Automotive sound-absorbing material

a technology for automotive sound absorption and sound insulation, which is applied in the direction of flooring, transportation and packaging, walls, etc., can solve the problems of partial unevenness of the basis weight of the felt, difficult to give uniform air permeability throughout the entire surface of the felt, and inferior sound absorption properties, etc., to achieve superior sound absorption and keep the interior of the automobile quiet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

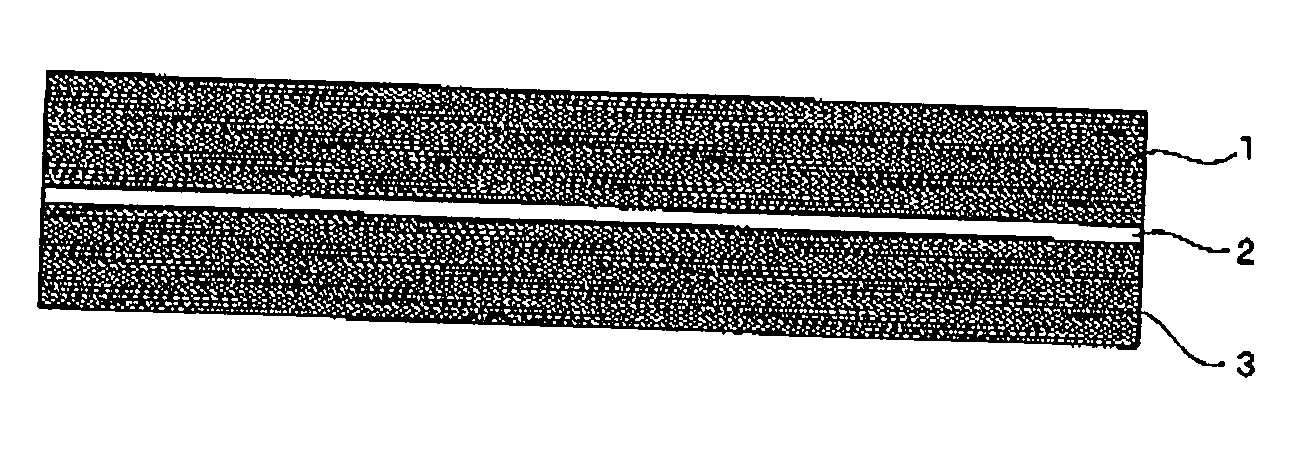

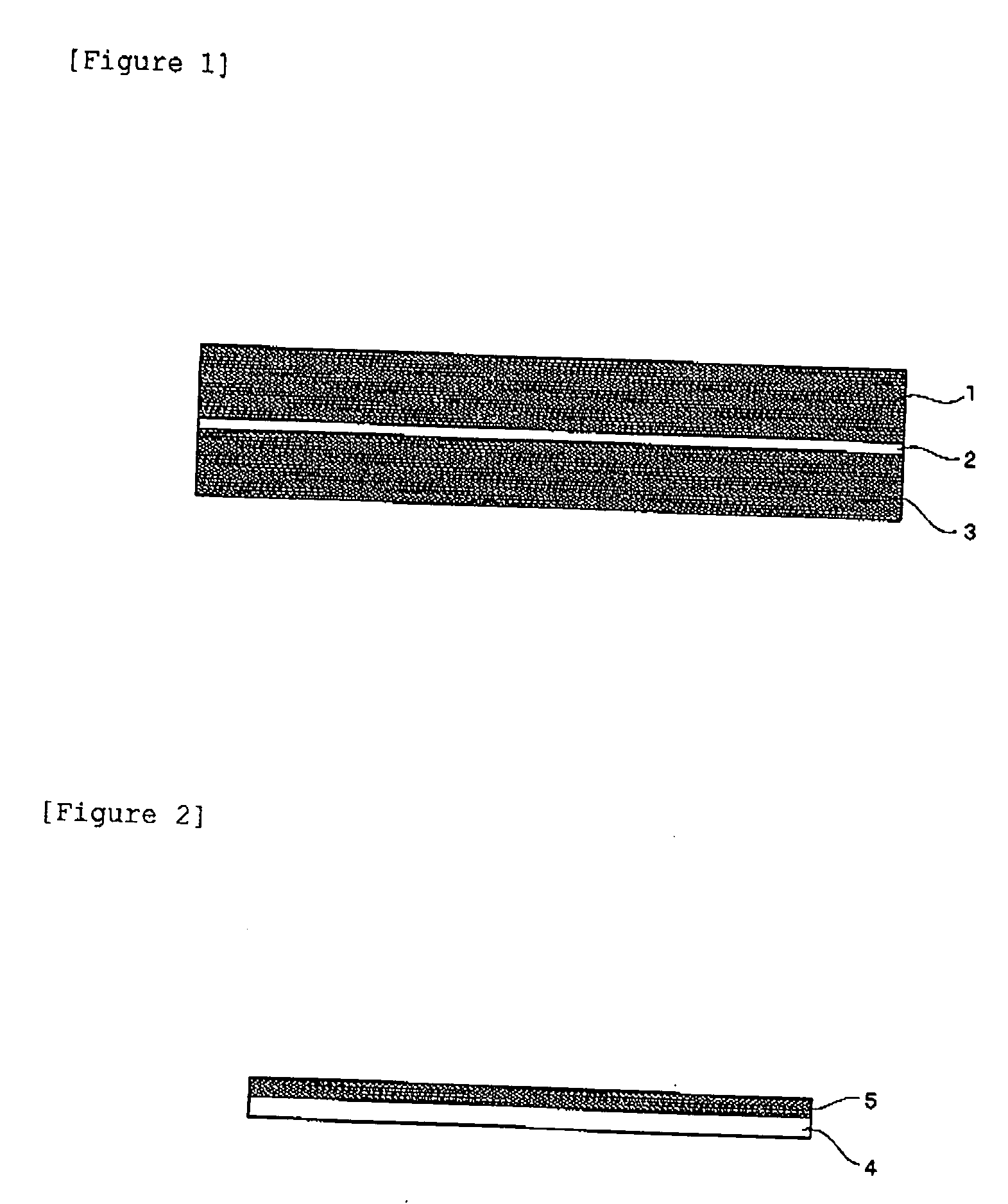

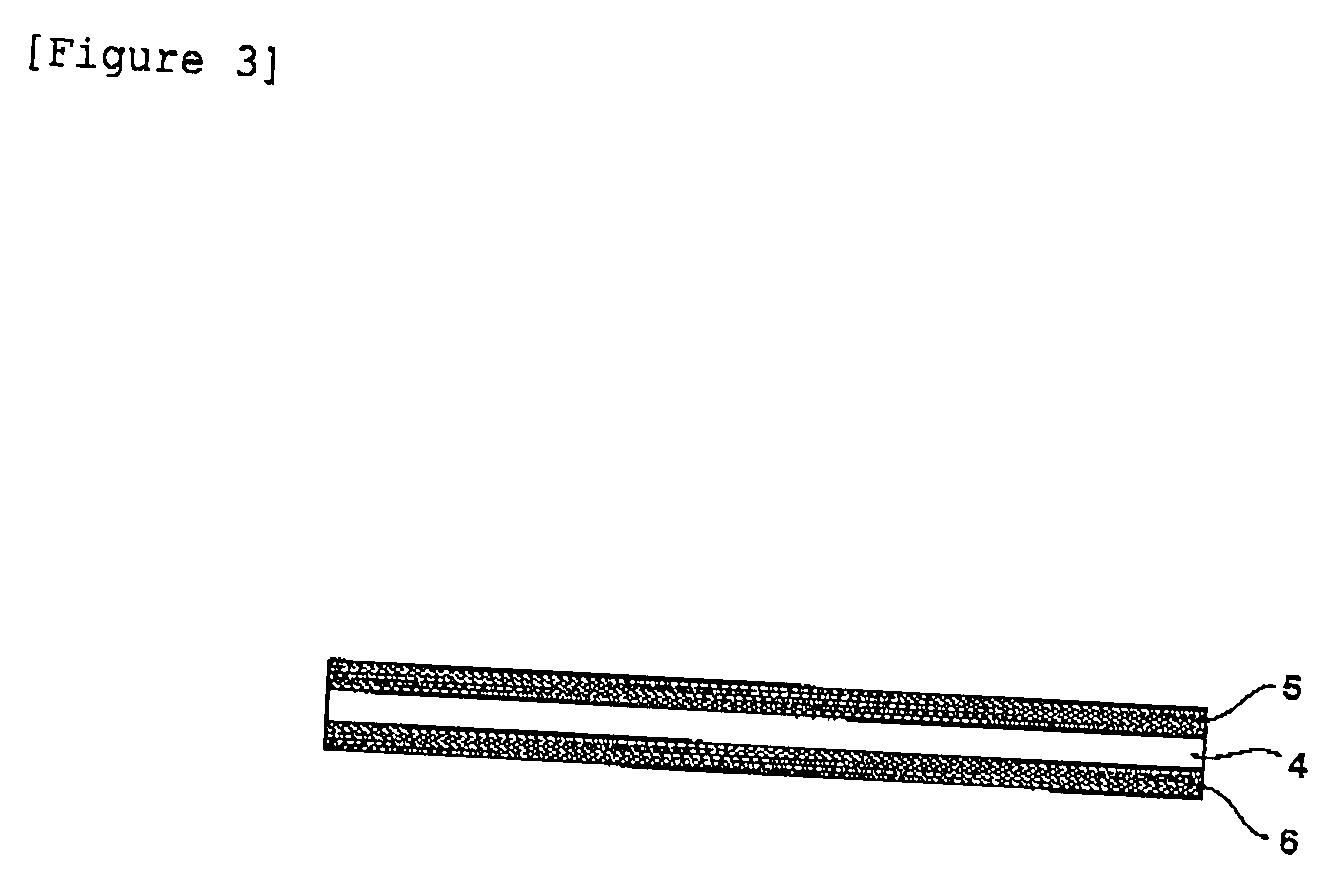

[0023]In this example, felt with a basis weight of 500 g / m2 mainly made of PET fiber of 2 to 6 dtex was used as the sound-absorbing layers (1, 3), and as the intermediate layer (2), a layer obtained by laminating a 20 μ-thick adhesive layer (5) comprising unsaturated polyester to a 20 μ-thick film (4) made of thermoplastic resin comprising polyethylene was used. Small pores with a diameter of 1 mm were formed onto the film (4) made of thermoplastic resin with a pitch of 5 mm, and the obtained pored film was adhered to the felt. The air-permeability of a surface area of 2 m2 of the obtained sound-absorbing material was measured at randomly chosen 10 measurement points. The results are shown in Table 2 in the same manner as in Table 1:

TABLE 2①②③④⑤⑥⑦⑧⑨⑩AV3σ10.810.310.410.311.010.710.310.310.610.310.50.77

[0024]As shown under 3σ in Table 2, the scattering of the air-permeability could be remarkably reduced in the example of the disclosure by adhering pored film to the felt, thereby makin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com