Water and oil repellent finishing agent for fabrics and preparation method of finishing agent

A water- and oil-repellent, finishing agent technology, applied in fiber treatment, textiles and papermaking, etc., can solve problems such as environmental hazards, achieve mild reaction conditions, excellent water- and oil-repellent effects, and is suitable for industrial production and popularization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

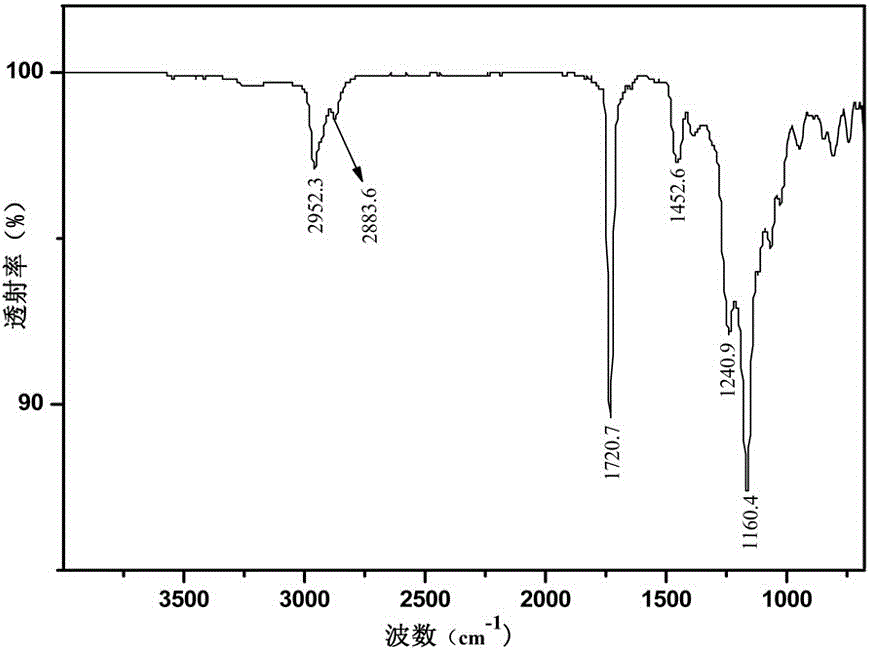

Embodiment 1

[0034] 1. Preparation of 3,3,4,4,5,5,6,6,7,7,8,8,8-tridecafluorooctyldimethylsilylpropyl acrylate monomer

[0035] In a three-necked flask equipped with magnetic stirring, a thermometer and a reflux condenser, add 3,3,4,4,5,5,6,6,7,7,8,8,8-tridecafluorooctyl bromide 42.7 gram, 7.2 grams of magnesium chips and 160 grams of tetrahydrofuran, heated to 65 ° C for 3 hours to generate the Grignard reagent tridecafluorooctylmagnesium bromide for subsequent use.

[0036] In a three-necked flask equipped with magnetic stirring, a thermometer and a reflux condenser, add 12.4 grams of allyl acrylate, 0.01 grams of chloroplatinic acid and 40 grams of toluene, stir to dissolve, raise the temperature to 71 ° C, and drop the dimethylformamide within 1 hour 10.4 grams of monochlorohydrogensilane. After reacting at 70° C. for 3 hours, the reaction was stopped. The solvent toluene and unreacted dimethyl monochlorohydrosilane were distilled off under reduced pressure, the distillation temperat...

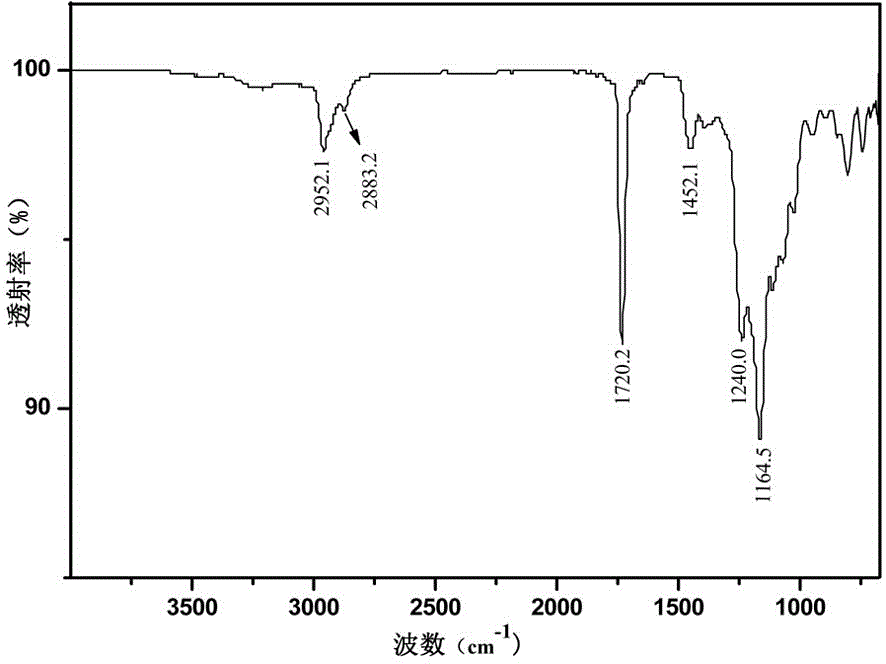

Embodiment 2

[0046] 1. Preparation of bis(3,3,4,4,5,5,6,6,7,7,8,8,8-tridecafluorooctyl)methylsilylpropyl acrylate

[0047] In a three-necked flask equipped with magnetic stirring, a thermometer and a reflux condenser, add 3,3,4,4,5,5,6,6,7,7,8,8,8-tridecafluorooctyl bromide 42.6 gram, 7.2 grams of magnesium chips and 150 grams of tetrahydrofuran, heated to 65° C. for 3 hours to generate the Grignard reagent tridecafluorooctylmagnesium bromide for subsequent use.

[0048] In a three-necked flask equipped with magnetic stirring, a thermometer and a reflux condenser, add 6.2 grams of allyl acrylate, 0.005 grams of chloroplatinic acid and 20 grams of toluene, stir to dissolve, raise the temperature to 71 ° C, drop the methyl alcohol within 1 hour Dichlorohydrosilane 6.0 g. After reacting at 70° C. for 3 hours, the reaction was stopped. The solvent toluene and unreacted methyldichlorohydrogensilane were distilled off under reduced pressure, the distillation temperature was 40° C., and the vac...

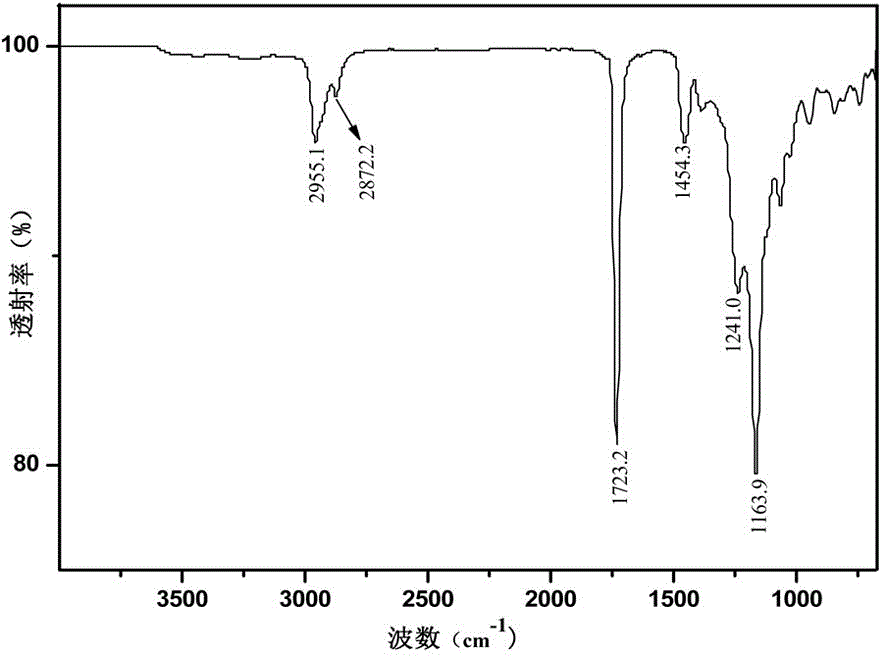

Embodiment 3

[0058] 1. Preparation of Tris(3,3,4,4,5,5,6,6,7,7,8,8,8-tridecafluorooctyl)silylpropyl acrylate monomer

[0059] In a three-necked flask equipped with magnetic stirring, a thermometer and a reflux condenser, add 3,3,4,4,5,5,6,6,7,7,8,8,8-tridecafluorooctyl bromide 42.8 gram, 7.3 grams of magnesium chips and 172 grams of tetrahydrofuran were heated to 65° C. for 3 hours to generate the Grignard reagent tridecafluorooctylmagnesium bromide for subsequent use.

[0060]In a three-neck flask equipped with magnetic stirring, a thermometer and a reflux condenser, add 4.1 grams of allyl acrylate, 0.004 grams of chloroplatinic acid and 15 grams of toluene, stir to dissolve, raise the temperature to 70 ° C, and drop the trichloride within 1.2 hours. Hydrogen silane 4.6 g. After reacting at 70° C. for 3 hours, the reaction was stopped. The solvent toluene and unreacted trichlorohydrosilane were distilled off under reduced pressure, the distillation temperature was 40° C., and the vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com