Furfuryl alcohol resin gas-phase modification method for wood material

A technology of wood material and furfuryl alcohol resin, which is applied in the functionalization and modification field of wood material, can solve the problems of increasing drying difficulty, increasing drying cost, increasing production cost, etc., so as to avoid the loss of modified solution and reduce drying energy. The effect of reducing consumption and reducing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

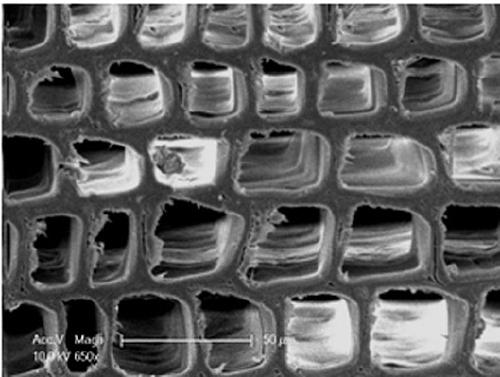

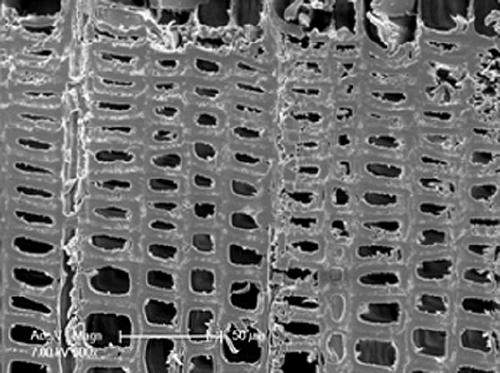

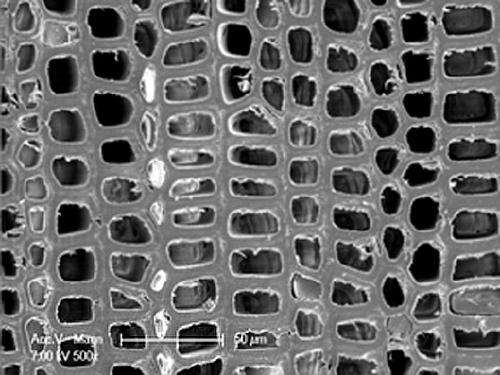

Image

Examples

Embodiment 1

[0029] This embodiment provides a gas-phase furfuryl alcohol resin modification method for wood materials.

[0030] 1. Modified object: Chinese fir plantation ( Cunninghamia lanceolata ).

[0031] 2. The specific process steps are as follows:

[0032] S1. Sample preparation, the specific steps: a) Process the fir into a 20 mm×20 mm×20 mm (T×R×L) sample and then sand it; b) Dry the sample in an oven at 103°C until it is absolutely dry In dry state, while at 22-25℃, prepare maleic anhydride solution with a concentration of 4.5wt% with water;

[0033] S2. Put the sample in a small vacuum reactor, first vacuum with a vacuum pump for 30 minutes to a vacuum of -0.09 MPa, then use the negative pressure in the reactor to suck in the prepared maleic anhydride solution, and then use industrial nitrogen Pressurize to 1.0 MPa, hold the pressure for 40 minutes;

[0034] S3. Take out the sample and dry it at 60°C for 2 hours, then raise it to 80°C for 2 hours, and then dry it at 103°C for 20 hours...

Embodiment 2

[0051] This embodiment provides a gas-phase furfuryl alcohol resin modification method for wood materials.

[0052] 1. Modification object: plantation poplar ( Populus spp ).

[0053] 2. The specific process steps are as follows:

[0054] S1. Sample preparation, the specific steps: a) Process the poplar wood into a 20 mm×20 mm×20 mm (T×R×L) sample and then sand it; b) Dry the sample in an oven at 103℃ In an absolutely dry state, at the same time, at 22-25℃, prepare a maleic anhydride solution with a concentration of 1.5wt% with water;

[0055] S2. Put the sample in a small vacuum reactor, first vacuum with a vacuum pump for 30 minutes to a vacuum of -0.09 MPa, then use the negative pressure in the reactor to suck in the prepared maleic anhydride solution, and then use industrial nitrogen Pressurize to 1.0 MPa, hold the pressure for 40 minutes;

[0056] S3. Take out the sample and dry it at 60°C for 2h, then raise it to 80°C for 2h, and then dry it at 103°C for 20h;

[0057] S4. Put th...

Embodiment 3

[0067] This embodiment provides a gas-phase furfuryl alcohol resin modification method for wood materials.

[0068] 1. Modification object: plantation poplar ( Populus spp ).

[0069] 2. The specific process steps are as follows:

[0070] S1. Sample preparation, the specific steps: a) Process the poplar wood into a 20 mm×20 mm×20 mm (T×R×L) sample and then sand it; b) Dry the sample in an oven at 103℃ In an absolutely dry state, at the same time, at 22-25℃, prepare a maleic anhydride solution with a concentration of 6.0wt% with water;

[0071] S2. Put the sample in a small vacuum reactor, first vacuum with a vacuum pump for 30 minutes to a vacuum of -0.09 MPa, then use the negative pressure in the reactor to suck in the prepared maleic anhydride solution, and then use industrial nitrogen Pressurize to 1.0 MPa, hold the pressure for 40 minutes;

[0072] S3. Take out the sample and dry it at 60°C for 2h, then raise it to 80°C for 2h, and then dry it at 103°C for 20h;

[0073] S4. Put th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com