Method for manufacturing three-dimensional circuit on surface of injection molded part

A technology of three-dimensional circuits and injection molded parts, which is applied in the direction of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of large loss of raw materials, complicated manufacturing process, and serious environmental pollution, and achieve volume and cost reduction, simple process, Reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

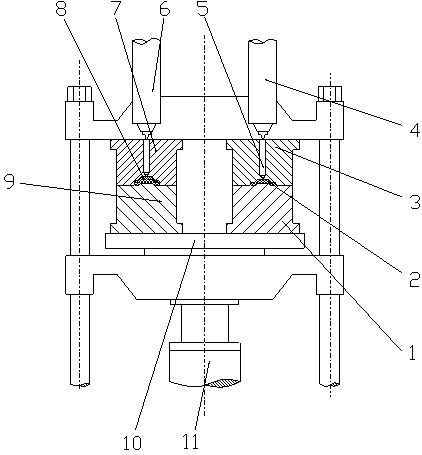

[0029] A method of manufacturing a three-dimensional circuit on the surface of an injection molded part, comprising the steps of:

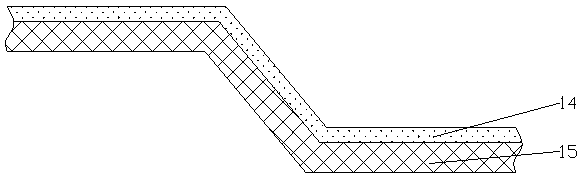

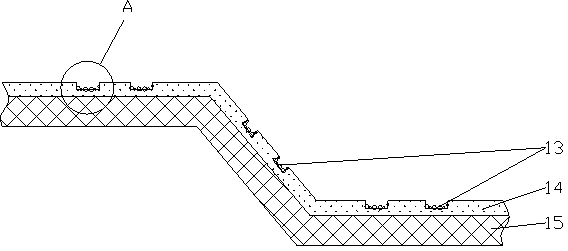

[0030] A. The base layer 15 is formed by injection molding the first layer of base material 2 through the common injection unit 4 of the double-material injection molding machine. The base material 2 of the first base is a common plastic, and the present embodiment selects a mixture of PC and ABS, wherein the Said PC mass percentage is 70%, and said ABS mass percentage is 30%;

[0031] B. Through the metal powder injection unit 6 and the mold of the double-material injection molding machine, the second layer of compound material 8 is injected onto the upper surface of the base layer 15 to form a metal powder injection layer 14. After cooling under pressure, the mold is opened to take out the injection molded part, and the second layer is mixed. Material 8 is made up of copper powder 13 and non-platable resin binder, and described copper powder 13 ...

Embodiment 2

[0041] A method of manufacturing a three-dimensional circuit on the surface of an injection molded part, comprising the steps of:

[0042] A. A base layer 15 is formed by injection molding the first layer of base material 2 through the common injection unit 4 of the double-material injection molding machine. The base material 2 of the first base is ordinary plastic, and PC is selected in this embodiment;

[0043] B. Through the metal powder injection unit 6 and the mold of the double-material injection molding machine, the second layer of compound material 8 is injected onto the upper surface of the base layer 15 to form a metal powder injection layer 14. After cooling under pressure, the mold is opened to take out the injection molded part, and the second layer is mixed. Material 8 is composed of copper powder 13 and non-platable resin binder, the size of the copper powder 13 is 220 mesh, and the mass percentage of 8 in the second layer of mixed material is 88%, and the volume...

Embodiment 3

[0048] A method of manufacturing a three-dimensional circuit on the surface of an injection molded part, comprising the steps of:

[0049] A. Form the matrix layer 15 through the ordinary injection unit 4 of the double-material injection molding machine and the first layer of matrix material 2 through the mold injection molding. The first layer of matrix material 2 is ordinary plastic, and ABS is selected in this embodiment;

[0050] B. Through the metal powder injection unit 6 and the mold of the double-material injection molding machine, the second layer of compound material 8 is injected onto the upper surface of the base layer 15 to form a metal powder injection layer 14. After cooling under pressure, the mold is opened to take out the injection molded part, and the second layer is mixed. Material 8 is made up of copper powder 13 and non-platable resin binder, and the size of described copper powder 13 is 250 mesh, and the mass percentage of 8 in the second layer of mixed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com