Plate head bending shape detection device based on nearing fared image and method thereof

A head bending and detection device technology, which is applied in the direction of measuring devices, length measuring devices, optical devices, etc., can solve the problem of not being able to detect the shape of the bending of the head of the plate, achieve fast detection speed, simple equipment installation, and eliminate interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

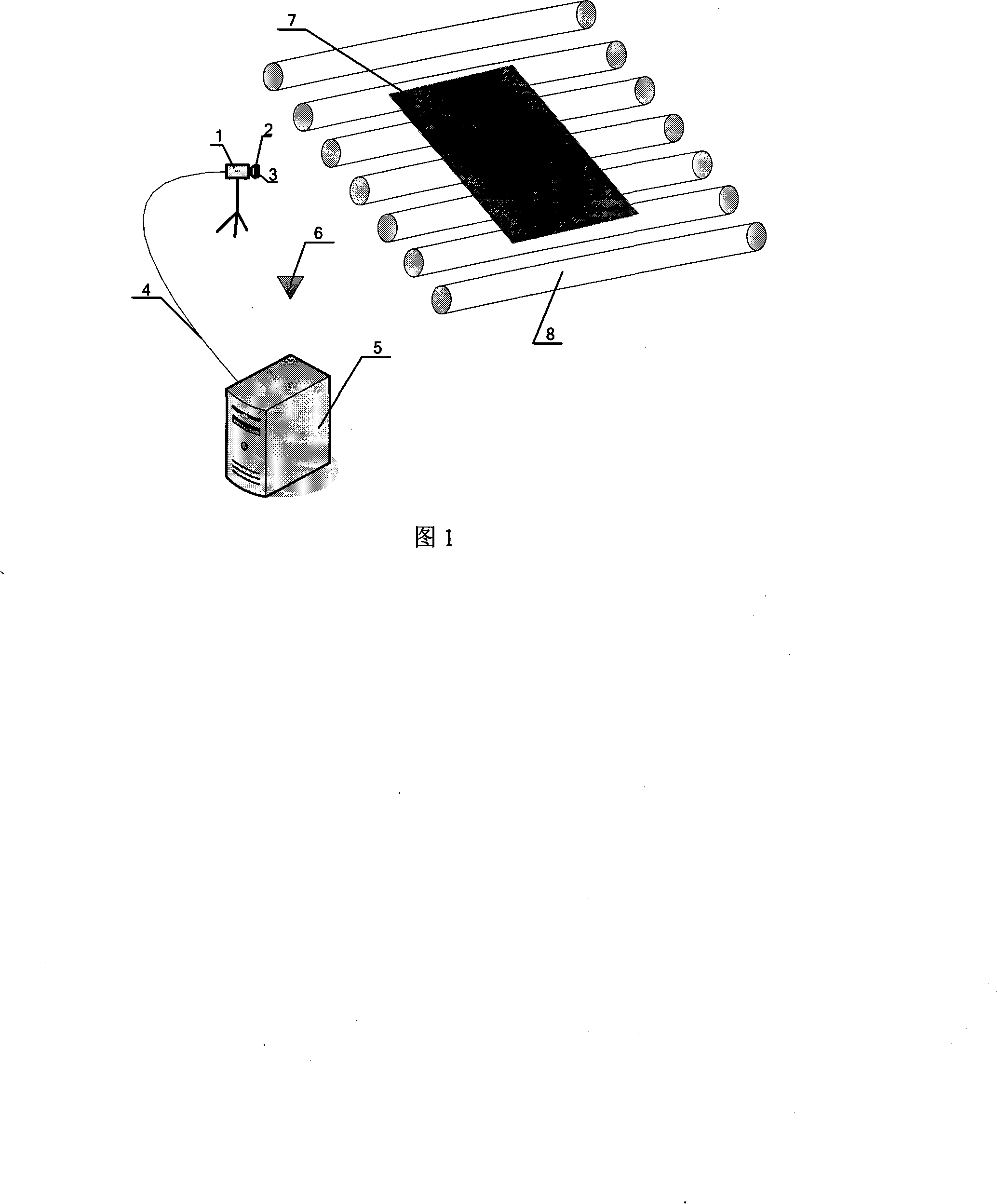

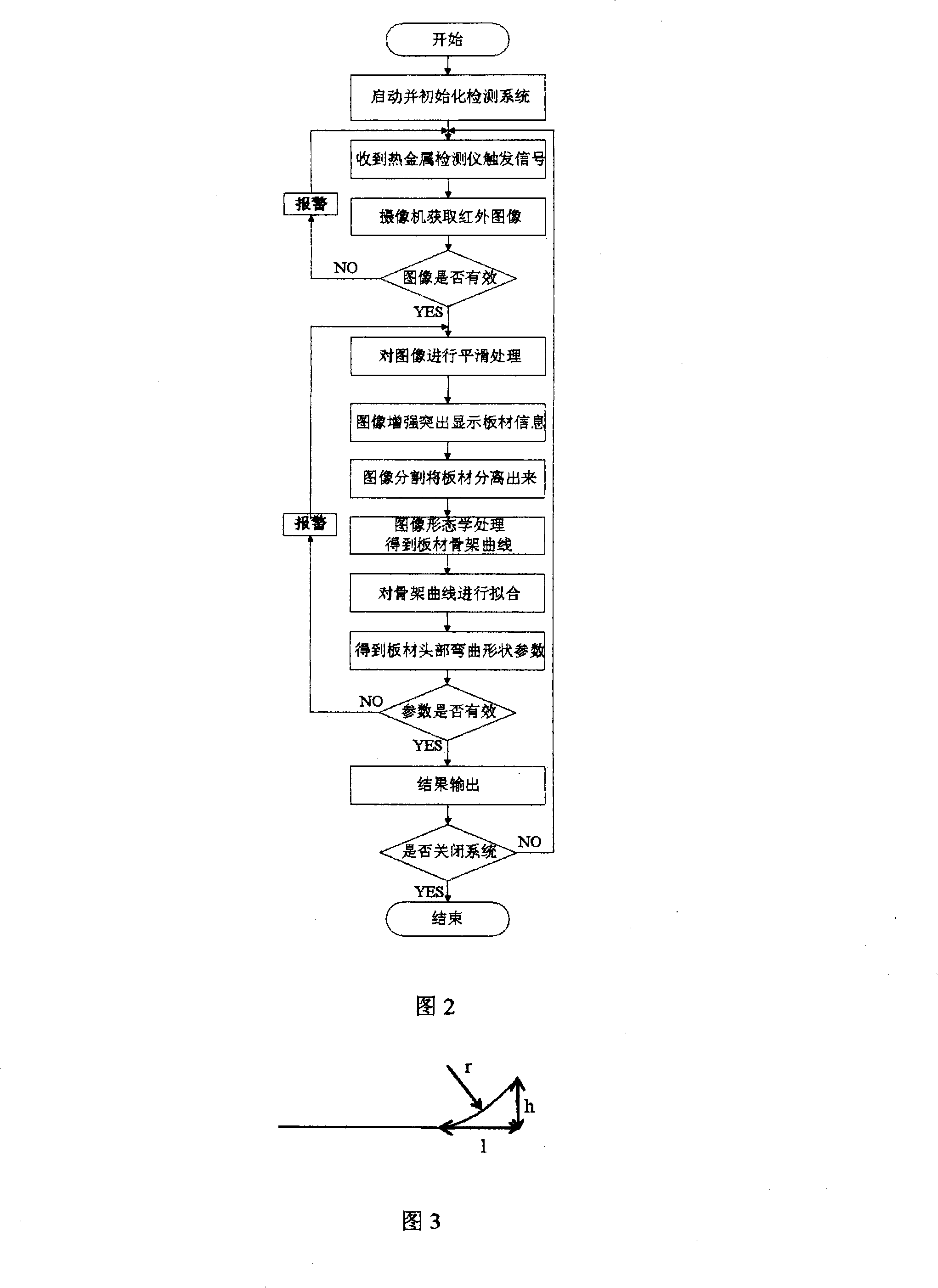

[0039] This embodiment will be described with reference to FIGS. 1 and 2 . The hardware consists of a CCD camera 1, a lens 2, an infrared optical filter 3, an image acquisition card, a computer 5, and a hot metal detector 6. The image acquisition card and the CCD camera are connected by cables. The CCD uses Taiwan Mintong's 1 / 2-inch black-and-white low-light high-resolution camera (MTV-1881EX), the lens uses TAMRON's 13VM308ASIR, and the infrared filter uses HWB900, which cuts off light below 900nm and passes near-infrared light above 900nm. mount on the lens. The image acquisition card adopts the U200 portable USB bus image acquisition box of Microvision Technology. The hot metal detector is RLK730 from Zhongchuan Optoelectronics, and its detection temperature range is 400-1500°C. The computer is an IBM portable laptop. Since the response spectrum of the selected CCD camera is below 400-1100nm, the spectral range of the system is 900-1100nm. With the above configuration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com