Hydrophobic type glass wool blanket and adhesive proportion thereof

A glass wool felt and adhesive technology, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve the problems of affecting the bonding strength of glass fiber and polymer resin, unsatisfactory, and reducing the strength of glass fiber. To achieve the effect of widening the scope of use, good mold release, and excellent hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

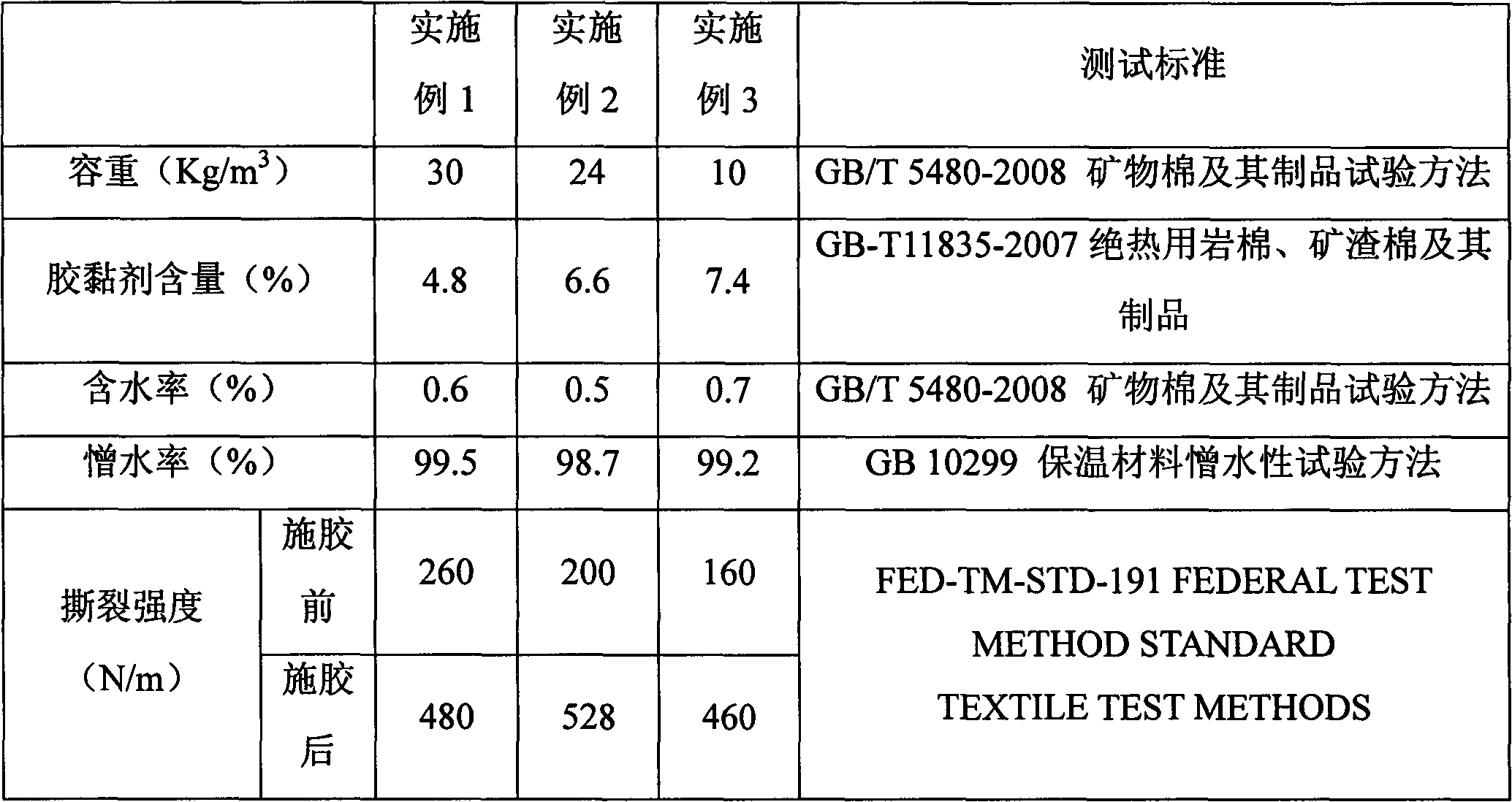

[0024] The adhesive is configured according to the following proportions: 471Kg of water-soluble phenolic resin with a solid content of 40.4%, 85Kg of urea with a nitrogen content of 46.4%, 700Kg of demineralized water, 15Kg of ammonium sulfate, and 8Kg of emulsified hydroxy silicone oil with a solid content of 25.5%. Silane coupling agent KH550 1.2Kg, concentration is 20.4% ammonia water 55Kg, solid content is 48.3% mineral oil 15Kg, demineralized water 798Kg. Spray the reacted adhesive on the surface of the glass fiber with an average diameter of 5-6 μm, and cure it at 230-250°C for 2 minutes. After curing, the surface of the glass fiber is evenly wrapped with the adhesive, and the cotton felt is light yellow. The performance test of hydrophobic glass wool felt is shown in Table 1.

Embodiment 2

[0026] The adhesive is configured according to the following proportions: 151.5Kg of water-soluble urea-formaldehyde resin with a solid content of 42%, 5.9Kg of ammonium chloride, 3.5Kg of emulsified amino silicone oil with a solid content of 23.8%, silane coupling agent KH5500.66Kg, concentration 18Kg of 20.4% ammonia water, 3Kg of mineral oil with a solid content of 48.3%, and 300Kg of demineralized water. Spray the reacted adhesive on the surface of the glass fiber with an average diameter of 4.5-6 μm, and cure it at 235-255°C for 2 minutes. After curing, the surface of the glass fiber is evenly wrapped with the adhesive, and the cotton felt is light yellow. The performance test of hydrophobic glass wool felt is shown in Table 1.

Embodiment 3

[0028] The adhesive is configured according to the following ratio: 150Kg of water-soluble urea-formaldehyde resin with a solid content of 41%, 7.5Kg of ammonium chloride, 5Kg of emulsified amino silicone oil with a solid content of 23.8%, and 1.2Kg of silane coupling agent KH550, with a concentration of 20Kg of 20.4% ammonia water, 14Kg of mineral oil with a solid content of 48.3%, and 270Kg of demineralized water. Spray the reacted adhesive on the surface of the glass fiber with an average diameter of 4-6 μm, and cure it at 235-255°C for 2 minutes. After curing, the surface of the glass fiber is evenly wrapped with the adhesive, and the cotton felt is light yellow. The performance test of hydrophobic glass wool felt is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com