Method for making stainless steel ware

A production method, stainless steel technology, applied in the direction of manufacturing tools, heat treatment process control, other manufacturing equipment/tools, etc., can solve the problems of damage to the inner wall and bottom thickness of stainless steel appliances, damage to human health, stainless steel appliances, short service life, etc., to achieve cost Low, long service life, increased hardness and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

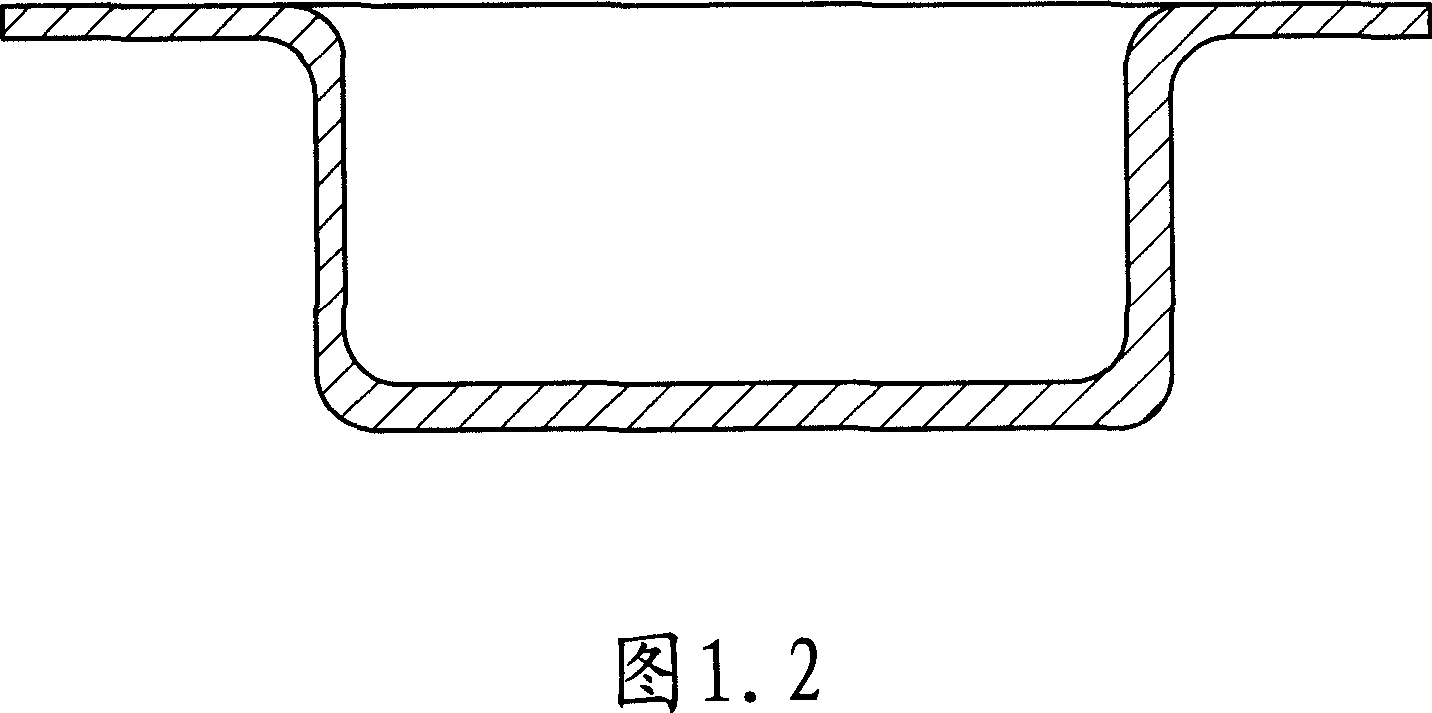

[0040] Select 304 stainless steel plates with a thickness of 1.4 mm, and use a mold made of (infiltrated alloy cast iron with 0.4% copper and 0.5% aluminum) according to the first stretching shape of the inner cylinder of the fryer to carry out the first stretching through a hydraulic press Stretching, the height of the semi-finished product in the frying furnace after stretching is 200 mm, as shown in Figure 1.2; the pressure of the hydraulic press is 20 kg / cm2, and the stretching time is 15 to 25 seconds; the first stretching The final semi-finished product in the frying furnace is heated to 1150 ° C for 5 minutes, and naturally cooled in the air;

[0041] The above-mentioned frying furnace inner cylinder semi-finished product through the first stretching is passed through the mold made of (infiltrating the alloy cast iron of 0.4% copper and 0.5% aluminum) according to the second stretching shape of the frying furnace inner cylinder The hydraulic press is stretched for the s...

Embodiment 2

[0052] Select 304 stainless steel plates with a thickness of 1.0 mm, and use a mold made of (infiltrated alloy cast iron with 0.4% copper and 0.5% aluminum) according to the first stretching shape of the inner cylinder of the fryer to carry out the first stretching through a hydraulic press Stretching, the height of the semi-finished product in the frying furnace after stretching is 100 mm, as shown in Figure 1.2; the pressure of the hydraulic press is 10 kg / cm2, and the stretching time is 10 to 20 seconds; the first stretching The final semi-finished product in the fryer is heated to 1000 ° C for 10 minutes, and naturally cooled in the air;

[0053] The above-mentioned frying furnace inner cylinder semi-finished product through the first stretching is passed through the mold made of (infiltrating the alloy cast iron of 0.4% copper and 0.5% aluminum) according to the second stretching shape of the frying furnace inner cylinder The hydraulic press is stretched for the second ti...

Embodiment 3

[0064] Select 304 stainless steel plates with a thickness of 1.8 mm, and use a mold made of (infiltrated alloy cast iron with 0.4% copper and 0.5% aluminum) according to the first stretching shape of the fryer inner cylinder to carry out the first stretching through a hydraulic press Stretching, the height of the semi-finished product in the frying furnace after stretching is 150 mm, as shown in Figure 1.2; the pressure of the hydraulic press is 22 kg / cm2, and the stretching time is 25 to 35 seconds; the first stretching The final semi-finished product in the fryer is heated to 1200 ° C for 3 minutes, and naturally cooled in the air;

[0065] The above-mentioned frying furnace inner cylinder semi-finished product through the first stretching is passed through the mold made of (infiltrating the alloy cast iron of 0.4% copper and 0.5% aluminum) according to the second stretching shape of the frying furnace inner cylinder The hydraulic press is stretched for the second time, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com