Orange velvet oat set yogurt and preparation method thereof

A technology of coagulated yogurt and oatmeal, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of narrow consumer choices, cumbersome process, single taste, etc., and achieve improved taste and sensory properties, good storage properties, The effect of enhancing sensory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

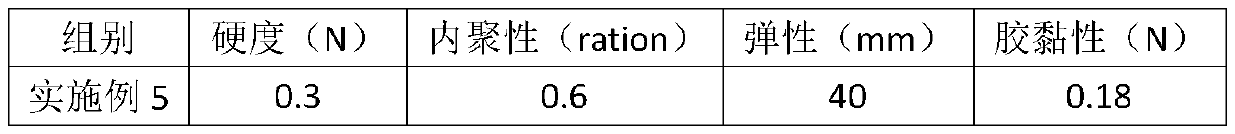

[0032]An orange velvet oat solidified yoghurt is made of the following raw materials in parts by weight based on 1000 kg of final product: 700 kg of raw milk, 5 kg of milk protein powder, 5 kg of skimmed milk powder, 70 kg of white sugar, 4 kg of compound stabilizer, 60 kg of jam and 0.5kg of direct throw type leavening agent; Wherein, described composite stabilizer is made up of agar, carrageenan, gellan gum and pectin, and the mass ratio of agar, carrageenan, gellan gum and pectin is 1:1:1 : 1; the volume ratio of Lactobacillus acidophilus, Lactobacillus fermentum grx07, Lactobacillus plantarum YDKY001 and Enterococcus faecalis grx28 in the direct-throwing starter is 2:1:2:0.3; the orange velvet oat solidified yogurt The preparation method comprises the following steps:

[0033] (1) Clean milk: Weigh the raw cow milk according to the above ratio and enter the factory for inspection, degassing, filtering, and cooling to obtain raw milk; (2) Ingredients: Take 20% of the total ...

Embodiment 2

[0035] An orange velvet oat solidified yoghurt is made of the following raw materials in parts by weight based on 1000 kg of final product: 950 kg of raw milk, 10 kg of milk protein powder, 10 kg of skimmed milk powder, 80 kg of white sugar, 8 kg of compound stabilizer, 80 kg of jam and Straight throw type leavening agent 1kg; Wherein, described composite stabilizer is made up of agar, carrageenan, gellan gum and pectin, and the mass ratio of agar, carrageenan, gellan gum and pectin is 1:1:1: 1; the volume ratio of Lactobacillus acidophilus, Lactobacillus fermentum grx07, Lactobacillus plantarum YDKY001 and Enterococcus faecalis grx28 in the direct-throwing starter is 2:1:2:0.3; the orange velvet oat coagulated yogurt The preparation method comprises the following steps:

[0036] (1) Clean milk: Weigh the raw milk according to the above ratio, enter the factory for inspection, degas, filter, and cool to obtain raw milk; (2) Ingredients: take 30% of the total weight of the raw ...

Embodiment 3

[0038] An orange velvet oat coagulated yoghurt, based on 1000 kg of final product, is made of the following raw materials in parts by weight: 800 kg of raw milk, 6 kg of milk protein powder, 6 kg of skimmed milk powder, 72 kg of white sugar, 5 kg of compound stabilizer, 65 kg of jam and 0.6kg of direct throw type leavening agent; Wherein, described composite stabilizer is made up of agar, carrageenan, gellan gum and pectin, and the mass ratio of agar, carrageenan, gellan gum and pectin is 1:1:1 : 1; the volume ratio of Lactobacillus acidophilus grx95, Lactobacillus fermentum grx07, Lactobacillus plantarum YDKY001 and Enterococcus faecalis grx28 in the direct-throwing starter is 2:1:2:0.3; the orange velvet oat coagulation type The preparation method of yogurt comprises the following steps:

[0039] (1) Clean milk: Weigh the raw milk according to the above proportion, enter the factory for inspection, degas, filter, and cool to obtain raw milk; (2) Ingredients: take 25% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com