Rigid vacuum insulating plate and manufacturing method thereof

A vacuum insulation panel and rigid technology, which is applied to heat exchange equipment, protects pipelines through heat insulation, heat preservation, etc., can solve the problems of increasing the thermal conductivity of vacuum insulation panels, increasing the difficulty and cost of use, and easy aging of the thin film barrier layer. To achieve the effect of easy recycling, good compactness and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

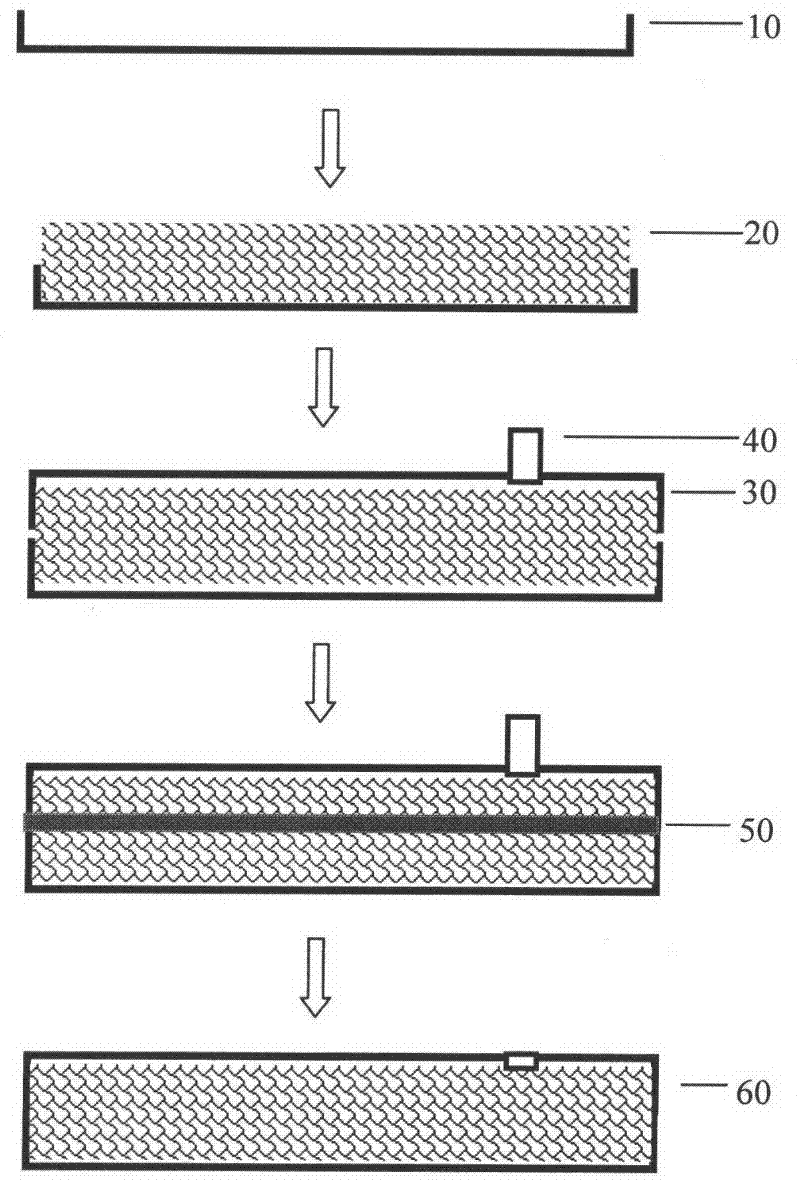

[0022] A rigid vacuum insulation panel 60. The vacuum insulation panel is assembled, welded, vacuumed and sealed by a metal barrier panel shell and an inorganic porous core material. The thermal conductivity of the vacuum insulation panel is 4mW / m·K. meters can withstand a counterweight weighing 1 ton. The rigid vacuum insulation panel 60 described in this example includes: a stainless steel metal barrier lower shell plate 10 with a thickness of 0.5 mm, a porous core material 20 of a fumed silica powder plate with a porosity of 50%, a stainless steel metal barrier plate and a shell plate 30. The specific steps of the manufacturing method of the rigid vacuum insulation panel 60 are as follows:

[0023] (1) Stamping a stainless steel flat plate into a lower shell plate 10 and an upper shell plate 30, and punching air extraction holes on the surface of the upper shell plate 30;

[0024] (2) copper air extraction pipe 40 is welded on the air extraction hole;

[0025] (3) Put th...

Embodiment 2

[0031] A rigid vacuum insulation panel 60. The vacuum insulation panel is assembled, welded, vacuumized and sealed by a metal barrier panel shell and an inorganic porous core material. The thermal conductivity of the vacuum insulation panel is 6mW / m·K, per square meter The meter can bear a counterweight of 1.2 tons. The rigid vacuum insulation panel 60 described in this example includes: a titanium alloy barrier lower shell plate 10 with a thickness of 0.7 mm, a porous core material 20 of glass wool felt with a porosity of 45%, and a titanium alloy barrier plate shell plate 30 . The specific steps of the manufacturing method of the rigid vacuum insulation panel 60 are as follows:

[0032] (1) Stamping the titanium alloy flat plate into the lower shell plate 10 and the upper shell plate 30, and punching out air extraction holes on the surface of the upper shell plate 30;

[0033] (2) copper air extraction pipe 40 is welded on the air extraction hole;

[0034] (3) Put the glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com