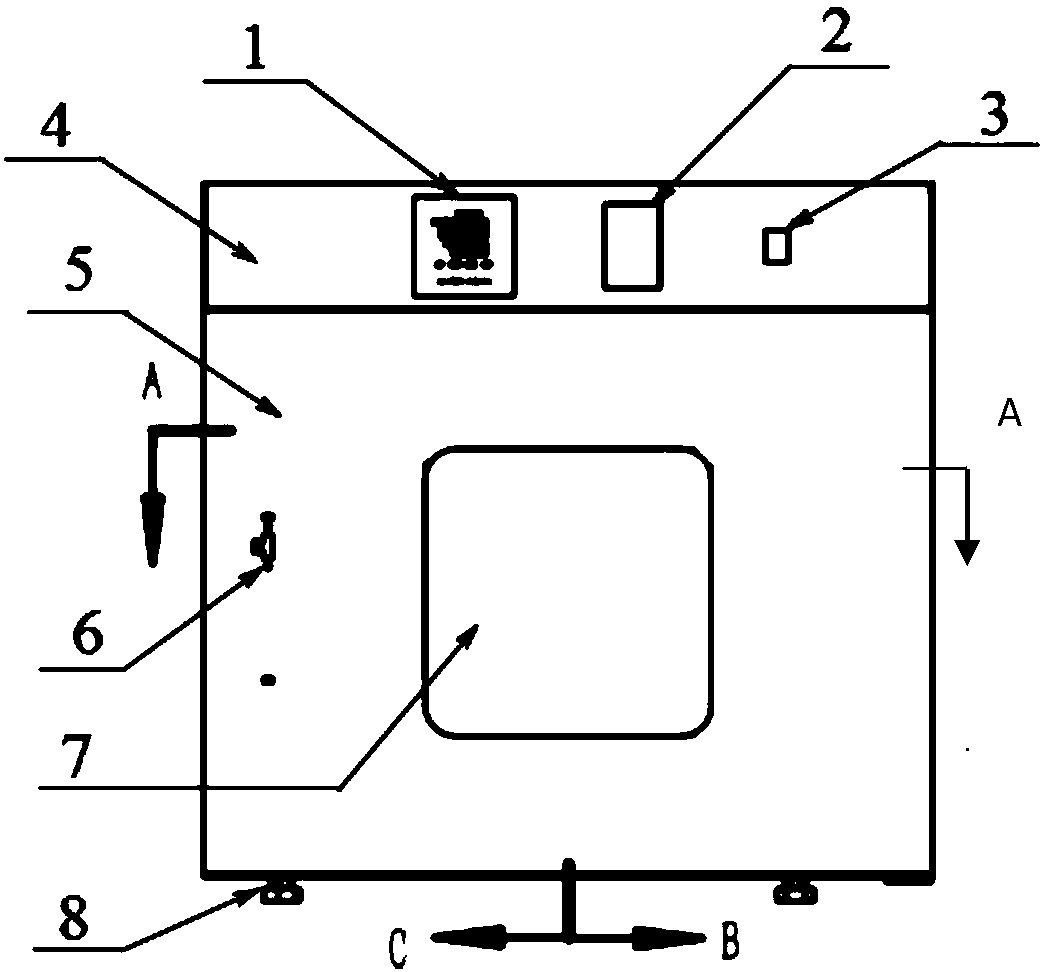

Internal rotation homogeneous reaction device with locating system

A homogeneous reaction and positioning system technology, applied in chemical/physical/physical chemical mobile reactors, chemical/physical/physical chemical processes, chemical instruments and methods, etc., can solve the problem that the rotating bracket is in a fixed state and the heating is uneven , difficult to place and other problems, to avoid serious corrosion of the motor, to avoid damage, to facilitate the effect of placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

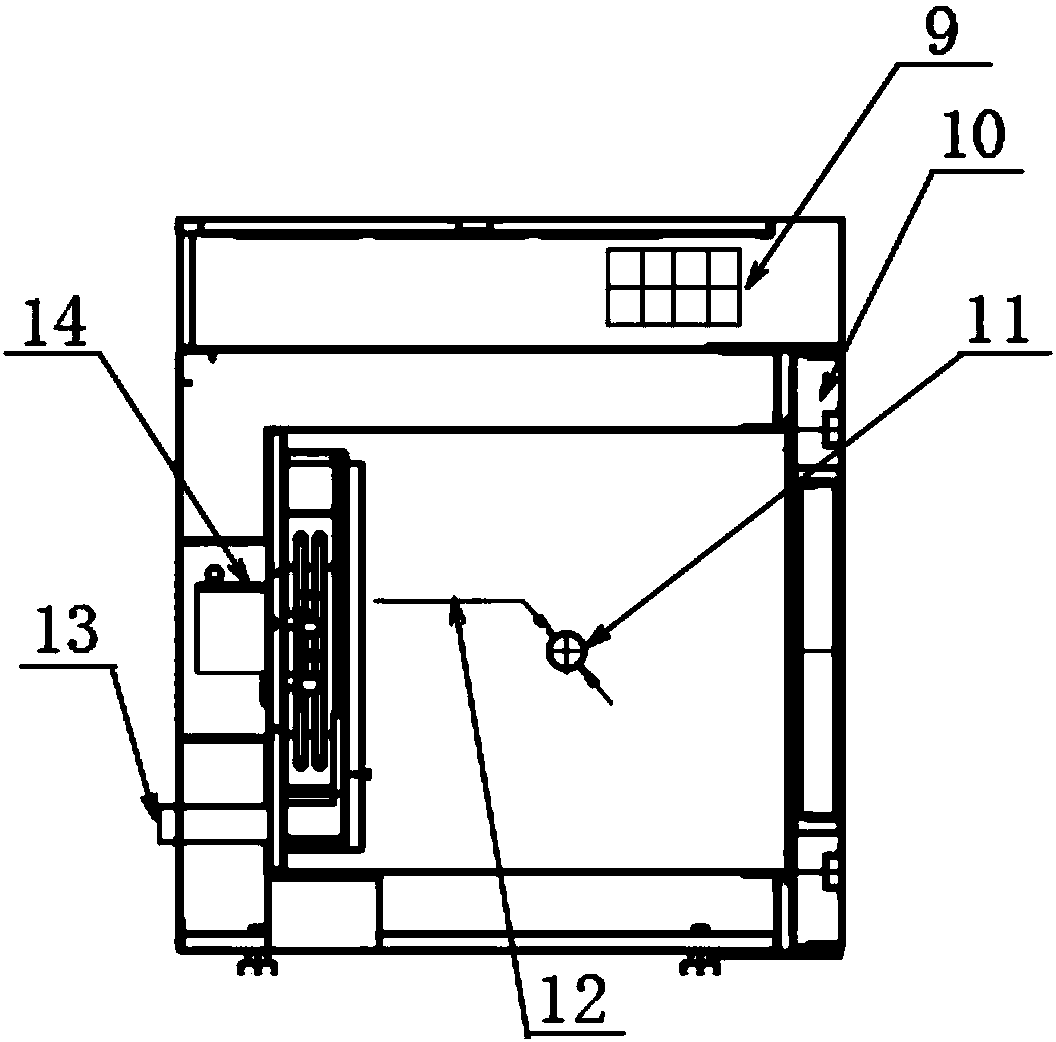

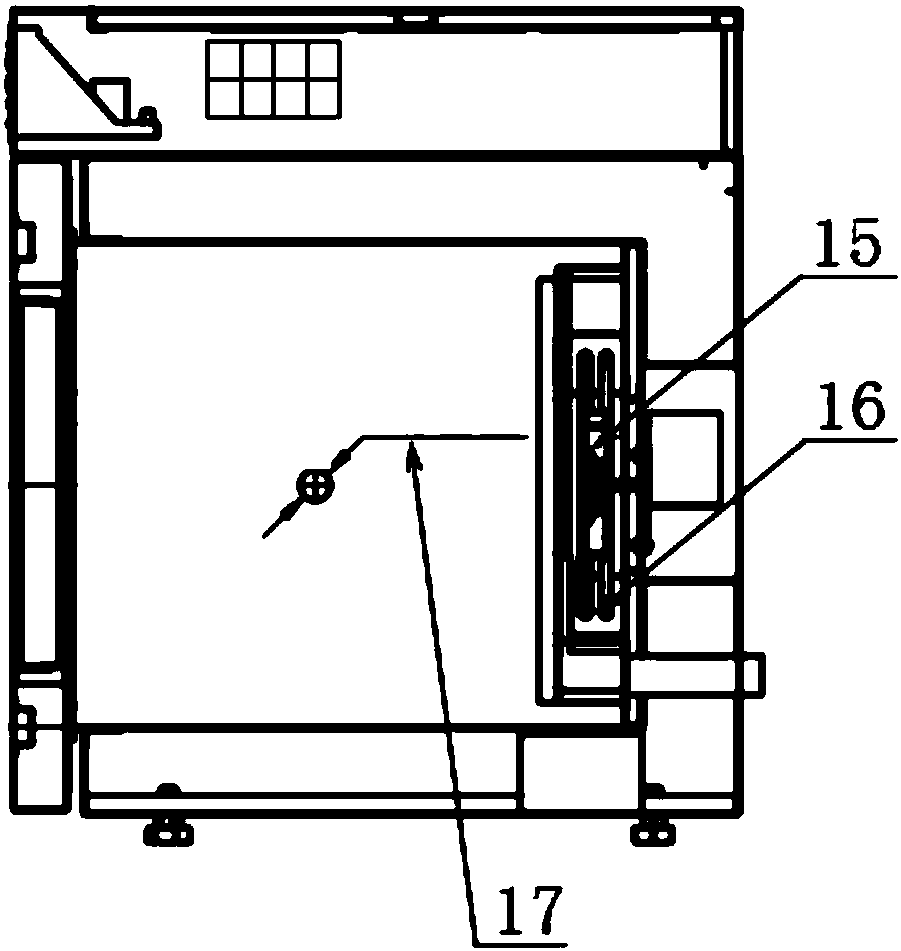

Method used

Image

Examples

Embodiment 1

[0049] HZSM-5 molecular sieves are usually synthesized in a conventional homogeneous reactor, and the synthesis conditions are:

[0050] First mix 12.50g Tetraethyl Tetrasilicate (silicon source), 12.00g Tetrapropylammonium Hydroxide (template), and 70g water (by adjusting the addition ratio of silicon source and water, the particle size of the synthetic molecular sieve can be changed) , stirred at 80°C, condensed and refluxed for 24h, then added 0.24g NaOH and 0.46g Al(NO 3 ) 3 9H 2 O (aluminum source), transferred to a polytetrafluoroethylene-lined stainless steel autoclave for static hydrothermal synthesis at 170°C for 24 hours, after quenching, centrifuged to wash the supernatant to pH ≈ 7, and then transferred to blast drying Oven dried at 110°C for 12 hours, then transferred to a muffle furnace and roasted at 550°C for 6 hours to remove the template agent, and after cooling, the sample was taken out to obtain NaZSM-5 zeolite, which was then treated with 1mol / L NH 4 NO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com