Directional solar panel assembly

a solar panel and assembly technology, applied in the direction of solar heat collectors, photovoltaics, solar radiation concentration, etc., can solve the problems of unusable surfaces, achieve the effect of avoiding vegetation loss, simple elements, and better adapted to withstand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The following describes in detail embodiments of the present disclosure. Examples of the embodiments are shown in the accompanying drawings, where reference signs that are the same or similar represent same or similar components or components that have same or similar functions.

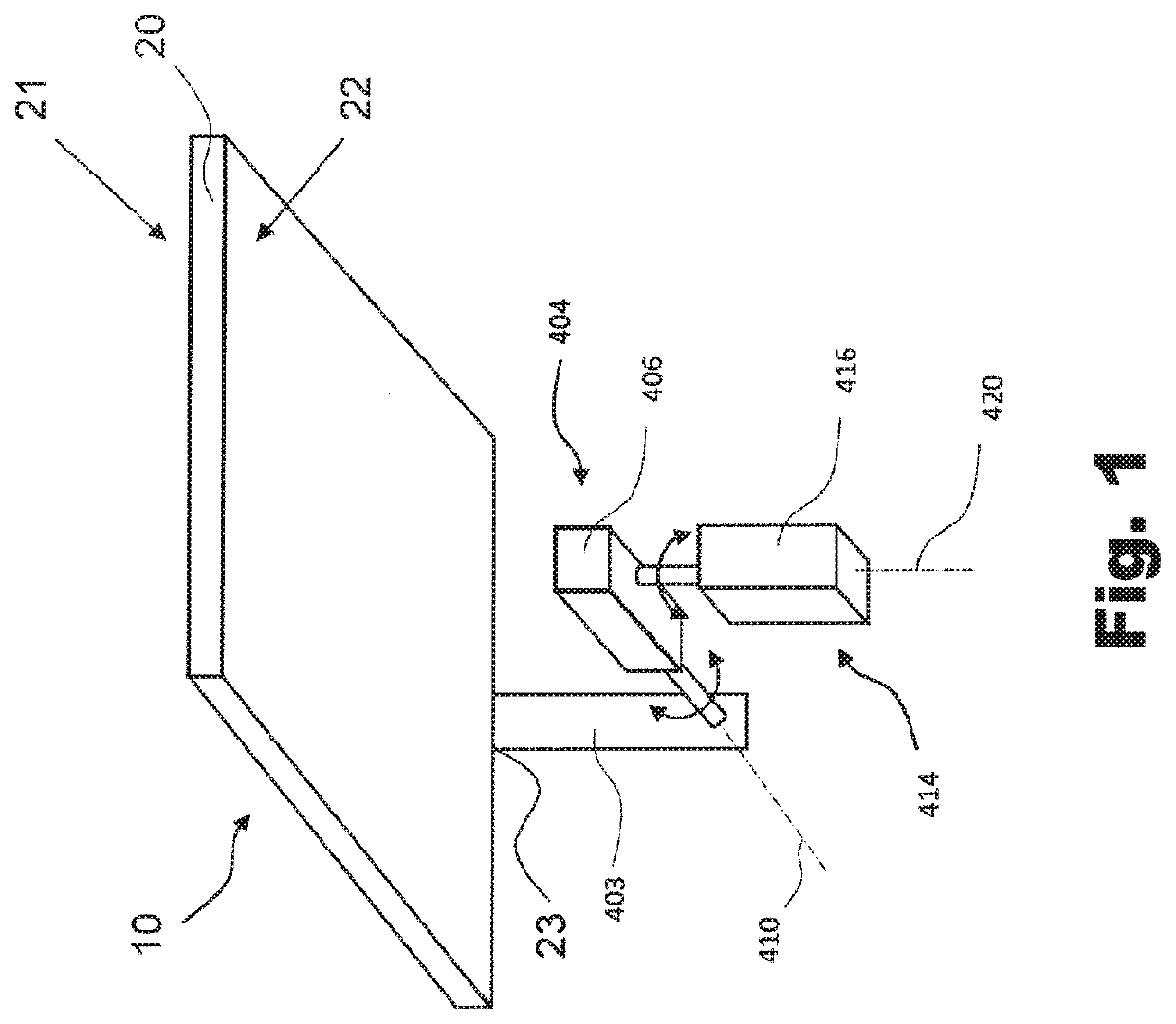

[0042]FIG. 1 is a schematic perspective view from below of a mechanism for directing a solar panel according to an embodiment of the invention. The solar panel assembly 10 comprises a platform 20. On the upper surface 21 of the platform 20, a photovoltaic, i.e. solar panel (not shown) as well as optional sensors of a tracking device are mounted. In an alternative embodiment, the platform 20 itself can comprise a solar cell module with a corresponding perimeter frame. In either case, the upper surface 21 of the platform 20 is to be oriented to the sky and provides the solar panel surface, whereas the underside 22 comprises one or more attachment points 23 for the adjustment, i.e. directional, mechanisms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com