Method of treating a substrate

a substrate and treatment method technology, applied in the direction of electrostatic cleaning, cleaning process and equipment, chemical equipment and processes, etc., can solve the problems of affecting the productivity of cleaning and modification tools, affecting the work efficiency of workers, and affecting the quality of substrate surfaces, etc., to achieve the effect of reducing the re-contamination of precision substrate surfaces during handling, eliminating wet processing and rinsing and drying steps, and reducing the risk of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

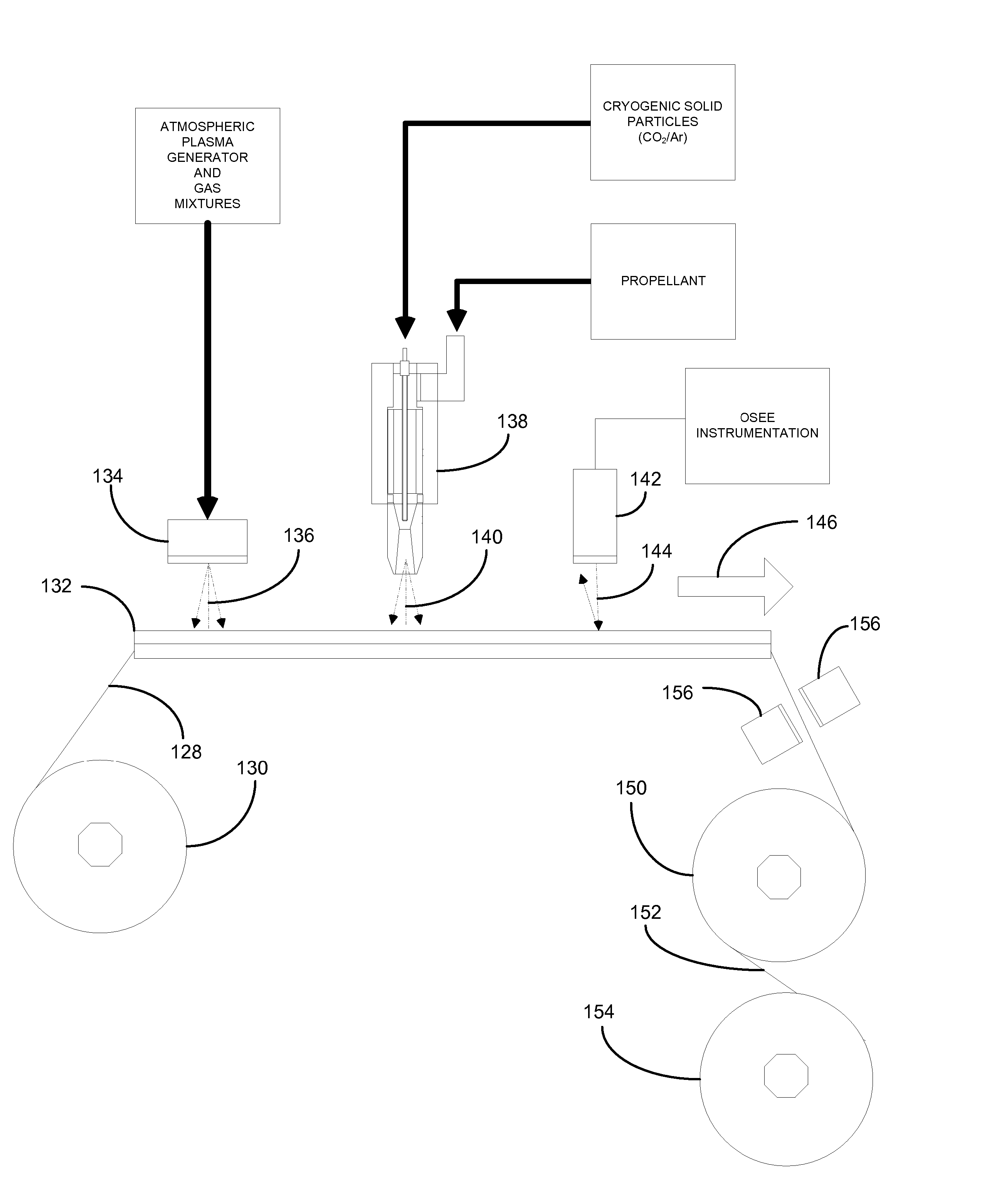

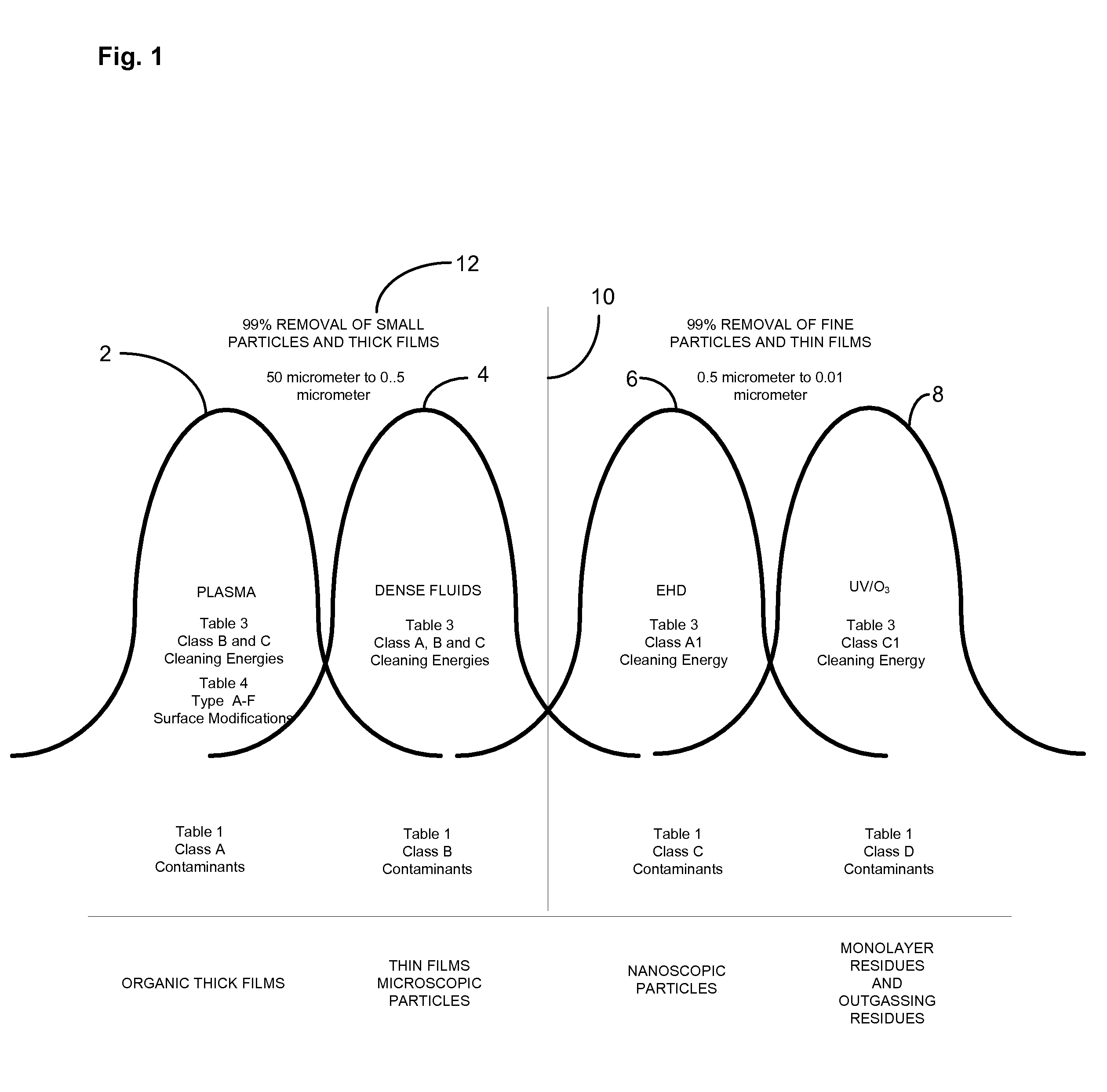

[0076]FIG. 1 shows performance profiles for the exemplary dry cleaning techniques; Plasma, Dense Fluids, EHD, and UV / O3 used in the present invention. Referring to FIG. 1, performance profiles for plasma (2), dense fluid (4), EHD (6), and UV / O3 (8) dry cleaning and surface preparation treatments are represented a Gaussian distribution curves. The performance profiles represent generalized upper and lower limits of cleaning efficiency for a certain class of contaminants. A generalized boundary condition (10) exists which demarks the transition from macro and microscopic layers (12) to nanoscopic layers (14) of contamination, and to the rough and porous native substrate surface. Furthermore, the individual treatment groups bisected by the boundary condition (10) may change in sequence, or may be used selectively. For example, plasma (2) and dense fluids (4) are used in combination with the present invention to address macroscopic and microscopic contaminations, as well as surface modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| operating pressures | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com