Method for preparing bioflocculation by Bacillus licheniformis

A technology of Bacillus licheniformis and biological flocculant, which is applied in the field of preparing biological flocculants by using Bacillus licheniformis, can solve the problems of low raw material cost, industrial application potential, high raw material cost, low flocculation efficiency, etc., and achieves good promotion value and raw material cost. Low, short fermentation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

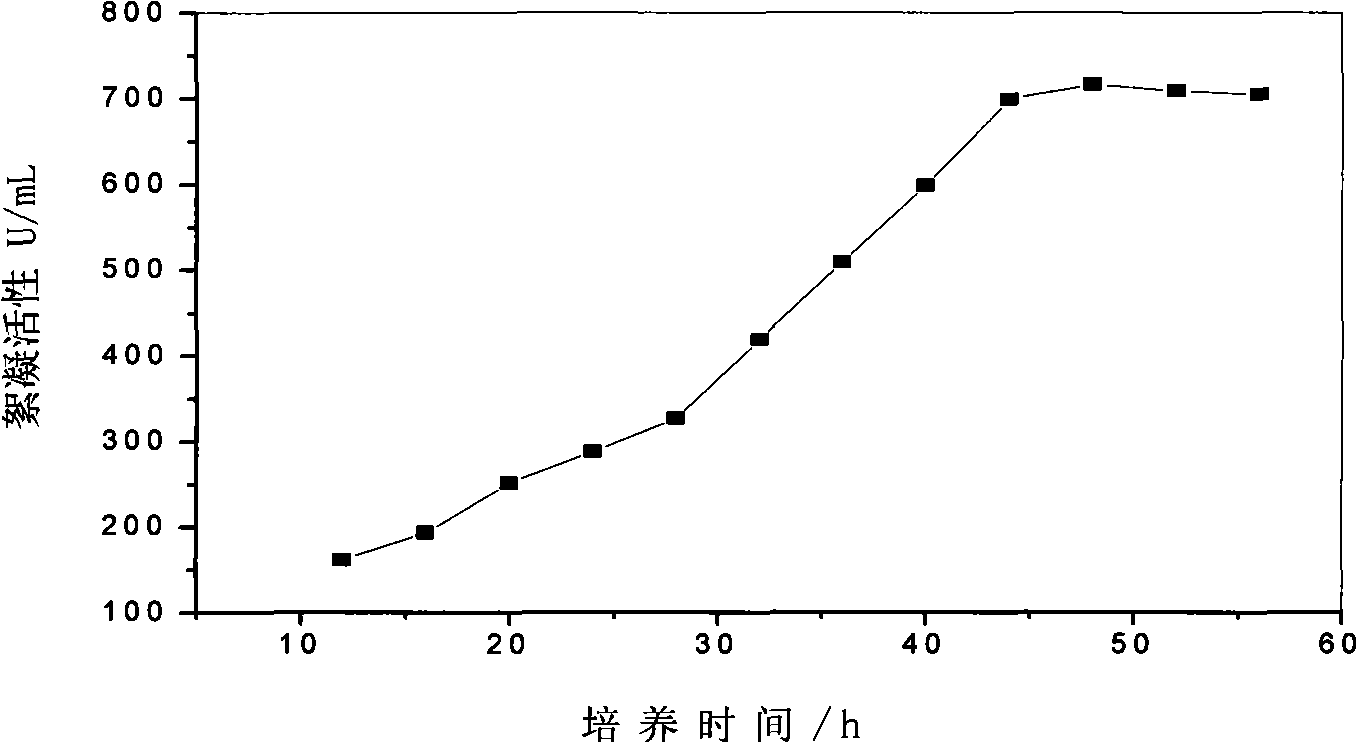

[0046] Example 1 Fermentation process curve of Bacillus licheniformis synthetic bioflocculant

[0047] The lawn on the fresh slope was transferred to 100 mL seed culture medium, and cultured on a shaker at 37°C at a rotation speed of 195 r / min. After 20 hours, the lawn was transferred to the fermentation medium at a 4% inoculum amount, and the cultivation was continued under the same conditions. Determine the flocculation activity of the fermentation broth at different times, the results are as follows figure 1 Shown. From figure 1 It can be seen that the flocculation activity reached 716U / mL at 44h of fermentation.

[0048] Seed medium (g / L): glucose 10, yeast extract 0.5, urea 0.5, KH 2 PO 4 0.1, NaCl 0.1, MgSO 4 ·7H 2 O0.2, distilled water, pH 7.2.

[0049] Fermentation medium (g / L): molasses 10, yeast extract 1, urea 1, KH 2 PO 4 0.1, K 2 HPO 4 0.1, NaCl 0.1, MgSO 4 ·7H 2 O 0.2, distilled water, pH 7.2.

Embodiment 2

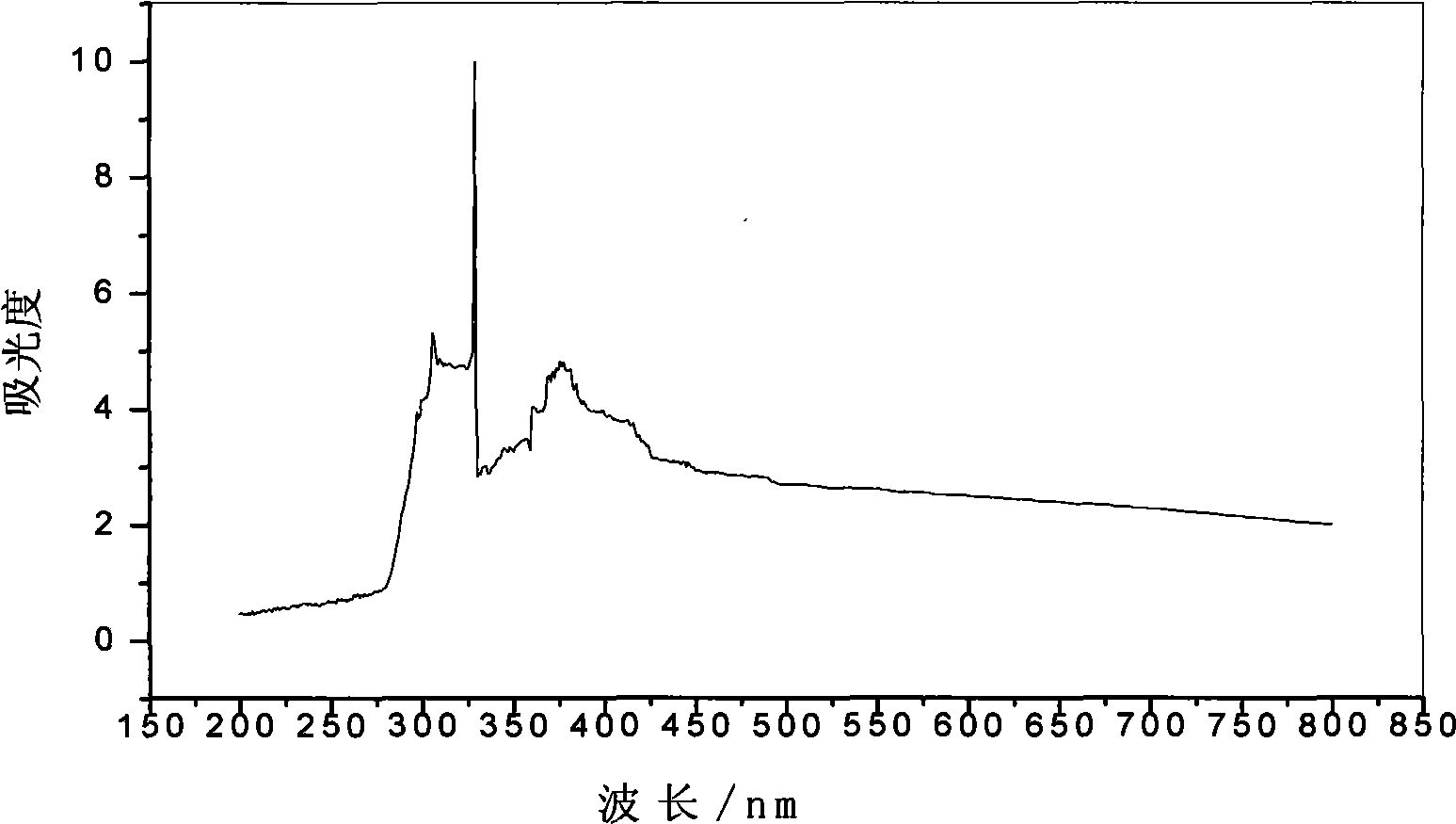

[0050] Example 2 Ultraviolet scanning spectrum of biological flocculant

[0051] Centrifuge 50 mL of fermentation broth at 4500 r / min for 20 min to remove the precipitate and collect the supernatant. Add 2 times the volume of 95% ethanol to the supernatant. After standing overnight at 4°C, centrifuge again at 4500r / min for 20min; repeat the above operation twice. Add 1 volume of hexadecyltrimethylammonium bromide with a concentration of 2% to the ethanol precipitate, centrifuge at 4500 r / min, remove the supernatant to collect the precipitate. Dissolve the precipitate in 4% NaCl solution and stir for 2 hours, add 2 times the volume of absolute ethanol, stir well, let stand overnight at 4°C, centrifuge to remove the supernatant to obtain the precipitate, freeze the precipitate and vacuum dry to obtain the pure product Biological flocculant. The purified biological flocculant is diluted with water and scanned by UV-Vis spectrophotometry, the results are as follows figure 2 Shown. Fr...

Embodiment 3

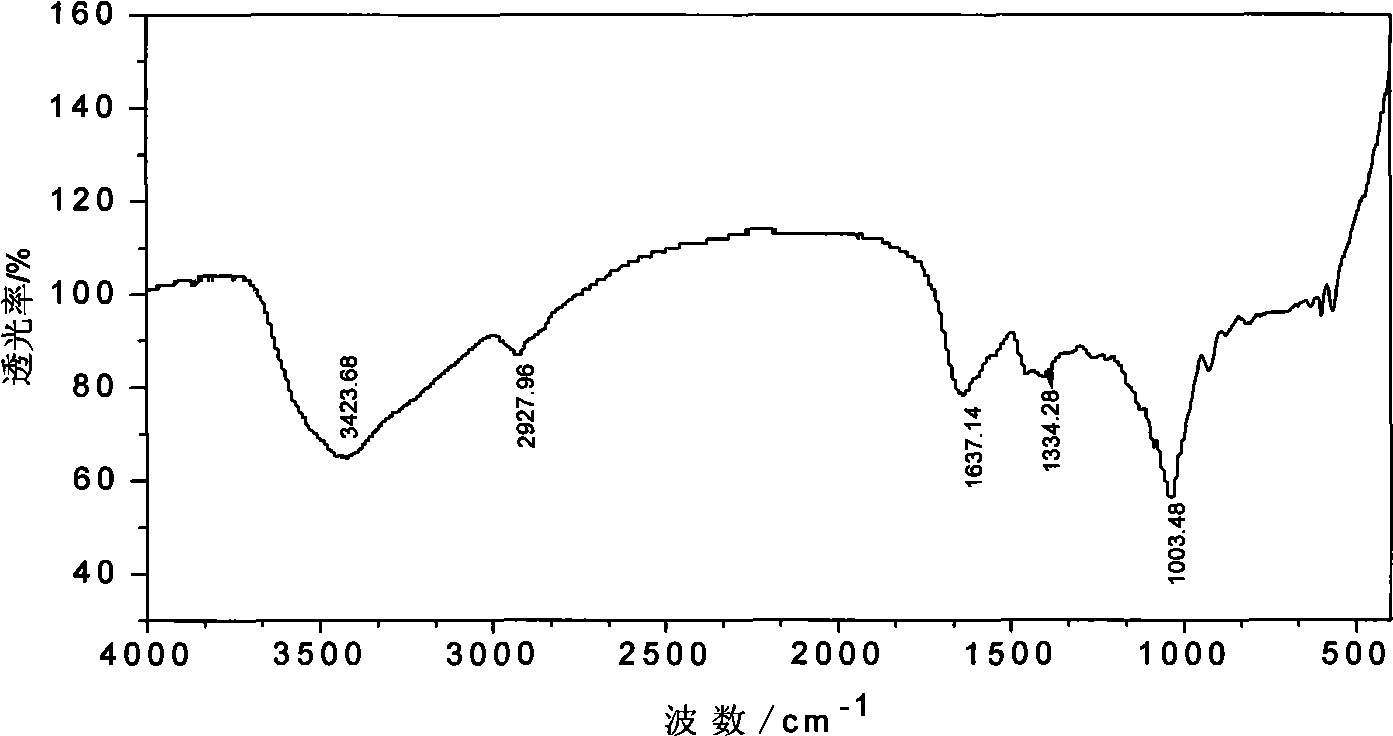

[0052] Example 3 Infrared spectrum of biological flocculant

[0053] The purified biological flocculant in Example 2 was scanned by a Fourier transform infrared spectrometer, and the results were as follows image 3 Shown. From image 3 It can be seen that the biological flocculant is at 2927.96cm -1 Absorption, the result of C-H asymmetric stretching vibration, this absorption peak is the characteristic peak of sugars; 3423.68cm -1 There is a strong and broad absorption peak, which is caused by the vibration of -OH and N-H in the sugar ring, indicating that there are hydrogen bonds in the molecule; 1637.14cm -1 The absorption peak is the acetylamino (-NHCOCH 3 ) Caused by the C=O bond stretching vibration; 1384.28cm -1 The absorption peak is -COO in the carboxyl group - The embodiment of the symmetrical stretching vibration of the C=O bond; 1003.48cm -1 The strong absorption peak is the C-O-C antisymmetric stretching vibration absorption band in the ester. The infrared spectrum not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com