Hair ring split charging machine

A technology of packing machine and material distributing device, which is applied in the field of machinery, can solve problems such as difficulty in finding workers, and achieve the effect of increasing production rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

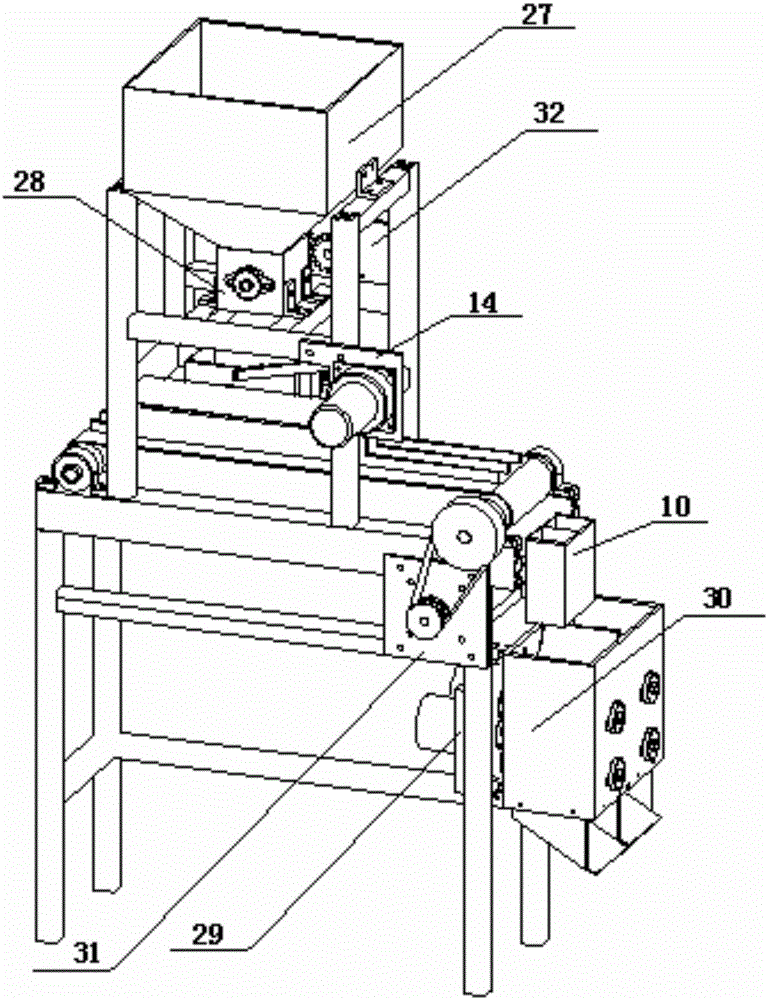

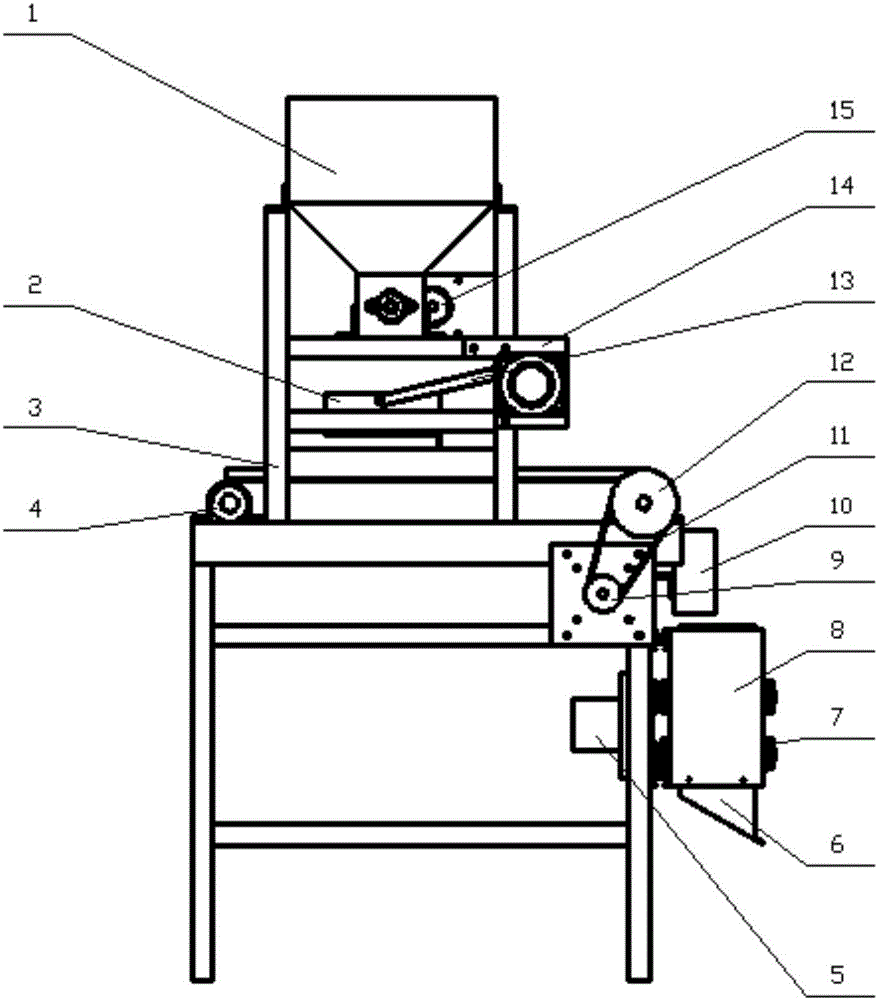

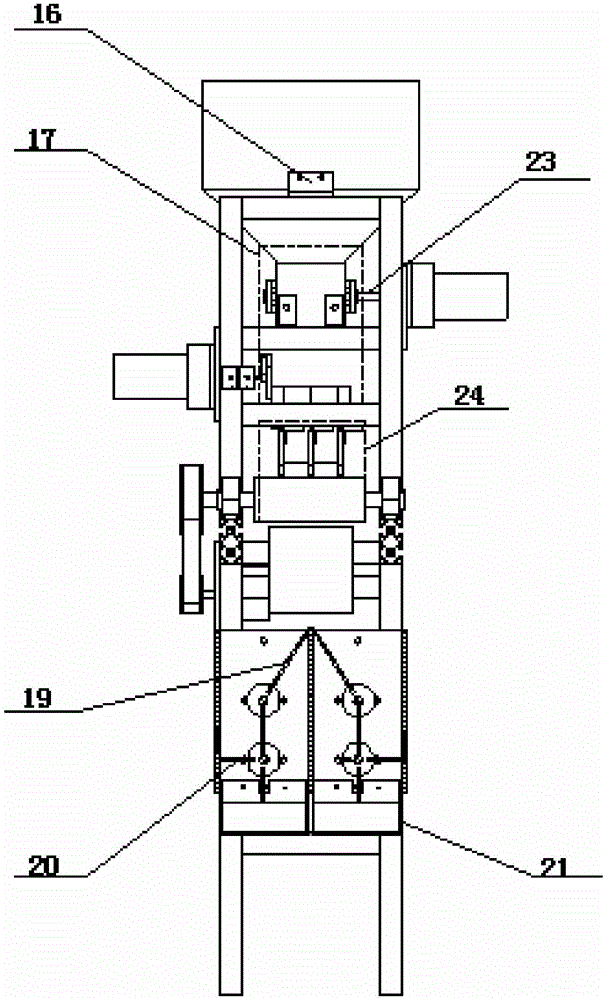

[0023] Such as figure 1 , 2 , 3 and 4, the hair ring subpackaging machine includes a feeding hopper 27, a feeding device 17, a feeding device 24, a counter 10 and a discharging device 30; the feeding hopper 27 is fixed on the top of the frame by an angle aluminum 16, The subpackaged raw materials are sent in by the feeding hopper 27; the unloading device 17 includes a rotating mechanism 28 and a translational screen mechanism 2; the rotating mechanism is arranged at the bottom of the feeding hopper 1; ; Distributing device 24 is below the translational screen mechanism 2 .

[0024] Such as figure 2 , 3 Shown in and 5, rotating mechanism 28 comprises blanking rotating shaft 23, blanking collar, stirring sheet, blanking driving gear 15 and blanking driven gear. The two ends of the blanking rotating shaft 23 are supported on two diamond-shaped seat b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com