Ejecting rotation-proof assembly

An anti-rotation and ejection technology, which is applied in the field of ejection and anti-rotation combinations, can solve problems such as mold core damage, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

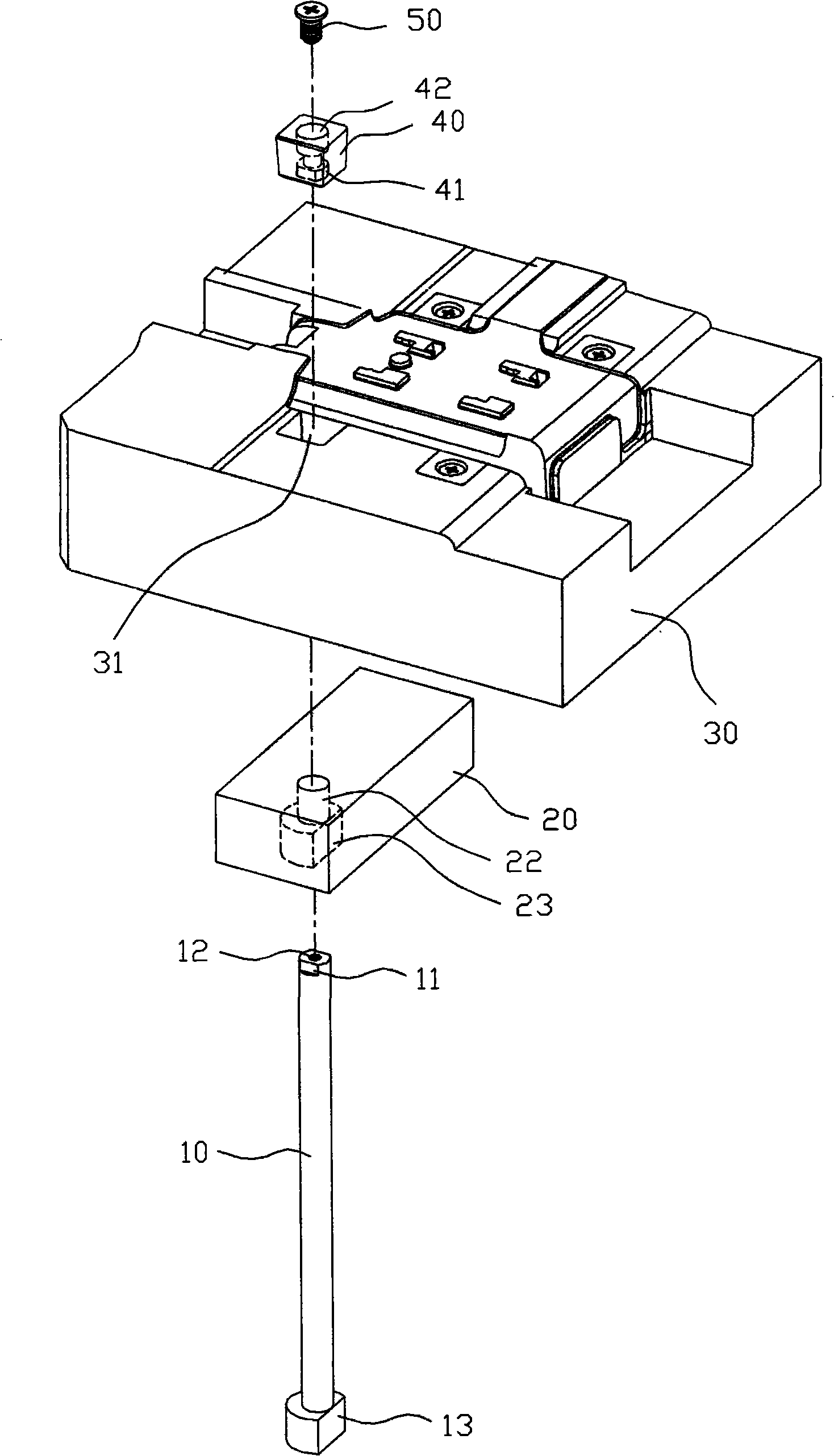

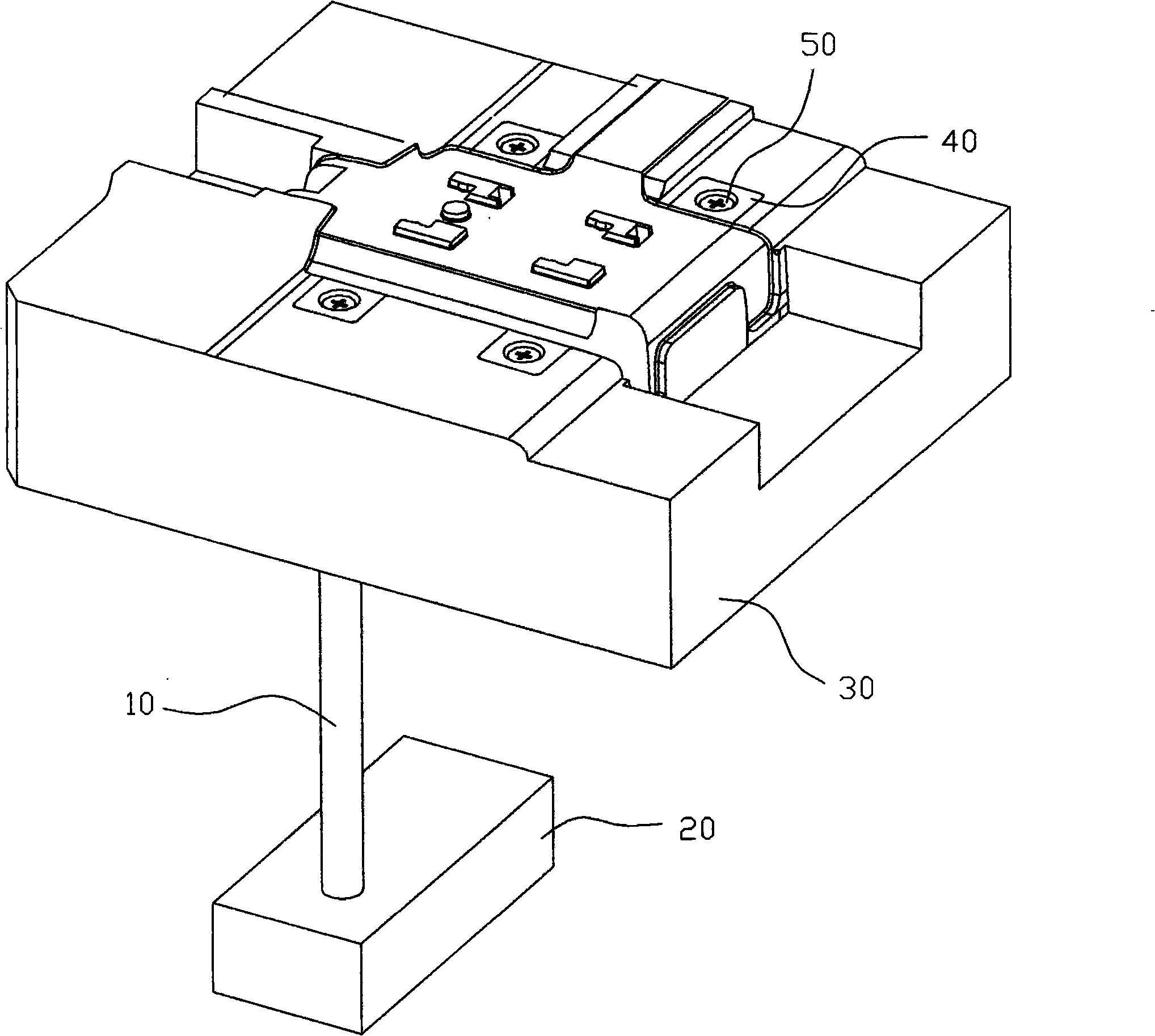

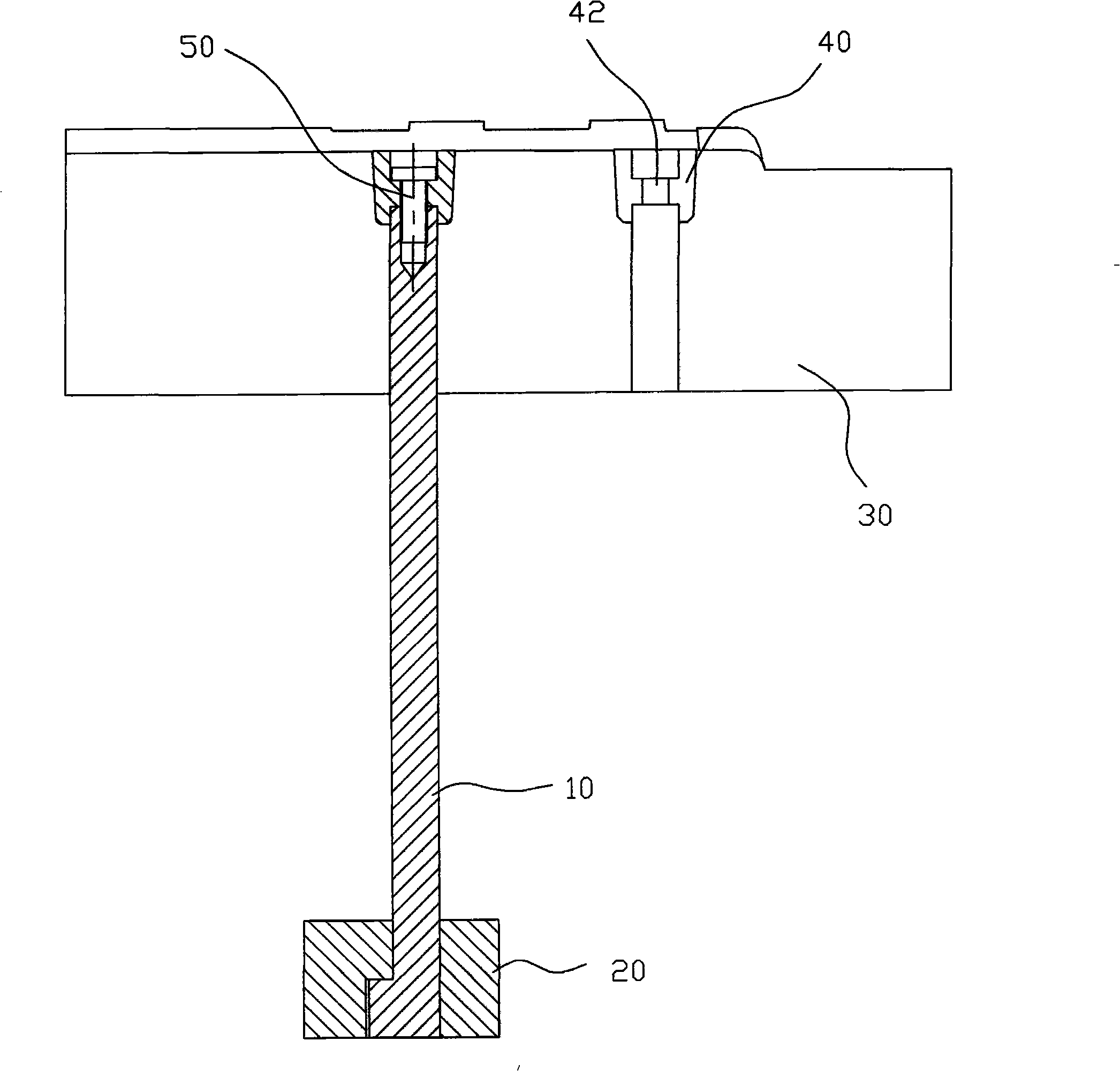

[0011] see figure 1 , figure 2 As shown, the ejection anti-rotation combination of the present invention is suitable for a mold structure, wherein the mold structure includes a mold core 30, and the mold core 30 is provided with an ejection groove 31 at the side edge of the molding area; and the mold structure An ejector plate 20 is disposed on one side of the mold core 30 , and a through hole 22 is formed in the ejector plate 20 , and an anti-rotation groove 23 is formed on one side of the through hole 22 .

[0012] The ejection anti-rotation combination includes a thimble 10, and one end of the thimble 10 is provided with an anti-rotation portion 11. In this embodiment, the outer surface of the anti-rotation portion 11 is composed of two opposite cylindrical curved surfaces and two opposite straight surfaces. And the anti-rotation part 11 is provided with a locking hole 12, in this embodiment, the locking hole 12 is a screw hole. The other end of the thimble 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com