Process for producing integrated energy saving neon lamp

A production process and technology of neon lights, applied in the direction of instruments, identification devices, etc., can solve the problems of high cost, high maintenance rate, easy damage of lamp tubes, etc., and achieve the effect of long service life, low power consumption, and uniform light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

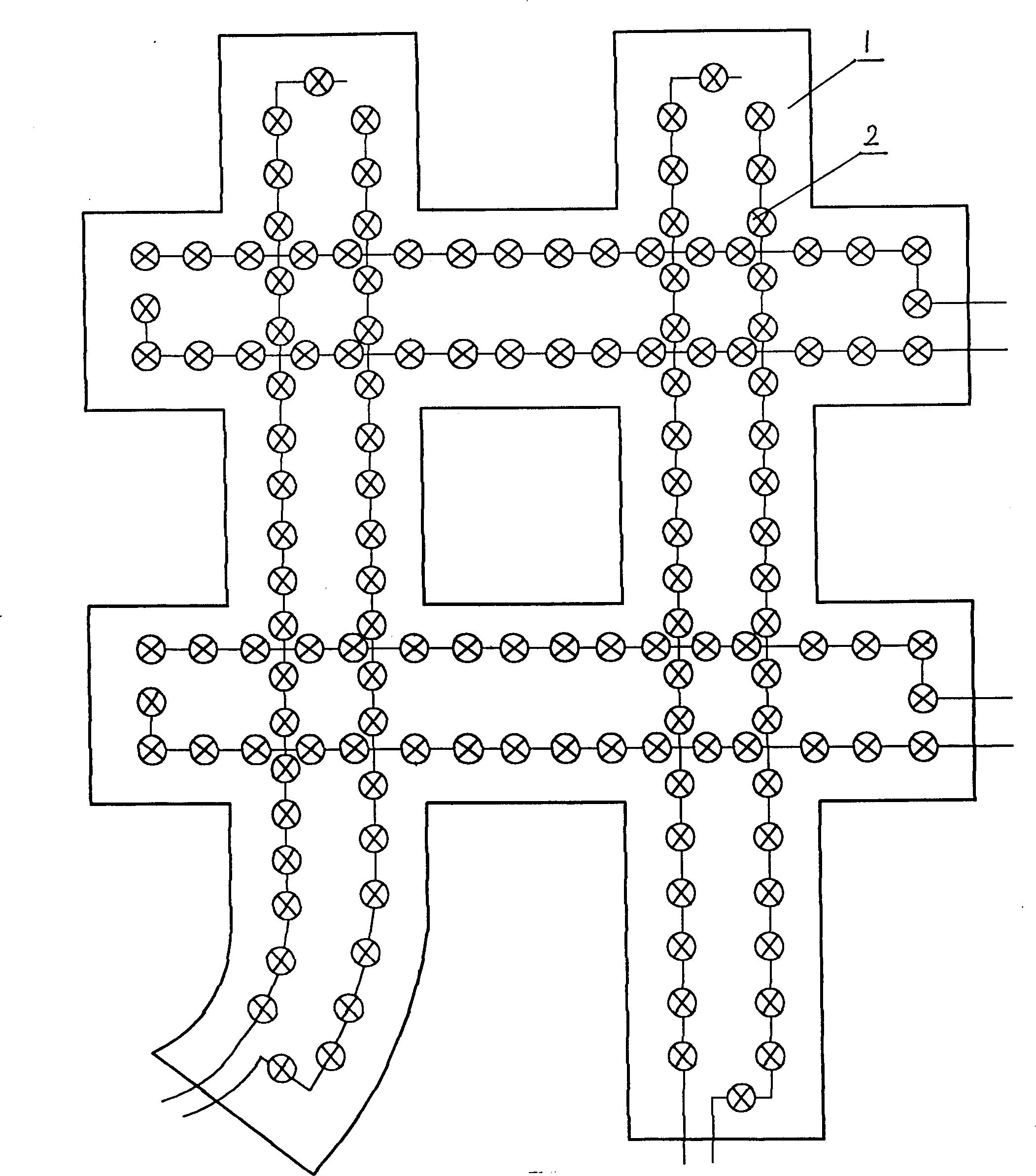

[0020] Such as figure 1 As shown, to make a neon light composed of "well" characters and capable of emitting light as a whole, the dimensions of its width x height x thickness are 100 x 120 x 5cm. The manufacturing process is divided into the following steps: mold making → ingredients → pre-installed bulbs → pouring → Demoulding → Combination debugging.

[0021] (1) Mold making: irradiate the word "well" on the template made of foamed plastics by a projector, draw the outline of the font, and then use a computer engraving machine to engrave and draw the mold core along the words, on the mold core Apply three layers of mold silicone rubber evenly on the outer surface successively, let it air for 5 hours until the mold glue is solidified, take out the mold core to make a hollow mold 1, and place it on the bottom surface of the mold with plaster.

[0022] (2), ingredients: at an ambient temperature of 23°C, first pour 0.7kg of viscous, type 6101 epoxy resin into a plastic contai...

Embodiment 2

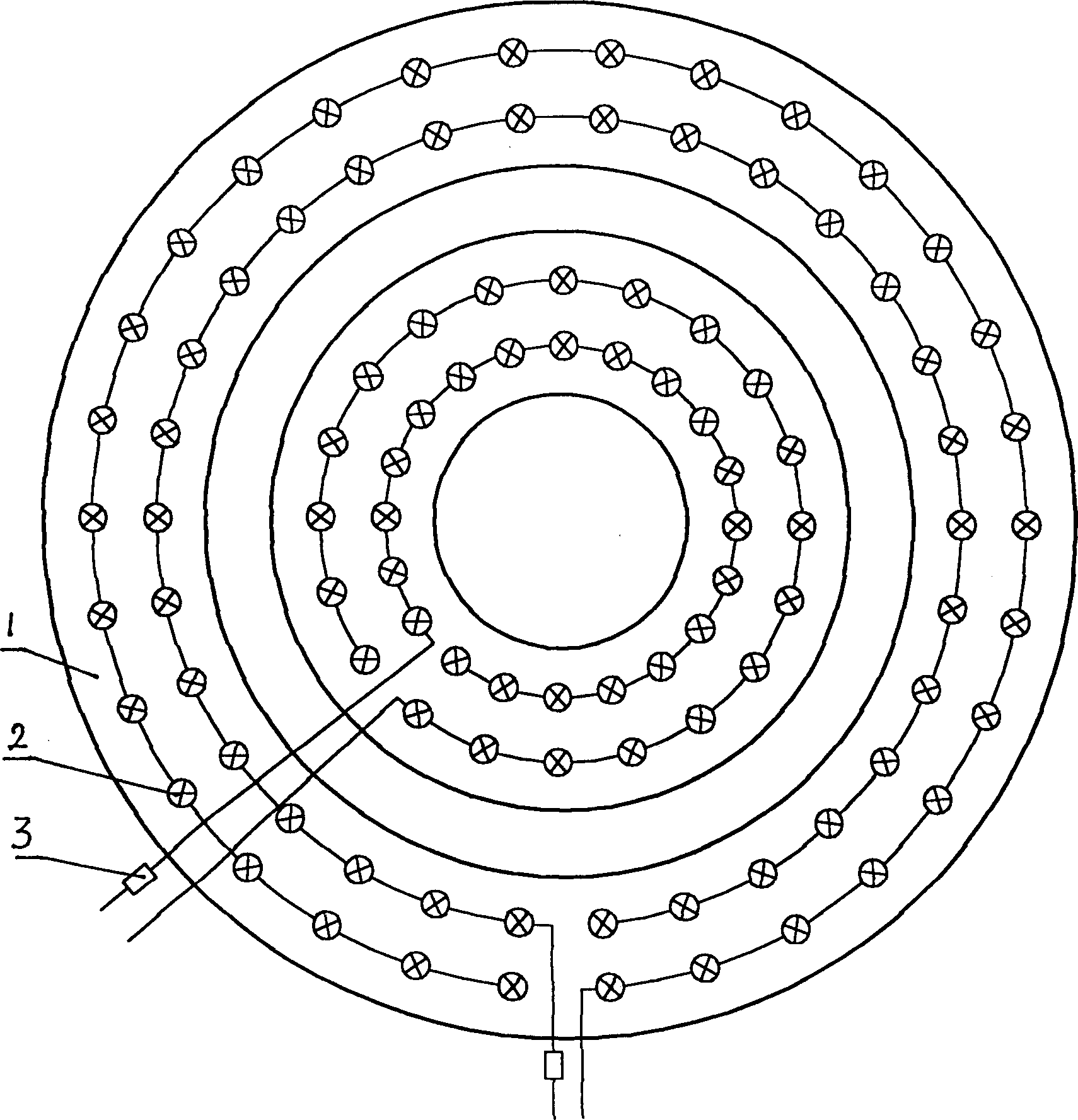

[0029] Such as figure 2 As shown, to make a neon light consisting of a double-ring pattern and capable of emitting light as a whole, the size of its width × height × thickness is 100 × 100 × 3cm. The manufacturing process is divided into the following steps: mold making → ingredients → pre-installed bulbs → pouring → detachment Mode→combined debugging.

[0030] (1) Mold making: irradiate the double-ring pattern on the template through a projector to draw the outline of the font, and then use a computer engraving machine to carve out the mold core along the pattern, and apply four layers of mold silicone rubber evenly on the outer surface of the mold core. , leave it in the air for 7 hours, until the mold glue is solidified, take out the mold core to make a hollowed-out mold 1, and support it on the bottom surface of the mold with glass fiber reinforced plastics.

[0031] (2), ingredients: under the condition of ambient temperature of 18°C, first pour 0.7kg of viscous barrele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com