Automatic proportioning machine, automatic proportioning system of powder coating and proportioning method of powder coating

An automatic batching and automatic technology, applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of heavy workload, waste of materials, lack of scientific basis for formula optimization, etc., and achieve reasonable structural design and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

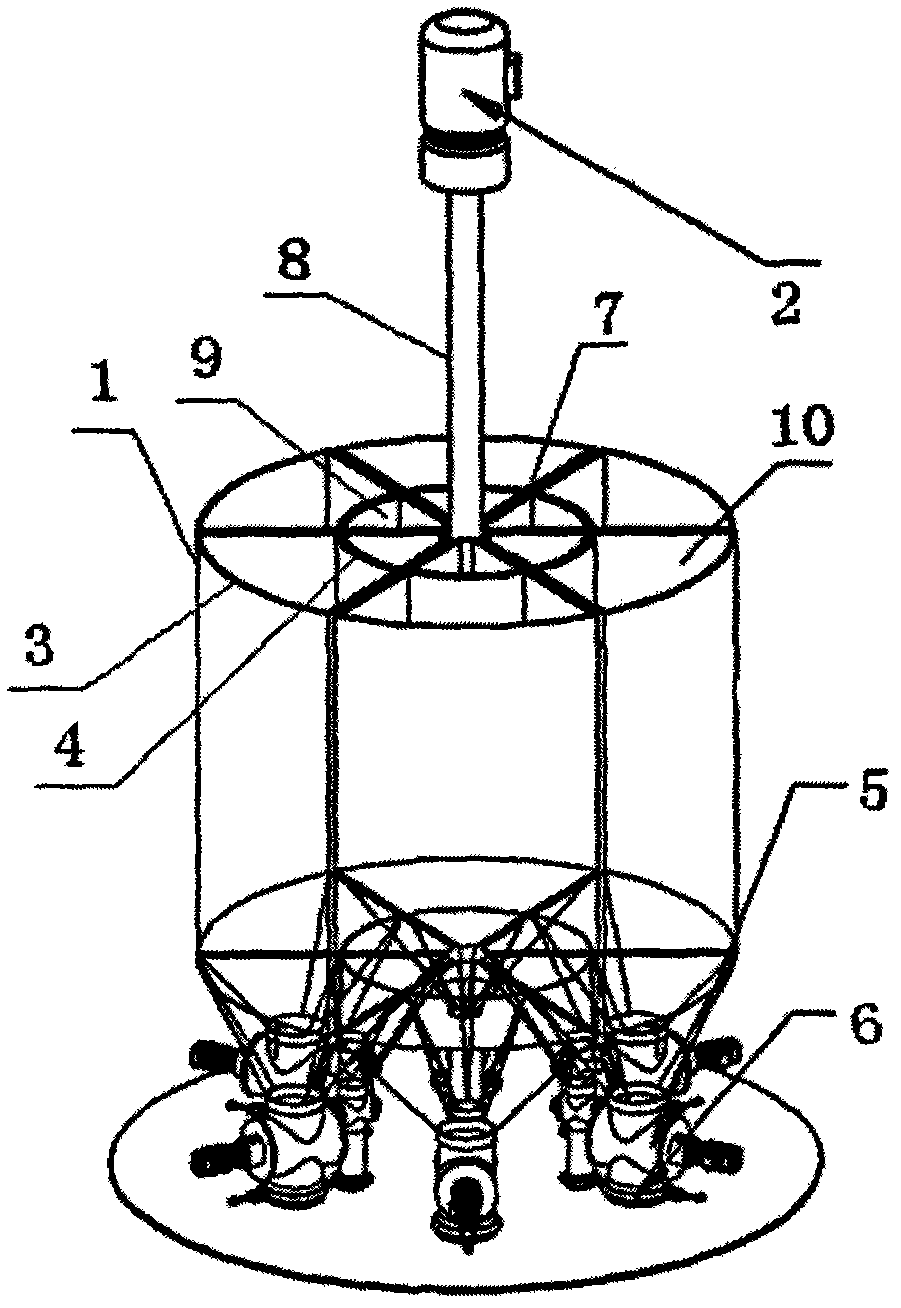

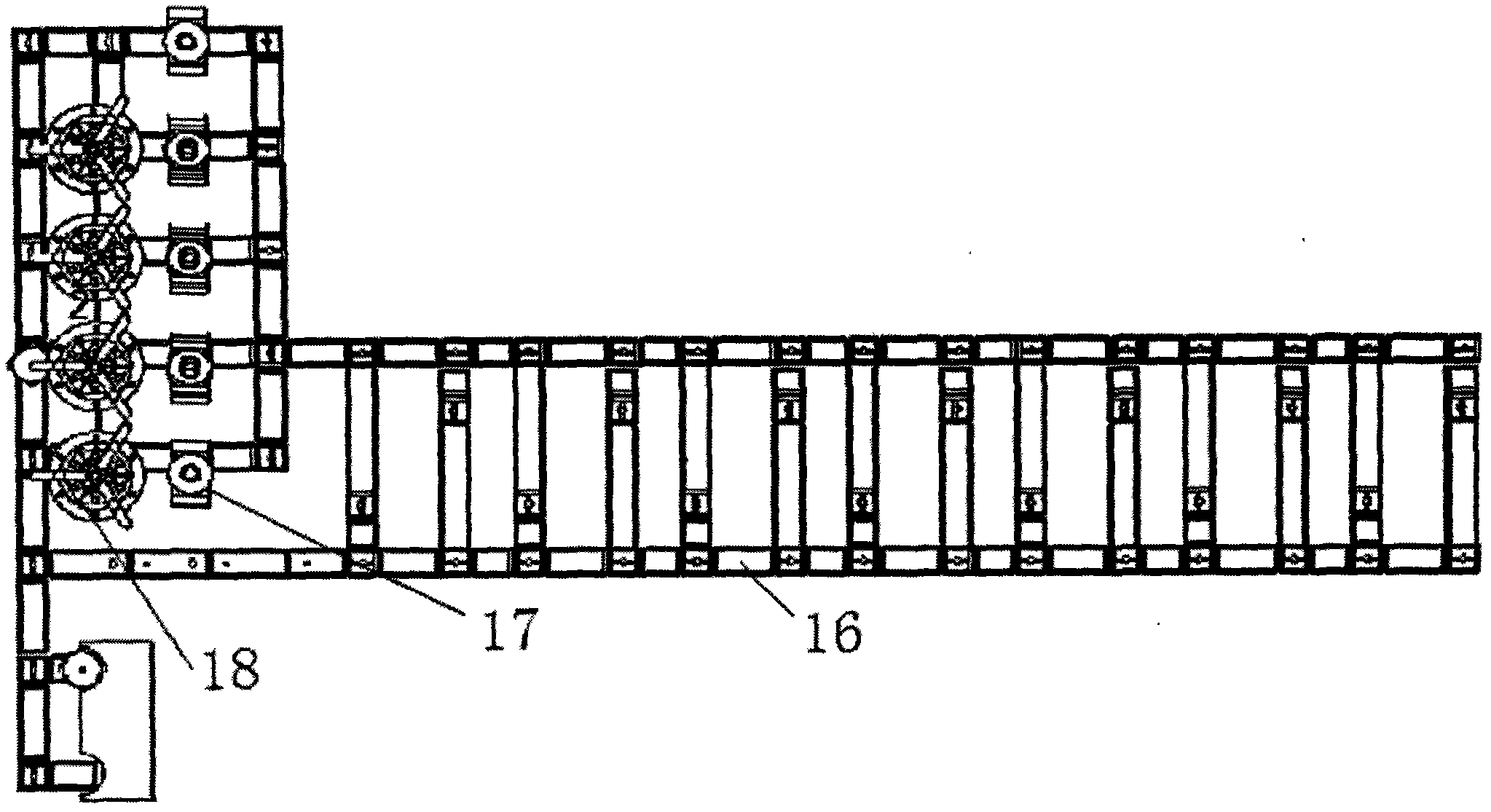

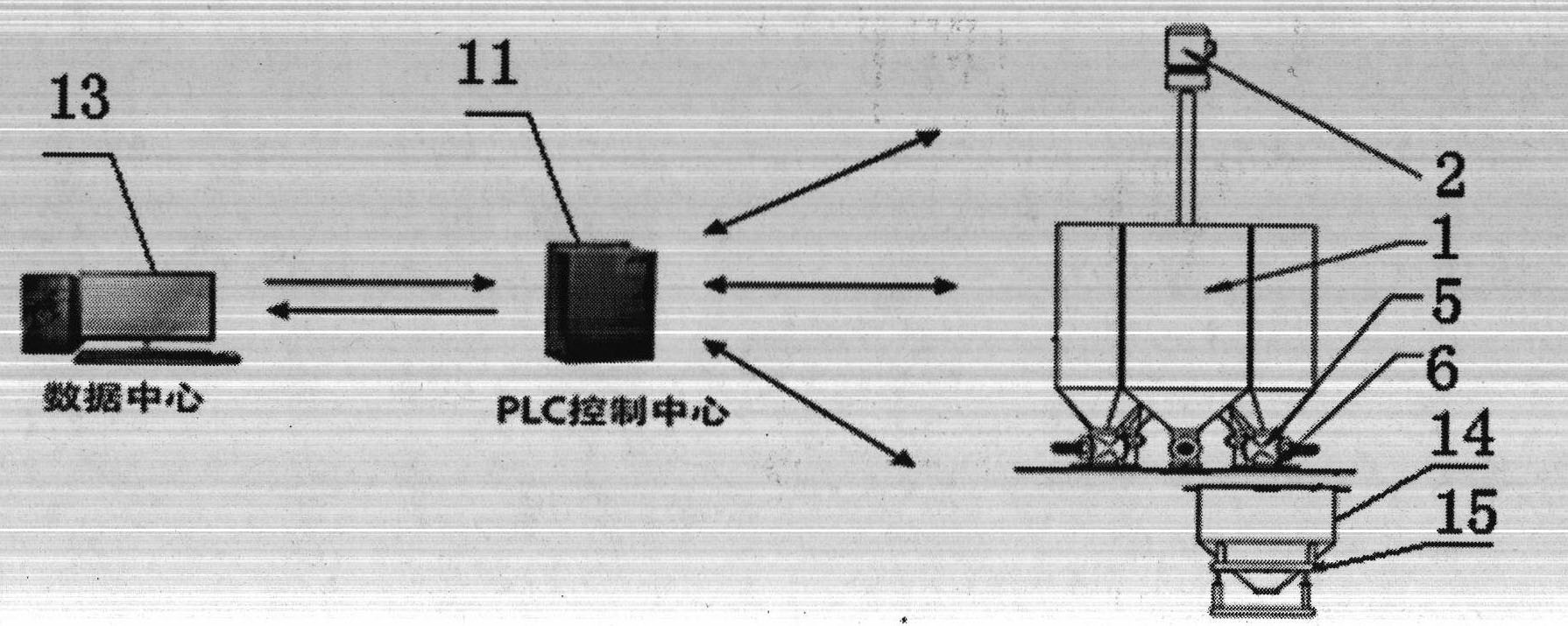

[0046] The specific embodiments of the present invention will be given below with reference to the accompanying drawings, and the present invention will be further described.

[0047] The three cores of the powder coating automatic deployment system in the embodiment of the present invention are:

[0048] Automatically select materials reasonably, automatically proportion ingredients, and automatically complete color matching.

[0049] Automatic and reasonable material selection is to free technicians from numerous materials, suppliers, and models, and display the required materials together for technicians to analyze and choose.

[0050] Automatic proportional batching is an intelligent equipment developed in view of the current manual batching time, poor precision, easy to mix, and high cost. Part of the manual operation is replaced by automatic equipment to improve efficiency and accuracy.

[0051] The automatic completion of grading has changed from relying entirely on e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com