Light guide fixing assembly for vehicle lamp, vehicle lamp and vehicle

A technology for fixing components and light guides, which is applied in the field of vehicles, can solve the problems of increasing the cost of parts, producing bright spots, increasing the cost of man-hours, etc., and achieve the effects of saving the number of parts, uniform luminous effect, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The making and using of the embodiments are discussed in detail below. It should be understood, however, that the specific embodiments discussed are merely illustrative of specific ways to make and use the invention, and do not limit the scope of the invention.

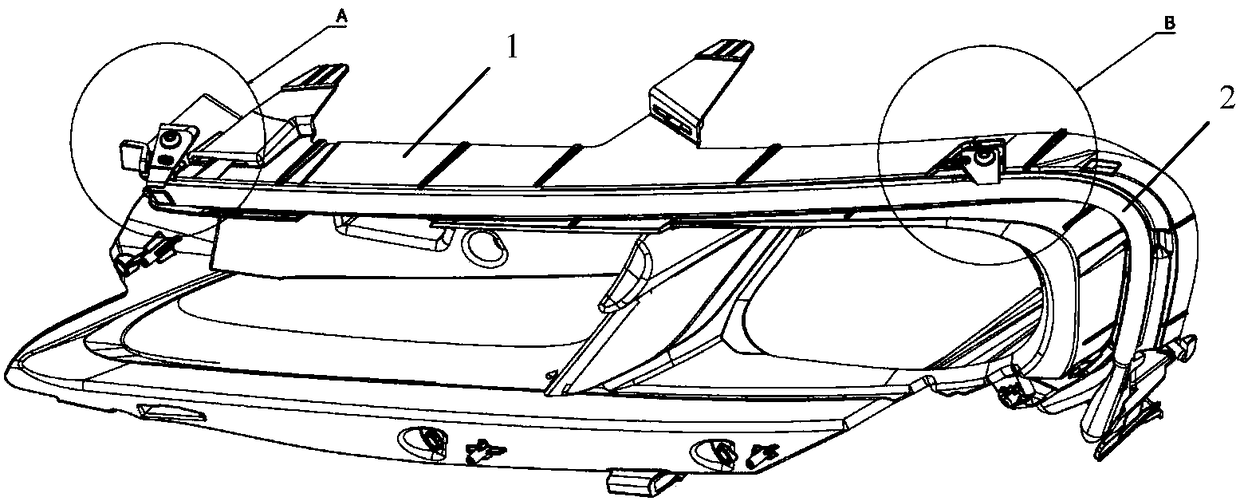

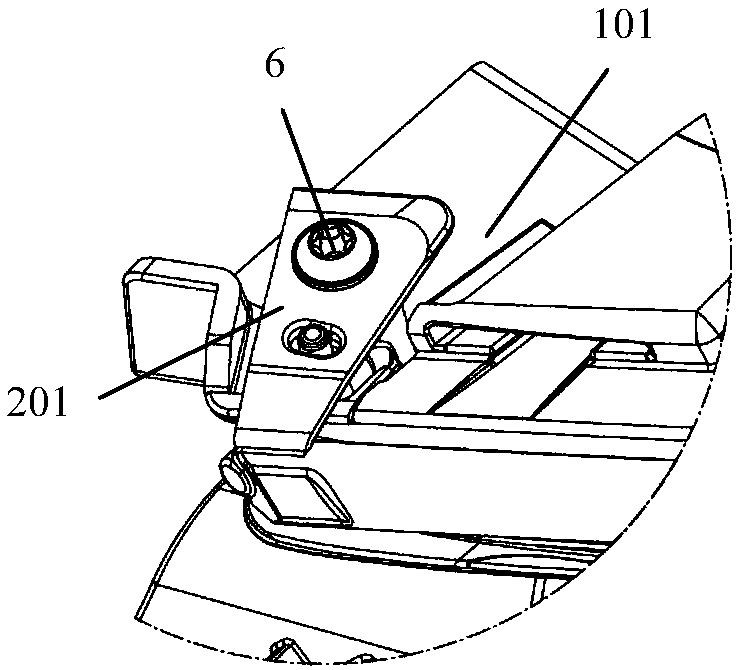

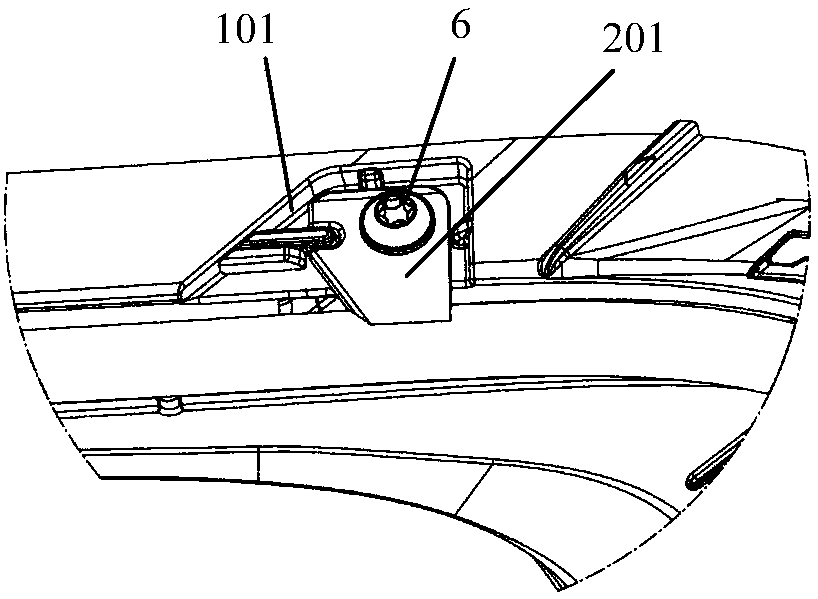

[0032] Figure 4 It is a schematic diagram of a light guide 2 with a relatively large length that can be used in vehicle headlights according to a preferred embodiment of the present invention. Figure 5 A cross-sectional view of the light guide 2 along section C-C is shown. Due to the different sizes of vehicle headlights and taillights, light guides of different sizes are required. Usually the size of the taillight is much smaller than that of the headlight, so the size of the light guide on both the side of the wing light and the side of the box light is less than 250mm, and the two ends can be fixed to meet the requirements of assembly and vibration. However, the solution according to the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com