Super-tenacity steel and iron material and manufacturing method thereof

A steel material and toughness technology, which is applied in the field of super tough steel material and its manufacturing, can solve the problems of brittle fracture impact toughness of metal materials, and achieve the effect of outstanding performance and simple composition elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Example 1: Fe-29.5%Mn-0.10%C, passed through 50% cold rolling and then annealed at 700°C for 1 hour.

Embodiment 2

[0102] Example 2: Fe-30%Mn-0.11%C, annealed at 700°C for 1 hour after passing 50% cold rolling.

Embodiment 3

[0103] Example 3: Fe-31.5%Mn-0.15%C, after passing 50% cold rolling, annealing at 700°C for 1 hour.

[0104] Table 3. Room temperature and liquid nitrogen temperature impact energy of steel samples with different compositions

[0105]

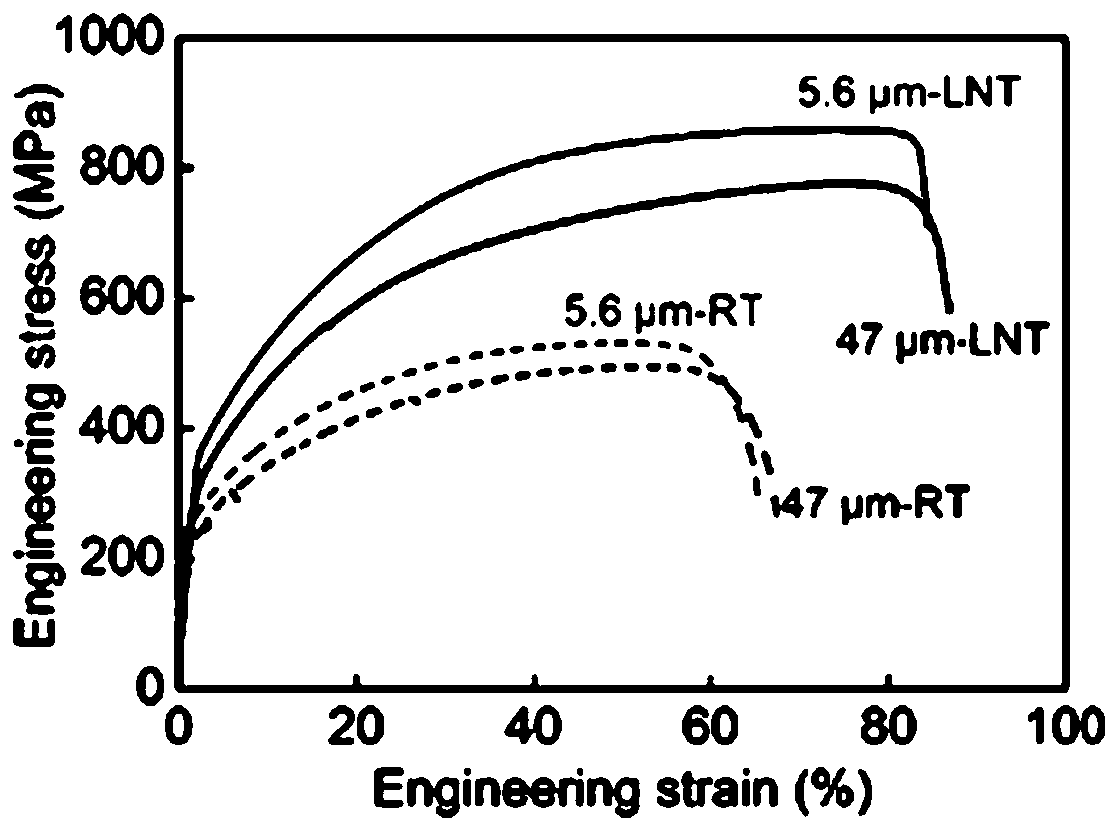

[0106] In the above examples, three samples were made in each case. It can be seen that, compared with the comparative example, the impact energy is greatly improved under low temperature conditions, and an inverse temperature effect occurs. Among them, the performance index of Example 2 is the best.

[0107] The following examples and comparative examples are aimed at the characteristics of Fe-30%Mn-0.11%C steel obtained by different processes.

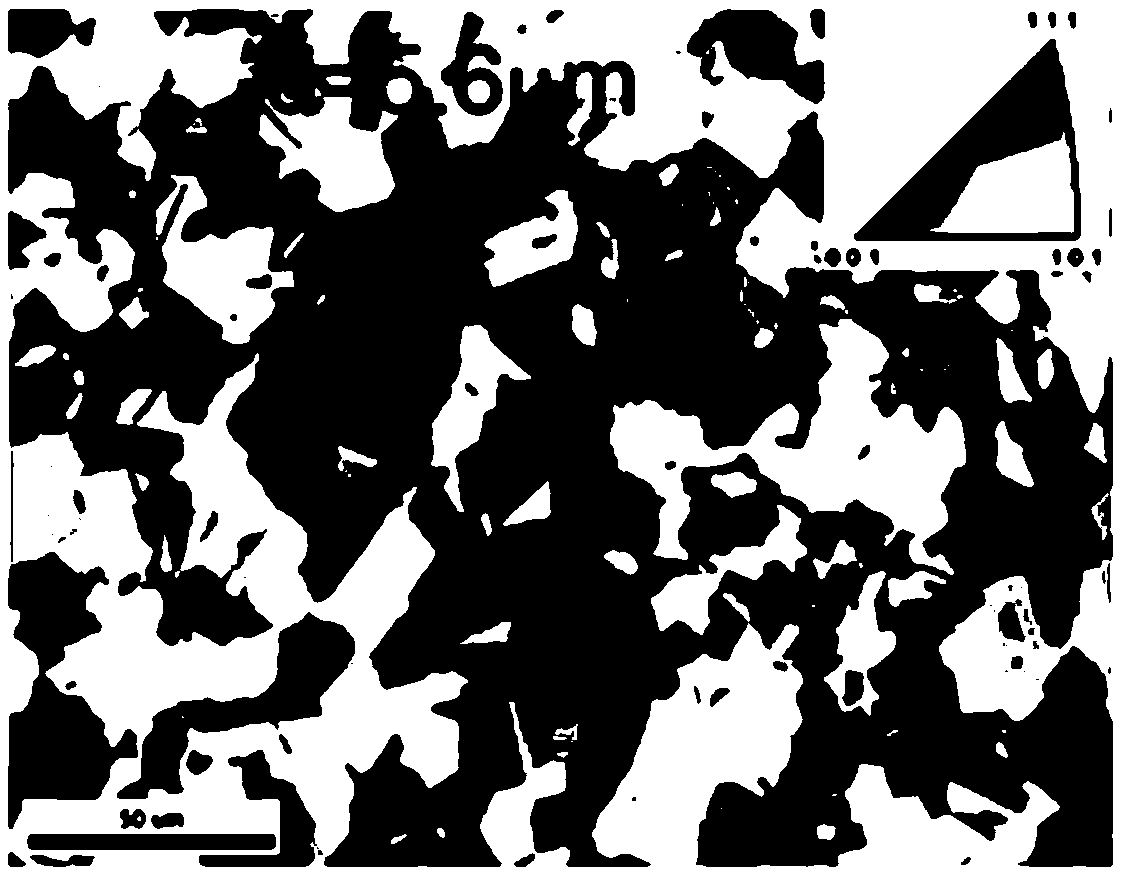

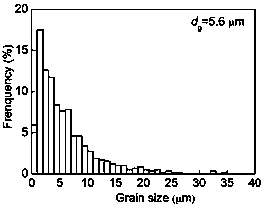

[0108] Example 2: 0.11% C, 30% Mn, the rest is Fe and inevitable impurities. After hot forging and annealing, 50% cold rolling, rolling speed of 4.2m / s, pass deformation of 1mm / pass; after cold rolling, annealing at 700℃ for 1 hour, Fe-30 with an average grain size of 5.6 microns is obtained %Mn-0.11%C stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com