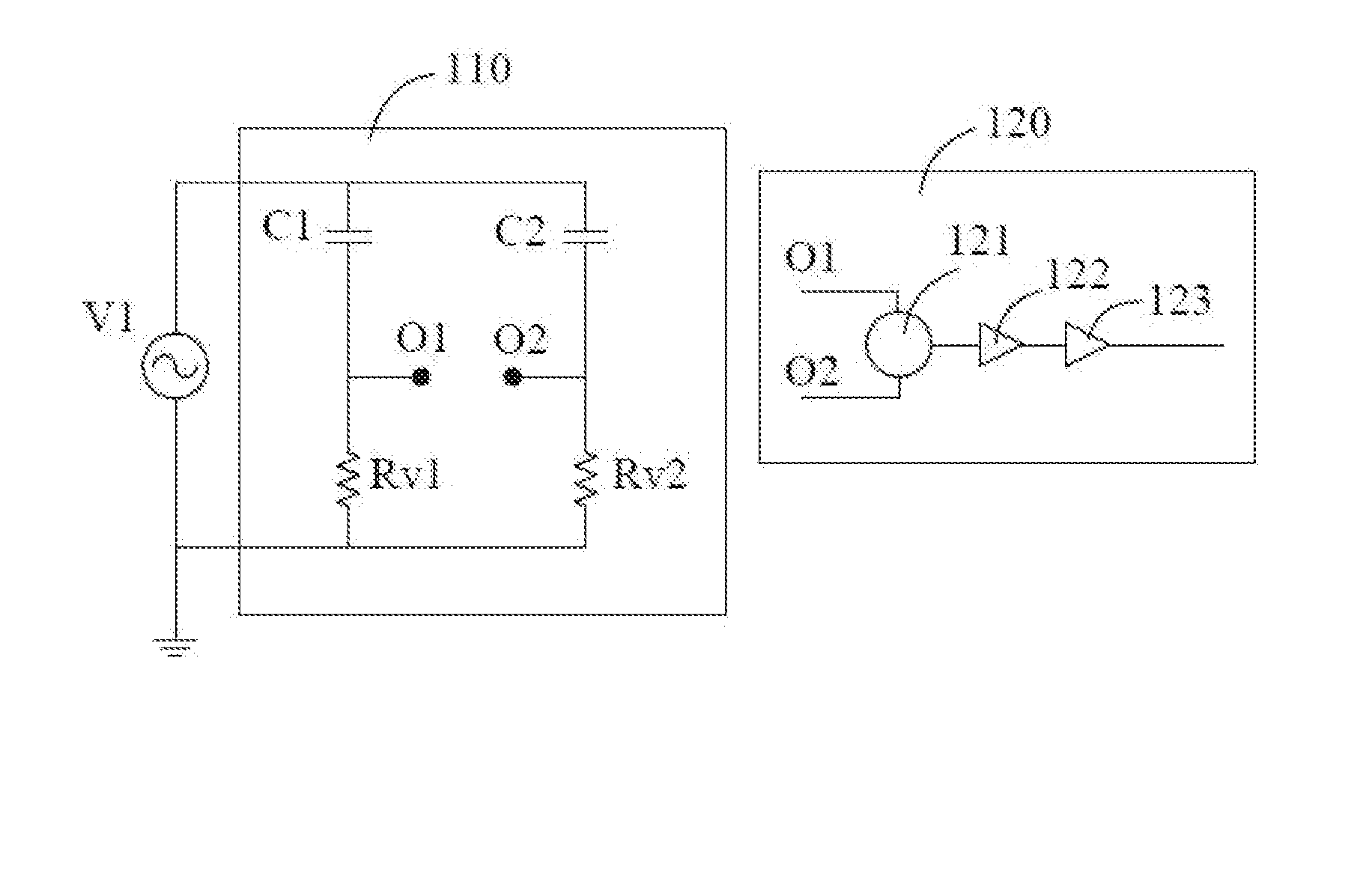

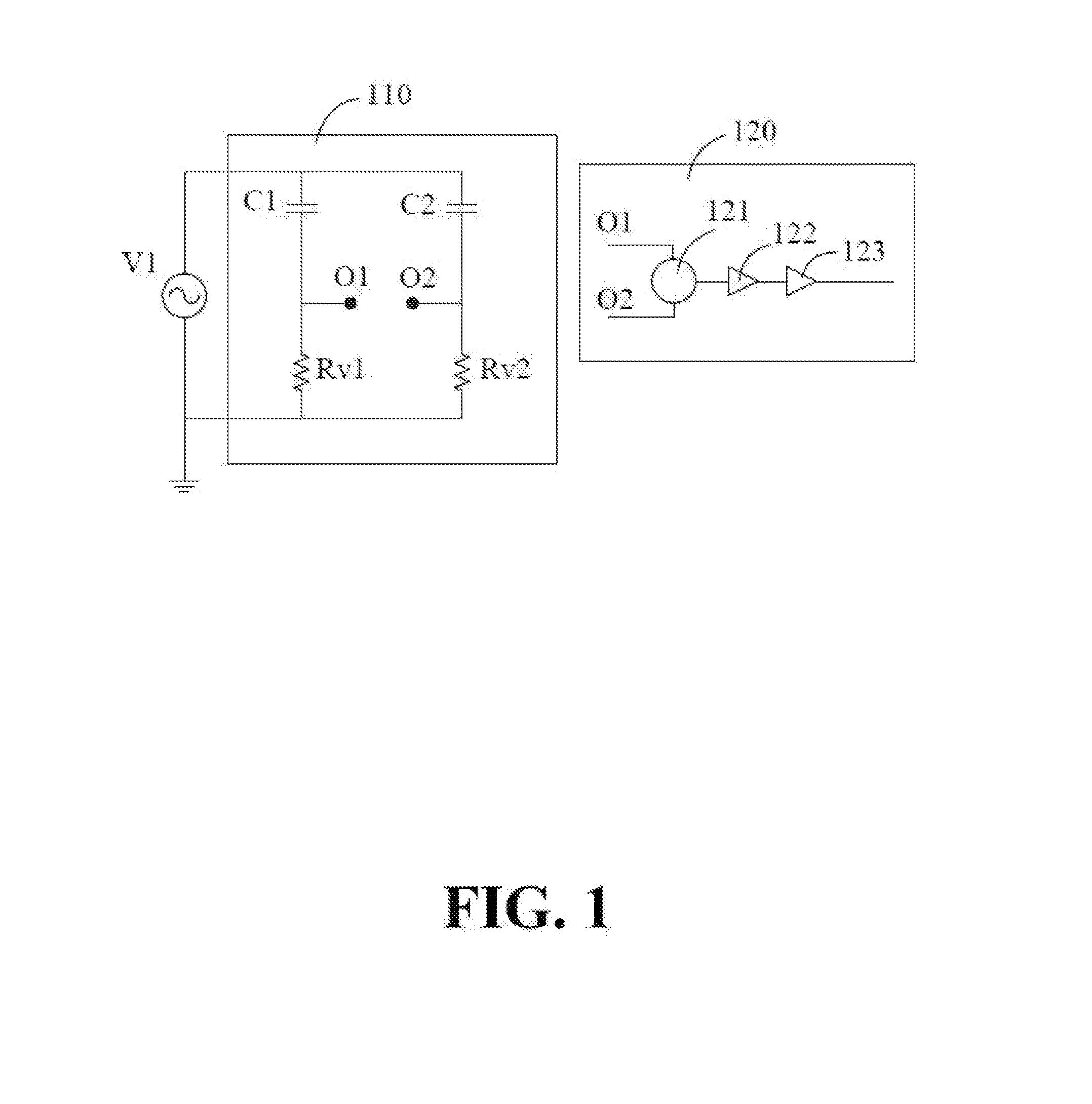

Touch sensing circuit and touch point detecting method thereof

ActiveUS20130015907A1Capacitance variation can be rapidly reflectedLow production costElectronic switchingInput/output processes for data processingTouch SensesCapacitor

A touch sensing circuit includes an alternative current (AC) source, a voltage division circuit, and a processing circuit. The voltage division circuit receives an AC signal outputted from the AC source and includes a first branch and a second branch on a touch sensing glass, wherein the first and second branches are adjacent to each other. The processing circuit is connected to the voltage division circuit for determining position of a touch point according to the voltages of the first branch and the second branch. In a preferred embodiment, the first branch comprises a first capacitor and a first voltage division resistor connected to the first capacitor, and the second branch comprises a second capacitor and a second voltage division resistor connected to the second capacitor.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

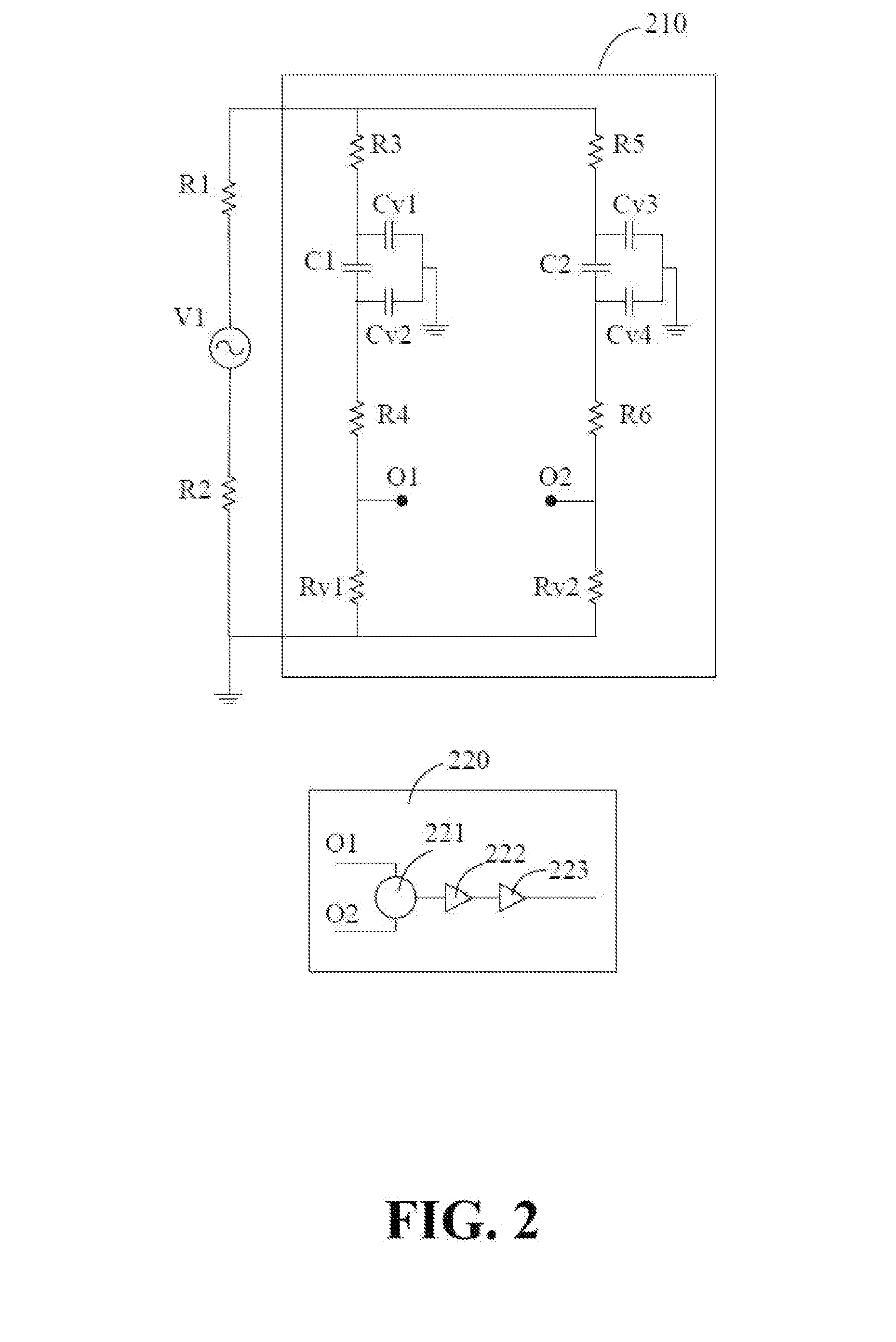

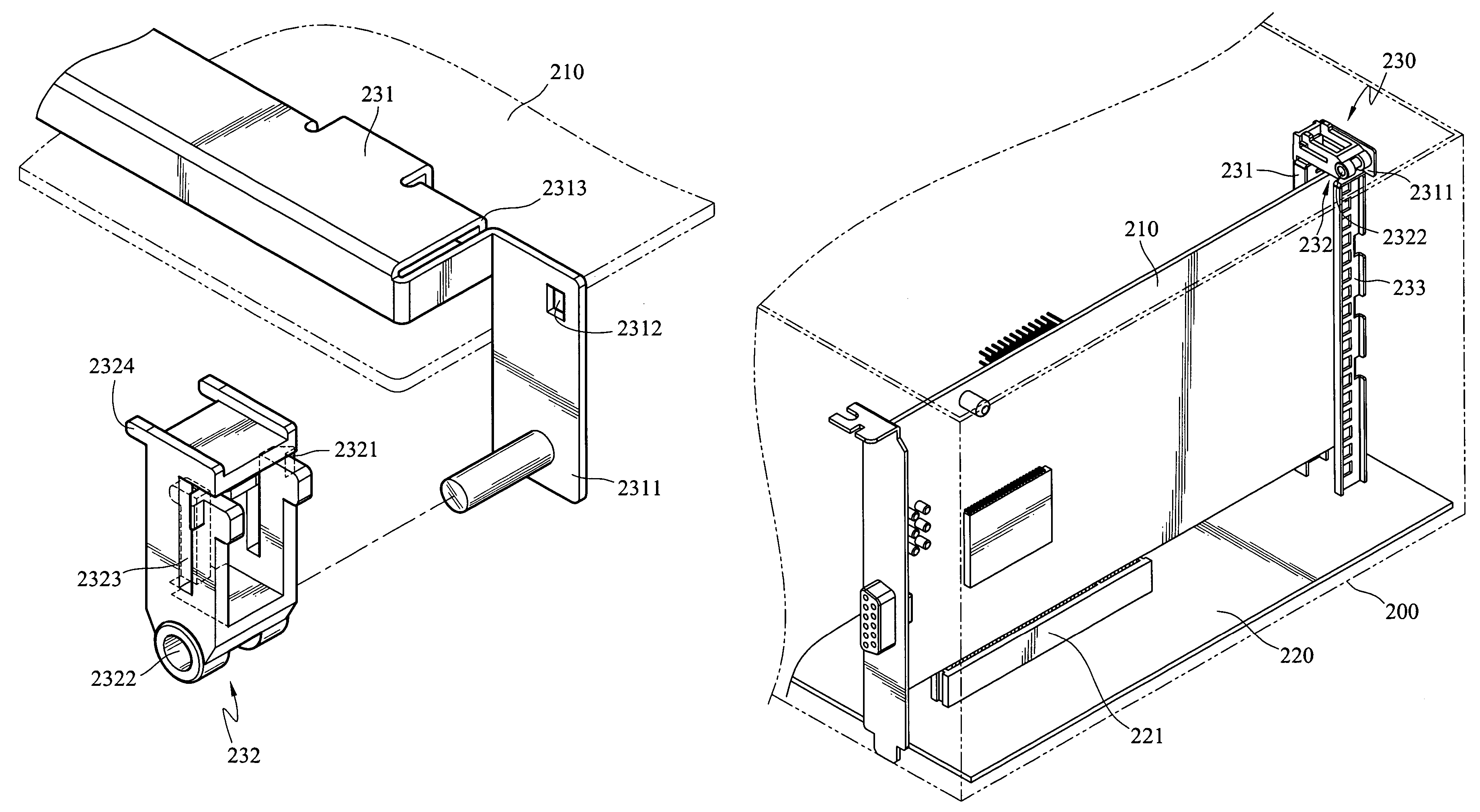

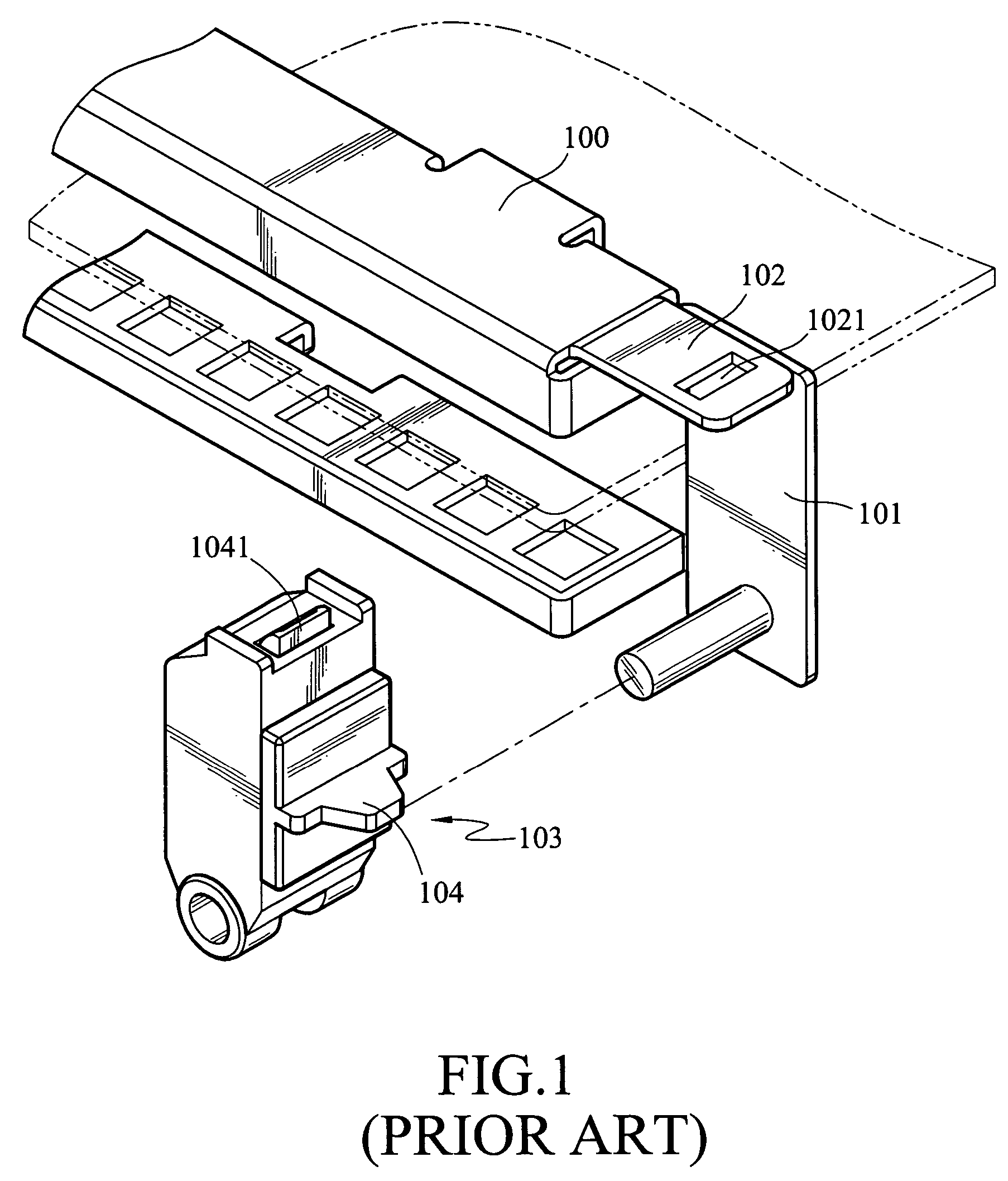

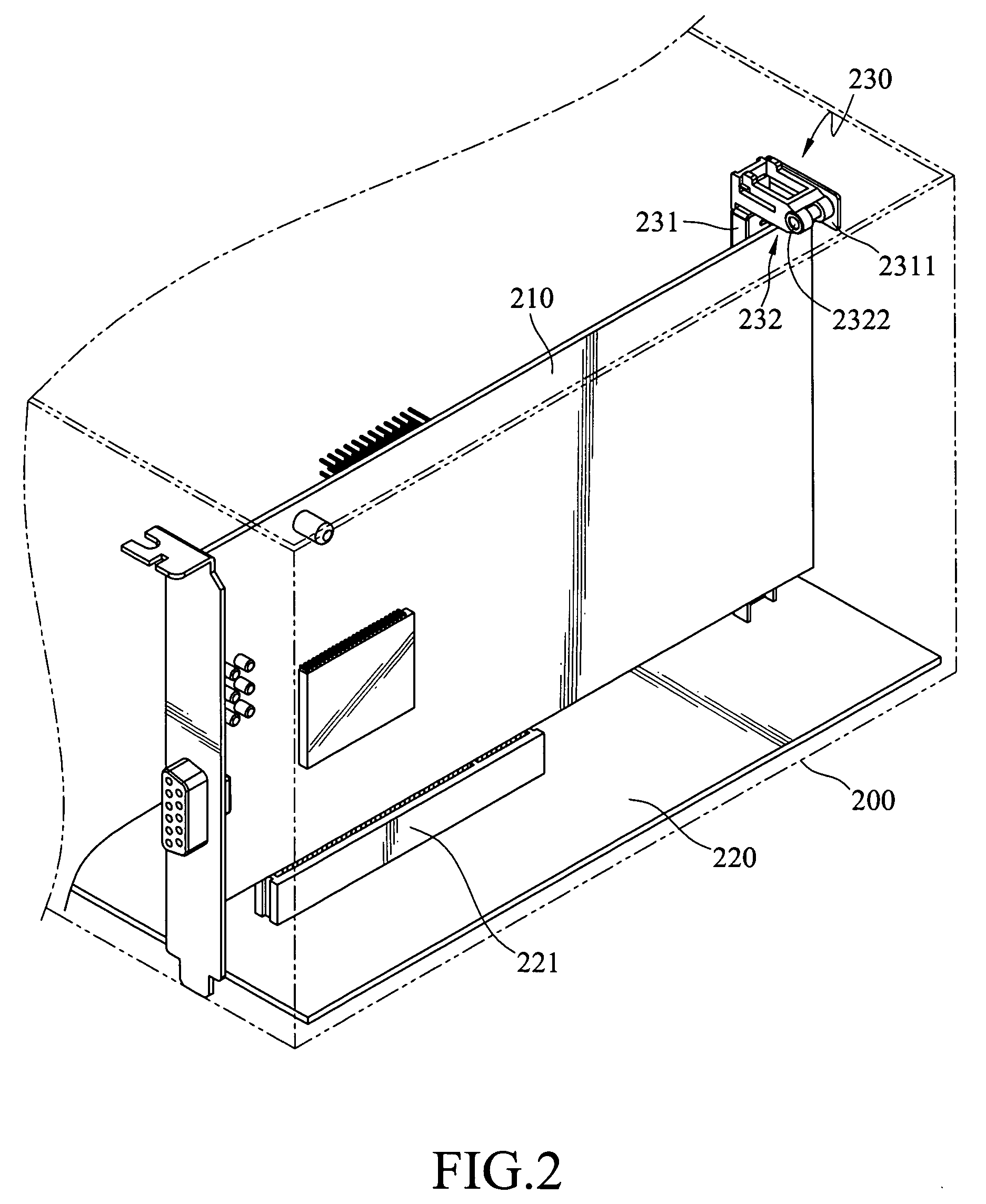

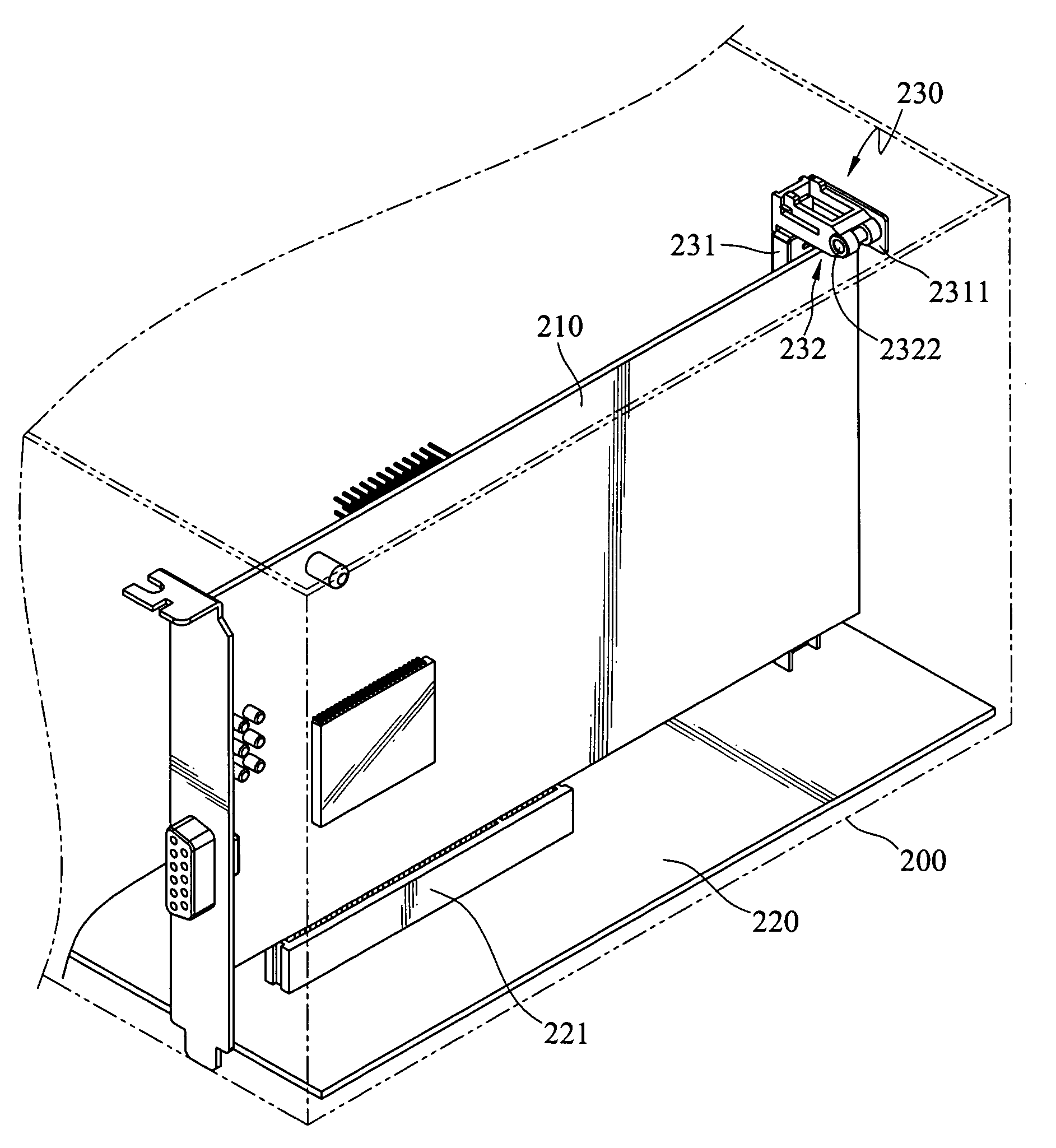

Removable hard disk module

InactiveUS7626813B2Increase the use of spaceSimple elementsDigital data processing detailsFurniture partsComputer engineeringServer system

A removable hard disk module is provided which is mainly applicable to a server system. The removable hard disk module includes a server rack and a hard disk removable enclosure which is detachable form the server rack. The server rack has at least one pair of accommodation slots with threads formed on an inner wall thereof. The hard disk removable enclosure defines a space to accommodate a hard disk and has a threaded engagement portion disposed therein corresponding to the threads. When the hard disk removable enclosure is inserted into the accommodation slots, the threaded engagement portion is contacted with the threads, and the hard disk removable enclosure is moved alone to the threads through the threaded engagement portion, thereby the hard disk removable enclosure is moved into and fixed within the accommodation slots of the server rack.

Owner:ACARD TECH CORP

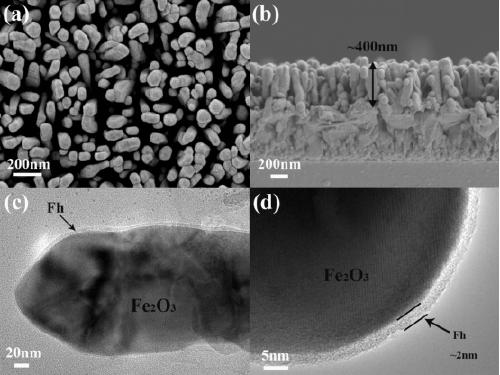

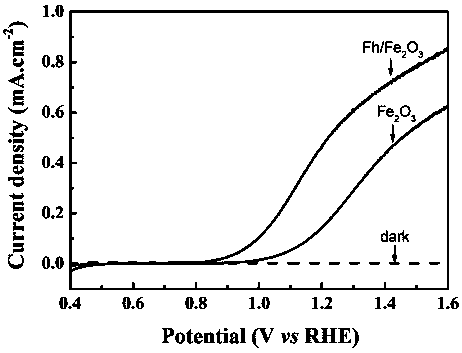

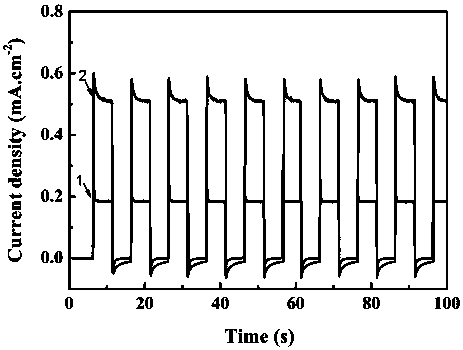

Modified ferrihydrite/hematite nano-rod core-shell structure compound light anode and application thereof

InactiveCN109825851ASimple elementsRich reservesEnergy inputNanotechnologySynthesis methodsCatalytic effect

The invention discloses a modified ferrihydrite / hematite nano-rod core-shell structure compound light anode and an application thereof. A preparation method of the light anode includes the steps: S1 preparing hematite growth solution, placing a conducting substrate into the hematite growth solution, synthesizing a FeOOH film on the conducting substrate by a solvent thermal synthesis method, washing the FeOOH film, and drying the washed FeOOH film for standby application; S2 performing high temperature annealing on the conducting substrate acquired in the step S1, and cooling the conducting substrate to obtain the conducting substrate with the hematite film surface; S3 preparing ferrihydrite growth solution, placing the conducting substrate acquired in the step S2 into the ferrihydrite growth solution, heating mixture, washing the conducting substrate after reaction is completed, and drying the washed conducting substrate to obtain the modified ferrihydrite / hematite nano-rod core-shellstructure compound light anode. According to the method, a ferrihydrite thin layer is loaded on the surface of the hematite to prepare the core-shell structure compound light anode which is resistantto light corrosion and good in photoelectrochemical property and stability, and the compound light anode can be used for decomposing water to generate hydrogen and is high in catalytic efficiency andstable in catalytic effect.

Owner:SOUTH CHINA NORMAL UNIVERSITY

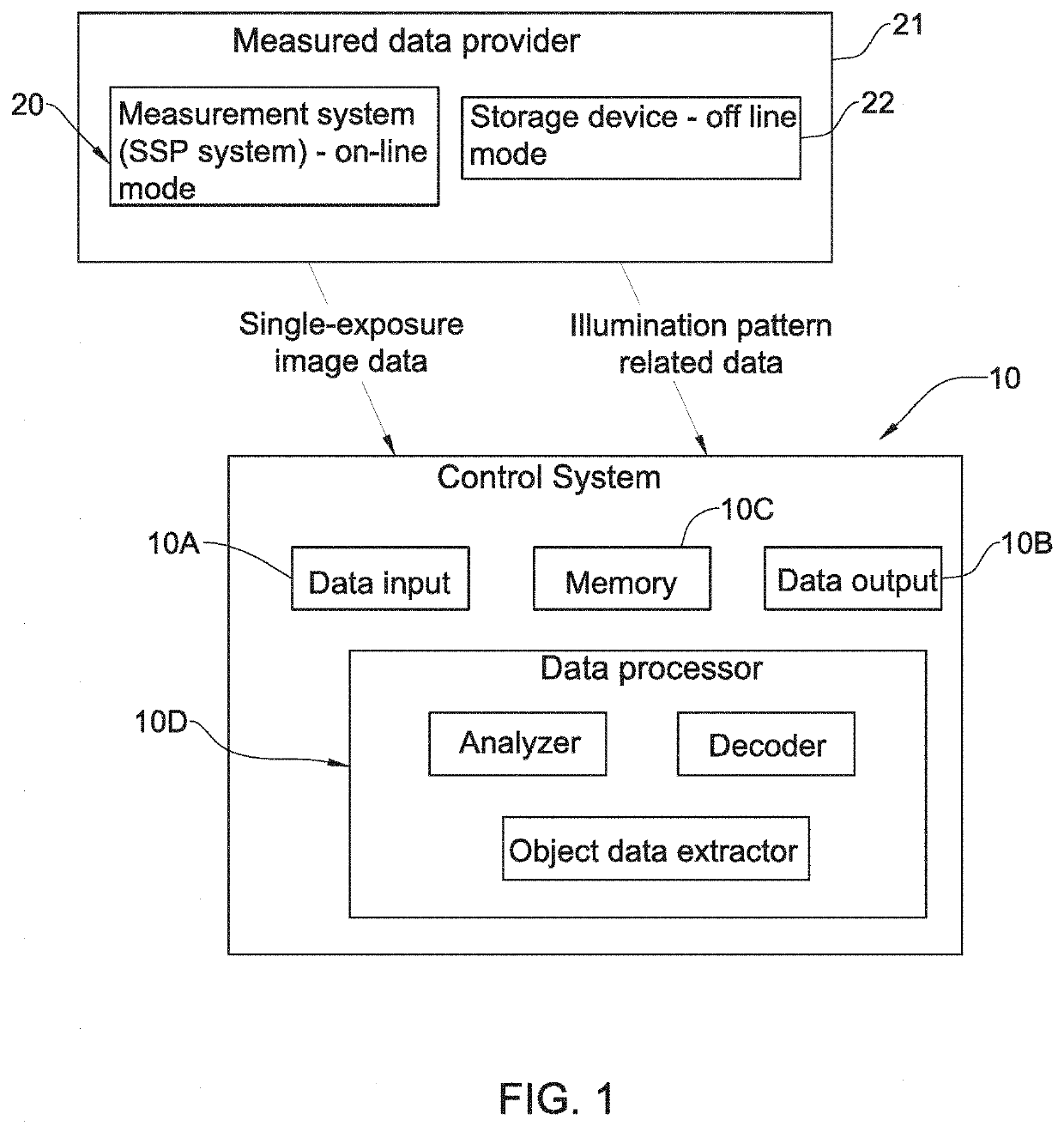

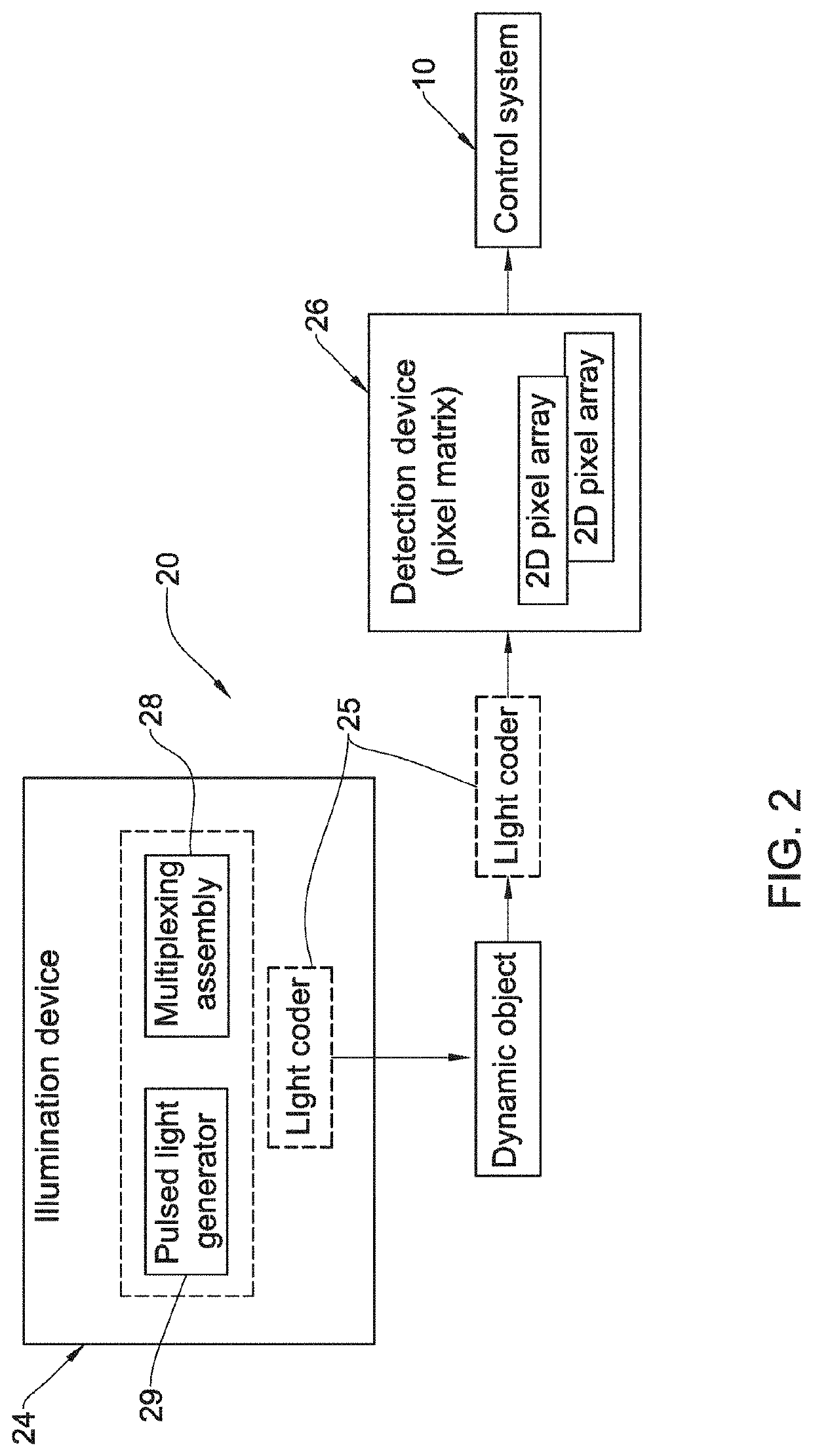

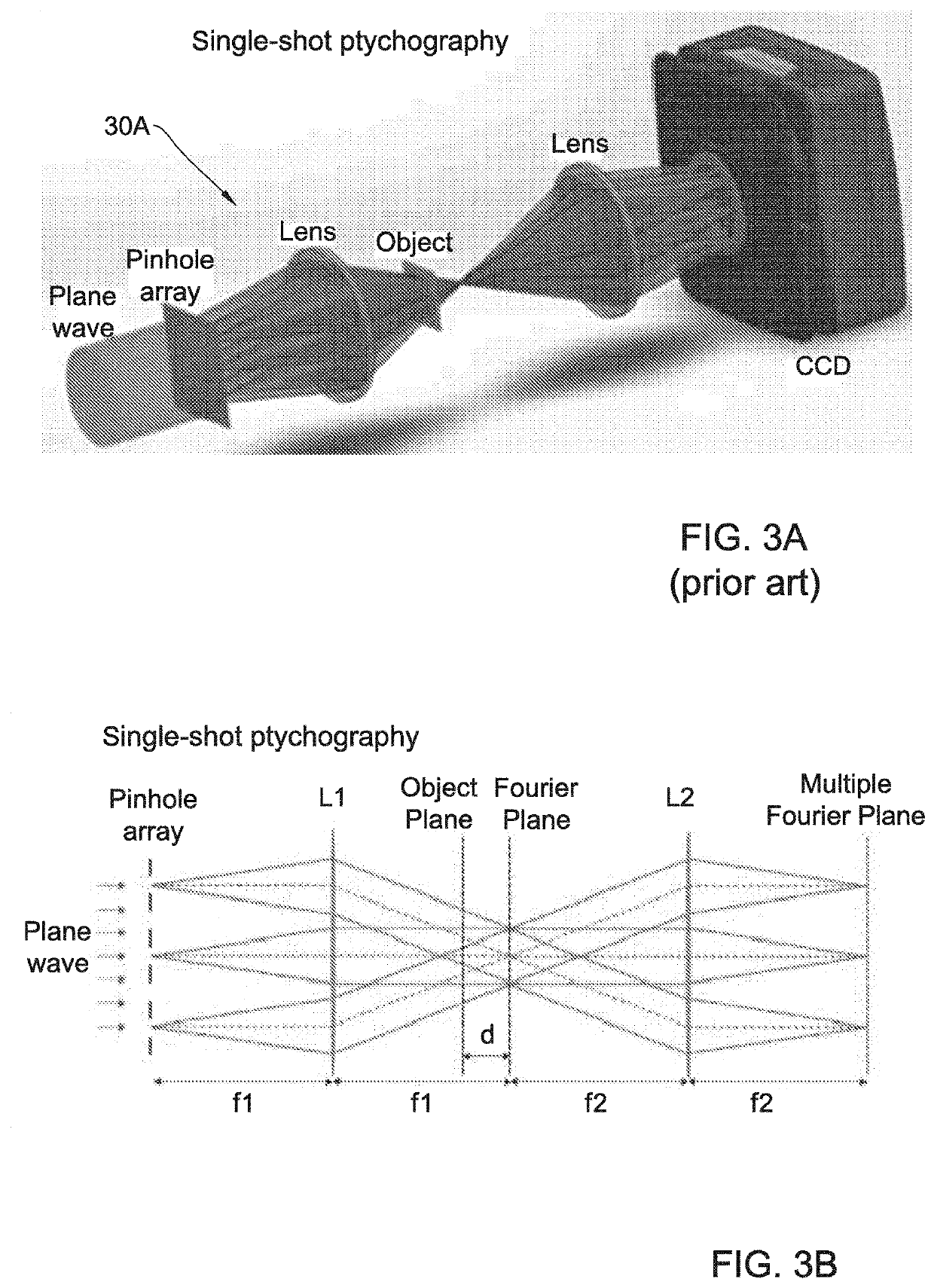

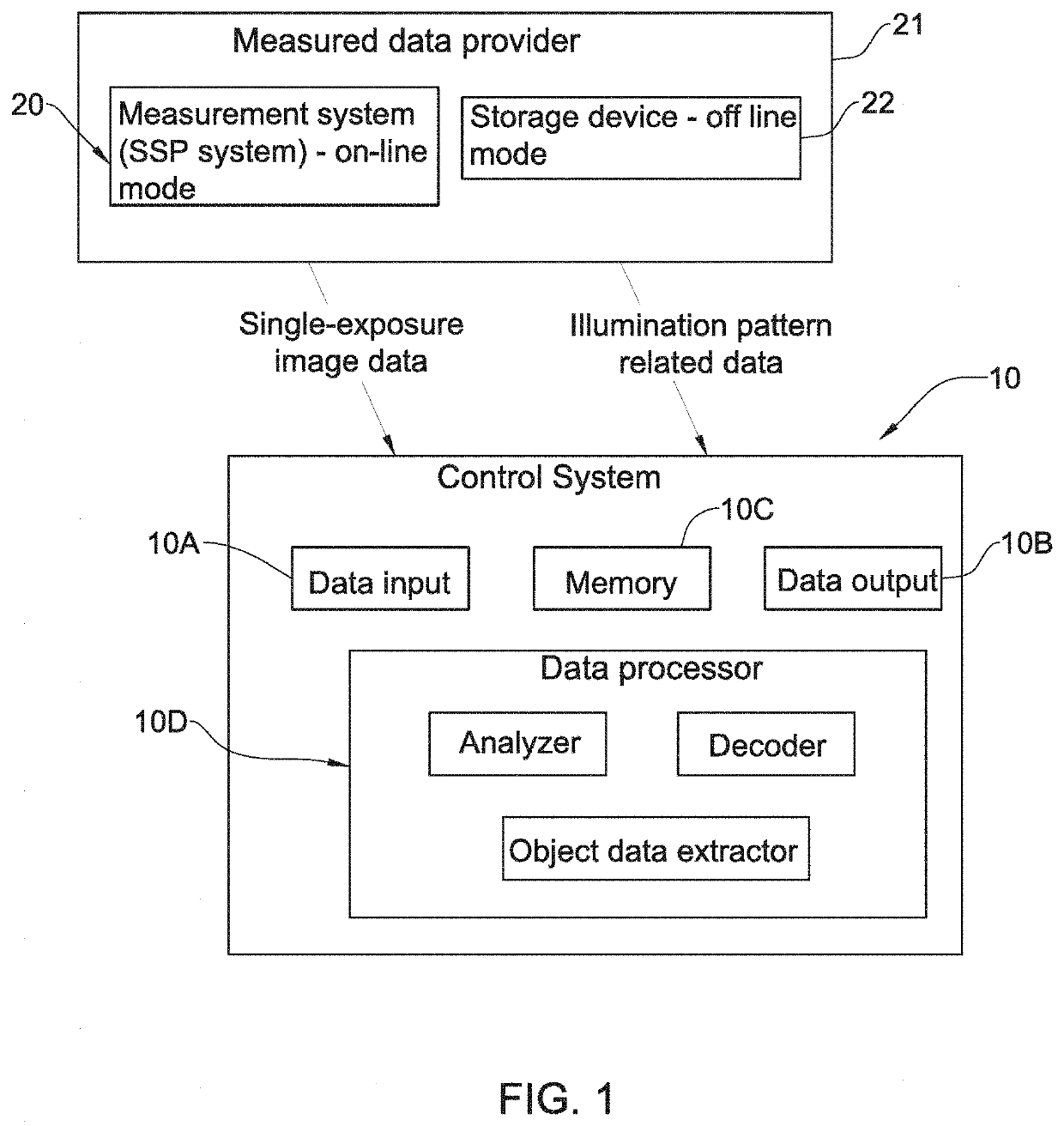

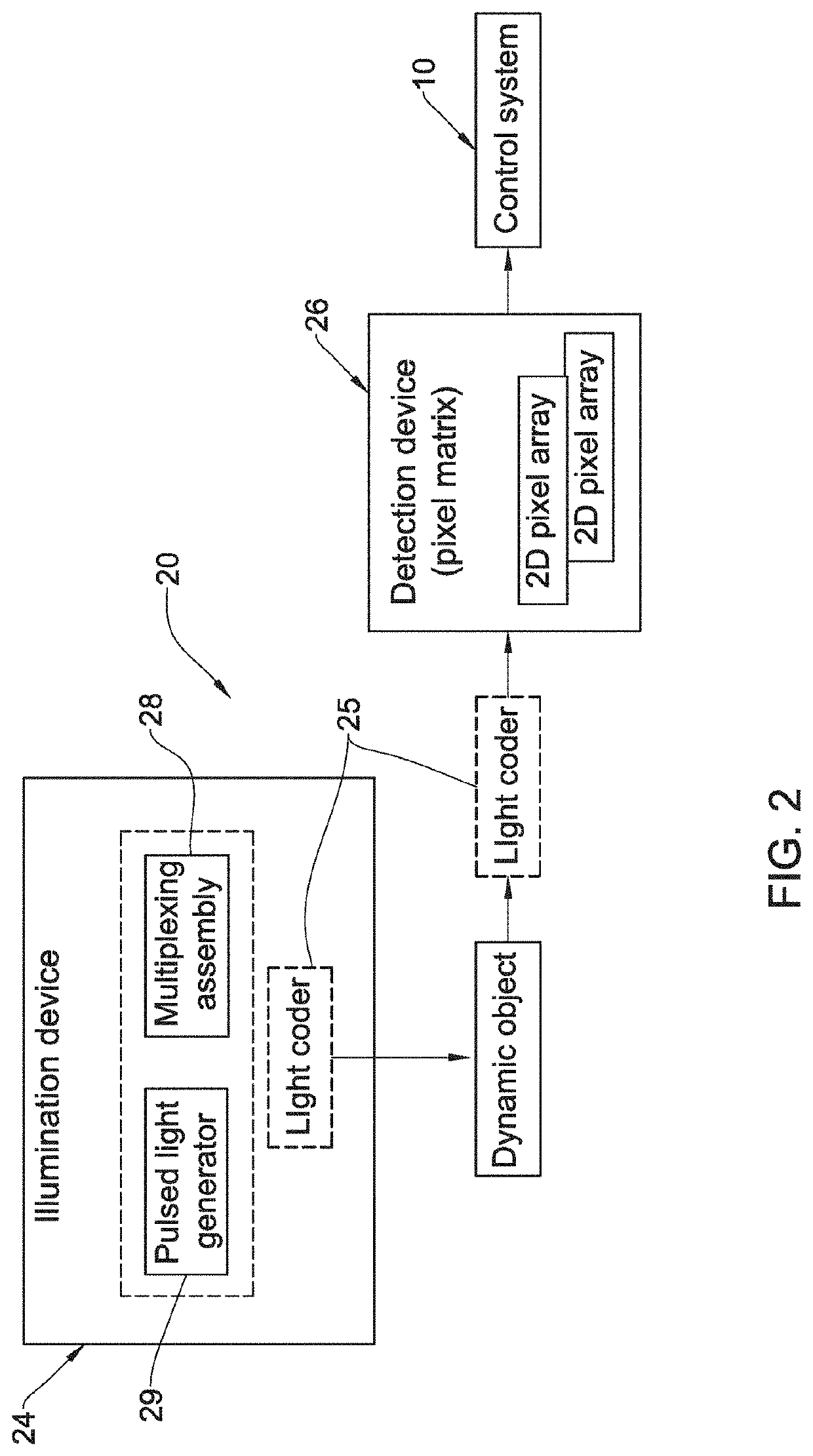

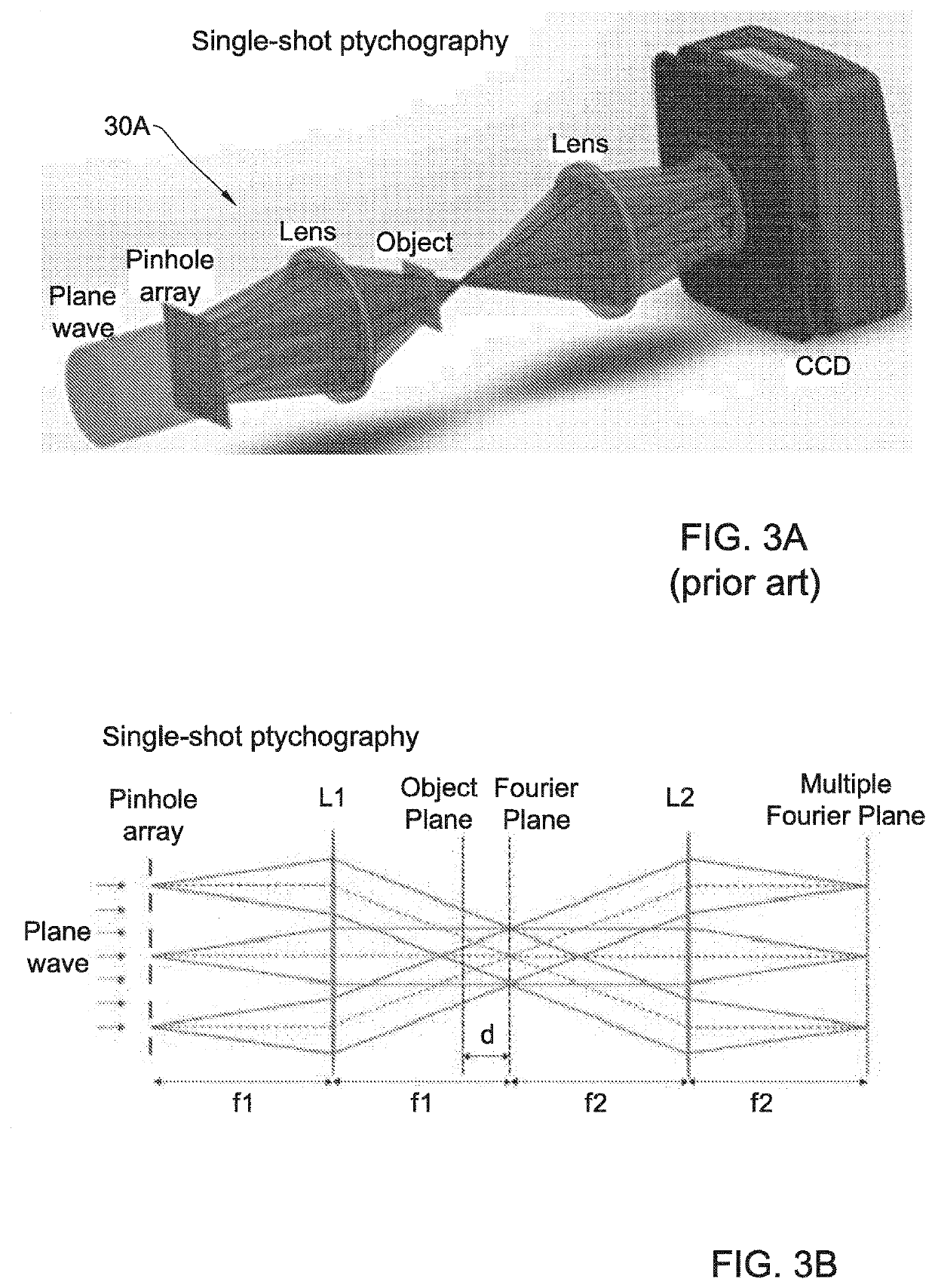

Ptychography based system and method

ActiveUS20200142175A1Improve noiseFaster and reliable reconstructionMicroscopesPtychographySingle exposure

A ptychography system is presented for imaging an object located in an object plane. The ptychography system comprises an optical system, and a detection device. The optical system comprises a single shot ptychography arrangement configured and operable to create light response patterns from the object in the object plane on a pixel matrix of the detection device during the same exposure session of the detection device, wherein the optical system further comprises at least one light coding device configured and operable to apply at least one predetermined coding function to at least one of illuminating light and the light response of the object being collected, and said detection device is configured and operable with a predetermined duration of the exposure session during which the pixel matrix detects the collected light, such that image data indicative of the detected light during a single exposure session is in the form of a coded light response of the object being illuminated.

Owner:TECHNION RES & DEV FOUND LTD

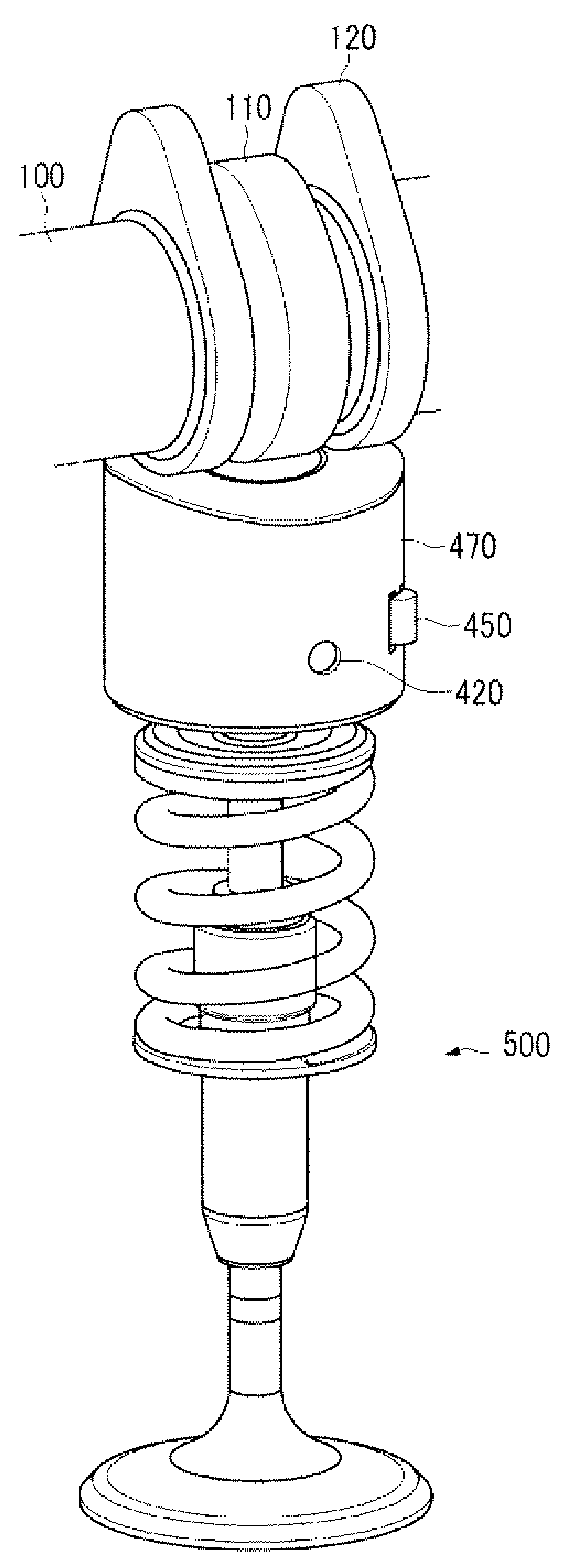

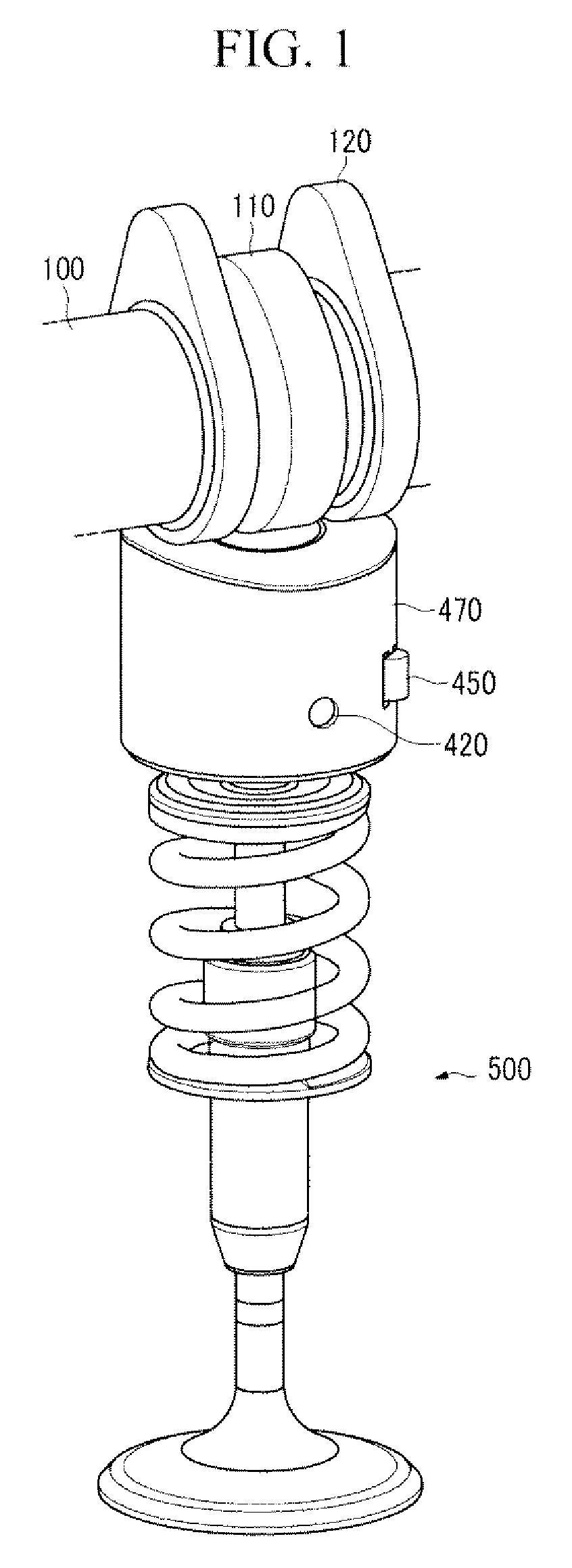

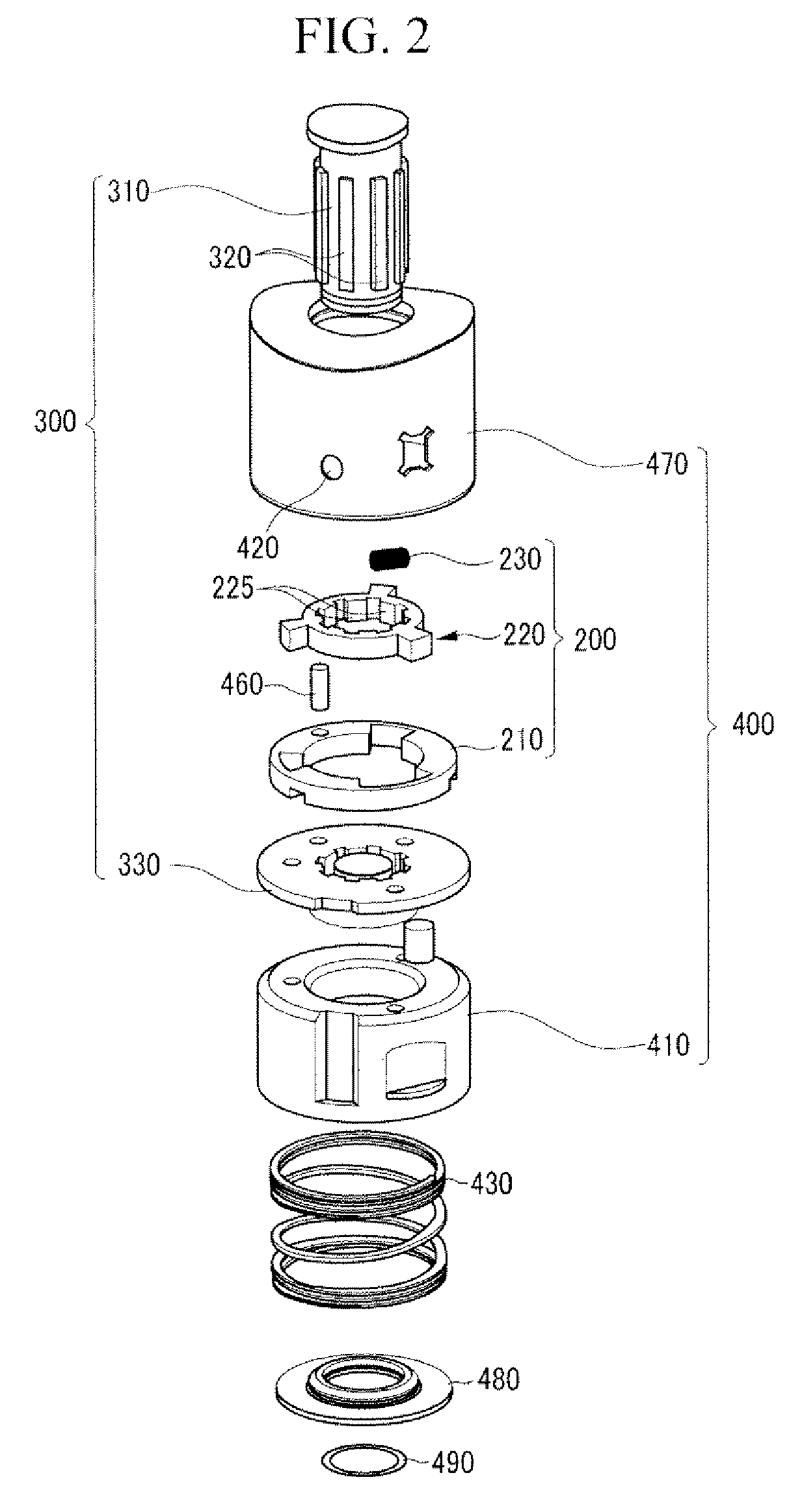

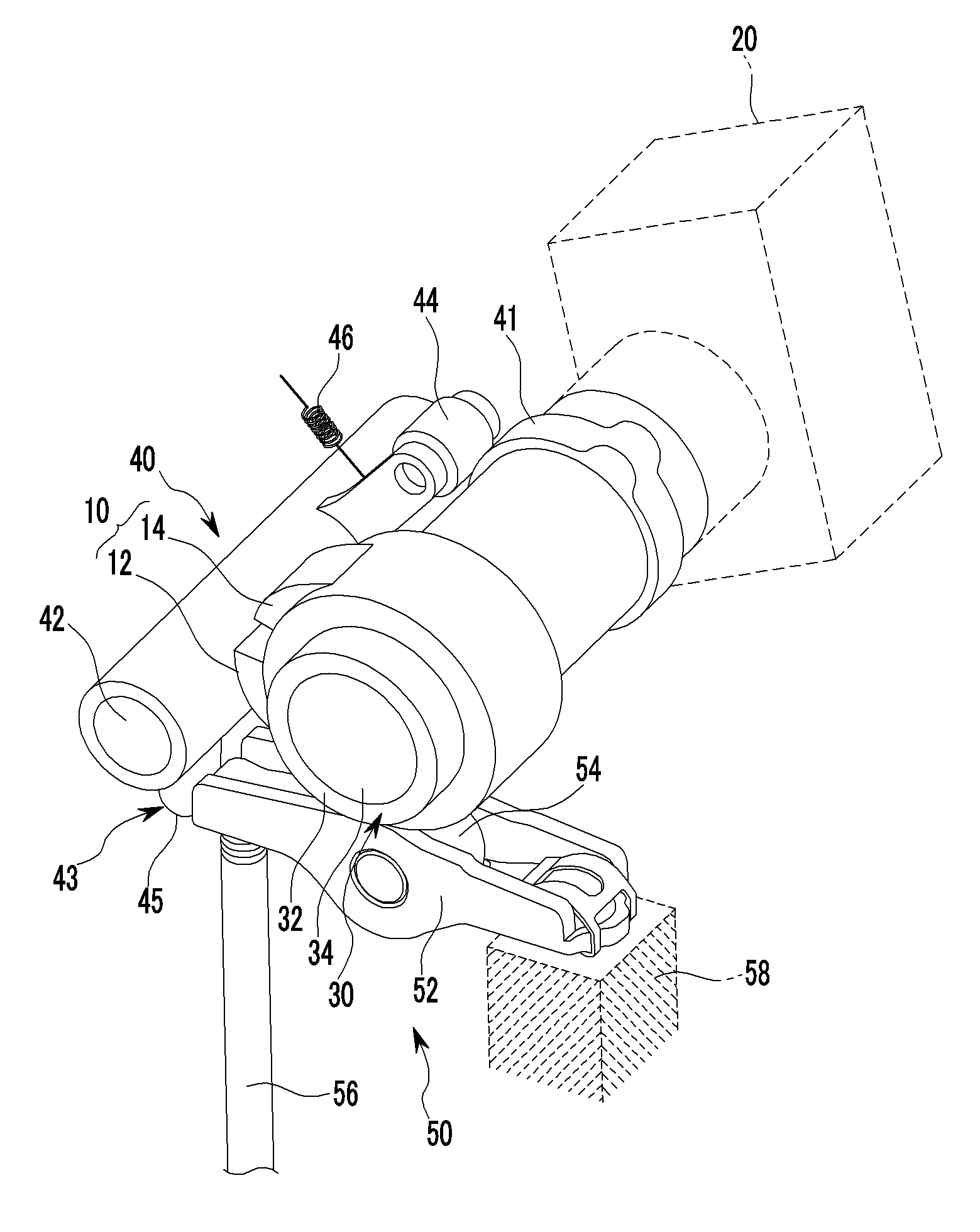

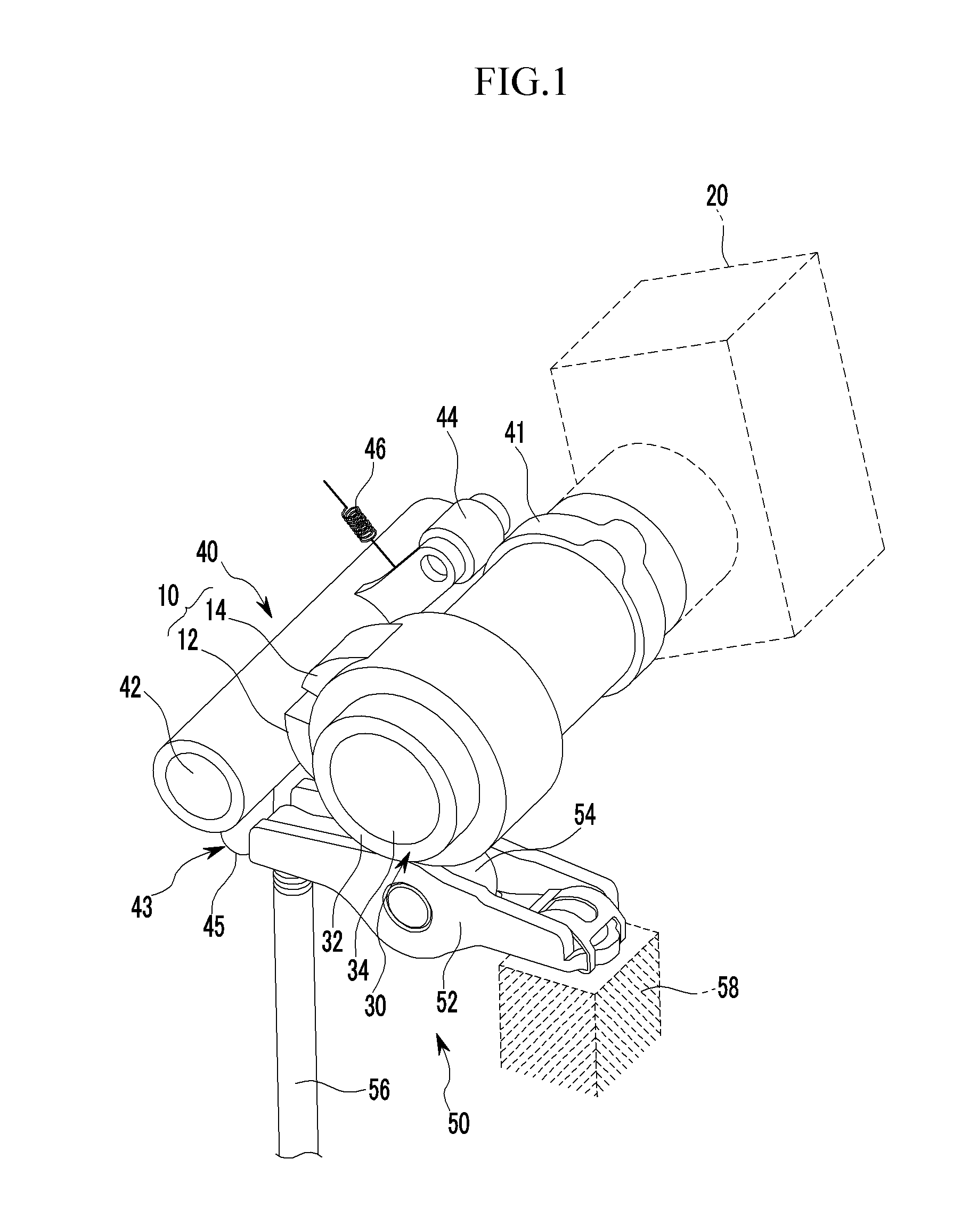

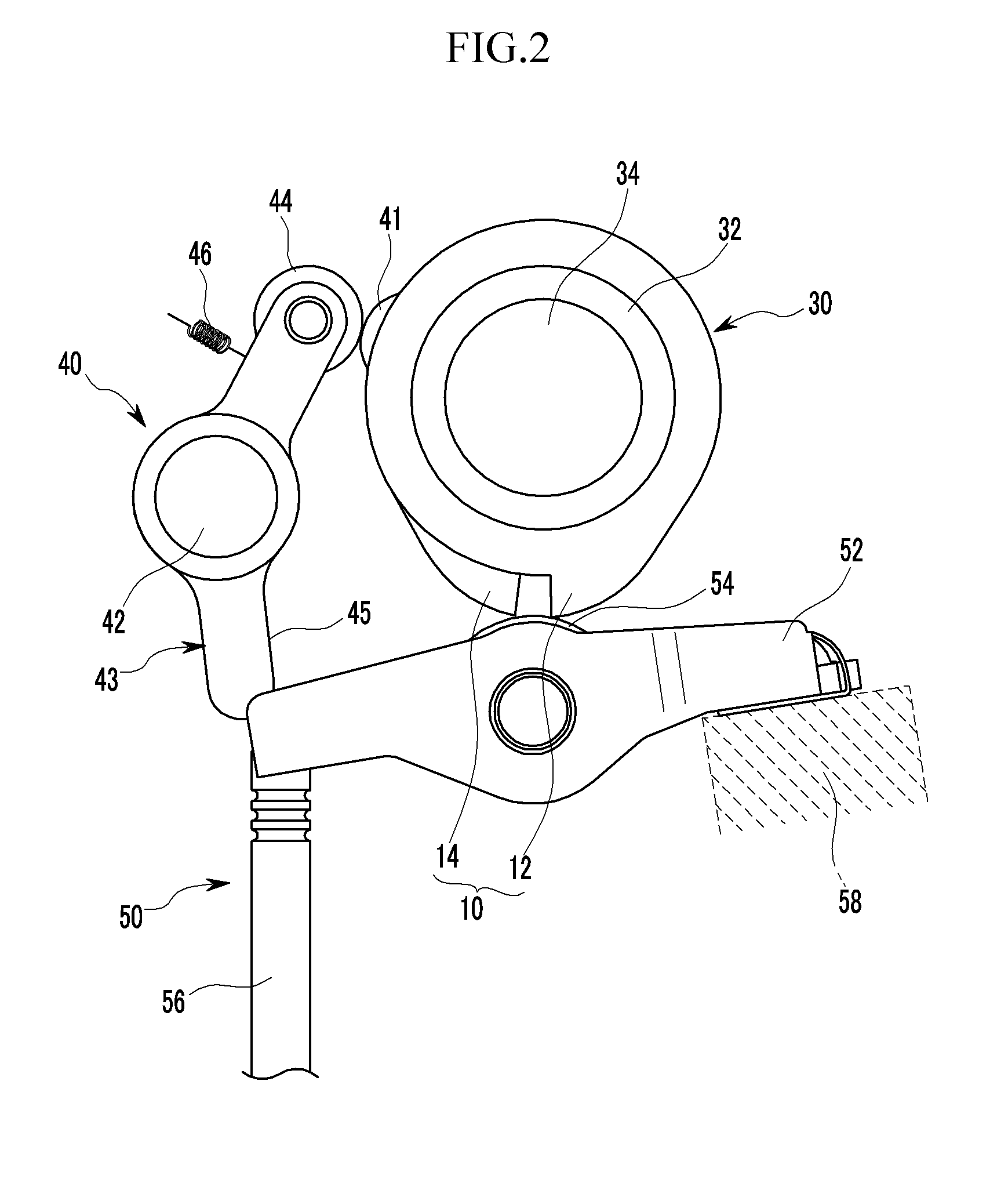

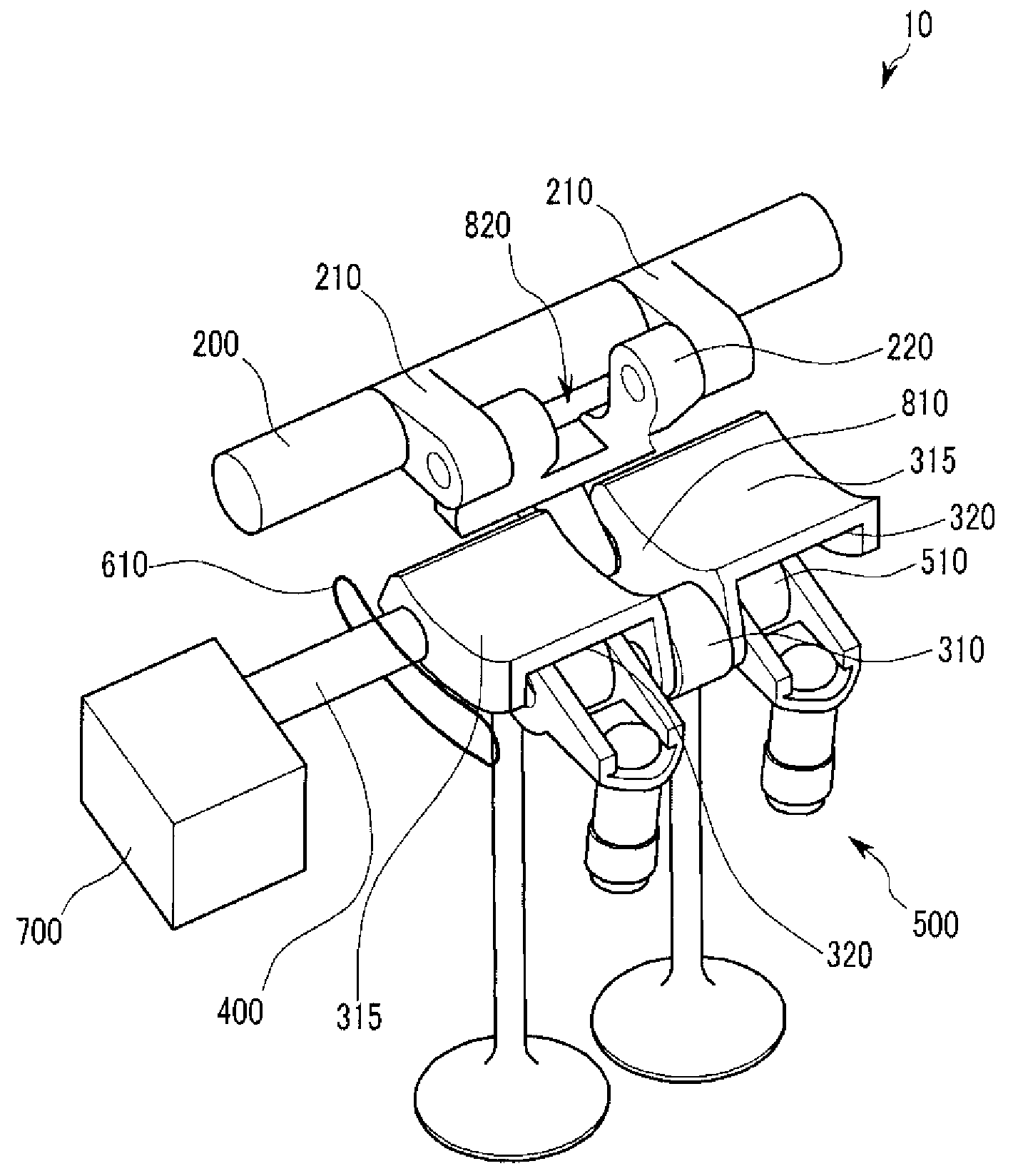

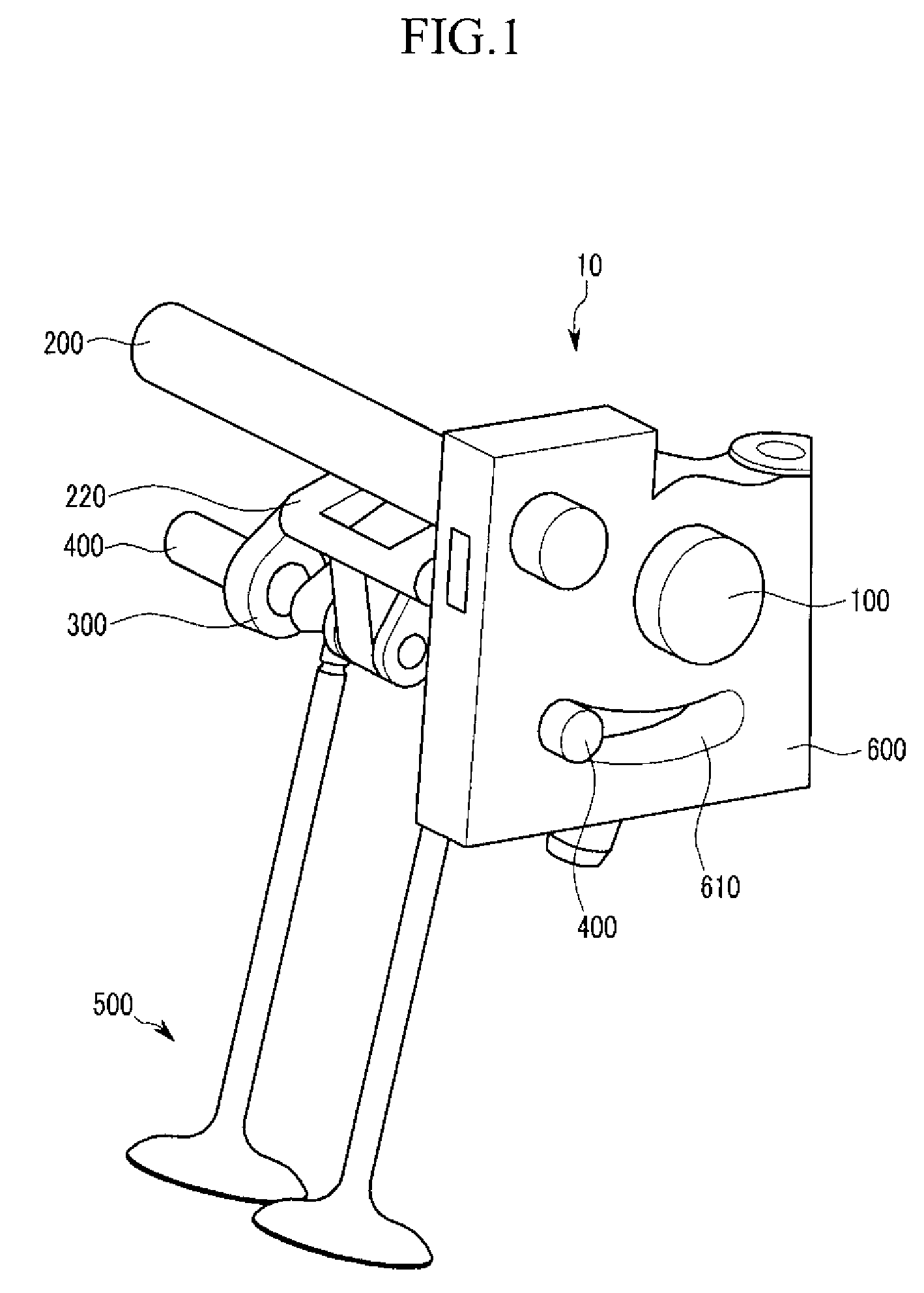

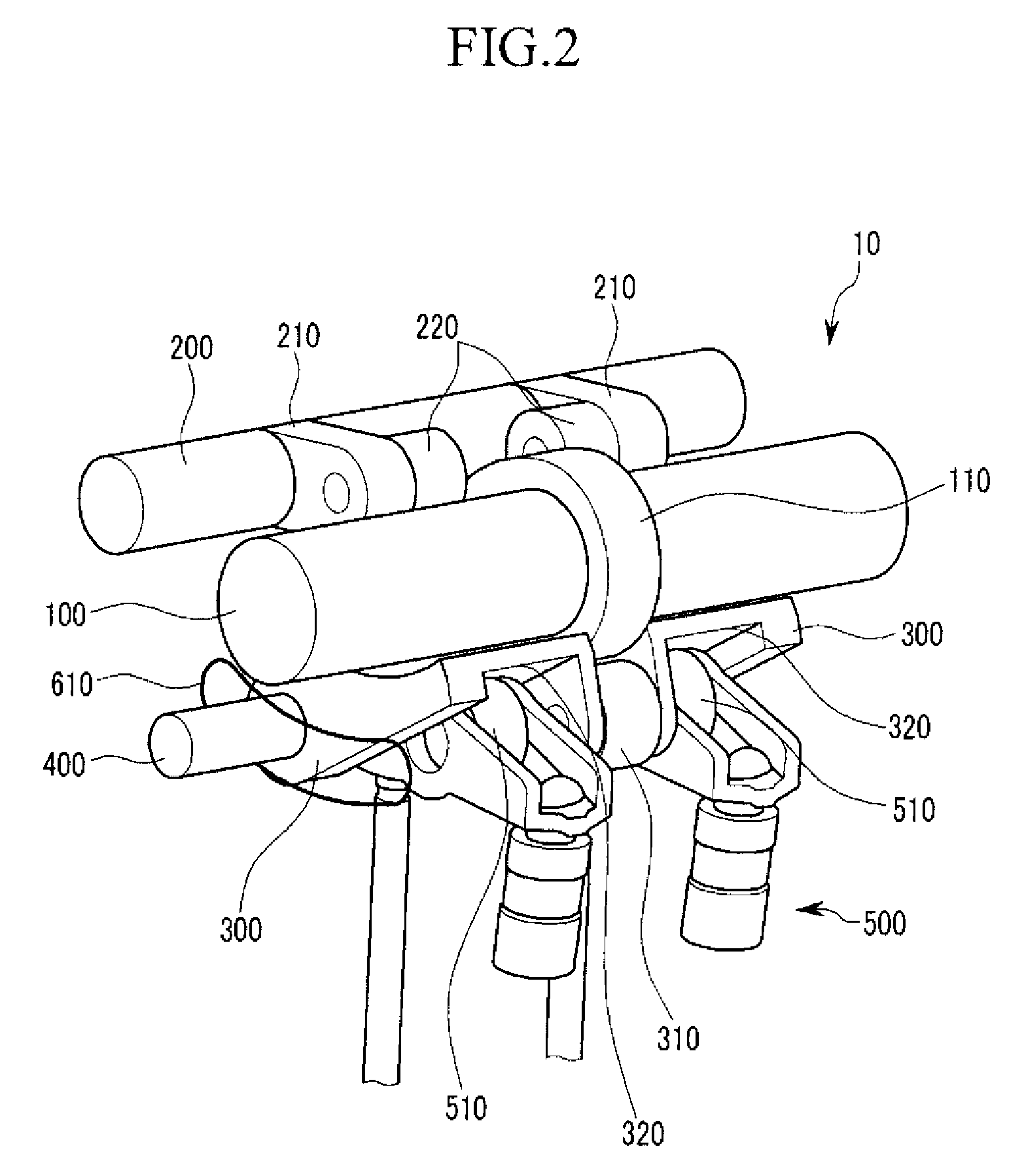

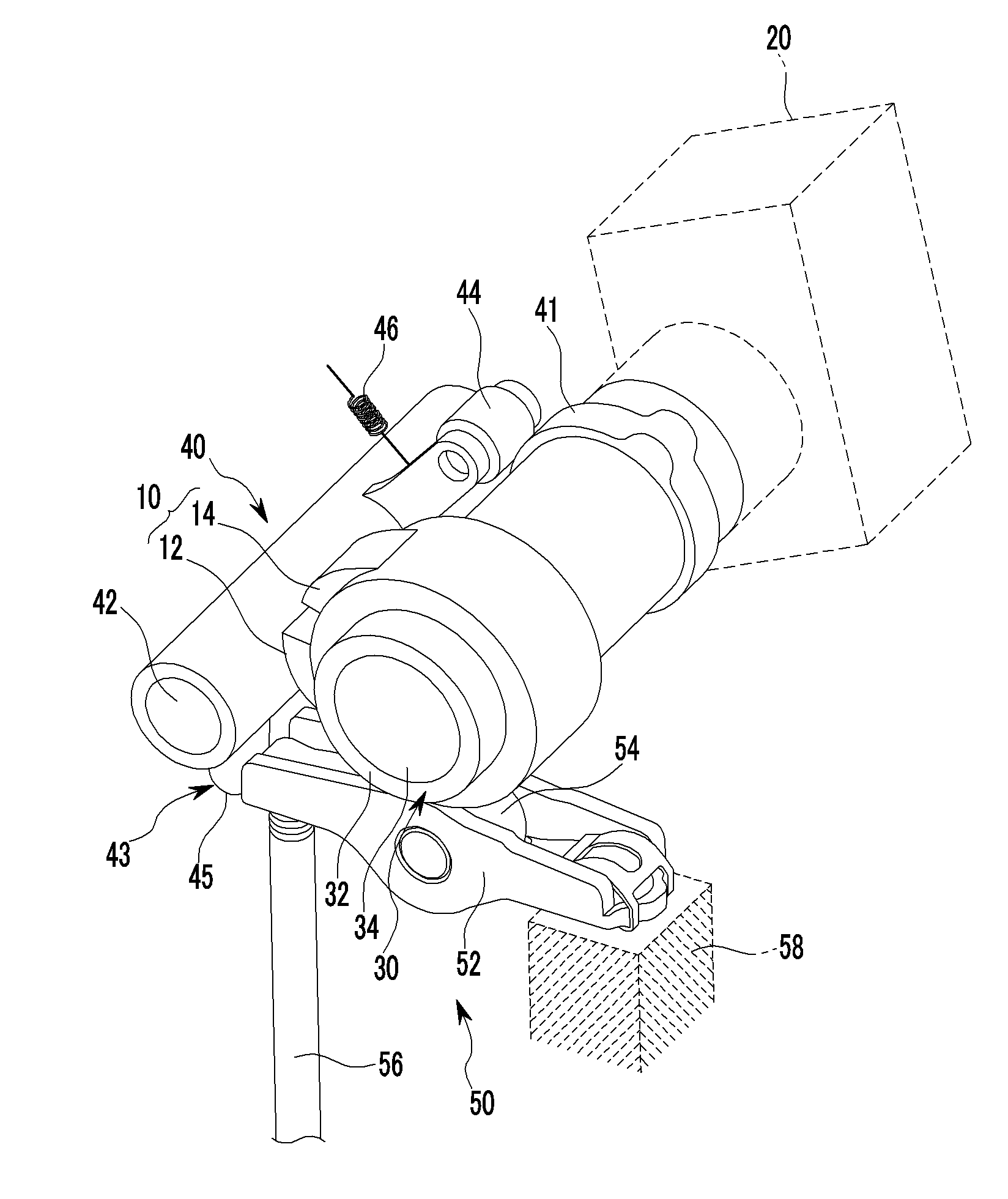

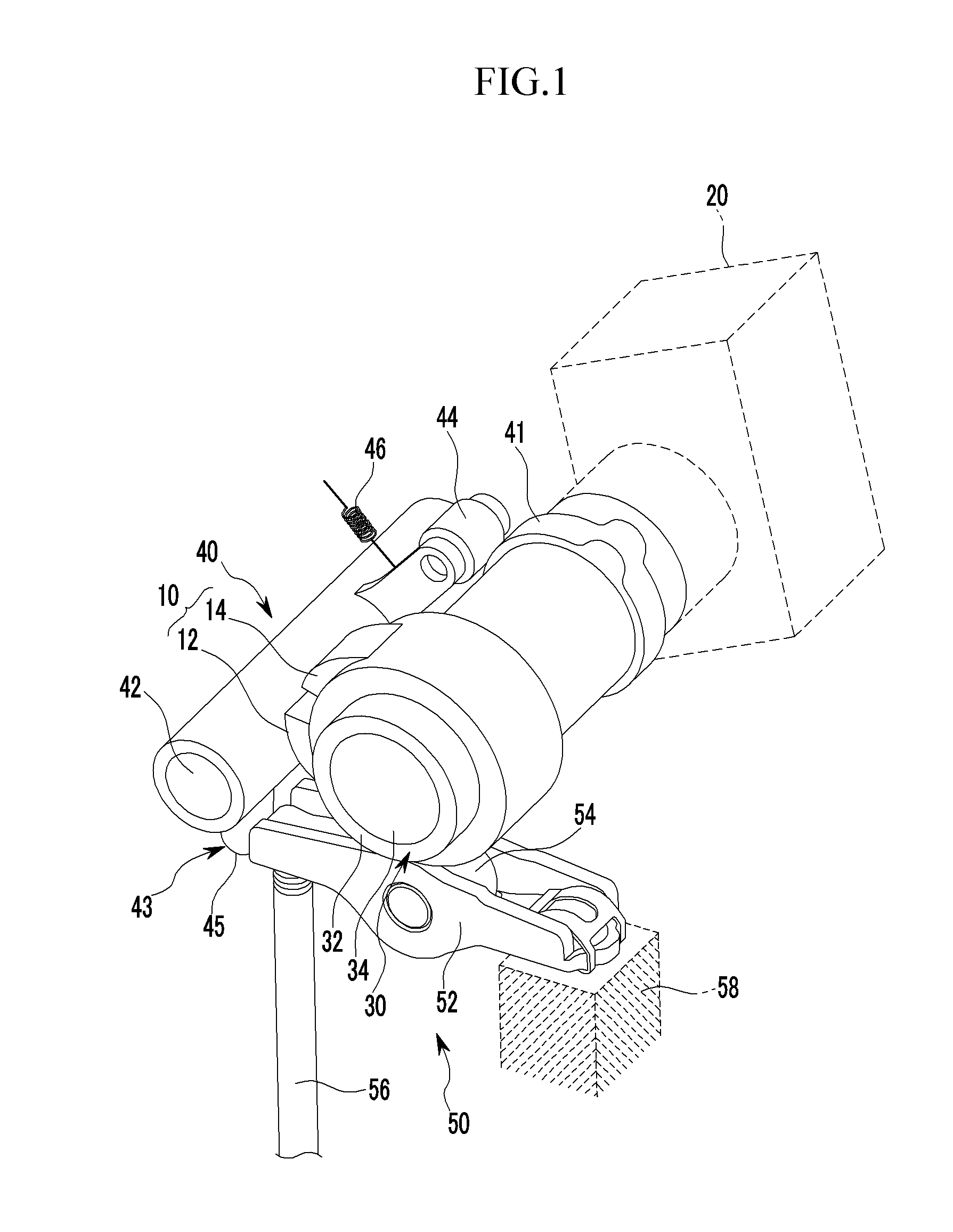

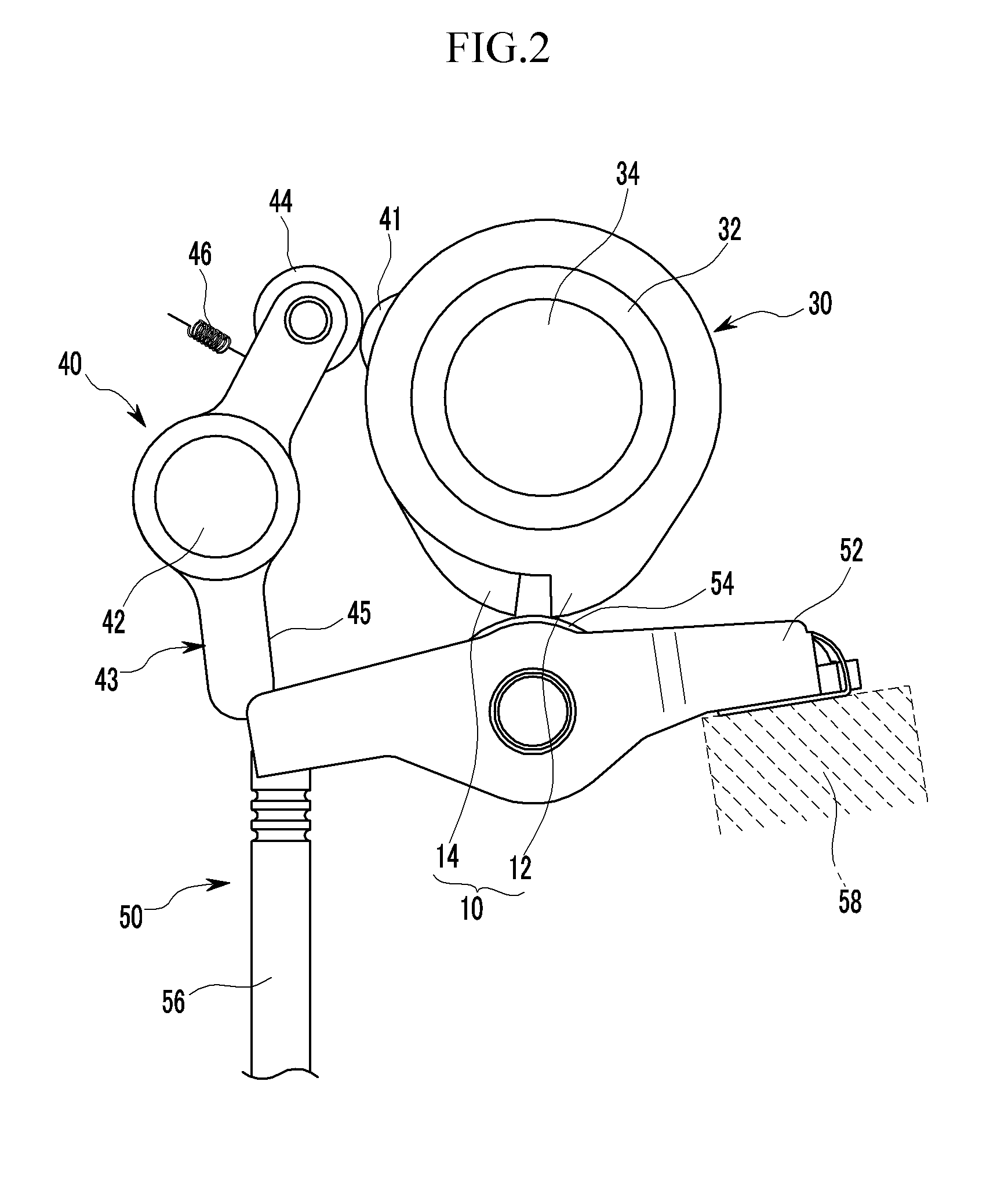

Variable valve lift apparatus

InactiveUS20090090320A1Simple design changeSimple elementsValve drivesMachines/enginesEngineeringHigh lift

A variable valve lift apparatus according to an exemplary embodiment of the present invention may include an outer part, an inner part disposed in the outer part and connected to a valve, a latching part that is disposed in the outer part and selectively connects the outer part and the inner part, a camshaft supplying torque, a low lift cam that is configured to the camshaft and selectively supplies torque to the inner part, and a high lift cam that is configured to the camshaft and supplies torque to the outer part.

Owner:HYUNDAI MOTOR CO LTD

Interface card coupling structure

InactiveUS7272016B2Simple structureIncrease productionEngagement/disengagement of coupling partsDigital data processing detailsCouplingStructural element

An interface card coupling structure includes a bracing member fastened to a case that has a retaining plate extending from an edge with a latch hole formed thereon, and a coupling member pivotally coupled on the retaining plate. The coupling member has a latch pin on one end facing the retaining plate to engage with the latch hole and anchor the coupling member on the retaining plate. The coupling member presses an interface card to form secure coupling. The coupling member may be made by injection forming. The structural elements of the bracing member of the interface card coupling structure are thus fewer. Hence the cost may be reduced and production speed increased.

Owner:INVENTEC CORP

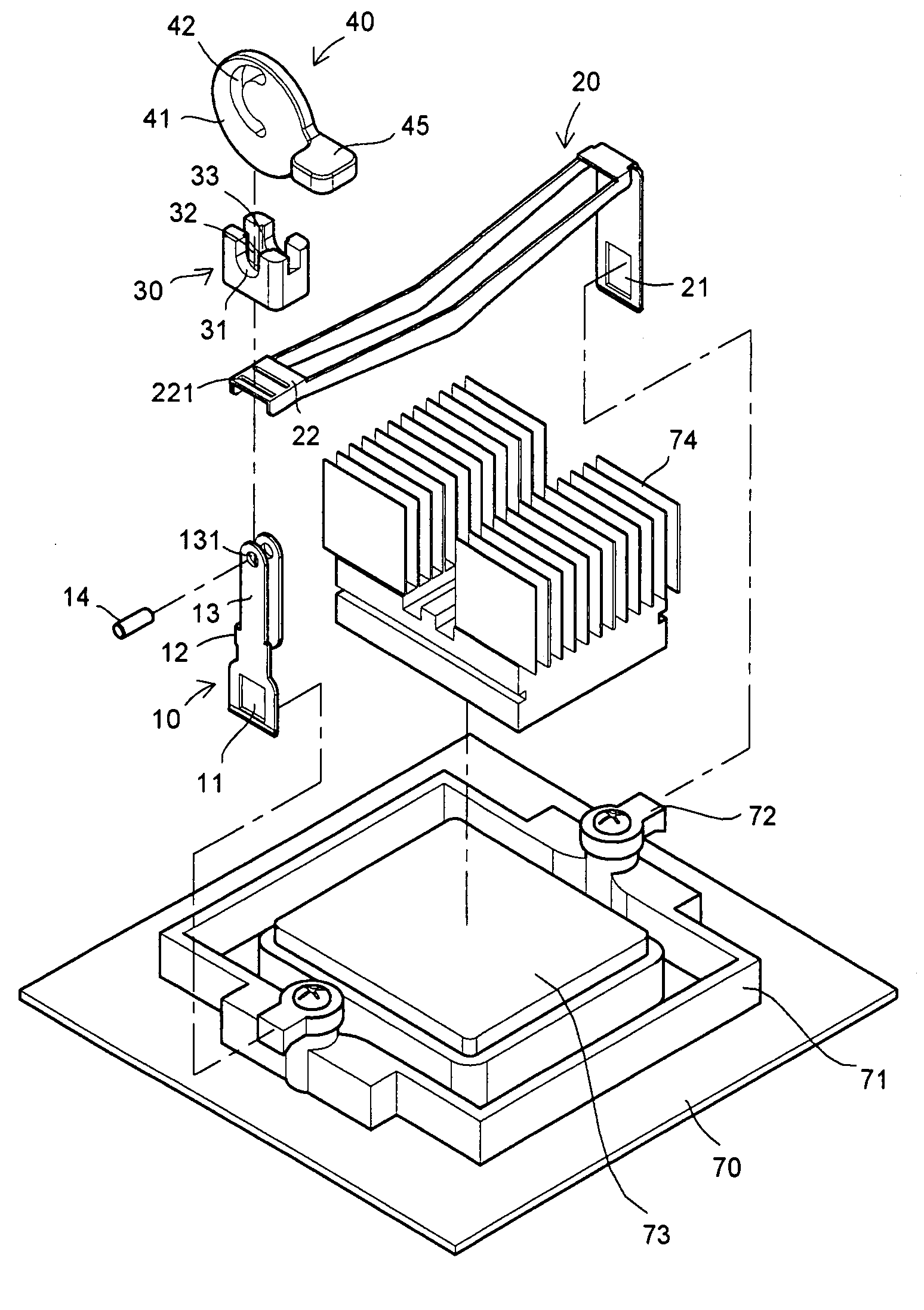

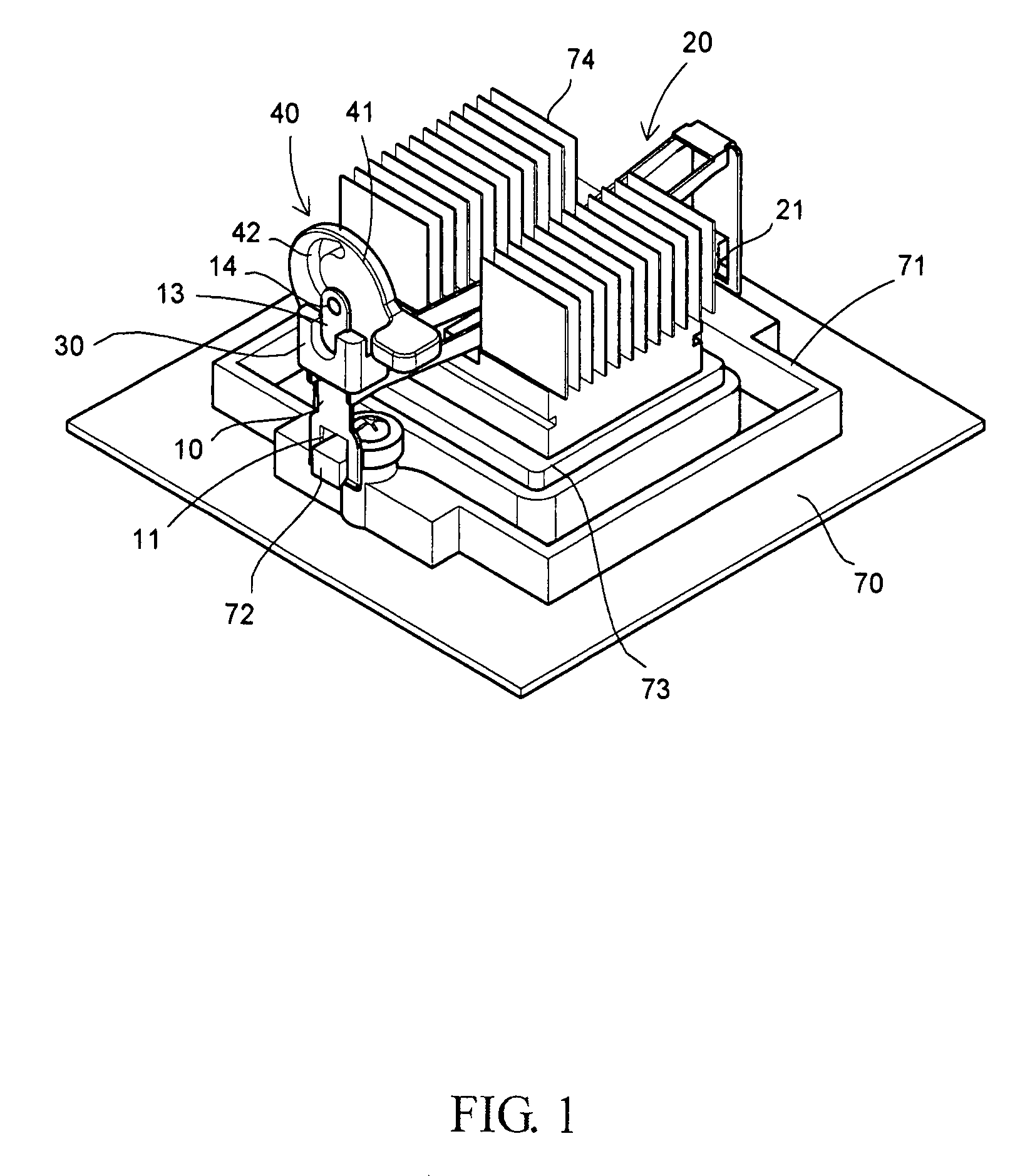

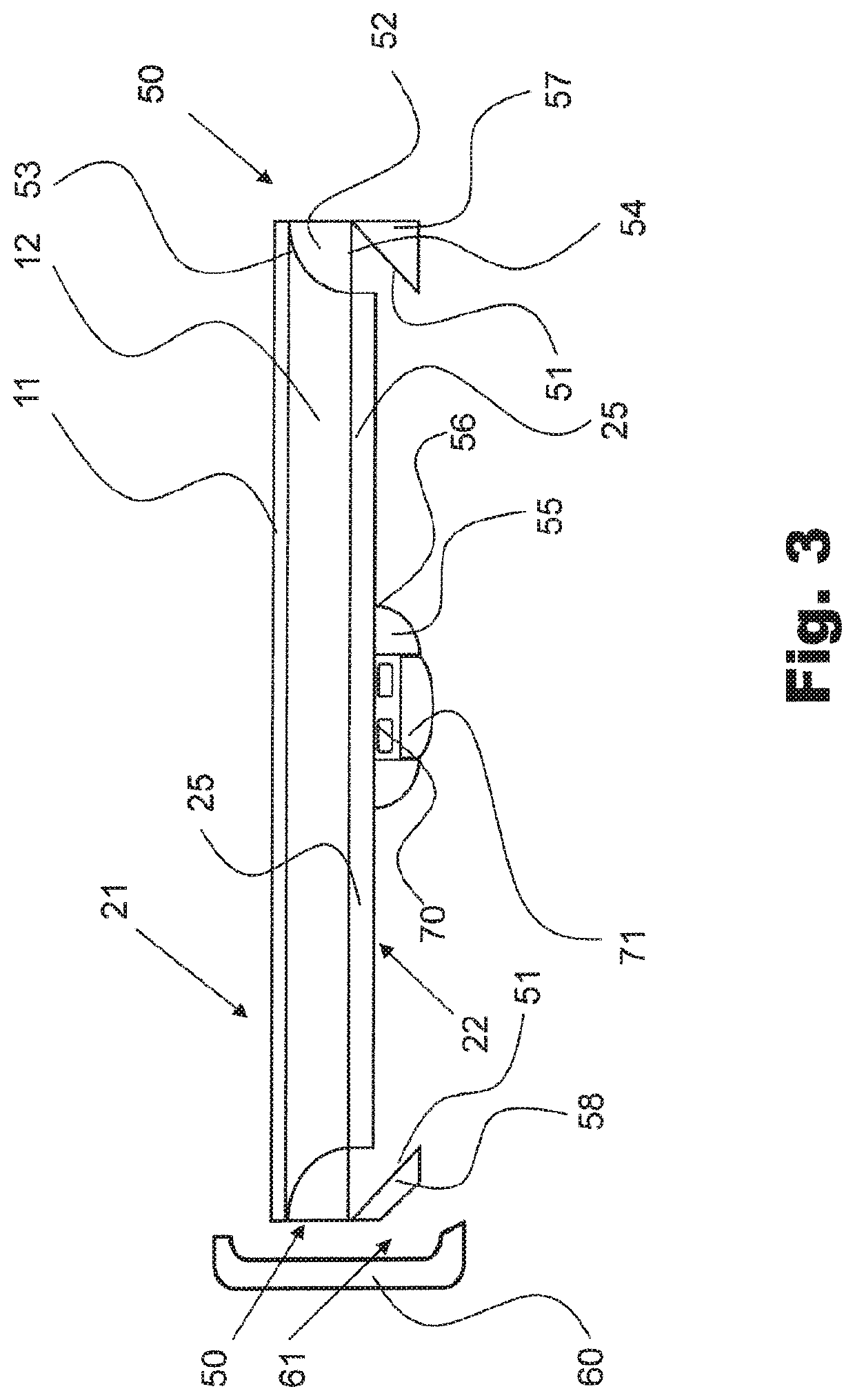

Retaining device for heat sink

InactiveUS7631402B2Simple structureLow costSnap fastenersSemiconductor/solid-state device detailsRelative motionEngineering

A retaining device for a heat sink includes a retaining piece, a retaining arm, a connection seat and a control member. The retaining piece has one end formed with a retaining hole and a top end formed with two tabs. The retaining arm has a vertical surface formed with a retaining hole. The tabs penetrate through the retaining arm and then the connection seat having an accommodating slot. The control member has a disk and a handle connected thereto. The disk in the accommodating slot has a hollow eccentric control slot. A pivot mounted to the tabs may slide in the control slot. The control member is rotated to move the pivot, which causes a relative movement between the retaining piece and the connection seat so that the retaining hole retains a mounting seat of the heat sink while the retaining arm tightly presses against the heat sink.

Owner:HUANG PO HUI

Roll

InactiveUS20060287177A1Powerful and efficient friction jointIncrease frictionShaft and bearingsRollsEngineeringMechanical engineering

Owner:SANDVIK INTELLECTUAL PROPERTY AB

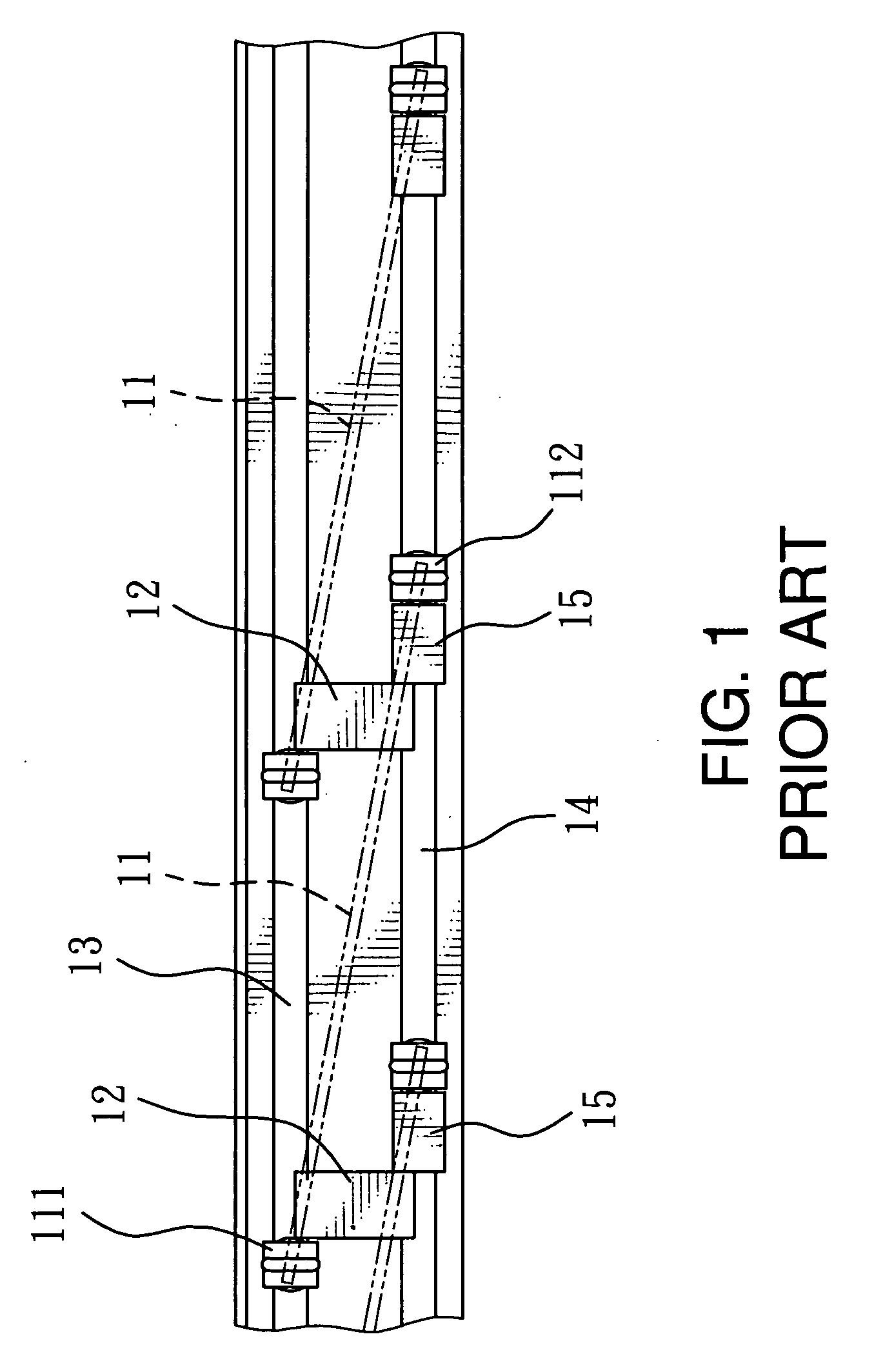

Window shade detention member

InactiveUS20080163986A1Precise positioningMore installedCurtain suspension devicesLight protection screensEngineeringMechanical engineering

A window shade detention member universally installable on a sliding flute of a upper beam to provide positioning and chained movement for window shades includes a first action side and a second action side. The first action side is located on a transverse side of a detention member and has side boards extended upwards and inwards from two sides of a base board to form a first trough and a second trough that form a transverse clipping trough which clips side wings of the sliding flute of the upper beam. The first action side also provides bucking for the chained movement of the window shades. The second action side is located on a longitudinal side of the detention member and has a third trough and a fourth trough on two ends of the connection junctures of the base board and side boards to form a longitudinal clipping trough. The longitudinal clipping trough clips the side wings of the sliding flute of the upper beam. The first action side provides lengthwise constraint while the second action side provide bucking so that the window shade can be installed on different tracks and confined without skewing. Chained movement of retraction and extension of the window shade can be done smoothly. The elements are simplified and universally applicable. Installation of the window shade is more flexible and versatile.

Owner:LI LIN YA

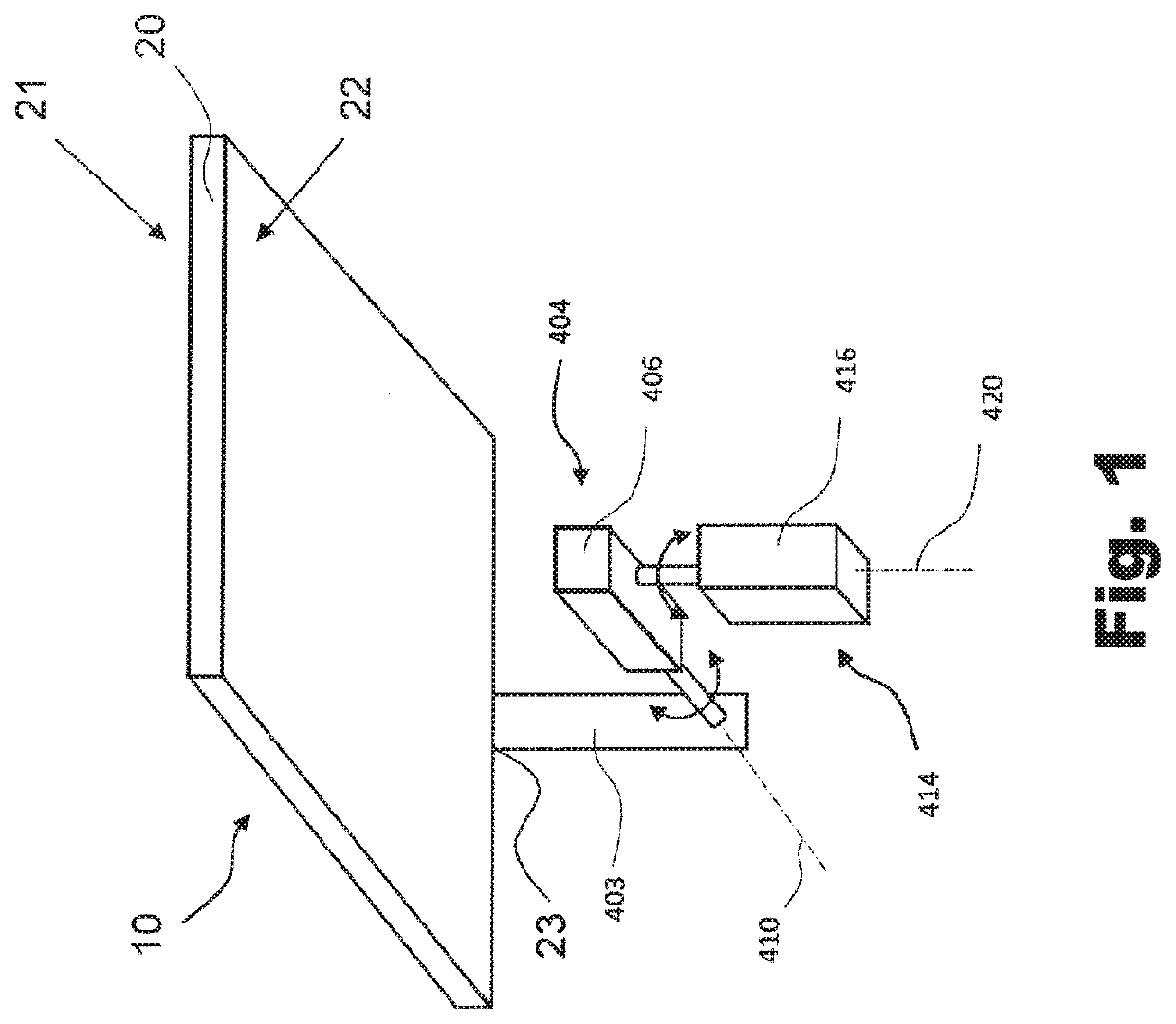

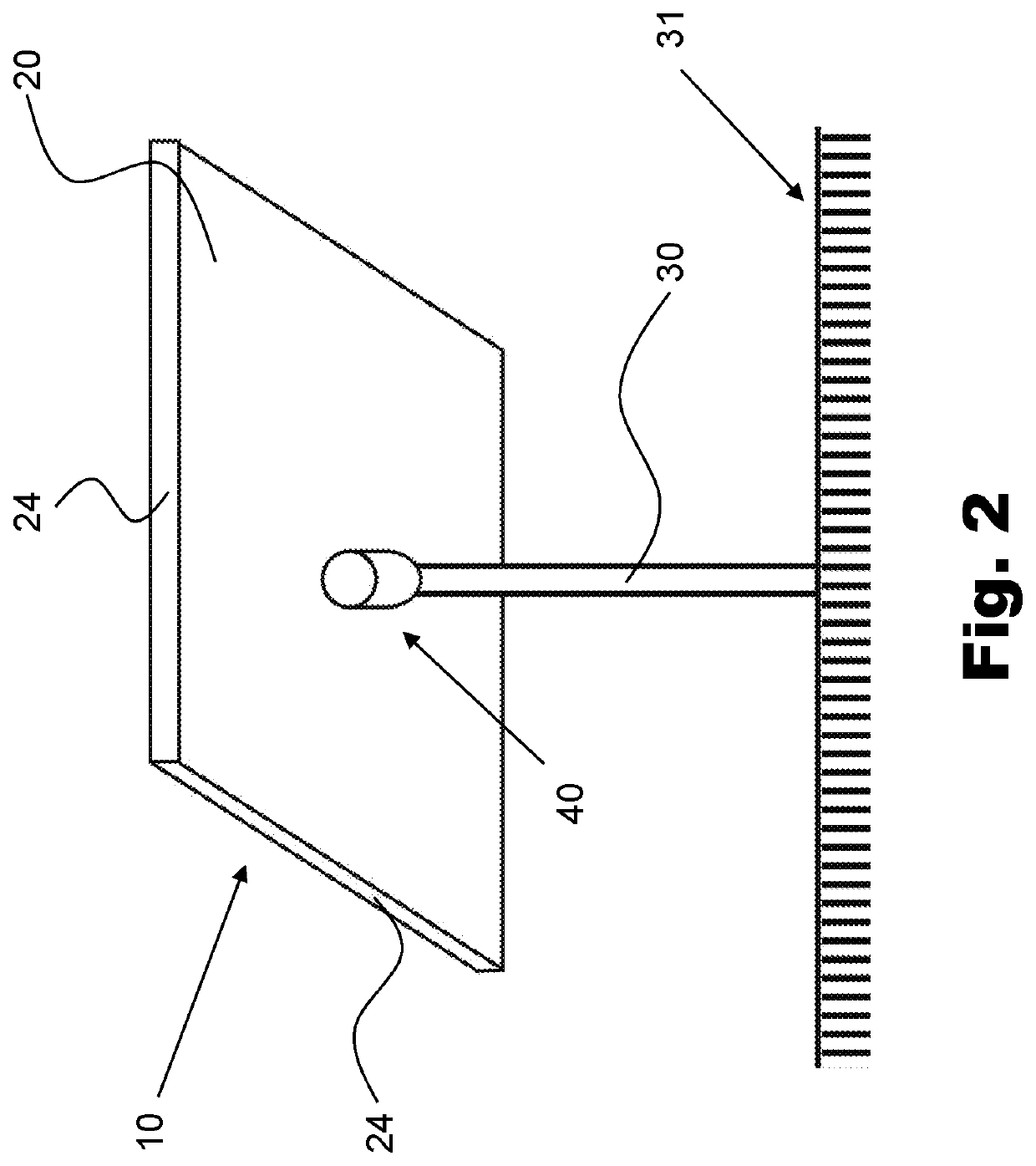

Directional solar panel assembly

ActiveUS20190353405A1Avoid lostSimple elementsPhotovoltaic supportsSolar heating energyNetwork connectionEngineering

A solar panel assembly (10) having a stand (30), a solar panel platform (20, 120) and one or more directional mechanisms (40; 404, 414) connecting the stand (30) with the solar panel platform. One or more optical elements (50; 161, 162) are provided at all or portions of the edges (24) of the platform around the solar panel directing the light under the platform (20, 120) or towards its underside (22), and then to the ground (31) under or near the solar panel assembly. One or more of the optical elements (161, 162) are mounted on an inner side of a profile (160). The profile (160) is connected via a web (164) to the solar panel platform (120) and the web is connected with a drive within the platform. The connection of the web extends the profile from the platform creating a passage (124) between the profile and the platform.

Owner:ELEMENTAL ENG

Retaining device for heat sink

InactiveUS20070212905A1Simple structureLow costSnap fastenersSemiconductor/solid-state device detailsRelative motionEngineering

A retaining device for a heat sink includes a retaining piece, a retaining arm, a connection seat and a control member. The retaining piece has one end formed with a retaining hole and a top end formed with two tabs. The retaining arm has a vertical surface formed with a retaining hole. The tabs penetrate through the retaining arm and then the connection seat having an accommodating slot. The control member has a disk and a handle connected thereto. The disk in the accommodating slot has a hollow eccentric control slot. A pivot mounted to the tabs may slide in the control slot. The control member is rotated to move the pivot, which causes a relative movement between the retaining piece and the connection seat so that the retaining hole retains a mounting seat of the heat sink while the retaining arm tightly presses against the heat sink.

Owner:HUANG PO HUI

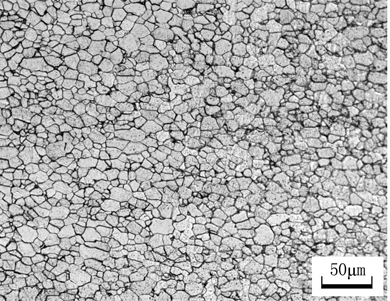

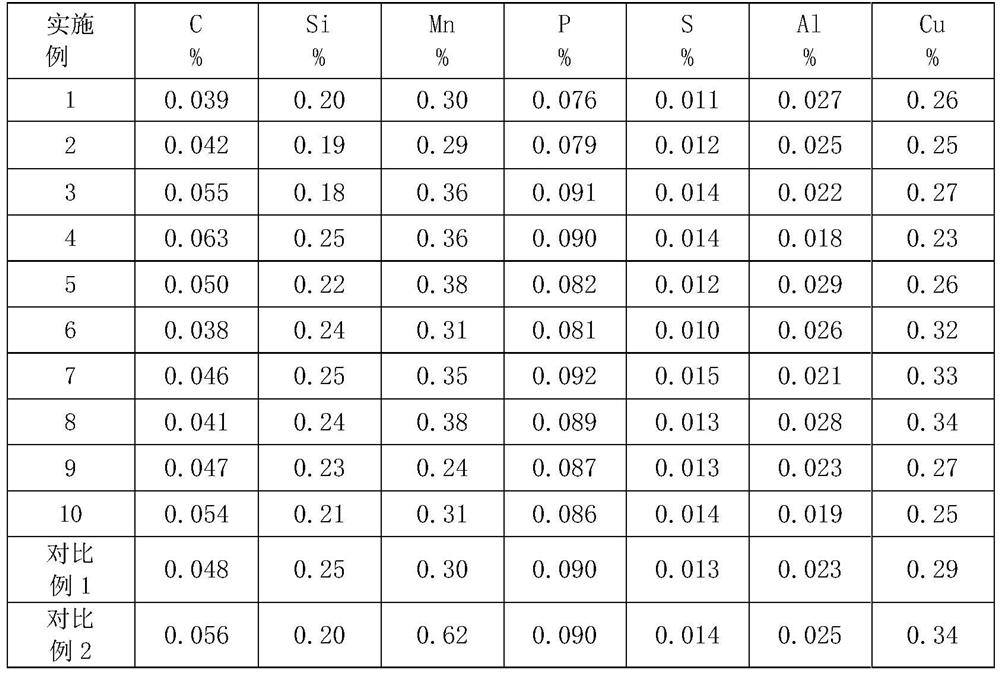

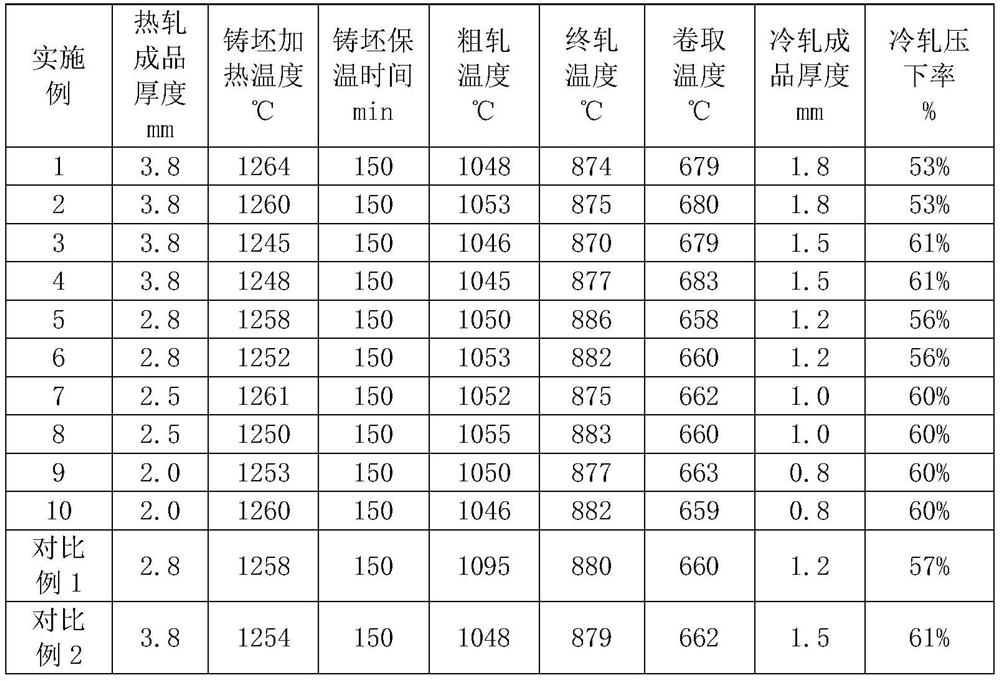

Cold-rolled economical weathering steel with yield strength of 280 MPa for automobiles and production method of cold-rolled economical weathering steel

PendingCN113637901AReduce the chance of occurrenceDegree of reductionTemperature control deviceFurnace typesContinuous annealingIron oxide

The invention discloses cold-rolled economical weathering steel with yield strength of 280 MPa for automobiles. The cold-rolled economical weathering steel comprises the following chemical components in percentage by weight: less than or equal to 0.09% of C, 0.10-0.40% of Si, 0.15-0.45% of Mn, 0.05-0.12% of P, less than or equal to 0.015% of S, 0.010-0.030% of Als and 0.2-0.4% of Cu. A production method comprises the following steps of: conducting desulfurizing; heating a casting blank; scouring the surface of the casting blank with high-pressure water; conducting rough rolling; conducting finish rolling; conducting coiling; conducting cold rolling after pickling; conducting continuous annealing; and conducting leveling according to the thickness of different cold-rolled finished products. According to the cold-rolled economical weathering steel, the elements are simple, and only cheap alloy elements such as Mn, Si and P are added; the occurrence probability and degree of Cu brittleness and scale are reduced, and the surface quality of a steel plate is improved; and the hot rolling coiling temperature and a cold rolling flattening elongation process are designed according to the thickness of the finished products, so that the uniformity and stability of the mechanical properties of the finished products with different thicknesses are ensured; the processing formability is good, the precision is high, and the atmospheric corrosion resistance is excellent; and the cold-rolled economical weathering steel is particularly suitable for structural parts which cannot be coated in the automobiles.

Owner:武汉钢铁有限公司

Variable valve driving apparatus

ActiveUS8596236B2Simple planReduce manufacturing costValve arrangementsYielding couplingDrive shaftRelative phase

A variable valve driving apparatus includes a driving shaft including a first camshaft and a second camshaft coaxially disposed to the first camshaft, a driving cam including an opening cam disposed to the first camshaft and a closing cam disposed to the second camshaft, a phase control portion controlling relative phases between the first camshaft and the second camshaft and a valve opening portion opened by the opening cam and the closing cam.

Owner:HYUNDAI MOTOR CO LTD

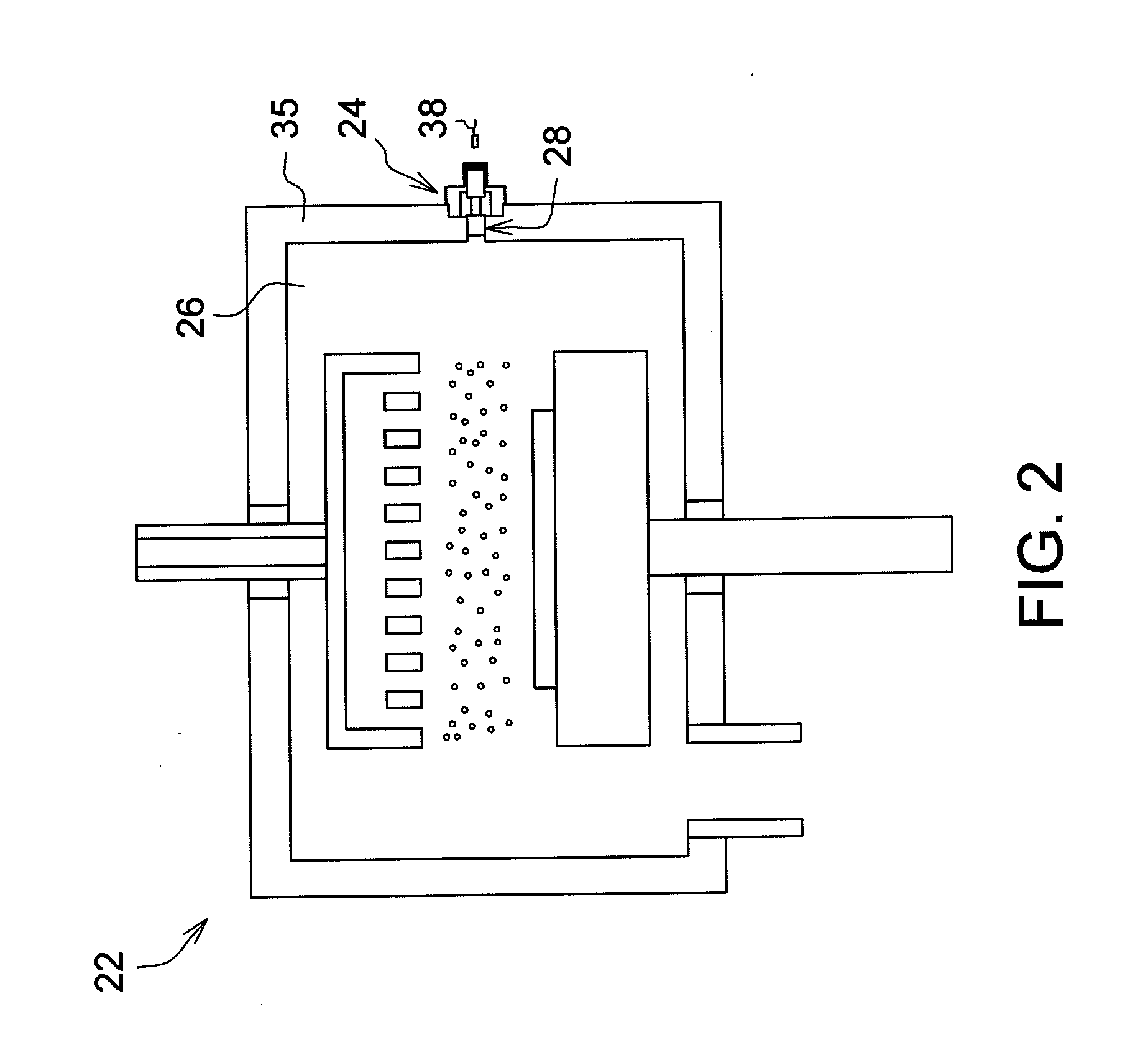

View port device for plasma process and process observation device of plasma apparatus

InactiveUS20120111269A1Low costReduce the amount requiredLiquid surface applicatorsElectric discharge tubesEngineering

A view port device for a plasma process and a process observation device of a plasma apparatus are provided. The view port device for a plasma process comprises a first substrate portion, a second substrate portion, and a connecting portion. The first substrate portion has a first through hole. The second substrate portion has a second through hole and a second diffusion space. A cross-sectional area of the second diffusion space is larger than that of the second through hole. The connecting portion is disposed between the first substrate portion and the second substrate portion.

Owner:IND TECH RES INST

Decoration panel

ActiveUS8459859B2Simple elementsOverall small sizePlanar/plate-like light guidesIlluminated signsLight guideReflective layer

A light guide module capable of illuminating and being applied in a device for decoration is provided. The light guide module includes a reflective layer, a light guide with a plurality of diffusing particles, and a light source. The light guide has a side surface, a reflective surface and a light-exiting surface, thereby allowing a light from the light source to enter and reflect and exit the light guide respectively. The reflective layer is disposed on the reflective surface of the light guide for reflecting the light to the light-exiting surface. The light guide forms a portion of an outer surface of the device.

Owner:COMPAL ELECTRONICS INC

Multi-piece jewelry set

Owner:LOGIAN ASHOT +1

Interface card coupling structure

InactiveUS20060232947A1Simple structureIncrease productionEngagement/disengagement of coupling partsDigital data processing detailsCouplingEngineering

An interface card coupling structure includes a bracing member fastened to a case that has a retaining plate extending from an edge with a latch hole formed thereon, and a coupling member pivotally coupled on the retaining plate. The coupling member has a latch pin on one end facing the retaining plate to engage with the latch hole and anchor the coupling member on the retaining plate. The coupling member presses an interface card to form secure coupling. The coupling member may be made by injection forming. The structural elements of the bracing member of the interface card coupling structure are thus fewer. Hence the cost may be reduced and production speed increased.

Owner:INVENTEC CORP

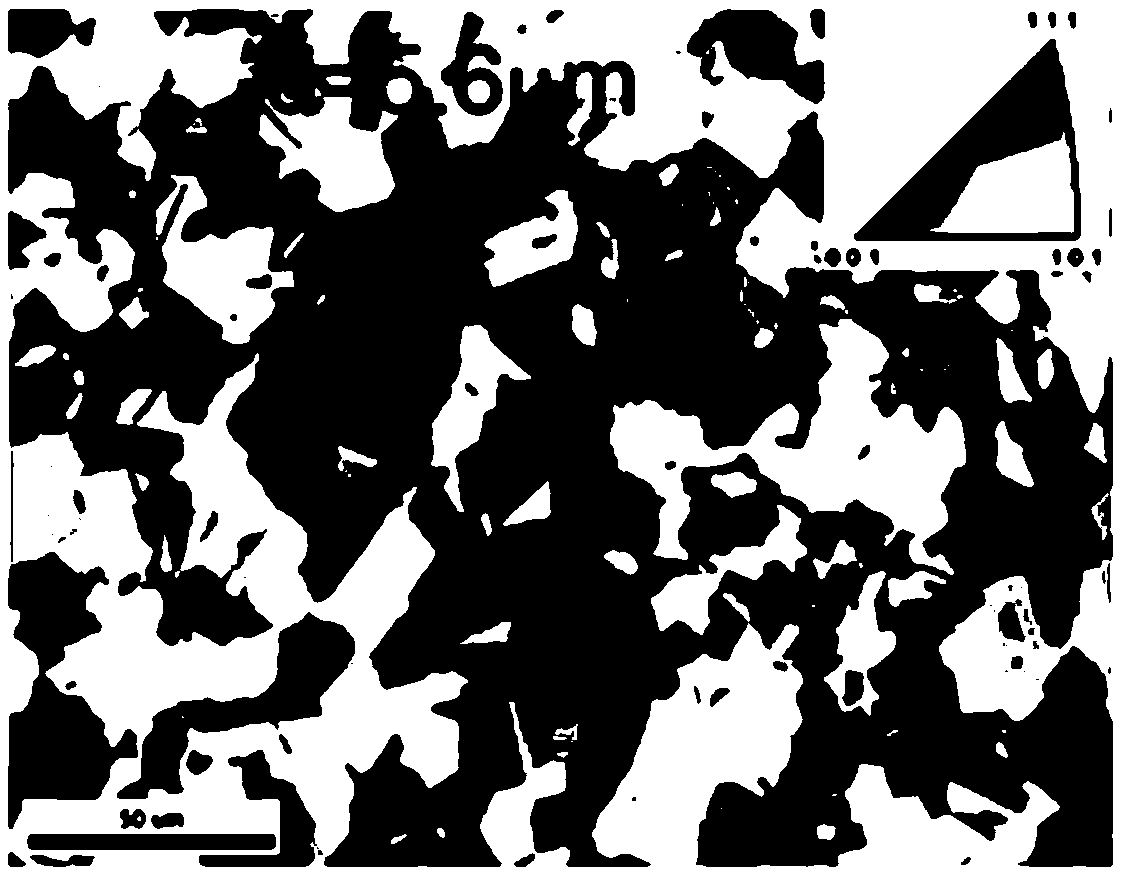

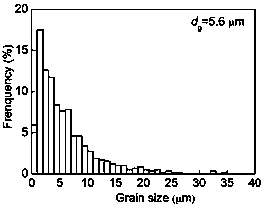

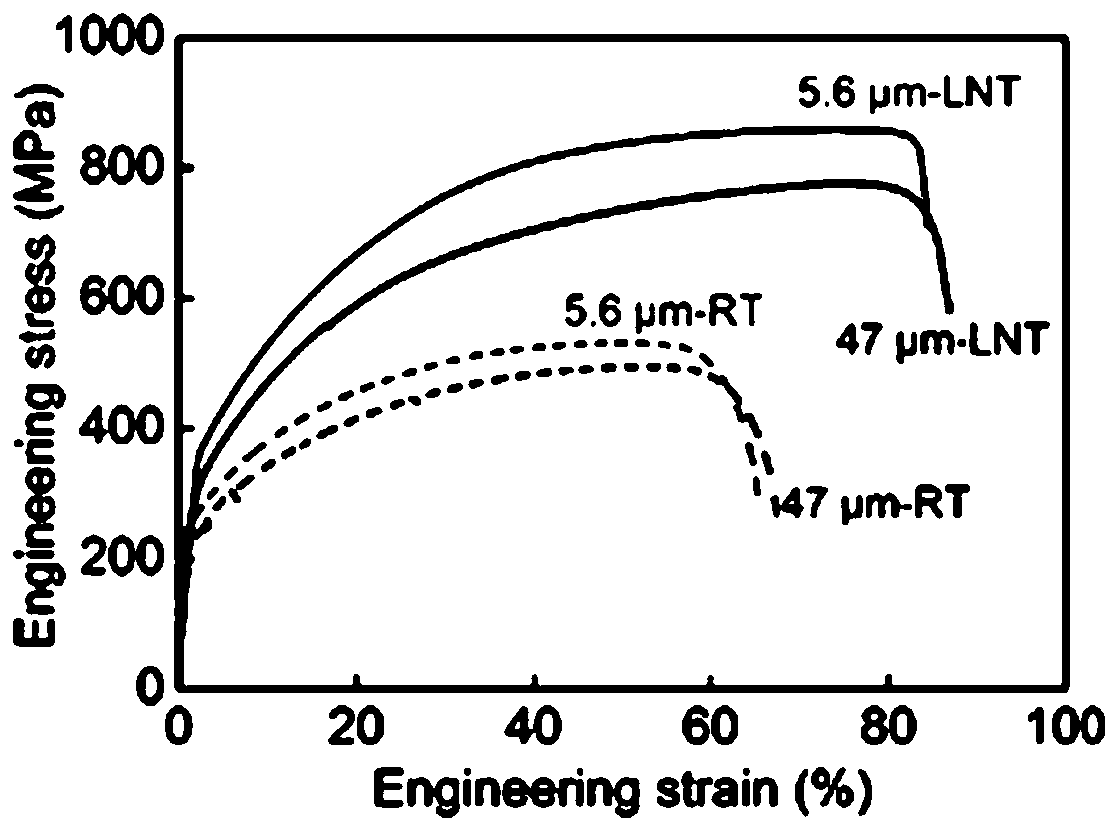

Super-tenacity steel and iron material and manufacturing method thereof

ActiveCN110983194ASimple elementsHas a complete face-centered cubic structureMetallic materialsQuenching

The invention provides a super-tenacity steel and iron material and a manufacturing method thereof, belongs to the field of steel and iron materials and processing and preparing of the steel and ironmaterials, and specifically relates to the super-tenacity steel and iron material used under low-temperature conditions and the manufacturing method of the super-tenacity steel and iron material. Thesteel and iron material comprises, by weight, 0.10%-0.15% of C, 29.5%-31.5% of Mn and the balance Fe and inevitable impurities. The manufacturing method includes the following steps that A1, argon-shielded smelting is conducted, and electroslag remelting processing is conducted; A2, hot rolling or hot forging is conducted; A3, annealing is conducted for 1 h at the temperature being 900 DEG C to 1100 DEG C, and quenching is conducted; A4, cold rolling is conducted, a cold-rolled sheet is subjected to annealing for 1 h at the temperature being 700 DEG C to 1200 DEG C, and quenching is conductedafter annealing. The steel material is simple in composition element and does not contain precious metal; and the average grain size is smaller than 30 micrometers, and the material has a complete face-centered cubic structure and does not have magnetism. Performance is particularly outstanding under low-temperature conditions, and the low-temperature impact energy exceeds that of all known metalmaterials at present.

Owner:YANSHAN UNIV

Ptychography based system and method

ActiveUS11347045B2Improve noiseFaster and reliable reconstructionColor television detailsMicroscopesPtychographySingle exposure

Owner:TECHNION RES & DEV FOUND LTD

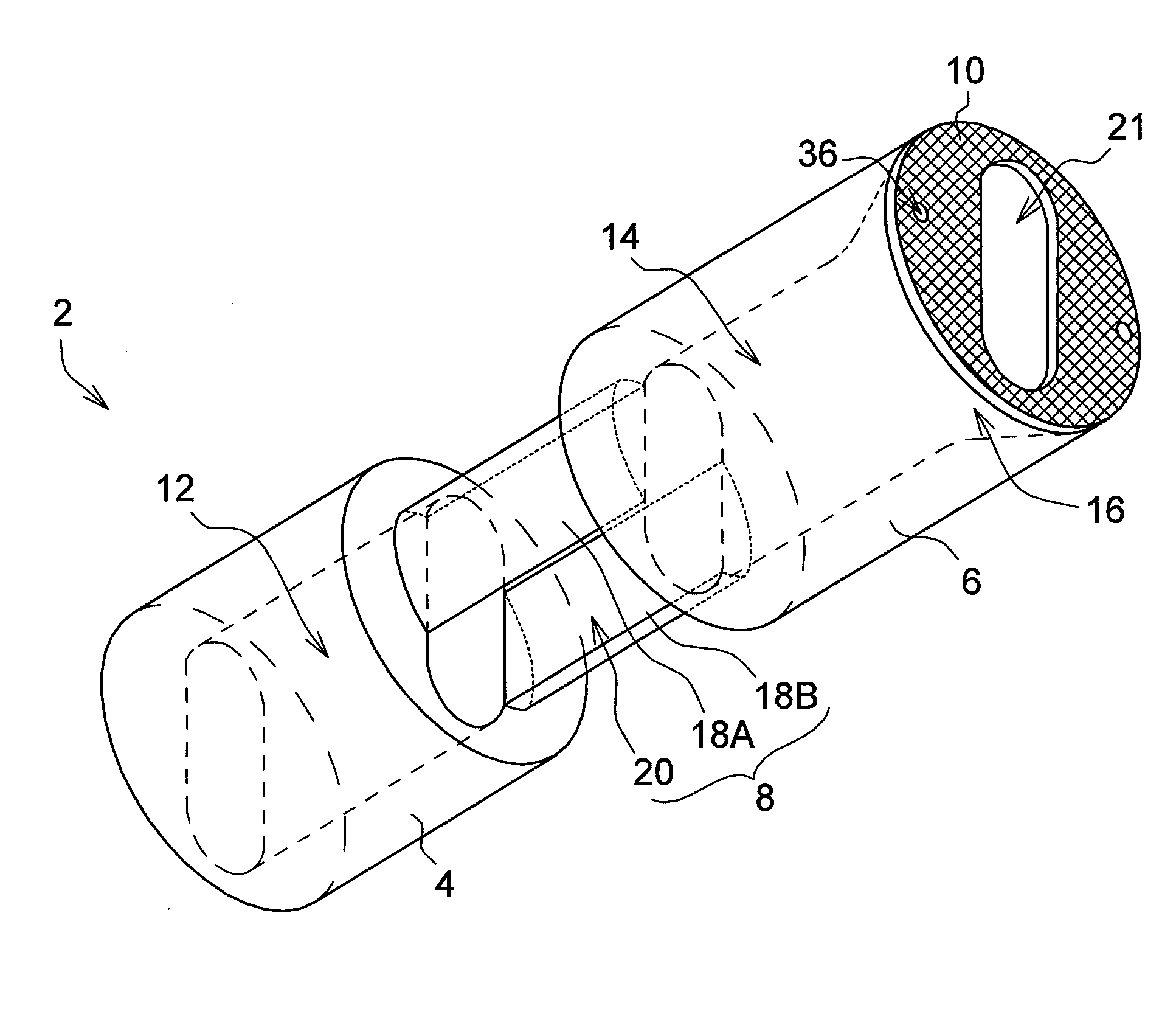

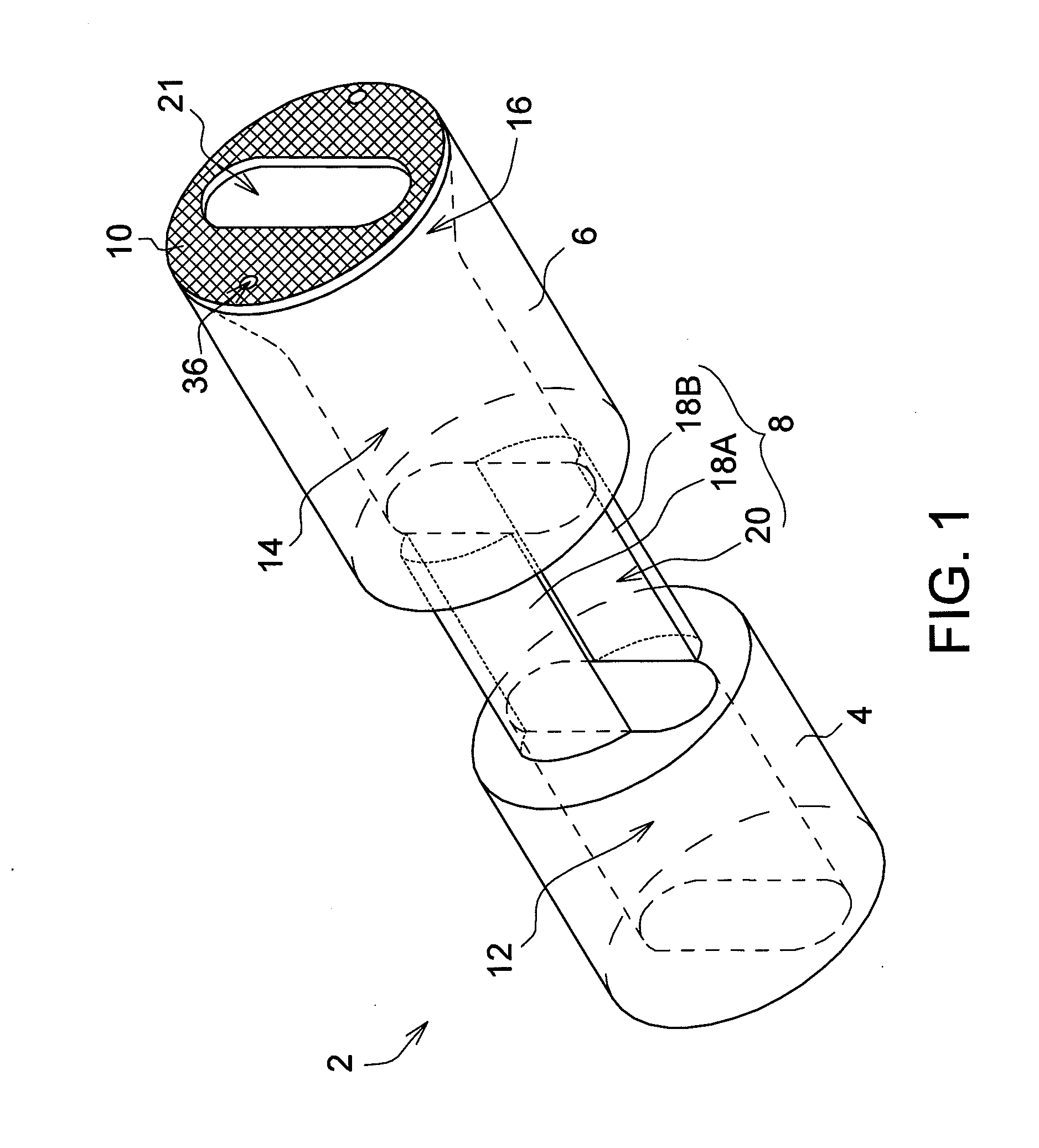

Continuous variable valve lift apparatus

InactiveUS20090151664A1Simple elementsIncreased durabilityValve arrangementsMachines/enginesEngineeringCam

A continuous variable valve lift apparatus according to an exemplary embodiment of the present invention includes an input cam disposed to an input shaft, a first shaft in parallel with the input shaft, a first link connected with the first shaft, a second link rotatably connected to the first link, an output cam that is rotatably connected with the second link and configured with a contact portion contacting the input cam, a second shaft disposed to the output cam parallel with the input shaft, at least one valve unit that is opened and closed by the output cam, and a control part that controls a position of the second shaft.

Owner:HYUNDAI MOTOR CO LTD

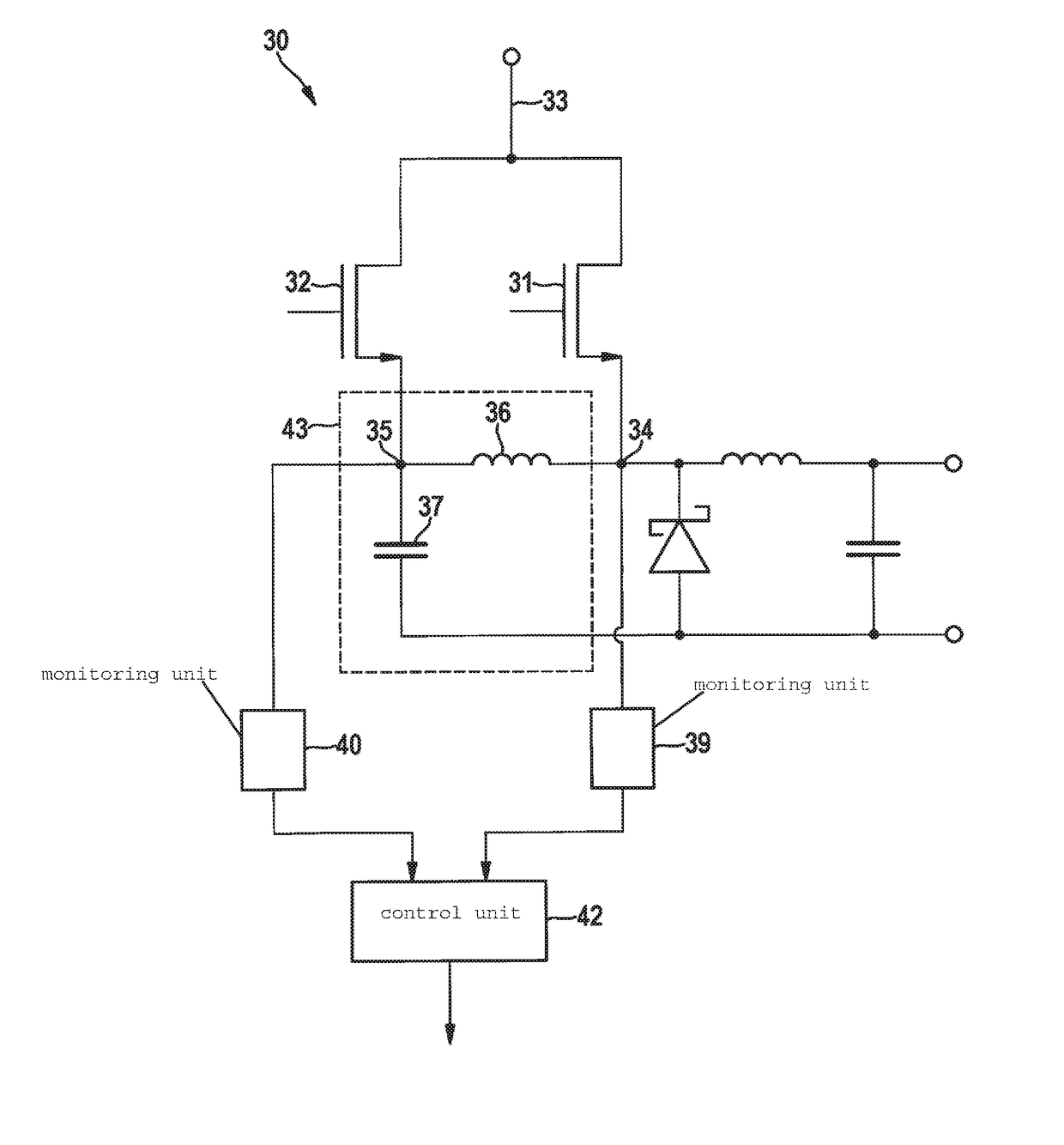

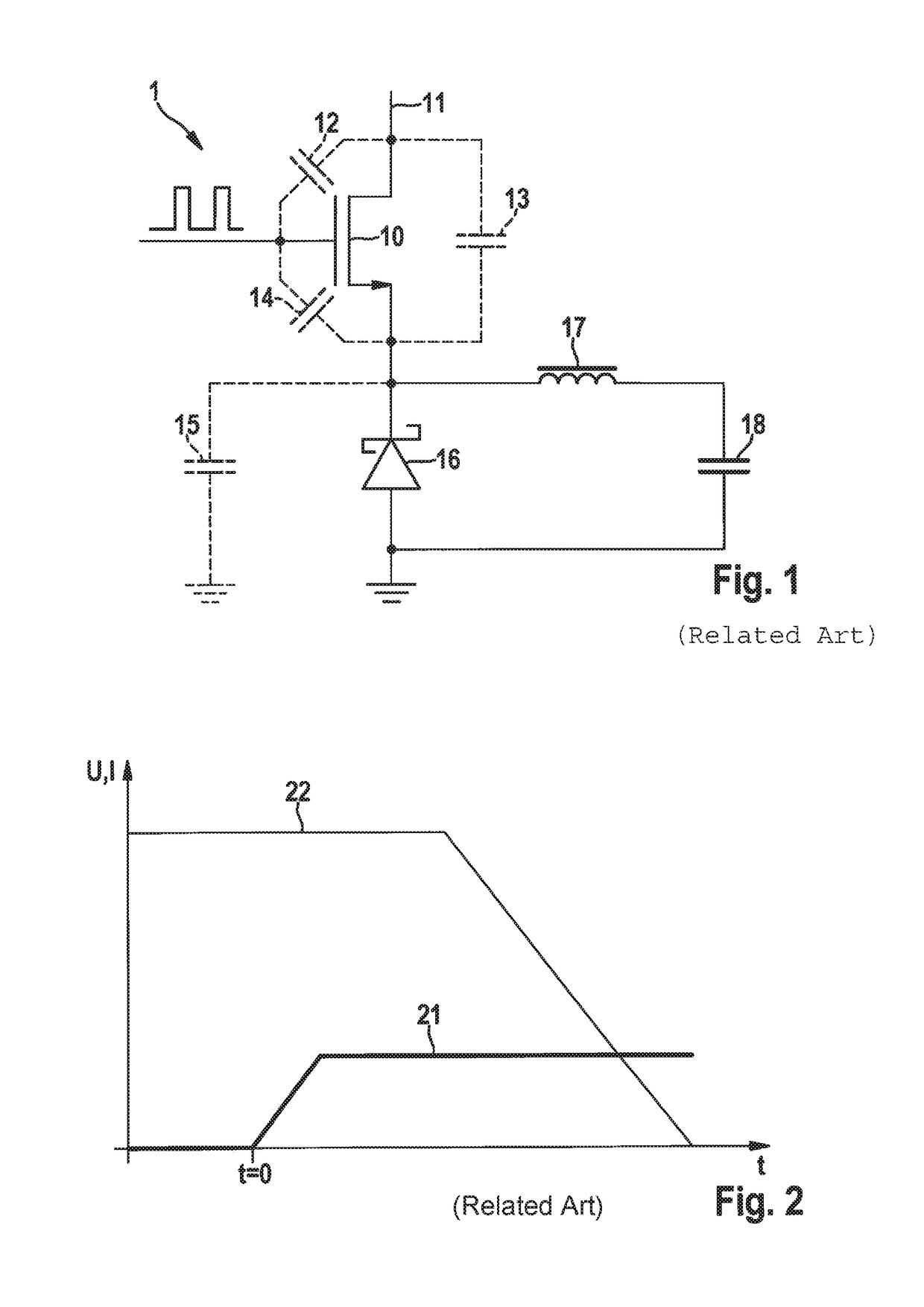

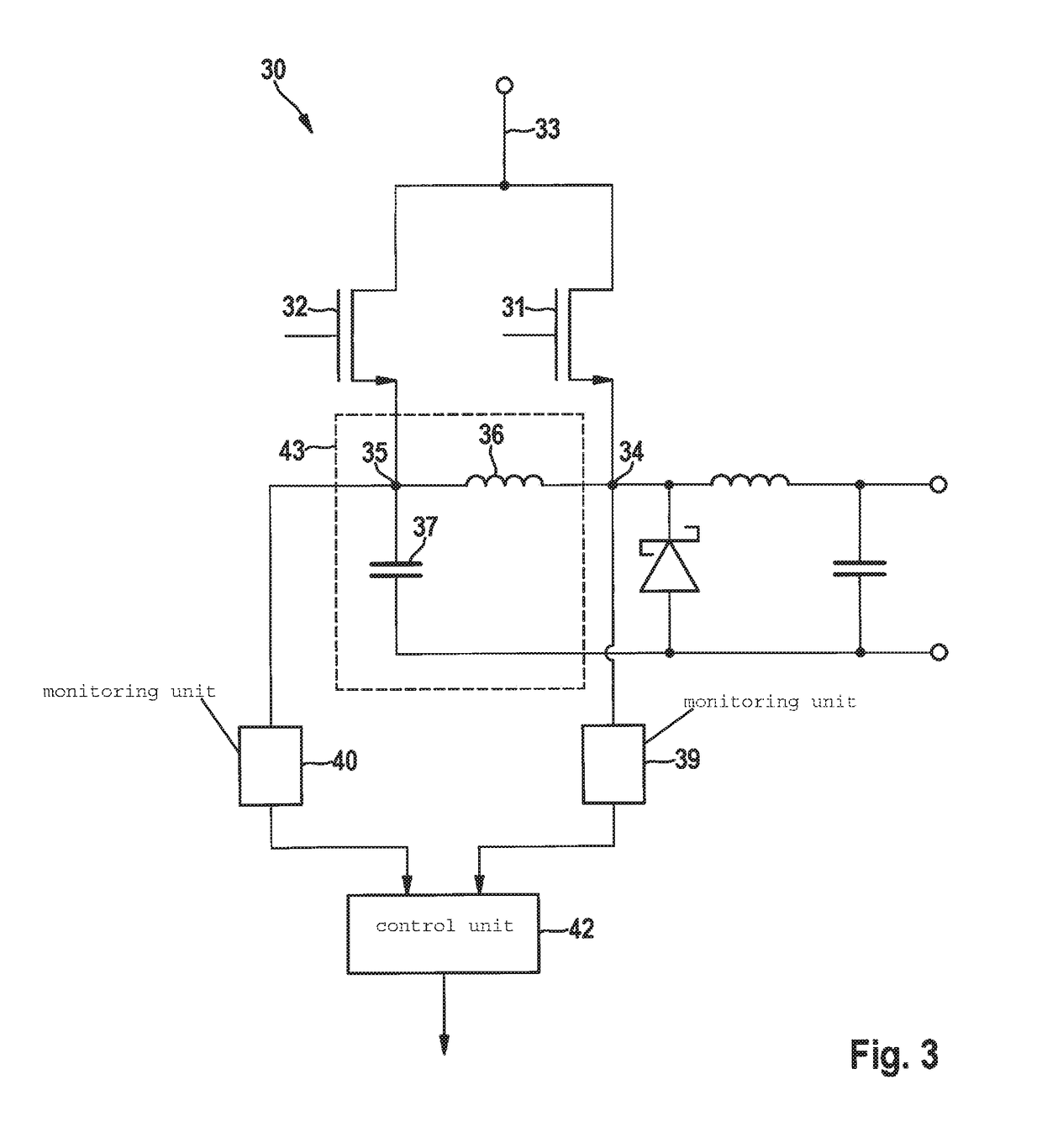

Device and method for reducing switching losses in power transistors

ActiveUS20170110957A1Reduce device sizeSmall sizeEfficient power electronics conversionDc-dc conversionTime switchingEngineering

A device including a first and second monitoring unit, the first monitoring unit detecting a first voltage potential and the second monitoring unit detecting a second voltage potential, the monitoring units comparing the first voltage potential and the second voltage potential to the value of the supply voltage and activate a control unit as a function of the comparisons, the control unit determining a switching point in time of a second power transistor, and an arrangement being present which generates current when the second power transistor is being switched on, the current changing the first voltage potential, and the control unit activates a first power transistor when the first voltage potential has the same value as the supply voltage, so that the first power transistor is de-energized.

Owner:ROBERT BOSCH GMBH

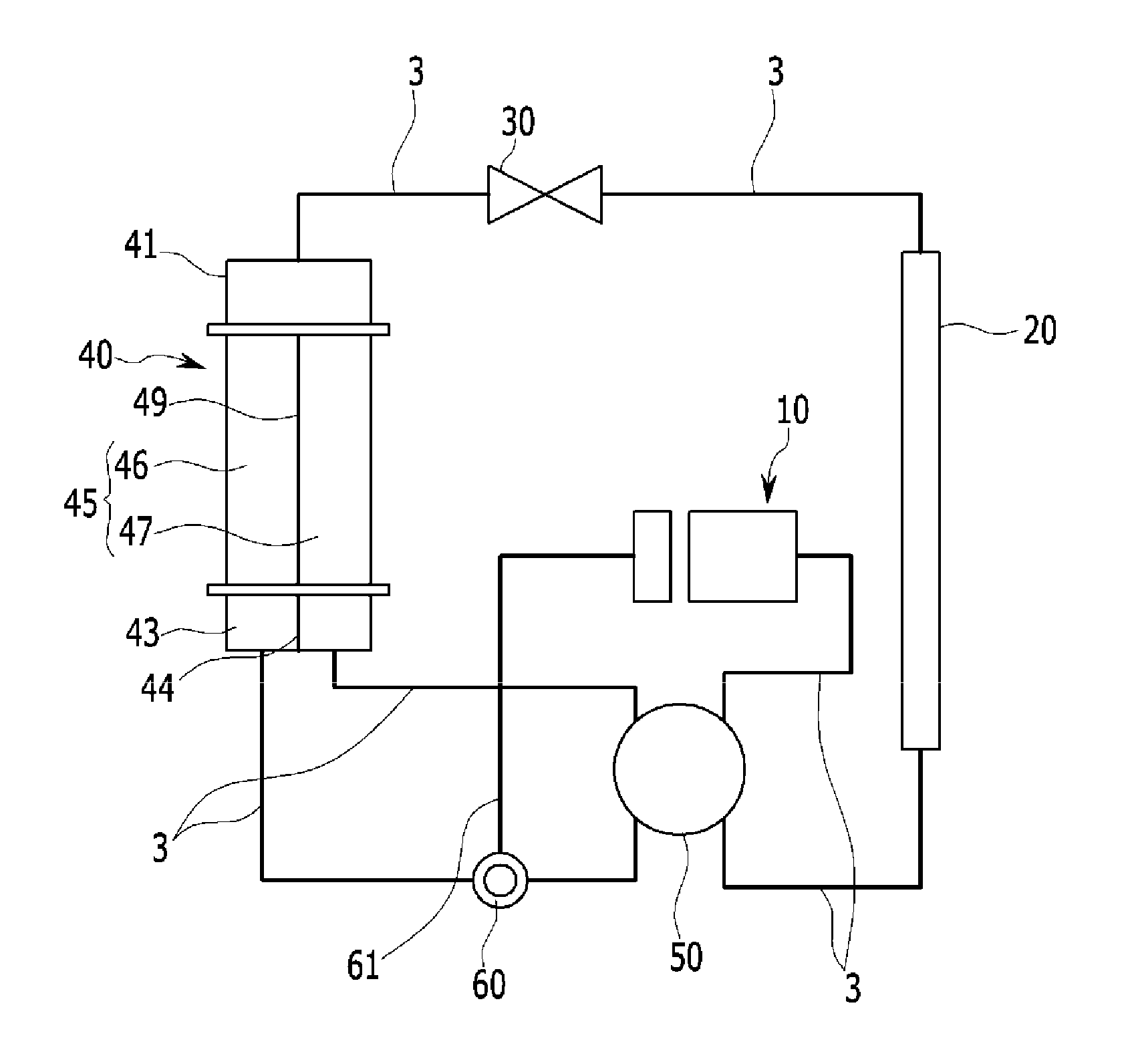

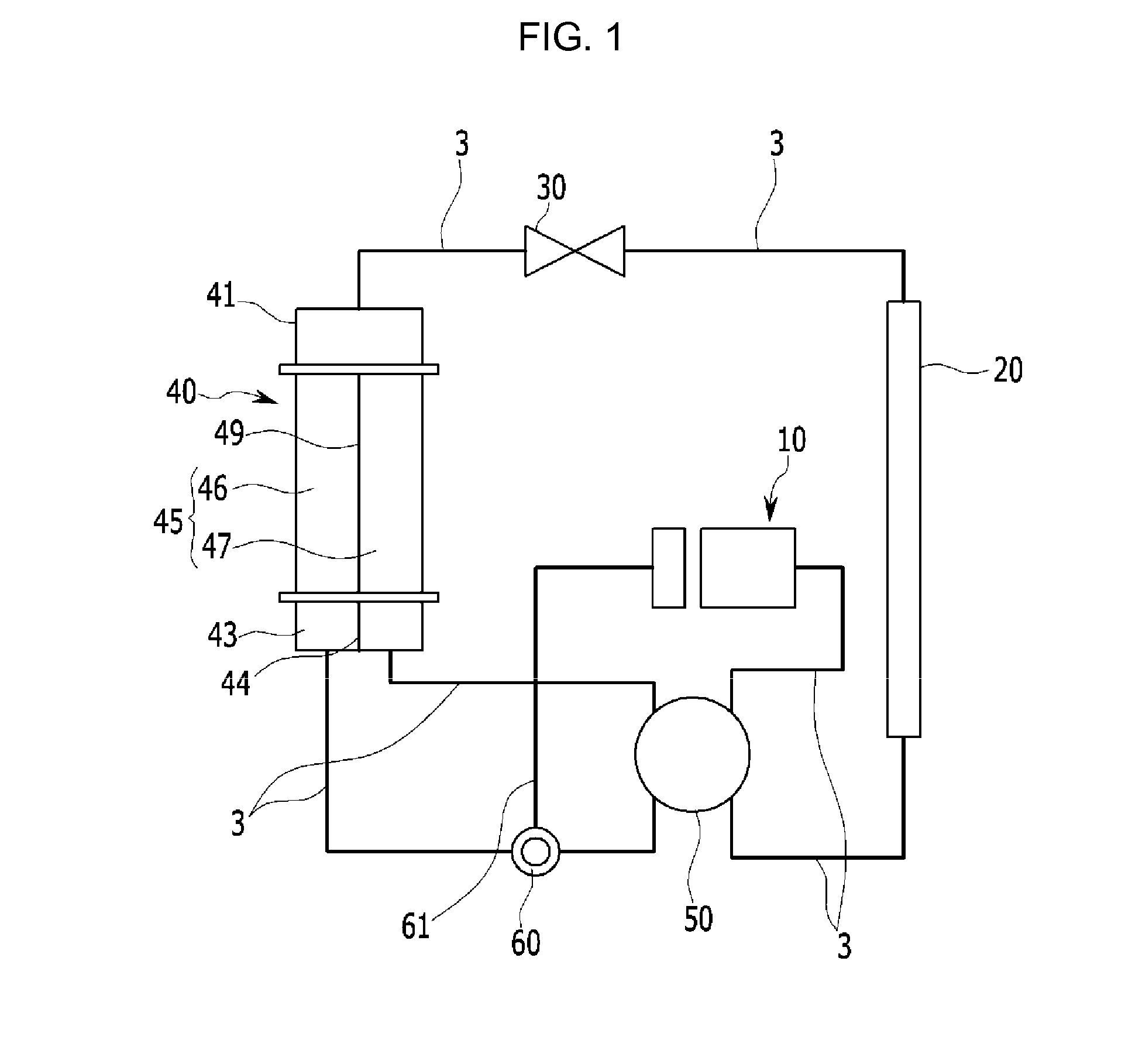

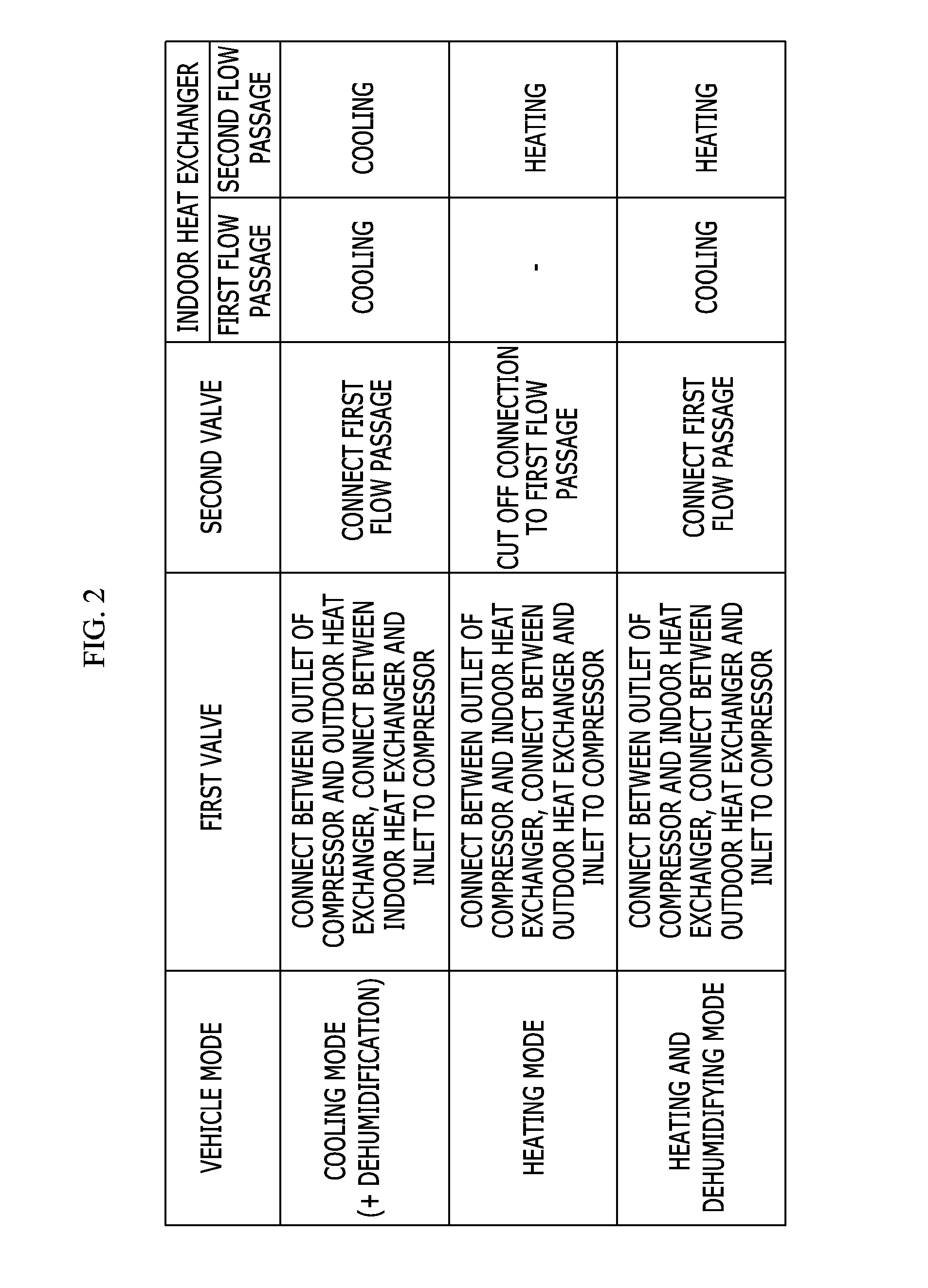

Heat Pump System in Vehicle

ActiveUS20150292781A1Simple elementsMinimize the numberAir-treating devicesVehicle heating/cooling devicesIn vehicleRefrigerant

A heat pump system in a vehicle connected with a refrigerant line through which refrigerant flows for controlling cooling / heating of a cabin of the vehicle, including a compressor for compressing refrigerant, an outdoor heat exchanger for condensing high temperature and high pressure refrigerant compressed at the compressor, and an expansion valve for expanding the refrigerant compressed thus, may include an indoor heat exchanger arranged between the compressor and the expansion valve connected to one another with the refrigerant line, and having a partitioned inside to form individual flow passages, and a first valve connected to the compressor, the outdoor heat exchanger and the indoor heat exchanger with the refrigerant line for changing a direction of a refrigerant flow according to cooling, heating, and dehumidifying modes of the vehicle to control the refrigerant flow along the refrigerant line.

Owner:HYUNDAI MOTOR CO LTD

Variable valve driving apparatus

ActiveUS20120137999A1Simple planReduce manufacturing costValve arrangementsYielding couplingRelative phaseDrive shaft

A variable valve driving apparatus includes a driving shaft including a first camshaft and a second camshaft coaxially disposed to the first camshaft, a driving cam including an opening cam disposed to the first camshaft and a closing cam disposed to the second camshaft, a phase control portion controlling relative phases between the first camshaft and the second camshaft and a valve opening portion opened by the opening cam and the closing cam.

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com