Method for producing an electrode material

A technology for preparing electrodes and electrode materials, which is applied in the direction of mixing methods, battery electrodes, chemical instruments and methods, etc., can solve time-consuming problems, achieve the effects of reducing the amount of binder, improving performance, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

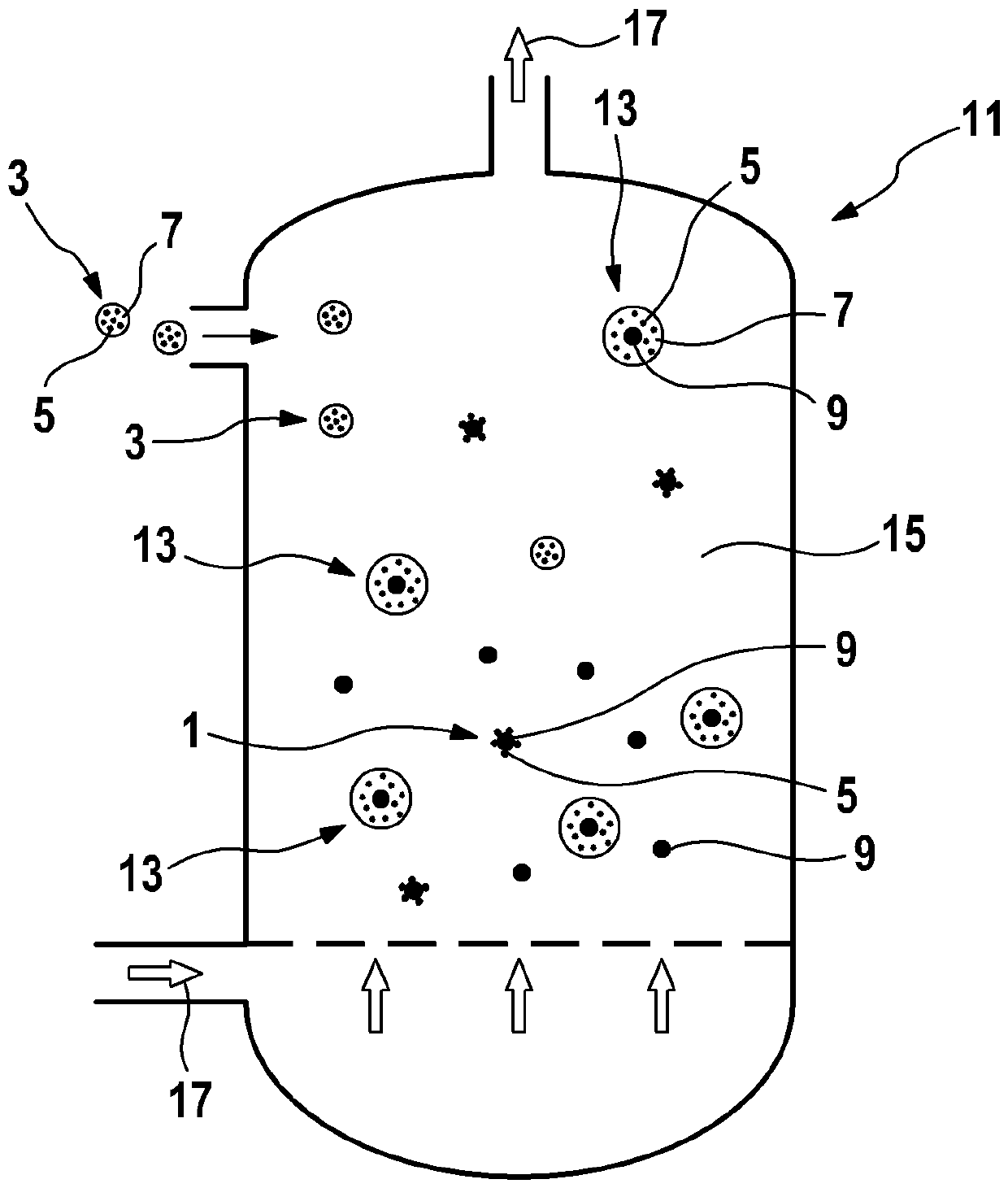

[0055] figure 1 A method for producing electrode material 1 according to the invention is shown.

[0056] In the mixing device 11 , the powdery active material 9 is preliminarily charged, so that a fluidized layer 15 is obtained. The gas flow 17 flows through the powdered active material 9 in the mixing device 11 from bottom to top.

[0057] Furthermore, a mixture 3 of binder 5 and solvent 7 is sprayed into the fluidized layer 15 of the mixing device 11 . The powdery active material 9 is coated with a binder 5 to obtain coated particles 13 . In the embodiment shown, the coated particles 13 contain not only the binder 5 but also the solvent 7 .

[0058] The solvent 7 is at least partially removed from the coated particles 13 by means of the gas flow 17 , so that particles of the electrode material 1 are obtained.

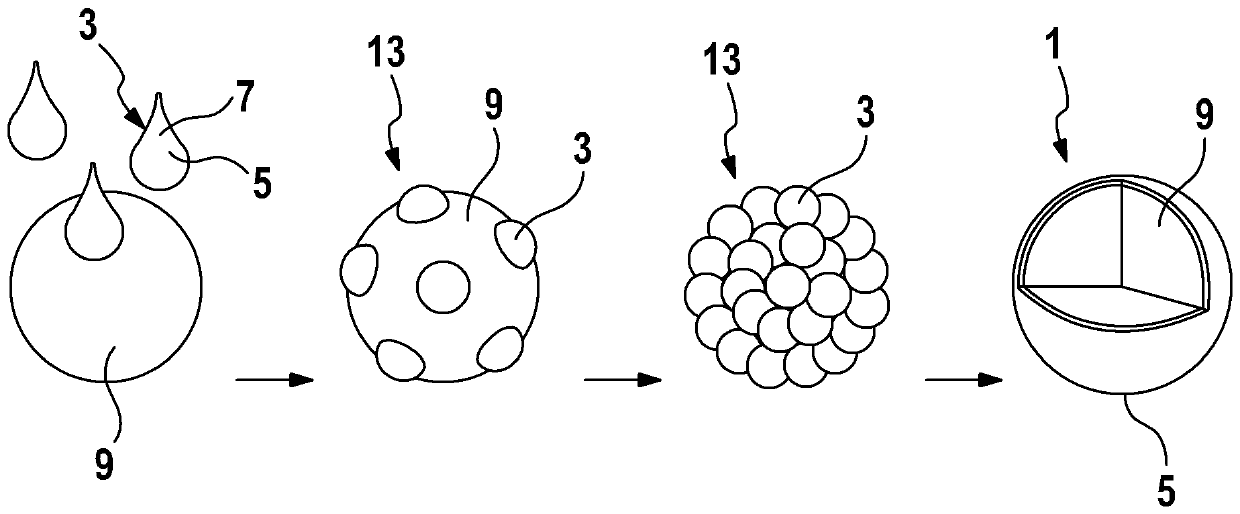

[0059] figure 2 The coating of powdered active material 9 with binder 5 is schematically shown. The powdery active material 9 is brought into contact with dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com