A method for continuously preparing inulin and pectin from Jerusalem artichoke and/or chicory

A technology of pectin and inulin, which is applied in the field of continuous preparation of inulin and pectin by using Jerusalem artichoke and/or chicory, can solve the problems of not using water-soluble pectin, increasing production cost, increasing drying process, etc., and achieves pectin The effect of increasing yield, reducing production energy consumption and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

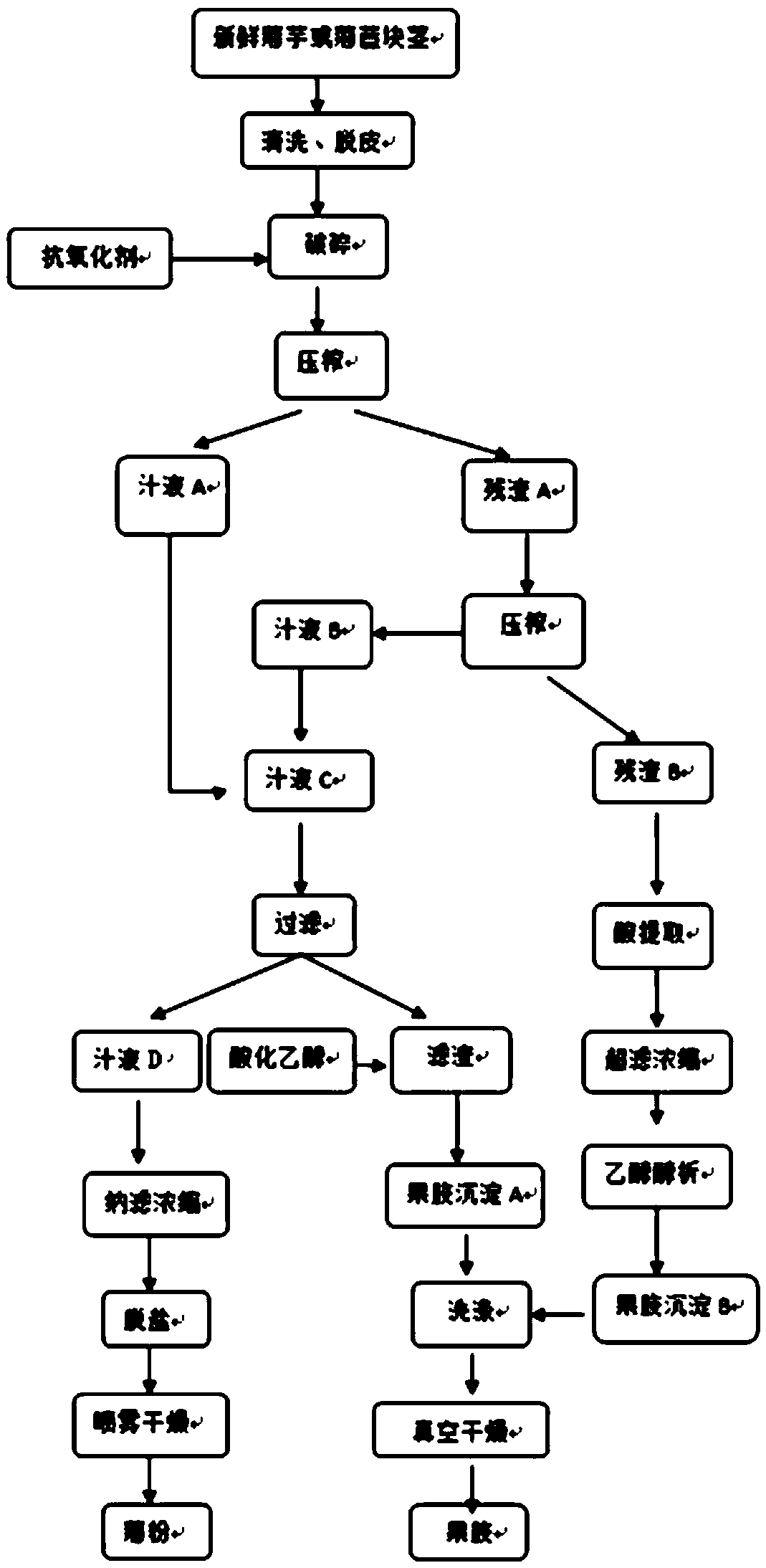

Method used

Image

Examples

Embodiment 1

[0024] The fresh Jerusalem artichoke of 100kg is taken by weighing, after cleaning, peeling, crushing, 3‰ sodium bisulfite solution is added in the crushing process, then sent to a belt press, after squeezing, Jerusalem artichoke juice A and Jerusalem artichoke residue A are obtained, and the Add 50L of pure water to the dregs A and press again, press to obtain the Jerusalem artichoke juice B and the Jerusalem artichoke dregs B, combine the juice A and the juice B and the juice C, add Ca(OH) 2 Solid powder to PH = 10, after stirring at 60°C for 30 minutes, pass CO 2 Gas to PH=7.0, filter to obtain filter residue and juice D, juice D is concentrated by nanofiltration to obtain concentrated solution A with 20% inulin concentration, concentrated solution A is desalted with ion exchange resin, and then spray-dried to obtain 11kg of white inulin powder . Add 10 L of acidified ethanol solution to the filter residue, wash at 60°C for 30 min, centrifuge to obtain pectin precipitate A...

Embodiment 2

[0026] Weigh 150kg of fresh Jerusalem artichoke, wash, peel, and crush, add 4‰ of NaHSO during the crushing process 3 The solution is then sent to a belt press, squeezed to obtain Jerusalem artichoke juice A and Jerusalem artichoke residue A, add 80L of pure water to Jerusalem artichoke residue A and squeeze again, press filter to obtain Jerusalem artichoke juice B and Jerusalem artichoke residue B, and combine juice A and juice B To obtain juice C, heat juice C to 75°C, add Ca(OH) 2 Solid powder to PH=10, after stirring for 30 minutes, inject CO 2 The gas made the PH=7.0, filtered to obtain the filter residue and juice D, and the juice D was concentrated by nanofiltration to obtain a concentrated solution A with an inulin concentration of 25%. After the concentrated solution A was desalted with an ion exchange resin, it was spray-dried to obtain 17 kg of white inulin powder. Add 15 L of acidified ethanol solution to the filter residue, wash at 70°C for 30 min, centrifuge to ...

Embodiment 3

[0028] Take by weighing the fresh chicory of 100kg, clean, break, add the citric acid solution of 5‰ in the broken process, send into belt press then, squeeze and obtain chicory juice A and chicory residue A, add 100L of pure chicory in chicory residue A Squeeze the water again, press filter to obtain chicory juice B and chicory residue B, combine juice A and juice B to obtain juice C, heat juice C to 80°C, add Ca(OH) 2 Solid powder to PH=10, after stirring for 30 minutes, inject CO 2 Gas to PH=7.0, filter to obtain filter residue and juice D. The juice D was concentrated by nanofiltration to obtain a concentrated solution A with an inulin concentration of 30%. After the concentrated solution A was desalted with an ion exchange resin, it was spray-dried to obtain 12.5 kg of white inulin powder. Add 10 L of acidified ethanol solution to the filter residue, wash at 50°C for 30 min, centrifuge to obtain pectin precipitate A, and wash three times with 70% ethanol. Add 75L of pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com