Thymalfasin peptide resin pyrolysis method

A thymosin and peptide resin technology, applied in the field of peptide solid-phase synthesis, can solve problems such as hidden dangers of explosion safety, product degradation, and long time, and achieve the effect of improving purity, reducing dosage, and eliminating centrifugation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

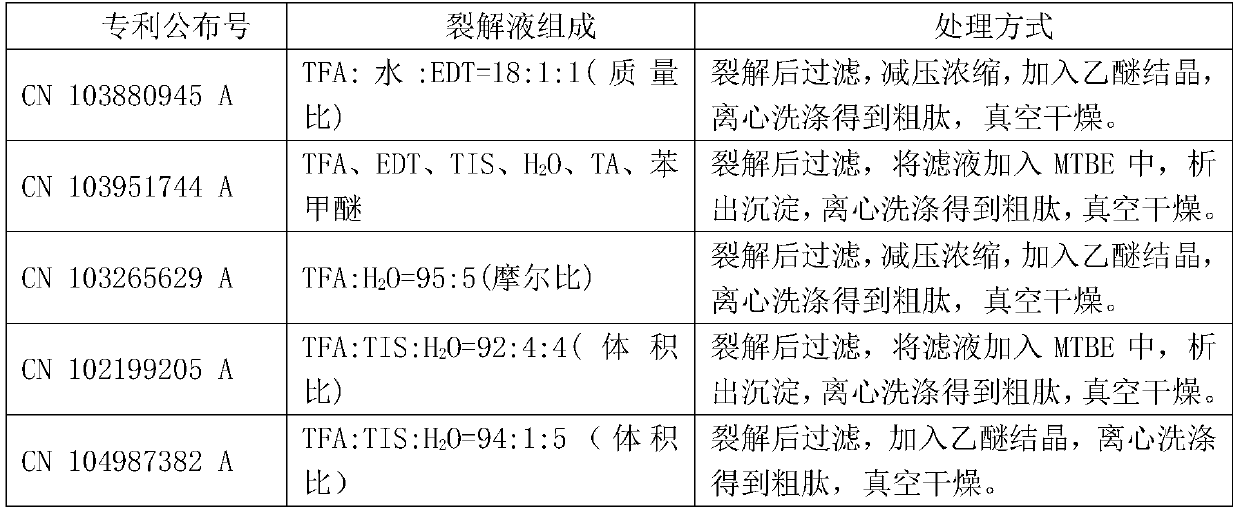

[0043] Embodiment 1, a kind of cracking method of thymofaxin peptide resin, its steps are as follows:

[0044](1) Take thymofasin resin and add 6 times the volume of lysate, crack at 10°C for 3 hours, filter off the resin to obtain the filtrate; the lysate is composed of TFA and TIS, and the volume ratio TFA:TIS=93:7;

[0045] (2) under stirring, add the filtrate to the ether at -10°C which is 6 times the volume of the filtrate; the ether is diethyl ether;

[0046] (3) under stirring, add 0.5M sodium bicarbonate solution of 0.5 times volume to the above solution;

[0047] (4) under stirring, add alkaline solution until the solution is clear; alkaline solution is sodium bicarbonate solution;

[0048] (5) Turn off the stirring, leave to stand for stratification, take the upper organic phase and add an appropriate amount of water to wash, and the water added in the washing is 30 times the quality of the resin; the lower water phase is combined, and the residual ether is removed ...

Embodiment 2

[0050] Embodiment 2, a kind of cracking method of thymofaxin peptide resin, its steps are as follows:

[0051] (1) Take thymofasin resin and add 12 times the volume of lysate, lyse at 30°C for 1 hour, filter out the resin to obtain the filtrate; the lysate is a mixed type composed of TFA and a combination of EDT, TA, and TC The lysate, wherein the content of TFA accounts for 90% of the mixed lysate;

[0052] (2) under stirring, the filtrate is added in the ether of 10 ℃ of 8 times of filtrate volume; Described ether is MTBE or sherwood oil;

[0053] (3) under stirring, add 1 times the volume of 1.5M ammonia solution to the above solution;

[0054] (4) under stirring, add alkaline solution until the solution is clear; alkaline solution is ammonia solution;

[0055] (5) Turn off the stirring, leave to stand for stratification, take the upper organic phase and add an appropriate amount of water to wash, and the water added in the washing is 40 times the quality of the resin; th...

Embodiment 3

[0057] Embodiment 3, a kind of cracking method of thymofasin resin, its steps are as follows:

[0058] (1) Take thymofasin resin and add 10 times the volume of lysate, crack at 25°C for 2 hours, filter off the resin to obtain the filtrate; the lysate is a mixed lysate composed of TFA and TIS, and the volume ratio TFA:TIS =95:5.

[0059] (2) under stirring, add the filtrate to the ether with 10 times the volume of the filtrate at 0° C.; the ether is selected from diethyl ether, MTBE, petroleum ether or isopropyl ether;

[0060] (3) under stirring, add 0.6 times the volume of 1.0M sodium bicarbonate or ammonia solution to the above solution;

[0061] (4) under stirring, add alkaline solution until the solution is clear; alkaline solution is sodium bicarbonate solution, ammonia solution, sodium hydroxide solution or sodium carbonate solution;

[0062] (5) Turn off the stirring, leave to stand for stratification, take the upper organic phase and add an appropriate amount of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com